ASTM D6640-01(2010)

(Practice)Standard Practice for Collection and Handling of Soils Obtained in Core Barrel Samplers for Environmental Investigations

Standard Practice for Collection and Handling of Soils Obtained in Core Barrel Samplers for Environmental Investigations

SIGNIFICANCE AND USE

Often during environmental investigations, soils are analyzed after being collected from the surface, the vadose zone (D653) and sometimes from below the ground water table to identify and quantify the presence of a chemical contaminant. A contaminant is a substance that is typically hazardous and either is not normally present or that occurs naturally but is of an uncharacteristically high concentration (D4687). A three-dimensional spatial array of samples can often provide information as to the source and route(s) of migration of the contaminant. The resultant information is used to direct remedial and corrective actions or can be used for monitoring purposes. Obtaining a soil sample with a core barrel sampler involves driving this device into the ground and then retrieving it for sample processing. Several methods for advancing a core barrel are generally acceptable (e.g., D1586, D1587, D3550, D4700, D5784, D5875, D5876, D6151, D6282, and D6286). Drilling methods that use drilling fluids (liquids or air) should be avoided because they are more susceptible to cross-contamination (See Section 5.1.6).

SCOPE

1.1 This practice covers procedures for obtaining soils from core barrel samplers for chemical and physical analysis, with an emphasis on the collection and handling procedures that maintain the representativeness of the chemical contaminants of concern. Core barrel samplers are initially empty (hollow) until they are pushed into the ground to collect and retrieve a cylindrical soil sample with minimal disturbance. The selection of equipment and the sample handling procedures are dependent on the soil properties, the depth of sampling, and the general properties of the chemical contaminants of concern, that is, volatile organic compounds, semi-volatile organic compounds, and inorganic constituents. The sampling procedures described are designed to maintain representative concentrations of the contaminants regardless of their physical state(s), that is, solid, liquid or gas.

1.2 Four general types of core barrel samplers are discussed in this practice: split-barrel, ring-lined barrel, thin-walled tube, and solid-barrel samplers.

1.3 This document does not cover all the core barrel devices that are available for the collection of soil samples.

1.4 The procedures described may or may not be applicable to handling of samples for assessing certain geotechnical properties, for example, soil porosity.

Note 1—Prior to commencement of any intrusive exploration, the site should be checked for underground utilities.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6640 − 01 (Reapproved 2010)

StandardPractice for

Collection and Handling of Soils Obtained in Core Barrel

Samplers for Environmental Investigations

This standard is issued under the fixed designation D6640; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice covers procedures for obtaining soils from

D653 Terminology Relating to Soil, Rock, and Contained

core barrel samplers for chemical and physical analysis, with

Fluids

an emphasis on the collection and handling procedures that

D1586 Test Method for Penetration Test (SPT) and Split-

maintain the representativeness of the chemical contaminants

Barrel Sampling of Soils

of concern. Core barrel samplers are initially empty (hollow)

D1587 Practice for Thin-Walled Tube Sampling of Soils for

until they are pushed into the ground to collect and retrieve a

Geotechnical Purposes

cylindricalsoilsamplewithminimaldisturbance.Theselection

D3550 Practice for Thick Wall, Ring-Lined, Split Barrel,

of equipment and the sample handling procedures are depen-

Drive Sampling of Soils

dent on the soil properties, the depth of sampling, and the

D3694 Practices for Preparation of Sample Containers and

general properties of the chemical contaminants of concern,

for Preservation of Organic Constituents

that is, volatile organic compounds, semi-volatile organic

D4547 Guide for Sampling Waste and Soils for Volatile

compounds, and inorganic constituents. The sampling proce-

Organic Compounds

dures described are designed to maintain representative con-

D4687 Guide for General Planning of Waste Sampling

centrations of the contaminants regardless of their physical

D4700 Guide for Soil Sampling from the Vadose Zone

state(s), that is, solid, liquid or gas.

