ASTM A804/A804M-04(2021)

(Test Method)Standard Test Methods for Alternating-Current Magnetic Properties of Materials at Power Frequencies Using Sheet-Type Test Specimens

Standard Test Methods for Alternating-Current Magnetic Properties of Materials at Power Frequencies Using Sheet-Type Test Specimens

SIGNIFICANCE AND USE

4.1 Materials Evaluation—These test methods were developed to supplement the testing of Epstein specimens for applications involving the use of flat, sheared laminations where the testing of Epstein specimens in either the as-sheared or stress-relief-annealed condition fails to provide the most satisfactory method of predicting magnetic performance in the application. As a principal example, the test methods have been found particularly applicable to the control and evaluation of the magnetic properties of thermally flattened, grain-oriented electrical steel (Condition F5, Specification A876) used as lamination stock for cores of power transformers. Inasmuch as the test methods can only be reliably used to determine unidirectional magnetic properties, the test methods have limited applicability to the testing of fully processed nonoriented electrical steels as normally practiced (Specification A677).

4.2 Specification Acceptance—The reproducibility of test results and the accuracy relative to the 25-cm [250-mm] Epstein method of test are considered such as to render the test methods suitable for materials specification testing.

4.3 Interpretation of Test Results—Because of specimen size, considerable variation in magnetic properties may be present within a single specimen or between specimens that may be combined for testing purposes. Also, variations may exist in test values that are combined to represent a test lot of material. Test results reported will therefore, in general, represent averages of magnetic quality and in certain applications, particularly those involving narrow widths of laminations, deviations in magnetic performance from those expected from reported data may occur at times. Additionally, application of test data to the design or evaluation of a particular magnetic device must recognize the influence of magnetic circuitry upon performance and the possible deterioration in magnetic properties arising from construction of the device.

4.4 ...

SCOPE

1.1 These test methods cover the determination of specific core loss and peak permeability of single layers of sheet-type specimens tested with normal excitation at a frequency of 50 or 60 Hz.

Note 1: These test methods have been applied only at the commercial power frequencies, 50 and 60 Hz, but with proper instrumentation and application of the principles of testing and calibration embodied in the test methods, they are believed to be adaptable to testing at frequencies ranging from 25 to 400 Hz.

1.2 These test methods use calibration procedures that provide correlation with the 25-cm [250-mm] Epstein test.

1.3 The range of test magnetic flux densities is governed by the properties of the test specimen and by the available instruments and other equipment components. Normally, nonoriented electrical steels can be tested over a range from 8 to 16 kG [0.8 to 1.6 T] for core loss. For oriented electrical steels, the normal range extends to 18 kG [1.8 T]. Maximum magnetic flux densities in peak permeability testing are limited principally by heating of the magnetizing winding and tests are limited normally to a maximum ac magnetic field strength of about 150 Oe [12 000 A/m].

1.4 These test methods cover two alternative procedures as follows:

Test Method 1—Sections 6 – 12

Test Method 2—Sections 13 – 19

1.4.1 Test Method 1 uses a test fixture having (1) two windings that encircle the test specimen, and (2) a ferromagnetic yoke structure that serves as the flux return path and has low core loss and low magnetic reluctance.

1.4.2 Test Method 2 uses a test fixture having (1) two windings that encircle the test specimen, (2) a third winding located inside the other two windings and immediately adjacent to one surface of the test specimen, and (3) a ferromagnetic yoke structure which serves as the flux-return path and has low magnetic reluctance.

1.5 The values and equations stated in customary (cgs-emu a...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A804/A804M − 04 (Reapproved 2021)

Standard Test Methods for

Alternating-Current Magnetic Properties of Materials at

Power Frequencies Using Sheet-Type Test Specimens

This standard is issued under the fixed designationA804/A804M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope netic yoke structure which serves as the flux-return path and

has low magnetic reluctance.

1.1 These test methods cover the determination of specific

1.5 The values and equations stated in customary (cgs-emu

core loss and peak permeability of single layers of sheet-type

and inch-pound) units or SI units are to be regarded separately

specimenstestedwithnormalexcitationatafrequencyof50or

as standard. Within this standard, SI units are shown in

60 Hz.

brackets except for the sections concerning calculations where

NOTE 1—These test methods have been applied only at the commercial

there are separate sections for the respective unit systems. The

power frequencies, 50 and 60 Hz, but with proper instrumentation and

values stated in each system may not be exact equivalents;

applicationoftheprinciplesoftestingandcalibrationembodiedinthetest

therefore,eachsystemshallbeusedindependentlyoftheother.

methods, they are believed to be adaptable to testing at frequencies

ranging from 25 to 400 Hz.

Combiningvaluesfromthetwosystemsmayresultinnoncon-

formance with this standard.

