ASTM D4796-88(1998)

(Test Method)Standard Test Method for Bond Strength of Thermoplastic Traffic Marking Materials

Standard Test Method for Bond Strength of Thermoplastic Traffic Marking Materials

SCOPE

1.1 This test method provides an instrumental means for the determination of thermoplastic traffic marking material bond strengths using cement bricks and steel cubes.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4796 – 88 (Reapproved 1998)

Standard Test Method for

Bond Strength of Thermoplastic Traffic Marking Materials

This standard is issued under the fixed designation D 4796; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method provides an instrumental means for the 4.1 The thermoplastic specimen is prepared for this test by

determination of thermoplastic traffic marking material bond first melting a sample to its application temperature under

strengths using cement bricks and steel cubes. continuous agitation. The specimen is then applied to the

1.2 The values stated in inch-pound units are to be regarded specified cement brick by a hot drawdown blade. Two steel

as the standard. The values given in parentheses are for cubes are then immediately placed onto the hot thermoplastic

information only. line and the excess thermoplastic trimmed away from around

1.3 This standard does not purport to address all of the the two steel cubes. After the trimming is complete, the steel

safety concerns, if any, associated with its use. It is the cubes are removed. A heated steel cube is bonded with epoxy

responsibility of the user of this standard to establish appro- to the square of thermoplastic and allowed to cure overnight

priate safety and health practices and determine the applica- before determining the bond strength on a Dillon dynamometer

bility of regulatory limitations prior to use. or similar device.

2. Referenced Documents 5. Significance and Use

2.1 ASTM Standards: 5.1 The function of this test method is to provide numerical

C 109 Test Method for Compressive Strength of Hydraulic instrumental results indicating the cohesive or adhesive, or

Cement Mortars (Using 2-in. or 50-mm Cube Specimens) both, bond strength of thermoplastic traffic marking to a

C 881 Specification for Epoxy-Resin-Base Bonding Sys- specified cement brick substrate.

tems for Concrete 5.2 The use of this test method allows the user and manu-

D 883 Terminology Relating to Plastics facturer to control the quality of the product and make

E 284 Terminology of Appearance inferences about the performance of the thermoplastic traffic

F 412 Terminology Relating to Plastic Piping Systems marking product. Results from these tests also provide infor-

mation helpful in researching and developing thermoplastic

3. Terminology

traffic marking materials.

3.1 Definitions—Definitions are in accordance with Termi-

5.3 Strict adherence to the procedures outlined is necessary

nology D 883, E 284, and F 412, unless otherwise indicated. for precision of the test method. Under no conditions should

3.2 Definitions of Terms Specific to This Standard:

the bond strength be accepted unless there is conformance to

3.2.1 cement brick—a brick formed by mixing cement and 9.14. Precise results are obtained only when one steel block is

fine sand together and allowing to harden.

epoxied to the thermoplastic traffic marking on the cement

3.2.2 thermoplastic—traffic marking (same as 3.2.3). brick.

3.2.3 thermoplastic traffıc marking—a highly filled 100 %

6. Types of Separation in Bond Strength Tests

total solids highway marking system that when heated to a

molten state can be extruded or sprayed onto a road surface and 6.1 Thermoplastic to Steel Cube Separation—This type of

when cooled forms a solid durable delineator. separation occurs where there is an insufficient bond between

the thermoplastic and steel cube probably due to insufficient

coverage of the epoxy adhesive.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

6.2 Thermoplastic to Thermoplastic Separation—This type

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.44 on Traffic Coatings. of separation is caused by internal cohesive failure of the

Current edition approved Oct. 31, 1988. Published December 1988.

thermoplastic. This separation is acceptable when it exceeds

Annual Book of ASTM Standards, Vol 04.01.

the specified bond strength.

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 06.01.

Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4796

6.3 Thermoplastic to Cement Brick Separation—This type

of separation is caused by the failure of the bond between the

thermoplastic specimen and the cement brick.

6.4 Cement Brick to Cement Brick—This type of separation

is caused by the internal cohesive failure of the brick. This is

due, in most cases, to a bond between the thermoplastic and

cement brick that exceeds the cohesive strength of the cement

brick. This separation is not acceptable when the bond strength

values are lower than specified.

7. Apparatus

7.1 Agitator Blade, 6 in. (150 mm) long with a ⁄2-in. (10

3 1

mm) steel shaft and a 1 ⁄4 by 1 in. by ⁄8-in. (45 by 25 by 3 mm)

straight horizontal steel blade.

7.2 Capped Bolts, two, ⁄8 in. (16 mm) in size.

1 1

7.3 Cement Bricks,3 ⁄2 by2by7 ⁄2-in. (9 by 5 by 19 cm) in

size with a compressive strength of 3000 to 5000 psi (Note 1).

NOTE 1—Concrete bricks conforming to Test Method C 109 have been

used but proved more variable due to migration of a thin veneer of cement

to the top of the brick making determinations erratic. The cement bricks

may be obtained from local block plants. The term “cement” brick is

common for the industry and is used in this test method extensively.

NOTE 2—The unit should be fitted with a steel frame to hold the cement

brick for testing.

