ASTM A982/A982M-10

(Specification)Standard Specification for Steel Forgings, Stainless, for Compressor and Turbine Airfoils

Standard Specification for Steel Forgings, Stainless, for Compressor and Turbine Airfoils

ABSTRACT

This specification covers stainless steel forgings for compressor and turbine bucket, blade, and airfoil applications. The stainless steel shall be made by the melting process and either the closed impression die or the open die forging processes may be utilized. Two complete heat treatments, consisting of an austenize, quench, and temper, are permitted. When heat treatment for mechanical properties is followed by straightening, a stress-relieving heat treatment is required. The forgings shall be subjected to tension, impact, hardness, and non-destructive tests. All forgings shall be free of cracks, seams, laps, shrinkage, and similar discontinuities.

SCOPE

1.1 This specification covers stainless steel forgings for compressor and turbine bucket, blade, and airfoil applications.

1.2 This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies the applicable M designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A982/A982M −10

StandardSpecification for

Steel Forgings, Stainless, for Compressor and Turbine

1

Airfoils

This standard is issued under the fixed designationA982/A982M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. General Requirements

1.1 This specification covers stainless steel forgings for

4.1 Materials supplied to this specification shall conform to

compressor and turbine bucket, blade, and airfoil applications.

the requirements of Specification A788/A788M, which out-

lines additional ordering information, manufacturing

1.2 This specification is expressed in both inch-pound units

requirements, testing and retesting methods and procedures,

and in SI units; however, unless the purchase order or contract

marking, certification, product analysis variations and addi-

specifies the applicable M designation (SI units), the inch-

tional supplementary requirements.

pound units shall apply. The values stated in either inch-pound

units or SI units are to be regarded separately as standard.

4.2 If the requirements of this specification are in conflict

Within the text, the SI units are shown in brackets. The values

with the requirements of Specification A788/A788M, the

stated in each system may not be exact equivalents; therefore,

requirements of this specification shall prevail.

each system shall be used independently of the other. Combin-

ing values from the two systems may result in nonconformance

5. Manufacture

with the standard.

5.1 MeltingProcess—AllmeltingprocessesofSpecification

2. Referenced Documents

A788/A788M are permitted unless Supplementary Require-

2

ment S1 is invoked by the purchaser.

2.1 ASTM Standards:

A275/A275M Practice for Magnetic Particle Examination of

5.2 Forging Process—Either the closed impression die or

Steel Forgings

the open die forging processes may be utilized unless the

A788/A788M Specification for Steel Forgings, General Re-

purchaser specifies one or the other.

quirements

5.2.1 Forging Temperature—The maximum part tempera-

E112 Test Methods for Determining Average Grain Size

ture during forging shall be 2150°F [1175°C].

E292 Test Methods for Conducting Time-for-Rupture Notch

5.3 HeatTreatment—Heattreatingallforgingsisrequiredin

Tension Tests of Materials

accordance with Table 1 to develop the required mechanical

E381 Method of Macroetch Testing Steel Bars, Billets,

properties.

Blooms, and Forgings

E562 Test Method for Determining Volume Fraction by 5.3.1 Number of Heat Treatments—Two complete heat

Systematic Manual Point Count treatments, consisting of an austenitize, quench, and temper,

are permitted. Purchaser approval is required prior to any

3. Ordering Information

additional heat treatments.

3.1 In addition to the ordering information required by

5.3.2 Temperature Variation—Heat treating temperatures

Specification A788/A788M, the purchaser shall include a

shall be controlled in the range of 625°F [614°C].

sketchorwrittendescriptionoftheforgingwiththeinquiryand

5.4 Stress Relief—When heat treatment for mechanical

order.

properties is followed by straightening, a stress-relieving heat

treatmentisrequiredatatemperaturemeetingtherequirements

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

of Table 1.

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets. 5.4.1 QuenchingafterStressRelief—Water or oil quenching

Current edition approved Nov. 1, 2010. Published December 2010. Originally

of stress-relieved forgings is prohibited.

published in 1998. Last previous edition approved in 2010 as A982/

A982M – 05 (2010). DOI: 10.1520/A0982_A0982M-10.

2

6. Chemical Composition

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Thesteelshallconformtotherequirementsforchemical

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. composition prescribed in Table 2.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A982/A982M − 10

