ASTM B106-08(2013)

(Test Method)Standard Test Methods for Flexivity of Thermostat Metals

Standard Test Methods for Flexivity of Thermostat Metals

SIGNIFICANCE AND USE

4.1 These test methods are used for determining response to temperature change or flexivity of thermostat metal. The flexivity is calculated from the temperatures, dimensions of specimen, and the relative movement of the specimen. The simple beam method (Method A) is the method for certification. Any use of the spiral coil method (Method B) is to be mutually agreed upon between the user and supplier.

SCOPE

1.1 These test methods cover the determination of flexivity (a measure of thermal deflection rate or deflection temperature characteristics) of thermostat metals.

1.1.1 Test Method A—Tested in the form of flat strip 0.015 in. (0.38 mm) or over in thickness.

1.1.2 Test Method B—Tested in the form of spiral coils less than 0.012 in. in thickness.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B106 − 08 (Reapproved 2013)

Standard Test Methods for

Flexivity of Thermostat Metals

This standard is issued under the fixed designation B106; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 flexivity (F), n—the change of curvature of the longi-

tudinalcenterlineofthespecimenperunittemperaturechange

1.1 These test methods cover the determination of flexivity

for unit thickness, given by the following equation:

(a measure of thermal deflection rate or deflection temperature

characteristics) of thermostat metals. 1/R 2 1/R

~ ! ~ !

2 1

F 5 t (1)

1.1.1 Test Method A—Tested in the form of flat strip T 2 T

2 1

0.015 in. (0.38 mm) or over in thickness.

To determine the flexivity between any two temperatures,

1.1.2 Test Method B—Tested in the form of spiral coils less

T and T , it is necessary to measure the curvature 1/R and

1 2 1

than 0.012 in. in thickness.