1.2 These test methods use calibration procedures that

provide correlation with the 25-cm [250-mm] Epstein test. 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.3 The range of test magnetic flux densities is governed by

responsibility of the user of this standard to establish appro-

the properties of the test specimen and by the available

priate safety, health, and environmental practices and deter-

instruments and other equipment components. Normally, non-

mine the applicability of regulatory limitations prior to use.

orientedelectricalsteelscanbetestedoverarangefrom8to16

1.7 This international standard was developed in accor-

kG[0.8to1.6T]forcoreloss.Fororientedelectricalsteels,the

dance with internationally recognized principles on standard-

normal range extends to 18 kG [1.8 T]. Maximum magnetic

ization established in the Decision on Principles for the

flux densities in peak permeability testing are limited princi-

Development of International Standards, Guides and Recom-

pally by heating of the magnetizing winding and tests are

mendations issued by the World Trade Organization Technical

limited normally to a maximum ac magnetic field strength of

Barriers to Trade (TBT) Committee.

about 150 Oe [12000 A/m].

1.4 These test methods cover two alternative procedures as 2. Referenced Documents

follows:

2.1 ASTM Standards:

Test Method 1—Sections6–12

A34/A34MPractice for Sampling and Procurement Testing

Test Method 2—Sections13–19

of Magnetic Materials

1.4.1 Test Method 1 uses a test fixture having (1) two

A340Terminology of Symbols and Definitions Relating to

windings that encircle the test specimen, and (2) a ferromag-

Magnetic Testing

netic yoke structure that serves as the flux return path and has

A343/A343MTest Method for Alternating-Current Mag-

low core loss and low magnetic reluctance.

netic Properties of Materials at Power Frequencies Using

1.4.2 Test Method 2 uses a test fixture having (1) two

Wattmeter-Ammeter-Voltmeter Method and 25-cm Ep-

windings that encircle the test specimen, (2) a third winding

stein Test Frame

located inside the other two windings and immediately adja-

A677Specification for Nonoriented Electrical Steel Fully

cent to one surface of the test specimen, and (3) a ferromag-

Processed Types

A683Specification for Nonoriented Electrical Steel, Semi-

processed Types

These test methods are under the jurisdiction of ASTM Committee A06 on

Magnetic Properties and are the direct responsibility of Subcommittee A06.01 on

Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2021. Published February 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1982. Last previous edition approved in 2015 as A804/A804M–04 Standards volume information, refer to the standard’s Document Summary page on

(2015). DOI: 10.1520/A0804_A0804M-04R21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A804/A804M − 04 (2021)

A876Specification for Flat-Rolled, Grain-Oriented, Silicon- exist in test values that are combined to represent a test lot of

Iron, Electrical Steel, Fully Processed Types material. Test results reported will therefore, in general, repre-

sent averages of magnetic quality and in certain applications,

3. Terminology

particularly those involving narrow widths of laminations,

deviations in magnetic performance from those expected from

3.1 Definitions:

reported data may occur at times. Additionally, application of

3.1.1 General—The definitions of terms, symbols, and con-

test data to the design or evaluation of a particular magnetic

version factors relating to magnetic testing found in Terminol-

devicemustrecognizetheinfluenceofmagneticcircuitryupon

ogy A340 are used in these test methods.

performance and the possible deterioration in magnetic prop-

3.2 Definitions of Terms Specific to This Standard:

erties arising from construction of the device.

3.2.1 sheet specimen—a rectangular specimen comprised of

4.4 RecommendedStandardTests—Thesetestmethodshave

a single piece of material or paralleled multiple strips of

been principally applied to the magnetic testing of thermally

material arranged in a single layer.

flattened, grain-oriented electrical steels at 50 and 60 Hz.

4. Significance and Use Specific core loss at 15 or 17 kG [1.5 or 1.7 T] and peak

permeability (if required) at 10 Oe [796 A/m] are the recom-

4.1 Materials Evaluation—These test methods were devel-

mended parameters for evaluating this class of material.

oped to supplement the testing of Epstein specimens for

applications involving the use of flat, sheared laminations

5. Sampling

where the testing of Epstein specimens in either the as-sheared

5.1 LotSizeandSampling—Unlessotherwiseestablishedby

or stress-relief-annealed condition fails to provide the most

mutualagreementbetweenthemanufacturerandthepurchaser,

satisfactory method of predicting magnetic performance in the

determination of a lot size and the sampling of a lot to obtain

application.Asaprincipalexample,thetestmethodshavebeen

sheets for specimen preparation shall follow the recommenda-

found particularly applicable to the control and evaluation of

tions of Practice A34/A34M, Sections 5 and 6.