D5088 Practice for Decontamination of Field Equipment

1.2 Four general types of core barrel samplers are discussed

Used at Waste Sites

in this practice: split-barrel, ring-lined barrel, thin-walled tube,

D5784 Guide for Use of Hollow-Stem Augers for Geoenvi-

and solid-barrel samplers.

ronmental Exploration and the Installation of Subsurface

1.3 This document does not cover all the core barrel devices

Water-Quality Monitoring Devices

that are available for the collection of soil samples.

D5792 Practice for Generation of Environmental Data Re-

lated to Waste Management Activities: Development of

1.4 The procedures described may or may not be applicable

Data Quality Objectives

to handling of samples for assessing certain geotechnical

D5875 Guide for Use of Cable-Tool Drilling and Sampling

properties, for example, soil porosity.

NOTE 1—Prior to commencement of any intrusive exploration, the site Methods for Geoenvironmental Exploration and Installa-

should be checked for underground utilities.

tion of Subsurface Water-Quality Monitoring Devices

1.5 This standard does not purport to address all of the D5876 Guide for Use of Direct Rotary Wireline Casing

Advancement Drilling Methods for Geoenvironmental

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- Exploration and Installation of Subsurface Water-Quality

Monitoring Devices

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. D6051 Guide for Composite Sampling and Field Subsam-

pling for Environmental Waste Management Activities

D6151 Practice for Using Hollow-StemAugers for Geotech-

nical Exploration and Soil Sampling

This practice is under the jurisdiction of ASTM Committee D34 on Waste

Management and is the direct responsibility of Subcommittee D34.01.03 on

Sampling Equipment. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2010. Published June 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2001. Last previous edition approved in 2005 as D6640-01 (2005). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D6640-01R10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6640 − 01 (Reapproved 2010)

D6169 Guide for Selection of Soil and Rock Sampling rule samples obtained for semi-volatile organic compound

Devices Used With Drill Rigs for Environmental Investi- analysiscanbeobtainedwithinacorebarrelorcorebarrelliner

gations that is composed of stainless steel, steel, or brass. When only

D6232 Guide for Selection of Sampling Equipment for inorganic constituents are of concern, a plastic core barrel liner

WasteandContaminatedMediaDataCollectionActivities would be more appropriate than the previously cited materials.

D6282 Guide for Direct Push Soil Sampling for Environ- All of these materials are suitable for volatile organic com-

mental Site Characterizations (Withdrawn 2014) pounds as long as the contact time is minimized. Often all of

D6286 Guide for Selection of Drilling Methods for Environ- the above samples (semi-volatile organic, inorganic, and vola-

mental Site Characterization tileorganiccompounds)areobtainedfromasinglesoilcore.In

this situation, soils should be taken from the interior of the soil

3. Summary of Practice

core to avoid potential interferences between the contaminants

3.1 Obtaining soil samples from the surface and subsurface of concern and the surface of the core barrel that is in direct

contact with the sample.

for chemical and physical analysis often involves the advance-

ment of a core barrel sampler into the ground. A core barrel 5.1.2 The design of the core barrel sampler should allow for

sampler can be operated by hand or mechanically, and it may easy access to the sampled substrate for all subsequent han-

beofaclosedoropendesign(D6282).Oncethecorebarrelhas dling procedures.

been filled, the sampler is recovered from the bore hole and the 5.1.3 Core barrel size requirements depend on the type and

soil sample is handled appropriately for the chemical constitu-

number of chemical constituents of concern. For example,

ents of concern. more soil is needed for the collection of samples intended for

semi-volatile organic compound analysis than for the analysis

3.2 This practice describes collection and handling proce-

of volatile organic compounds or inorganic constituents or

dures used with four types of core barrel samplers. The

both. Typically, a 250-mL(8-oz) bottle is filled for the analysis

standardsrelatedtodataqualityobjectives(D5792),equipment

ofsemi-volatileorganiccompounds,a125-mL(4-oz)bottlefor

specifications (D6232, D6169 and D4700), their limitations

inorganic constituents, and only 5-g subsamples are taken for

and advantages (D6282), and the site-specific geological and

volatile organic compounds.

hydrological data should be reviewed to determine the soil

5.1.4 Suitability for soil type, that is, grain size, cohesion

coring equipment that is best suited for a specific project.