7.4 Dynamometer, with a capacity of 6000 lbs in 25-lb

(2700 kg in 10 kg) divisions having a pull-rate capability of

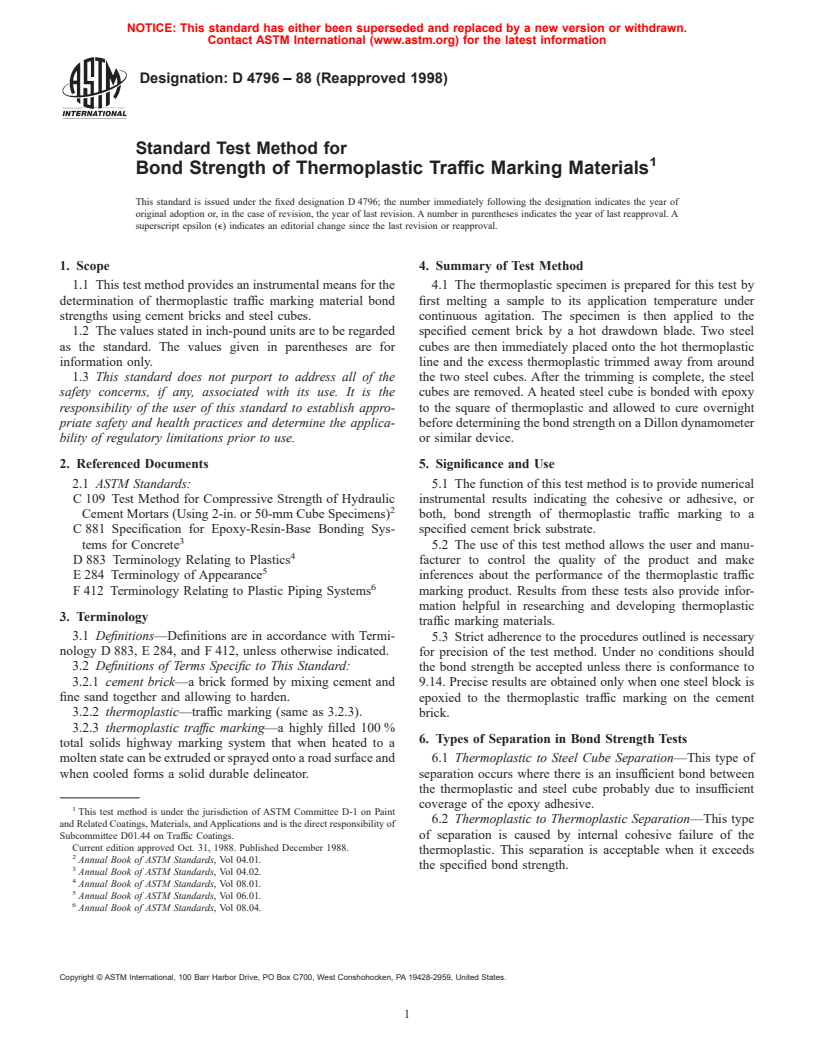

FIG. 2 Tension Bed

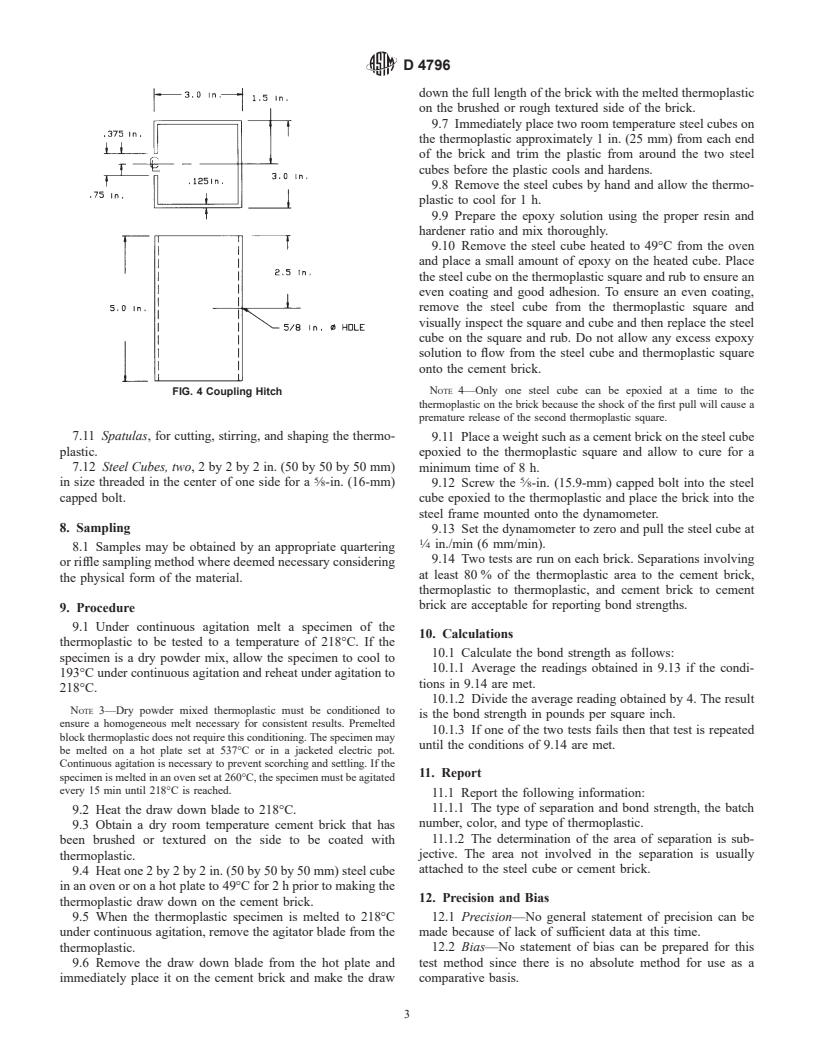

⁄4in./min. (6 mm/min) (Note 2) (See Fig. 1, Fig. 2, Fig. 3, and

Fig. 4).

7.5 Draw Down Blade, 2 by 1 by 4 in. (5 by 2.5 by 10 cm)

in size capable of laying down a 125 mil (0.125 in.) wet

thermoplastic film 2-in. wide.

7.6 Drill Press, or other apparatus capable of agitating the

thermoplastic during meltdown to the application tempera

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.