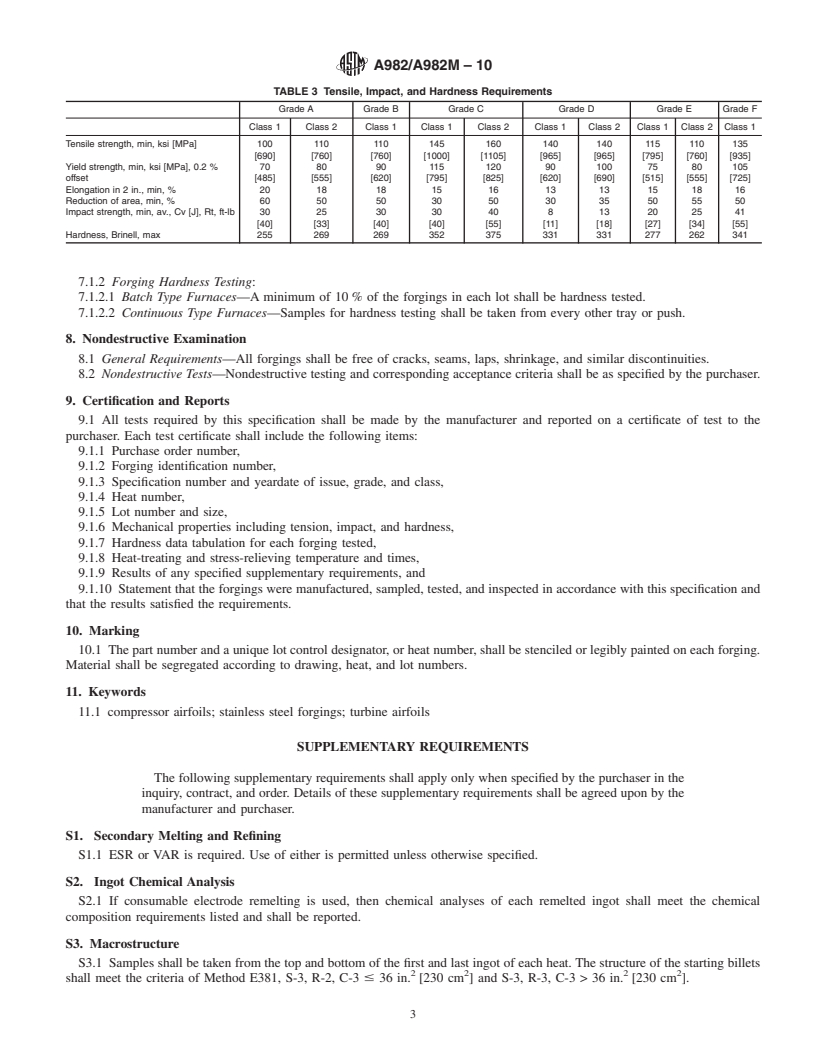

TABLE 1 Heat Treatment, °F [°C]

Grade A Grade B Grade C Grade D Grade E Grade F

Classes1&2 Class1 Class1 Class2 Classes1&2 Class1 Class2 Class1

Austenitizing 1725-1775 1600-1750 1825-1875 1725-1875 1875-1925 2075-2125 1725-1775 1875-1925

[940-970] [870-955] [995-1025] [940-1025] [1025-1050] [1135-1165] [940-970] [1025-1050]

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A982/A982M–05 (Reapproved 2010) Designation: A982/A982M – 10

Standard Specification for

Steel Forgings, Stainless, for Compressor and Turbine

1

Airfoils

This standard is issued under the fixed designationA982/A982M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers stainless steel forgings for compressor and turbine bucket, blade, and airfoil applications.

1.2 This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract

specifies the applicable M designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units or

SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in nonconformance with the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A275/A275M Practice for Magnetic Particle Examination of Steel Forgings

A788/A788M Specification for Steel Forgings, General Requirements

E112 Test Methods for Determining Average Grain Size

E292 Test Methods for Conducting Time-for-Rupture Notch Tension Tests of Materials

E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

E562 Test Method for Determining Volume Fraction by Systematic Manual Point Count

3. Ordering Information

3.1 In addition to the ordering information required by Specification A788/A788M, the purchaser shall include a sketch or

written description of the forging with the inquiry and order.

4. General Requirements

4.1 Materials supplied to this specification shall conform to the requirements of Specification A788/A788M, which outlines

additional ordering information, manufacturing requirements, testing and retesting methods and procedures, marking, certification,

product analysis variations and additional supplementary requirements.

4.2 IftherequirementsofthisspecificationareinconflictwiththerequirementsofSpecificationA788/A788M,therequirements

of this specification shall prevail.

5. Manufacture

5.1 MeltingProcess—AllmeltingprocessesofSpecificationA788/A788MarepermittedunlessSupplementaryRequirementS1

is invoked by the purchaser.

5.2 Forging Process—Either the closed impression die or the open die forging processes may be utilized unless the purchaser

specifies one or the other.

5.2.1 Forging Temperature—The maximum part temperature during forging shall be 2150°F [1175°C].

5.3 Heat Treatment—Heat treating all forgings is required in accordance with Table 1 to develop the required mechanical

properties.

5.3.1 Number of Heat Treatments—Two complete heat treatments, consisting of an austenitize, quench, and temper, are

permitted. Purchaser approval is required prior to any additional heat treatments.

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.06

on Steel Forgings and Billets.

Current edition approved AprilNov. 1, 2010. Published MayDecember 2010. Originally published in 1998. Last previous edition approved in 20052010 as

A982/A982M – 05 (2010). DOI: 10.1520/A0982_A0982M-05R10.10.1520/A0982_A0982M-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A982/A982M – 10

TABLE 1 Heat Treatment, °F [°C]

Grade A Grade B Grade C Grade D Grade E Grade F

Classes1&2 Class1 Class1 Class2 Classes1&2 Class1 Class2 Class1

Austenitizing 1725-1775 1600-1750 1825-1875 1725-1875 1875-1925 2075-2125 1725-1775 1875-1925

[940-970] [870-955] [995-1025] [940-1025] [1025-1050] [1135-1165] [940-970] [1025-1050]

Quenching Air or liquid Air or liquid Air or liquid Air or liquid Air or liquid Air or liquid Air or liquid Air or liquid

Single tempering 1050 min 1050 min 1050 min 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.