the magnetic properties of thermally flattened, grain-oriented

electrical steel (Condition F5, Specification A876) used as

METHOD 1 TWO-WINDING YOKE-FIXTURE TEST

lamination stock for cores of power transformers. Inasmuch as

METHOD

the test methods can only be reliably used to determine

unidirectional magnetic properties, the test methods have

6. Basic Test Circuit

limited applicability to the testing of fully processed nonori-

6.1 Fig. 1 provides a schematic circuit diagram for the test

ented electrical steels as normally practiced (Specification

method.Apowersourceofpreciselycontrollableacsinusoidal

A677).

voltage is used to energize the primary circuit. To minimize

4.2 Specification Acceptance—The reproducibility of test

flux-waveform distortion, current ratings of the power source

results and the accuracy relative to the 25-cm [250-mm]

and of the wiring and switches in the primary circuit shall be

Epsteinmethodoftestareconsideredsuchastorenderthetest

such as to provide very low impedance relative to the imped-

methods suitable for materials specification testing.

ance arising from the test fixture and test specimen. Ratings of

4.3 Interpretation of Test Results—Because of specimen switches and wiring in the secondary circuit also shall be such

size, considerable variation in magnetic properties may be astocausenegligiblevoltagedropbetweentheterminalsofthe

present within a single specimen or between specimens that secondary test winding and the terminals of the measuring

may be combined for testing purposes. Also, variations may instruments.

FIG. 1 Basic Circuit Diagram for Method 1

A804/A804M − 04 (2021)

7. Apparatus

7.1 The test circuit shall incorporate as many of the follow-

ing components as are required to perform the desired mea-

surements.

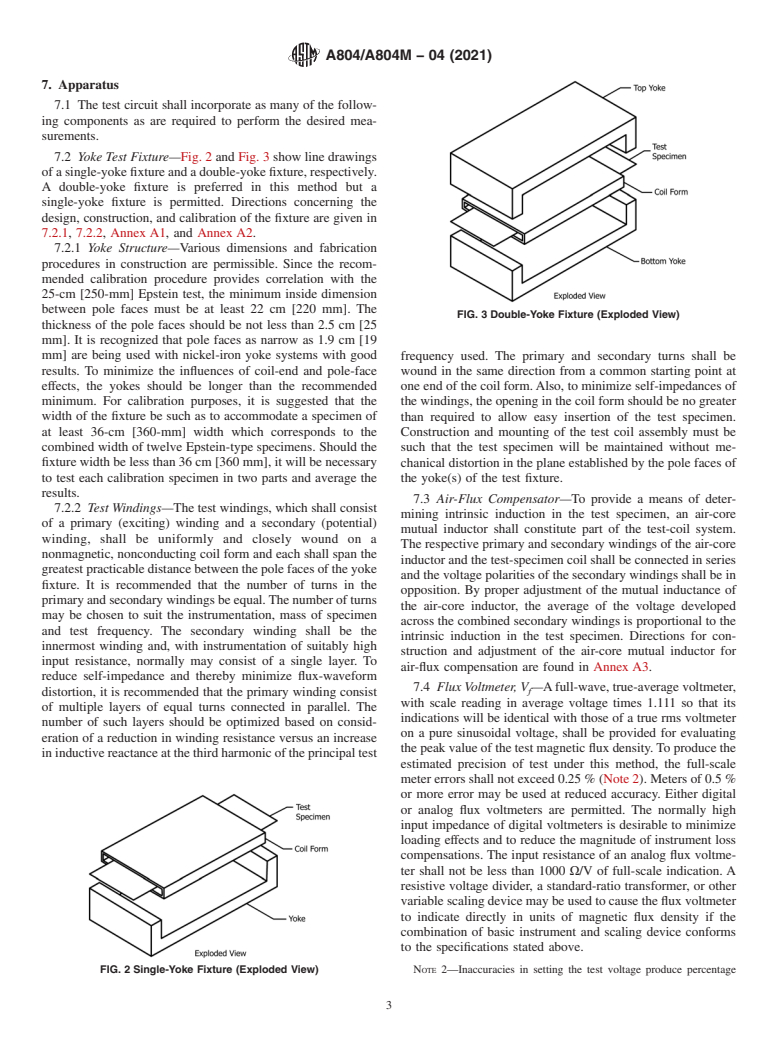

7.2 Yoke Test Fixture—Fig. 2 and Fig. 3 show line drawings

ofasingle-yokefixtureandadouble-yokefixture,respectively.

A double-yoke fixture is preferred in this method but a

single-yoke fixture is permitted. Directions concerning the

design, construction, and calibration of the fixture are given in

7.2.1, 7.2.2, Annex A1, and Annex A2.