1/R at temperature T and T , respectively. To find the cur-

2 1 2

1.2 The values stated in inch-pound units are to be regarded

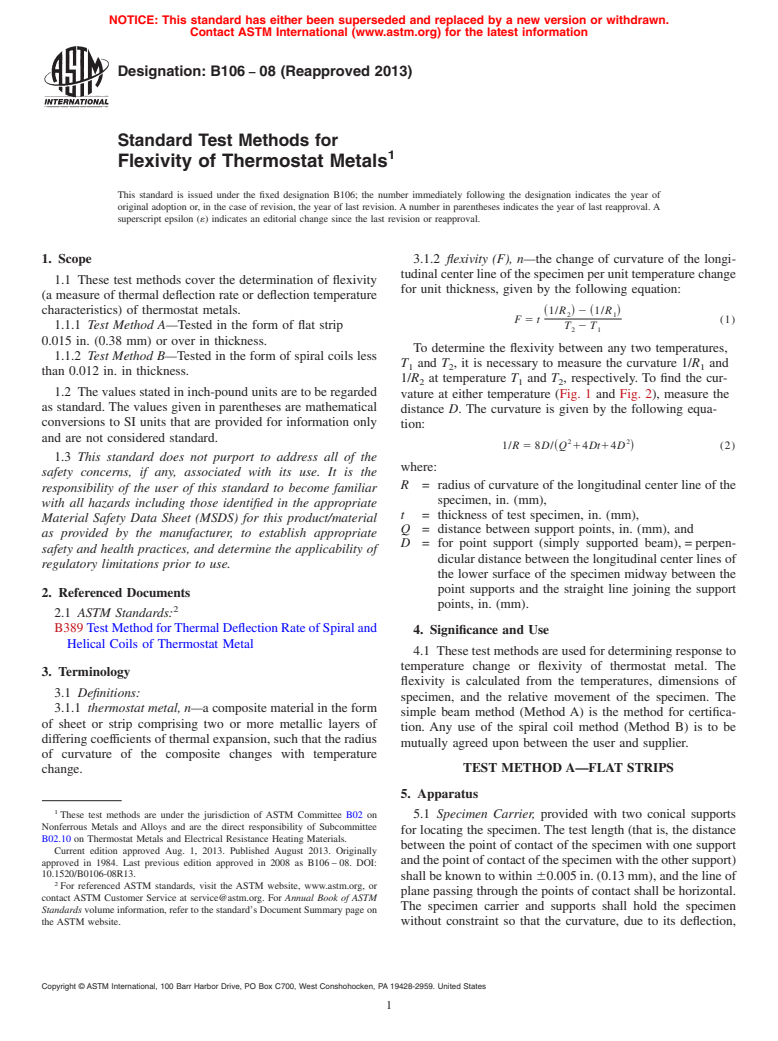

vature at either temperature (Fig. 1 and Fig. 2), measure the

as standard. The values given in parentheses are mathematical

distance D. The curvature is given by the following equa-

conversions to SI units that are provided for information only

tion:

and are not considered standard.

2 2

1/R 5 8D/ Q 14Dt14D (2)

~ !

1.3 This standard does not purport to address all of the

where:

safety concerns, if any, associated with its use. It is the

R = radius of curvature of the longitudinal center line of the

responsibility of the user of this standard to become familiar

specimen, in. (mm),

with all hazards including those identified in the appropriate

t = thickness of test specimen, in. (mm),

Material Safety Data Sheet (MSDS) for this product/material

Q = distance between support points, in. (mm), and

as provided by the manufacturer, to establish appropriate

D = for point support (simply supported beam),=perpen-

safety and health practices, and determine the applicability of

dicular distance between the longitudinal center lines of

regulatory limitations prior to use.

the lower surface of the specimen midway between the

point supports and the straight line joining the support

2. Referenced Documents

points, in. (mm).

2.1 ASTM Standards:

B389TestMethodforThermalDeflectionRateofSpiraland

4. Significance and Use

Helical Coils of Thermostat Metal

4.1 Thesetestmethodsareusedfordeterminingresponseto

temperature change or flexivity of thermostat metal. The

3. Terminology

flexivity is calculated from the temperatures, dimensions of

3.1 Definitions:

specimen, and the relative movement of the specimen. The

3.1.1 thermostat metal, n—a composite material in the form

simple beam method (Method A) is the method for certifica-

of sheet or strip comprising two or more metallic layers of

tion. Any use of the spiral coil method (Method B) is to be

differingcoefficientsofthermalexpansion,suchthattheradius

mutually agreed upon between the user and supplier.

of curvature of the composite changes with temperature

TEST METHOD A—FLAT STRIPS

change.

5. Apparatus

These test methods are under the jurisdiction of ASTM Committee B02 on

5.1 Specimen Carrier, provided with two conical supports

Nonferrous Metals and Alloys and are the direct responsibility of Subcommittee

for locating the specimen. The test length (that is, the distance

B02.10 on Thermostat Metals and Electrical Resistance Heating Materials.

between the point of contact of the specimen with one support

Current edition approved Aug. 1, 2013. Published August 2013. Originally

andthepointofcontactofthespecimenwiththeothersupport)

approved in 1984. Last previous edition approved in 2008 as B106–08. DOI:

10.1520/B0106-08R13.

shallbeknowntowithin 60.005in.(0.13mm),andthelineof

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

plane passing through the points of contact shall be horizontal.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The specimen carrier and supports shall hold the specimen

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. without constraint so that the curvature, due to its deflection,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B106 − 08 (2013)

thepointsofsupportandalongtheverticallineintersectingthe

line joining the points of support. Such means may comprise a

transmissionroddisposedwithitsaxisverticalandterminating

in a point or knife-edge, which shall engage the specimen

midway between the points of contact with the supports.

5.5.1 The transmission rod shall be mounted in such a

manner that it is free to move in the direction of its axis. The

rodshallbearatitsfreeendanindexsuitableformicroscopical

observation,orelseanelectricalcontactwithwhichamicrom-

eterwillpermitthechangesofthedeflectionofspecimentobe

accurately observed. Alternatively, the deflection of the mid-

point of the specimen may be directly observed by optical

means whose line of sight is horizontal and passes through the

vertical line through the midpoint of the specimen.Amicrom-

eter screw with extended spindle making direct contact with

the specimen may be used. In this case, electrical means shall

be provided that will indicate contact without significant

FIG. 1 Test for Flexivity of Thermostat Metals

disturbance of the specimen. The measurement of the position

of the midpoint of the test specimen shall be of such accuracy

that the individual positions at the test temperatures shall be

known to within 60.0002 in. (0.005 mm).