properties, and moisture content. For example, when sampling

4. Significance and Use non-cohesive materials or when sampling below the water

table, a core catcher (basket) should be used to limit the loss of

4.1 Often during environmental investigations, soils are

sample and ground water during retrieval (D4700 and D6282).

analyzed after being collected from the surface, the vadose

5.1.5 The spreading of contamination between sampling

zone(D653)andsometimesfrombelowthegroundwatertable

depths should be minimized. Sealed hollow-barrel samplers

to identify and quantify the presence of a chemical contami-

(6.1.4) or cased bore holes and proper advancement techniques

nant. A contaminant is a substance that is typically hazardous

should be used to limit cross-contamination between sampling

and either is not normally present or that occurs naturally but

depths in the vadose zone.Although a cased bore hole does not

is of an uncharacteristically high concentration (D4687). A

guarantee that contamination will not be spread from one

three-dimensional spatial array of samples can often provide

sampling depth to another, it lowers the possibility and

information as to the source and route(s) of migration of the

eliminates the potential for bore hole collapse and side wall

contaminant. The resultant information is used to direct reme-

slough that can compromise the integrity of the samples

dial and corrective actions or can be used for monitoring

removed from uncased bore holes. When there is standing

purposes. Obtaining a soil sample with a core barrel sampler

ground water in the bore hole, a sealed sampler system should

involves driving this device into the ground and then retrieving

be used.

it for sample processing. Several methods for advancing a core

5.1.6 Other criteria that should be considered when select-

barrel are generally acceptable (e.g., D1586, D1587, D3550,

ing a core barrel sampler for soil sampling include sampling

D4700, D5784, D5875, D5876, D6151, D6282, and D6286).

depth (see Guide D6286, for selection of drilling method), site

Drilling methods that use drilling fluids (liquids or air) should

accessibility, time constraints, and appropriate equipment

be avoided because they are more susceptible to cross-

availability.

contamination (See Section 5.1.6).

5. Equipment Selection Criteria

6. Sampling Equipment

5.1 Important criteria to consider when selecting a core

6.1 The types of core barrel samplers discussed in this

barrel sampler for soil sampling are:

practice are the split-barrel, ring-lined barrel, thin-walled tube,

5.1.1 The materials that come into direct contact with the

and solid-barrel samplers. These samplers are part of equip-

soil sample (barrel or barrel liner) should be compatible with

ment that is either manually or mechanically powered, are

the chemical or physical properties of the contaminant(s) of

designed to excavate a bore hole to the sampling depth, and

concern and the chemical properties of the soil. As a general

may remain in the bore hole during the sample collection

activity (i.e., cased bore hole or dual-walled casing).

6.1.1 Split-Barrel Sampler—As described in Methods

The last approved version of this historical standard is referenced on

www.astm.org. D1586 and D4700, the split-barrel sampler is composed of a

D6640 − 01 (Reapproved 2010)