7.2.1 Yoke Structure—Various dimensions and fabrication

procedures in construction are permissible. Since the recom-

mended calibration procedure provides correlation with the

25-cm [250-mm] Epstein test, the minimum inside dimension

between pole faces must be at least 22 cm [220 mm]. The

FIG. 3 Double-Yoke Fixture (Exploded View)

thickness of the pole faces should be not less than 2.5 cm [25

mm]. It is recognized that pole faces as narrow as 1.9 cm [19

mm] are being used with nickel-iron yoke systems with good

frequency used. The primary and secondary turns shall be

results. To minimize the influences of coil-end and pole-face wound in the same direction from a common starting point at

effects, the yokes should be longer than the recommended

one end of the coil form.Also, to minimize self-impedances of

minimum. For calibration purposes, it is suggested that the thewindings,theopeninginthecoilformshouldbenogreater

width of the fixture be such as to accommodate a specimen of

than required to allow easy insertion of the test specimen.

at least 36-cm [360-mm] width which corresponds to the Construction and mounting of the test coil assembly must be

combined width of twelve Epstein-type specimens. Should the such that the test specimen will be maintained without me-

fixturewidthbelessthan36cm[360mm],itwillbenecessary chanical distortion in the plane established by the pole faces of

to test each calibration specimen in two parts and average the the yoke(s) of the test fixture.

results.

7.3 Air-Flux Compensator—To provide a means of deter-

7.2.2 Test Windings—The test windings, which shall consist

mining intrinsic induction in the test specimen, an air-core

of a primary (exciting) winding and a secondary (potential)

mutual inductor shall constitute part of the test-coil system.

winding, shall be uniformly and closely wound on a

The respective primary and secondary windings of the air-core

nonmagnetic, nonconducting coil form and each shall span the

inductorandthetest-specimencoilshallbeconnectedinseries

greatestpracticabledistancebetweenthepolefacesoftheyoke

andthevoltagepolaritiesofthesecondarywindingsshallbein

fixture. It is recommended that the number of turns in the

opposition. By proper adjustment of the mutual inductance of

primaryandsecondarywindingsbeequal.Thenumberofturns

the air-core inductor, the average of the voltage developed

may be chosen to suit the instrumentation, mass of specimen

across the combined secondary windings is proportional to the

and test frequency. The secondary winding shall be the

intrinsic induction in the test specimen. Directions for con-

innermost winding and, with instrumentation of suitably high

struction and adjustment of the air-core mutual inductor for

input resistance, normally may consist of a single layer. To

air-flux compensation are found in Annex A3.

reduce self-impedance and thereby minimize flux-waveform

7.4 Flux Voltmeter, V—Afull-wave,true-averagevoltmeter,

f

distortion, it is recommended that the primary winding consist

with scale reading in average voltage times 1.111 so that its

of multiple layers of equal turns connected in parallel. The

indications will be identical with those of a true rms voltmeter

number of such layers should be optimized based on consid-

on a pure sinusoidal voltage, shall be provided for evaluating

eration of a reduction in winding resistance versus an increase

thepeakvalueofthetestmagneticfluxdensity.Toproducethe

ininductivereactanceatthethirdharmonicoftheprincipaltest

estimated precision of test under this method, the full-scale

metererrorsshallnotexceed0.25%(Note2).Metersof0.5%

or more error may be used at reduced accuracy. Either digital

or analog flux voltmeters are permitted. The normally high

input impedance of digital voltmeters is desirable to minimize

loading effects and to reduce the magnitude of instrument loss

compensations. The input resistance of an analog flux voltme-

ter shall not be less than 1000 Ω/V of full-scale indication. A

resistive voltage divider, a standard-ratio transformer, or other

variablescalingdevicemaybeusedtocausethefluxvoltmeter

to indicate directly in units of magnetic flux density if the

combination of basic instrument and scaling device conforms

to the specifications stated above.

FIG. 2 Single-Yoke Fixture (Exploded View) NOTE 2—Inaccuracies in setting the test voltage produce percentage

A804/A804M − 04 (2021)

errors approximately two times as large in the specific core loss. Care

maximum rms primary current to be encountered during

should also be taken to avoid errors caused by temperature and frequency

core-loss testing. Preferably the current-carrying capacity

effects in the instrument.

should be at least 10 rms amperes.

7.4.1 If used with a mutual inductor as a peak ammeter at

7.6.2 Electronic Digital Wattmeter—Electronic digital watt-

magnetic flux densities well above the knee of the magnetiza-

meters have been developed that have proven satisfactory for

tion curve, the flux voltmeter must be capable of accurately

use under the provisions of this test method. Usage of a

measuringtheextremelynonsinusoidal(peaked)voltagethatis

suitable electronic digital wattmeter is permitted as an alterna-

induced in the secondary winding of the mutual inductor.

tive to an electrodynamometer wattmeter in this test method.

Additionally, if so used, an analog flux voltmeter should have

An electronic digital w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.