5.5.2 If a transmission rod is used, it and any attached parts

shallbeofsuchweightorsocounterweightedthattheywillnot

cause a deflection greater than 1% of the maximum to be

produced by the action of the thermostat metal alone. When

free, the thermostat metal assumed very nearly a circular

curvature. Concentrated loading at the center of the specimen

willcausethecurvaturetobeotherthancircularandmaycause

significant errors in the evaluation of flexivity. The location of

the line passing through the points of contact between speci-

menandsupportsshallbeknown,withreferencetothescaleof

the micrometer, to within 60.002 in. (0.05 mm).

5.6 All metallic components of the flexivity apparatus

should be made of very low coefficient of thermal expansion

components. The recommended material is Invar.

FIG. 2 Typical Apparatus Design

6. Test Specimens

6.1 The test specimen shall be in the form of a strip that

displays no apparent initial irregularity of curvature.

willfollowaverticalplanepassingthroughthelinejoiningthe

points of contact between specimen and supports. Suitable

6.2 The maximum thickness shall not be greater than the

means shall be used to ensure test length.

minimum thickness by more than 1% of the latter.

5.2 Micrometer—traveling microscope, or equivalent

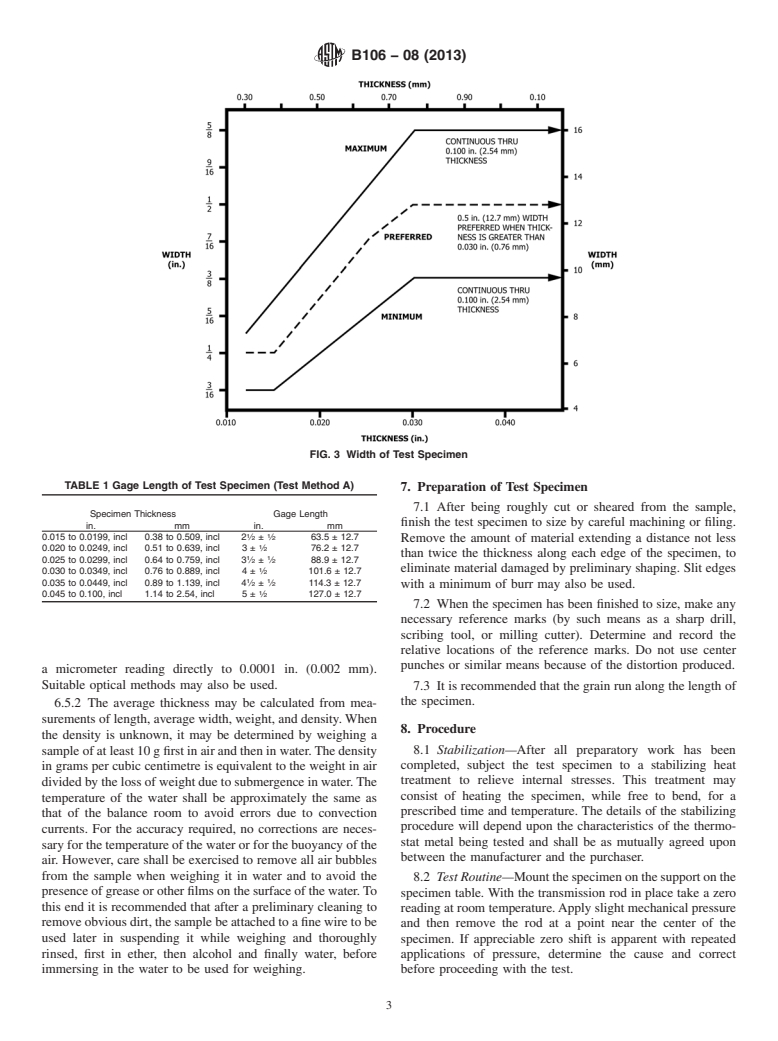

6.3 Thewidthshallberelatedtothethicknessinaccordance

device, so connected to the specimen carrier that expansion

withFig.3.Preferredwidthsaretobeusedwheneverpossible.

