ASTM F734-95(2006)

(Test Method)Standard Test Method for Shear Strength of Fusion Bonded Polycarbonate Aerospace Glazing Material

Standard Test Method for Shear Strength of Fusion Bonded Polycarbonate Aerospace Glazing Material

SIGNIFICANCE AND USE

At this writing, aerospace quality extruded transparent polycarbonate material is not available in thicknesses greater than 0.5 in. (12.7 mm). When a requirement exists for sheets thicker than 0.5 in. (12.7 mm), two or more sheets are fusion bonded together to form a single sheet of the desired thickness.

The structural integrity of the completed transparency depends on the integrity of the fusion bond. This test applies torsional shear loads to measure the structural integrity of the fusion bond. This test method is considered more reliable and more reproducible than shear tests in tension or compression.

SCOPE

1.1 This test method determines the shear yield strength Fsy and shear ultimate strength Fsu of fusion bonds in polycarbonate by applying torsional shear loads to the fusion-bond line.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F734–95 (Reapproved 2006)

Standard Test Method for

Shear Strength of Fusion Bonded Polycarbonate Aerospace

Glazing Material

ThisstandardisissuedunderthefixeddesignationF734;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope blocks. A twisting action is applied to one block and the load

required to fracture the fusion bond is transformed into the

1.1 This test method determines the shear yield strength F

sy

torsional shear strength of the fusion bond.

and shear ultimate strength F of fusion bonds in polycarbon-

su

ate by applying torsional shear loads to the fusion-bond line.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

5.1 At this writing, aerospace quality extruded transparent

2.1 ASTM Standards:

polycarbonate material is not available in thicknesses greater

D618 Practice for Conditioning Plastics for Testing

than 0.5 in. (12.7 mm). When a requirement exists for sheets

3. Terminology

thicker than 0.5 in. (12.7 mm), two or more sheets are fusion

bondedtogethertoformasinglesheetofthedesiredthickness.

3.1 Definitions of Terms Specific to This Standard:

5.2 The structural integrity of the completed transparency

3.1.1 fusion bond, n—thebondingoftwopiecesofthesame

depends on the integrity of the fusion bond. This test applies

material using heat and pressure.

torsional shear loads to measure the structural integrity of the

3.1.2 shear, n—internal force tangential to the section on

fusion bond. This test method is considered more reliable and

which it acts.

more reproducible than shear tests in tension or compression.

3.1.3 shear strength, n—the maximum allowable stress in a

bodyresultingfromforceswhichtendtocausetwocontiguous

6. Apparatus

parts of the body to slide relative to each other in a direction

parallel to their plane of contact. NOTE 1—A standard torsional test machine may be substituted for the

apparatus described in this section. The machine shall have variable

3.1.4 torsional shear fixture, n—a device used to apply a

angular displacement rates from 8 to 800°/min. (0.14 to 14 rad/min.). If a

shear force in the circular section of the test specimen to

torsional test machine is used, the calibration and standardization in

produce a peripherally uniform stress distribution.

Section 8 should be disregarded.