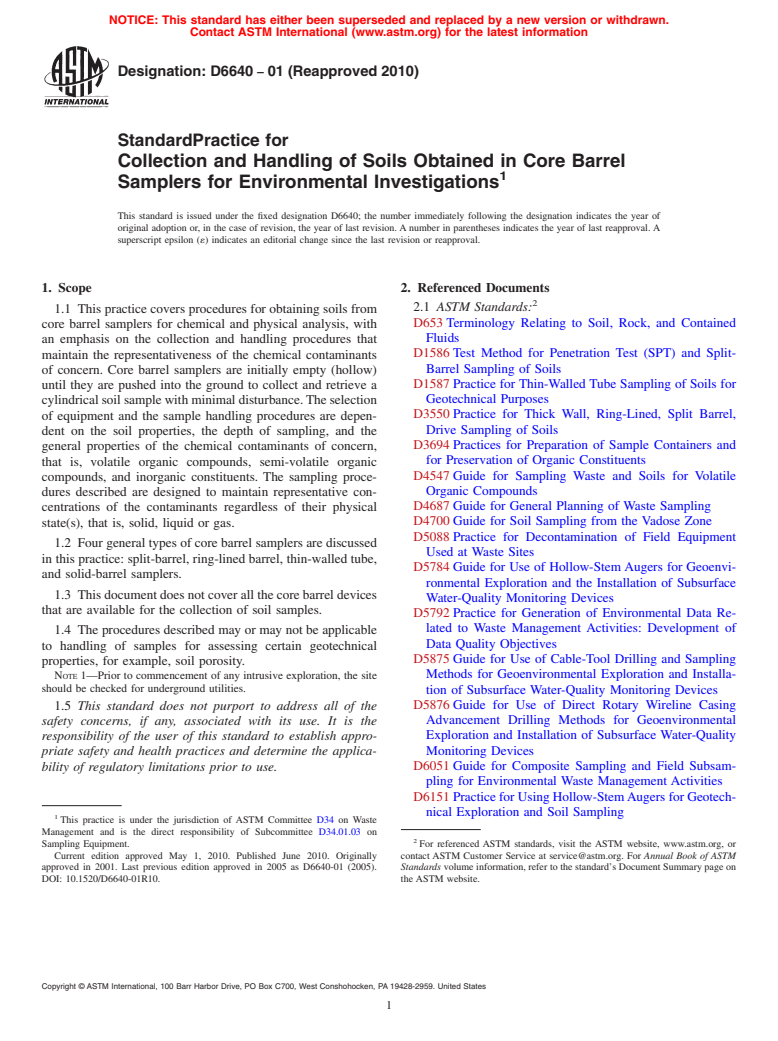

core barrel cut in half along the length of the barrel, a hardened

metal drive shoe (cutting tip) and a sample head that vents

(e.g., a ball check valve) to allow air to be displaced as it is

filled (see Fig. 1). The shoe and the head thread onto opposite

ends of the split barrel and hold the two halves together. A

common barrel size is 5.08 cm (2 in.) outside diameter and

3.81 cm (1.5 in.) inside diameter.The drive shoe used with this

particular barrel size has an inside diameter of 3.49 cm (1.375

in.). If fitted with a liner for encasing the sample, the inside

diameter of the core barrel liner should not be less than the

drive shoe. Several other sizes of split-barrel samplers are

available, with inside diameters ranging from 2.5 to 10 cm. A

core barrel catcher (basket) can be used with this type of

sampler to help retain non-cohesive materials. The split-barrel

sampler is often used in conjunction with hollow-stem

continuous-flightaugersoranequivalentdrillingordirect-push

probe system (D4700 and D6282).

