ASTM D6080-97(2007)

(Practice)Standard Practice for Defining the Viscosity Characteristics of Hydraulic Fluids

Standard Practice for Defining the Viscosity Characteristics of Hydraulic Fluids

SIGNIFICANCE AND USE

The purpose of this practice is to establish viscosity designations derived from viscosities measured by test methods which have a meaningful relationship to hydraulic fluid performance. This permits lubricant suppliers, lubricant users, and equipment designers to have a uniform and common basis for designating, specifying, or selecting the viscosity characteristics of hydraulic fluids.

This practice is not intended to be a replacement for Classification D 2422. Rather, it is an enhancement intended to provide a better description of the viscosity characteristics of lubricants used as hydraulic fluids.

This practice implies no evaluation of hydraulic oil quality other than its viscosity and shear stability under the conditions specified.

While it is not intended for other functional fluids, this practice may be useful in high-shear-stress applications where viscosity index (VI) improvers are used to extend the useful operating temperature range of the fluid.

This practice does not apply to other lubricants for which viscosity classification systems already exist, for example, SAE J300 for automotive engine oils and SAE J306 for axle and manual transmission lubricants.

SCOPE

1.1 This practice covers all hydraulic fluids based either on petroleum, synthetic, or naturally-occurring base stocks. It is not intended for water-containing hydraulic fluids.

1.2 For determination of viscosities at low temperature, this practice uses millipascal·second (mPa·s) as the unit of viscosity. For reference, 1 mPa·s is equivalent to 1 centipoise (cP). For determination of viscosities at high temperature, this practice uses millimetre squared per second (mm2/s) as the unit of kinematic viscosity. For reference, 1 mm2/s is equivalent to 1 centistoke (cSt).

1.3 This practice is applicable to fluids ranging in kinematic viscosity from about 4 to 150 mm2/s as measured at a reference temperature of 40°C and to temperatures from −50 to +16°C for a fluid viscosity of 750 mPa·s.

Note 1—Fluids of lesser or greater viscosity than the range described in 1.3 are seldom used as hydraulic fluids. Any mathematical extrapolation of the system to either higher or lower viscosity grades may not be appropriate. Any need to expand the system should be evaluated on its own merit.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6080 – 97 (Reapproved 2007)

Standard Practice for

Defining the Viscosity Characteristics of Hydraulic Fluids

This standard is issued under the fixed designation D6080; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2983 Test Method for Low-Temperature Viscosity of

Lubricants Measured by Brookfield Viscometer

1.1 This practice covers all hydraulic fluids based either on

D5621 Test Method for Sonic Shear Stability of Hydraulic

petroleum, synthetic, or naturally-occurring base stocks. It is

Fluids

not intended for water-containing hydraulic fluids.

E29 Practice for Using Significant Digits in Test Data to

1.2 For determination of viscosities at low temperature, this

Determine Conformance with Specifications

practice uses millipascal·second (mPa·s) as the unit of viscos-

2.2 Society of Automotive Engineers (SAE) Standards:

ity. For reference, 1 mPa·s is equivalent to 1 centipoise (cP).

J300 Engine Oil Viscosity Classification

For determination of viscosities at high temperature, this

J306 Axle and Manual Transmission Lubricant Viscosity

practiceusesmillimetresquaredpersecond(mm /s)astheunit

Classification

of kinematic viscosity. For reference, 1 mm /s is equivalent to

1 centistoke (cSt).

3. Terminology

1.3 Thispracticeisapplicabletofluidsranginginkinematic

3.1 Definitions:

viscosityfromabout4to150mm /sasmeasuredatareference

3.1.1 density—the mass per unit volume.

temperature of 40°C and to temperatures from−50 to+16°C

3.1.2 hydraulic fluid—a fluid used in hydraulic systems for

for a fluid viscosity of 750 mPa·s.

transmitting power.

NOTE 1—Fluids of lesser or greater viscosity than the range described

3.1.3 in-service viscosity—the viscosity of fluid during

in1.3areseldomusedashydraulicfluids.Anymathematicalextrapolation

operation of a hydraulic pump or circuit components.

of the system to either higher or lower viscosity grades may not be

3.1.4 kinematic viscosity—the ratio of the viscosity to the

appropriate. Any need to expand the system should be evaluated on its

density of a liquid.

own merit.

3.1.4.1 Discussion—Kinematicviscosityisameasureofthe

2. Referenced Documents

resistance to flow of a liquid under gravity.

3.1.5 Newtonian fluid—a fluid that at a given temperature

2.1 ASTM Standards:

exhibits a constant viscosity at all shear rates or shear stresses.

D445 Test Method for Kinematic Viscosity of Transparent

3.1.6 non-Newtonian fluid—a fluid that exhibits a viscosity

and Opaque Liquids (and Calculation of Dynamic Viscos-

that varies with changing shear stress or shear rate.

ity)

3.1.7 shear degradation—the decrease in molecular weight

D2270 Practice for Calculating Viscosity Index from Kine-

of a polymeric thickener (VI improver) as a result of exposure

matic Viscosity at 40 and 100°C

to high shear stress.