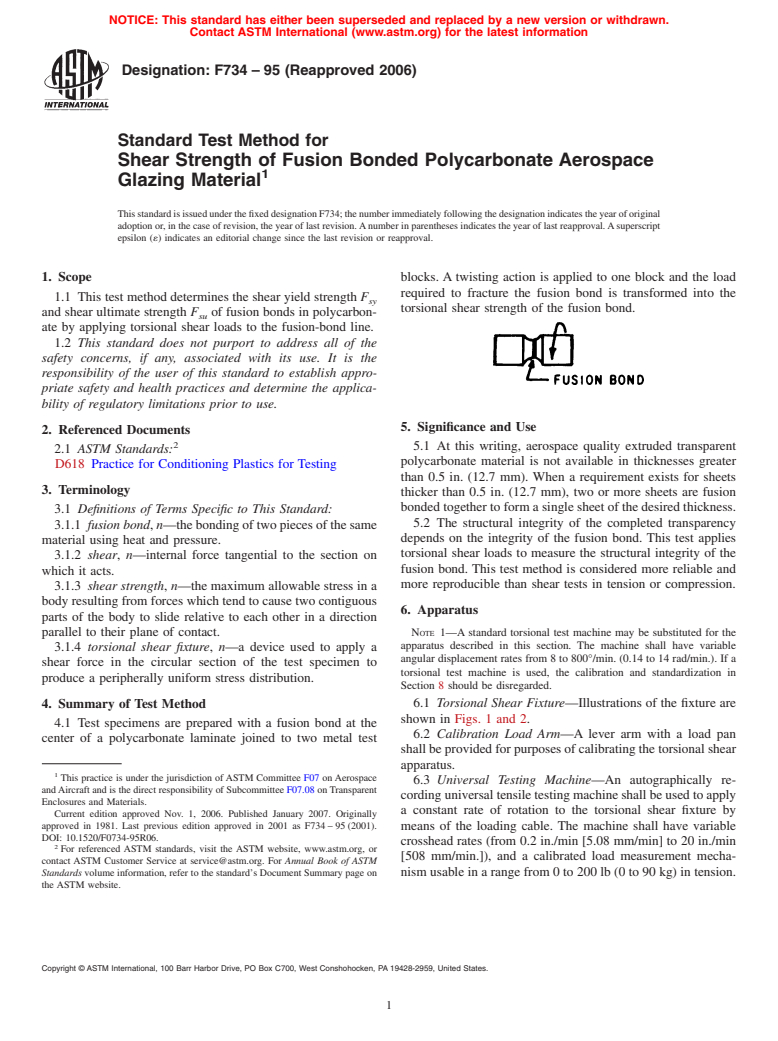

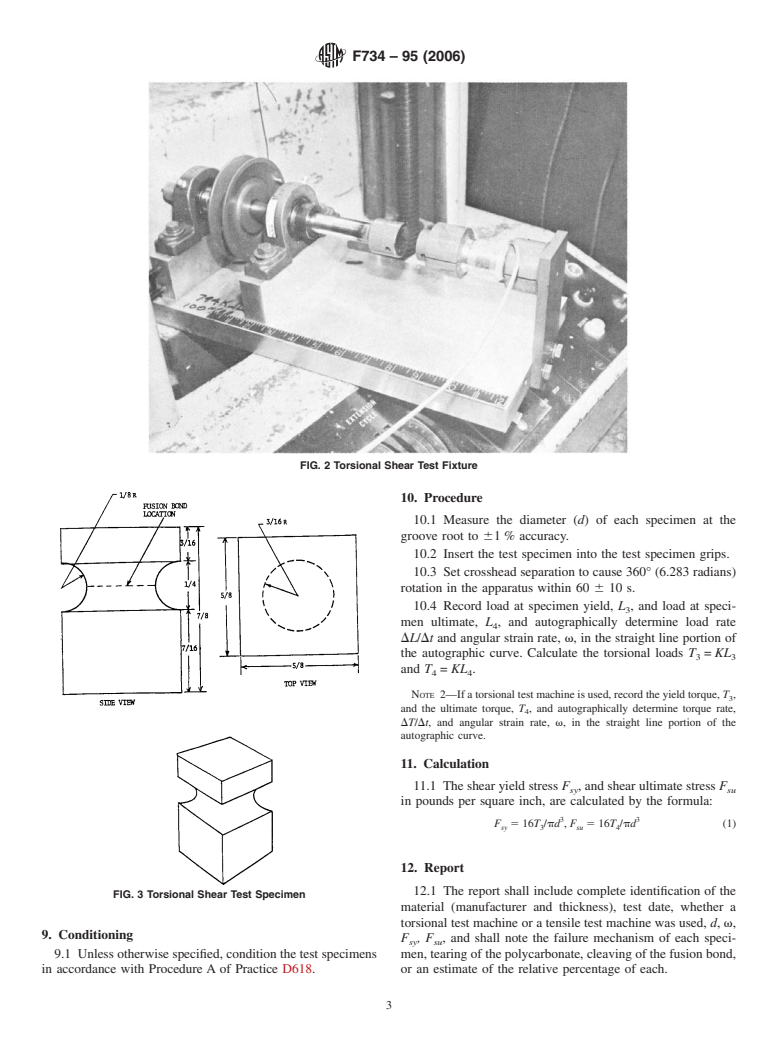

4. Summary of Test Method 6.1 Torsional Shear Fixture—Illustrations of the fixture are

shown in Figs. 1 and 2.

4.1 Test specimens are prepared with a fusion bond at the

6.2 Calibration Load Arm—A lever arm with a load pan

center of a polycarbonate laminate joined to two metal test

shallbeprovidedforpurposesofcalibratingthetorsionalshear

apparatus.

This practice is under the jurisdiction ofASTM Committee F07 onAerospace

6.3 Universal Testing Machine—An autographically re-

andAircraft and is the direct responsibility of Subcommittee F07.08 onTransparent

cordinguniversaltensiletestingmachineshallbeusedtoapply

Enclosures and Materials.

a constant rate of rotation to the torsional shear fixture by

Current edition approved Nov. 1, 2006. Published January 2007. Originally

approved in 1981. Last previous edition approved in 2001 as F734–95(2001). means of the loading cable. The machine shall have variable

DOI: 10.1520/F0734-95R06.

crosshead rates (from 0.2 in./min [5.08 mm/min] to 20 in./min

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

[508 mm/min.]), and a calibrated load measurement mecha-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on nism usable in a range from 0 to 200 lb (0 to 90 kg) in tension.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F734–95 (2006)

FIG. 1 Torsional Shear Test Fixture (All Dimensions in Inches)

6.4 Calibrated Spring Scales, 0 to 10 lb (4.54 kg) 61%, 8.2 Attachthecalibrationloadarmtotherotatableshaftand

are required for calibration purposes. tighten screw to preclude slippage. See Fig. 4.

8.3 Determine the equivalent weight of the calibrating arm

7. Test Specimens and Sample

attheloadpanwithnotorsionalresistanceintheapparatusand

7.1 Machine tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.