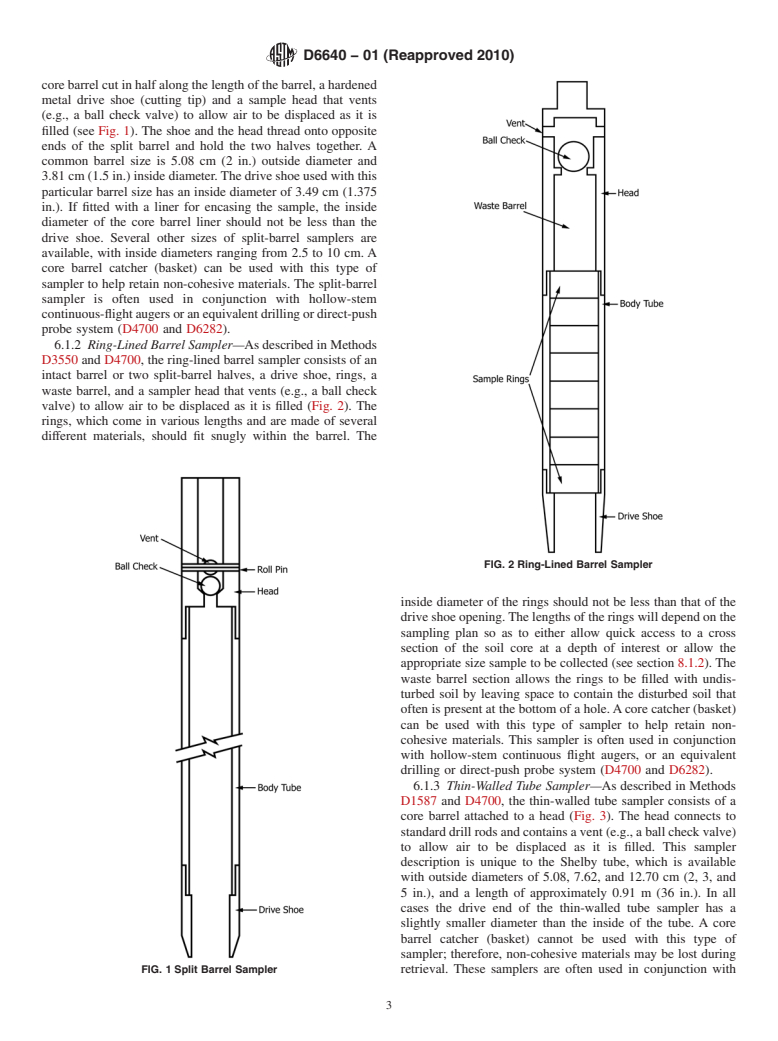

6.1.2 Ring-LinedBarrelSampler—As described in Methods

D3550 and D4700, the ring-lined barrel sampler consists of an

intact barrel or two split-barrel halves, a drive shoe, rings, a

waste barrel, and a sampler head that vents (e.g., a ball check

valve) to allow air to be displaced as it is filled (Fig. 2). The

rings, which come in various lengths and are made of several

different materials, should fit snugly within the barrel. The

FIG. 2 Ring-Lined Barrel Sampler

inside diameter of the rings should not be less than that of the

drive shoe opening.The lengths of the rings will depend on the

sampling plan so as to either allow quick access to a cross

section of the soil core at a depth of interest or allow the

appropriate size sample to be collected (see section 8.1.2). The

waste barrel section allows the rings to be filled with undis-

turbed soil by leaving space to contain the disturbed soil that

often is present at the bottom of a hole.Acore catcher (basket)

can be used with this type of sampler to help retain non-

cohesive materials. This sampler is often used in conjunction

with hollow-stem continuous flight augers, or an equivalent

drilling or direct-push probe system (D4700 and D6282).

6.1.3 Thin-Walled Tube Sampler—As described in Methods

D1587 and D4700, the thin-walled tube sampler consists of a

core barrel attached to a head (Fig. 3). The head connects to

standard drill rods and contains a vent (e.g., a ball check valve)

to allow air to be displaced as it is filled. This sampler

description is unique to the Shelby tube, which is available

with outside diameters of 5.08, 7.62, and 12.70 cm (2, 3, and

5 in.), and a length of approximately 0.91 m (36 in.). In all

cases the drive end of the thin-walled tube sampler has a

slightly smaller diameter than the inside of the tube. A core

barrel catcher (basket) cannot be used with this type of

sampler; therefore, non-cohesive materials may be lost during

FIG. 1 Split Barrel Sampler retrieval. These samplers are often used in conjunction with

D6640 − 01 (Reapproved 2010)

FIG. 3 Thin-Walled Tube Sampler

hollow-stem continuous-flight augers or an equivalent drilling

FIG. 4 Direct Push, Single Tube Sampler

or direct-push probe system (D4700 and D6282).

6.1.4 Solid Barrel Sampler—The solid-barrel sampler is

7.1.2 Thecuttingtiporshoeshouldhaveasharpedge.Once

similar in design to the thin-tube sampler, with some important

dulled, the cutting tip or shoe should be sharpened or replaced.

exceptions; the walls are thicker and they often can be

7.1.3 A work station should be set up for capping the core

equippedwithaliner(s)andacorecatcher(MethodD6282,see

barrel sampler or when opening to remove subsamples. This

Figs. 4 and 5). Most of the core barrel samplers in D6282 are

work station should consist of a flat clean surface and be set up

designed to be a closed chamber until the depth of interest is

in a location which provides protection from extreme weather

reached, then either the entire sampler or an inner barrel is

conditions and that is upwind of any loca

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.