during heating of the carrier or connecting parts will not cause

The maximum width shall not exceed the minimum width by

appreciable displacement of the measuring device with respect

more than 2% of the latter.

to the supports.

6.4 The length shall be such as to allow a distance between

5.3 Bath—A stirred liquid bath or uniformly heated enclo-

supports that bears the relation to the thickness in accordance

sure in which the specimen carrier, together with adjustable

with Table 1 and to allow a distance beyond the supports not

electric heating source is placed. The specimen needs to be

less than the width.

maintained at the desired temperatures, with a variation in

6.5 The thickness of the specimen shall be determined

temperature throughout the gage length of the specimen not to

within 60.0001 in. (0.002 mm) by means of a screw microm-

exceed 0.5% of the temperature range used in the test.

eter or an equivalent method.

5.4 Temperature Measuring Apparatus, of such accuracy

6.5.1 For specimens less than 0.050 in. (1.27 mm) in

that the individual temperatures shall be known to within

thickness, special precautions are necessary, such as the use of

60.5°F (0.3°C).

5.5 Deflection Index—Means shall be provided for measur-

Invar is a registered trademark of CRS Holding, a subsidiary of Carpenter

ing the deflection of the specimen at a point midway between Technologies.

B106 − 08 (2013)

FIG. 3 Width of Test Specimen

TABLE 1 Gage Length of Test Specimen (Test Method A)

7. Preparation of Test Specimen

7.1 After being roughly cut or sheared from the sample,

Specimen Thickness Gage Length

finish the test specimen to size by careful machining or filing.

in. mm in. mm

1 1

0.015 to 0.0199, incl 0.38 to 0.509, incl 2 ⁄2 ± ⁄2 63.5 ± 12.7

Remove the amount of material extending a distance not less

0.020 to 0.0249, incl 0.51 to 0.639, incl 3 ± ⁄2 76.2 ± 12.7

than twice the thickness along each edge of the specimen, to

1 1

0.025 to 0.0299, incl 0.64 to 0.759, incl 3 ⁄2 ± ⁄2 88.9 ± 12.7

1 eliminate material damaged by preliminary shaping. Slit edges

0.030 to 0.0349, incl 0.76 to 0.889, incl 4 ± ⁄2 101.6 ± 12.7

1 1

0.035 to 0.0449, incl 0.89 to 1.139, incl 4 ⁄2 ± ⁄2 114.3 ± 12.7

with a minimum of burr may also be used.

0.045 to 0.100, incl 1.14 to 2.54, incl 5 ± ⁄2 127.0 ± 12.7

7.2 When the specimen has been finished to size, make any

necessary reference marks (by such means as a sharp drill,

scribing tool, or milling cutter). Determine and record the

relative locations of the reference marks. Do not use center

punches or similar means because of the distortion produced.

a micrometer reading directly to 0.0001 in. (0.002 mm).

Suitable optical methods may also be used.

7.3 It is recommended that the grain run along the length of

the specimen.

6.5.2 The average thickness may be calculated from mea-

surements of length, average width, weight, and density.When

8. Procedure

the density is unknown, it may be determined by weighing a

8.1 Stabilization—After all preparatory work has been

sampleofatleast10gfirstinairandtheninwater.Thedensity

completed, subject the test specimen to a stabilizing heat

in grams per cubic centimetre is equivalent to the weight in air

treatment to relieve internal stresses. This treatment may

dividedbythelossofweightduetosubmergenceinwater.The

consist of heating the specimen, while free to bend, for a

temperature of the water shall be approximately the same as

prescribed time and temperature. The details of the stabilizing

that of the balance room to avoid errors due to convection

procedure will depend upon the characteristics of the thermo-

currents. For the accuracy required, no corrections are neces-

stat metal being tested and shall be as mutually agreed upon

saryforthetemperatureofthewaterorforthebuoyancyofthe

between the manufacturer and the purchaser.

air. However, care shall be exercised to remove all air bubbles

from the sample when weighing it in water and to avoid the

8.2 Test Routine—Mountthespecimenonthesupportonthe

presenceofgreaseorotherfilmsonthesurfaceofthewater.To

specimen table. With the transmission rod in place take a zero

this end it is recommended that after a preliminary cleaning to

readingatroomtemperature.Applyslightmechanicalpressure

removeobviousdirt,thesamplebeattachedtoafinewiretobe

and then remove the rod at a point near the center of the

used later in suspending it while weighing and thoroughly specimen. If appreciable zero shift is apparent with repeated

rinsed, first in ether, then alcohol and finally water, before

applications of pressure, determine the cause and correct

immersing in the water to be used for weighing. before proceeding with the test.

B106 − 08 (2013)

8.3 When satisfactory initial conditions have been 8.8.1 Test the same specimen over the same temperature

established,makeobservationsofdeflectionandtemperatureat range and over a different temperature range.

low temperature and record the results. 8.8.2 Test another specimen over the same temperature

range and over a different temperature range.

8.4 Adjustthetemperatureofthespecimentothehighvalue

desired.Measureandrecordthetemperatureofthespecimenat

9. Calculation

points on or near the center and ends after sufficient time for

9.1 For the calculation, see 3.1.2, Eq 1 and Eq 2.

stabilization.

8.5 Measure and record the deflection.

10. Report

8.6 Remeasureandrecordthetemperaturemeasurementsas

10.1 The report shall include the following:

described in 6.4. If significant discrepancies of temperature or

10.1.1 Type of thermostat metal,

its distribution are found, correct them and again measure and

10.1.2 Dimensions of specimen,

record the deflection.

10.1.3 Temperature and type of stabilizing heat treatment,

8.7 After having secured satisfactory temperature measure-

10.1.4 Temperature range of test, and

ments and corresponding deflection data, establish the next

10.1.5 Flexivity.

chosen temperature and follow the preceding routine over the

agreed upon range of temperatures. 11. Precision and Bias

8.8 In all cases, make a final set of measurements at or near 11.1 Cumulativeerrorsinthemeasurementofactivelength,

room temperature to determine whether or not there has been temperature, thickness, and deflection positions can produce

permanent distortion or any mechanical incident that would discrepanciesbetweenflexivitydeterminationsonthesametest

prevent determination of flexivity within the desired limits of specimen.Table2andTable3tabulatecumulativeerrorsusing

accuracy. If such is evident, repeat the test under one of the a statistical approach for various sample sizes, flexivities, and

following conditions as agreed upon by the manufacturer and temperature differences as percent at one standard deviation.

the purchaser. Bias was not detected in round-robin measurements.

TABLE 2 Cumulative Errors in Flexivity Determination of Flat Strips (Test Method A)

NOTE 1—Interpolate for values not given in Table 2.

Flexivity tQ One Standard Deviation Error in Flexivity, ± %

in./in.°F (mm/mm°C) in. (mm) in. (mm) ∆T = 100°F ∆T = 200°F ∆T = 300°F

(55.5°C) (111.0°C) (166.5°C)

High flexivity samples typically

–6 –6

21×10 (37.8 × 10 ) 0.100 (2.54) 5 (127.0) 0.82 0.44 0.32

0.090 (2.29) 5 (127.0) 0.80 0.43 0.32

0.080 (2.03) 5 (127.0) 0.79 0.43 0.32

0.070 (1.78) 5 (127.0) 0.78 0.43 0.32

0.060 (1.52) 5 (127.0) 0.78 0.43 0.34

0.050 (1.27) 5 (127.0) 0.77 0.44 0.35

0.040 (1.02) 4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.