D2422 Classification of Industrial Fluid Lubricants by Vis-

3.1.8 shear rate—the velocity gradient in fluid flow.

cosity System

3.1.9 shear stability—the resistance of a polymer-thickened

fluid to shear degradation.

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

3.1.10 shear stress—the motivating force per unit area for

ProductsandLubricantsandisthedirectresponsibilityofSubcommitteeD02.N0.10

on Specifications. fluid flow.

Current edition approved Nov. 1, 2007. Published January 2008. Originally

3.1.11 viscosity—the ratio between the applied shear stress

approved in 1997. Last previous edition approved in 2002 as D6080–97(2002).

and shear rate.

DOI: 10.1520/D6080-97R07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6080 – 97 (2007)

3.1.11.1 Discussion—Viscosity is sometimes called the co- 6. Procedure

efficient of dynamic viscosity. This coefficient is a measure of

6.1 The low temperature viscosity grade of a fluid is based

the resistance to flow of the liquid.

on the viscosity of new oil measured using a Brookfield

3.1.12 viscosity index (VI)—an arbitrary number used to viscometer, Test Method D2983.

characterize the variation of the kinematic viscosity of a fluid 6.1.1 Theviscosityshallbeinterpolatedfrommeasurements

with temperature. at three temperatures spanning the temperature at which the

viscosity is 750 mPa·s. A smooth graph of these data (log

viscosity versus temperature) determines the temperature at

4. Summary of Practice

which the oil has a viscosity of 750 mPa·s.

4.1 High VI hydraulic fluids often contain high molecular

6.1.2 The lower viscosity limit for Test Method D2983 is

weight thickeners, called viscosity index (VI) improvers,

currently stated to be 1000 mPa·s.This equipment limitation is

whichimpartnon-Newtoniancharacteristicstothefluid.These

shown in Table1 of that test method. Newer equipment is

polymers may shear degrade with use, and reduce the in-

available which permits measurement of lower viscosities and

service viscosity of the fluids.

Test Method D2983 is currently being revised with a lower

4.2 This practice provides uniform guidelines for character-

viscosity limit of 500 mPa·s.

izing oils in terms of both their high and low temperature

6.1.3 The temperature determined in 6.1.1 shall be rounded

viscosities before and after exposure to high shear stress.

to a whole number in accordance with Practice E29.

6.1.4 The low temperature viscosity grade is determined by

4.2.1 Sincetheperformanceoffluidsattemperatureshigher

matchingthetemperaturedeterminedin6.1.3withtherequire-

than 40°C is determined in the worst case, that is, most severe

ments shown in Table 1.

situation, by the sheared oil viscosity, the viscosity and

6.2 The high temperature viscosity designation of a fluid is

viscosity index used to characterize fluids in this practice are

the 40°C kinematic viscosity (Test Method D445) of a fluid

those of the sheared fluid.

which has been sheared using Test Method D5621.

4.2.2 Thispracticeclassifiesoilsatlowtemperaturebytheir

6.2.1 The kinematic viscosity determined in 6.2 shall be

new oil properties. Low temperature viscosities do not de-

rounded to a whole number in accordance with Practice E29.

crease greatly, if at all, with polymer shear degradation.

6.2.2 For a fluid known to contain no polymeric compo-

Furthermore, this approach ensures that the fluid will be

nents which will shear degrade, the high temperature viscosity

properly classified under the worst-case conditions, that is,

designation is the 40°C kinematic viscosity (Test Method

when the fluid is new.

D445) of the new fluid, rounded per 6.2.1.

4.3 This practice may be used with either Newtonian or

6.2.3 If the 40°C kinematic viscosity from 6.2.1 fails to

non-Newtonian hydraulic fluids. This provides the user with a

meet the same designation consistently (for example, it varies

more reasonable basis to compare fluids than previous prac-

becauseofspreadinbasestockorcomponentspecifications,or

tices.

variability in kinematic viscosity or shear stability measure-

ments),thelowerdesignationmustbeusedtoensureconform-

5. Significance and Use

ance with 6.5 below.

6.3 The viscosity index designation of the fluid is based on

5.1 The purpose of this practice is to establish viscosity

the viscosity index as determined using Practice D2270 on

designations derived from viscosities measured by test meth-

fluid which has been sheared using Test Method D5621.

ods which have a meaningful relationship to hydraulic fluid

6.3.1 Theviscosityindexdeterminedin6.3shallberounded

performance. This permits lubricant suppliers, lubricant users,

to the nearest ten units in accordance with Practice E29. This

and equipment designers to have a uniform and common basis

value is the viscosity index designation.

for designating, specifying, or selecting the viscosity charac-

teristics of hydraulic fluids.

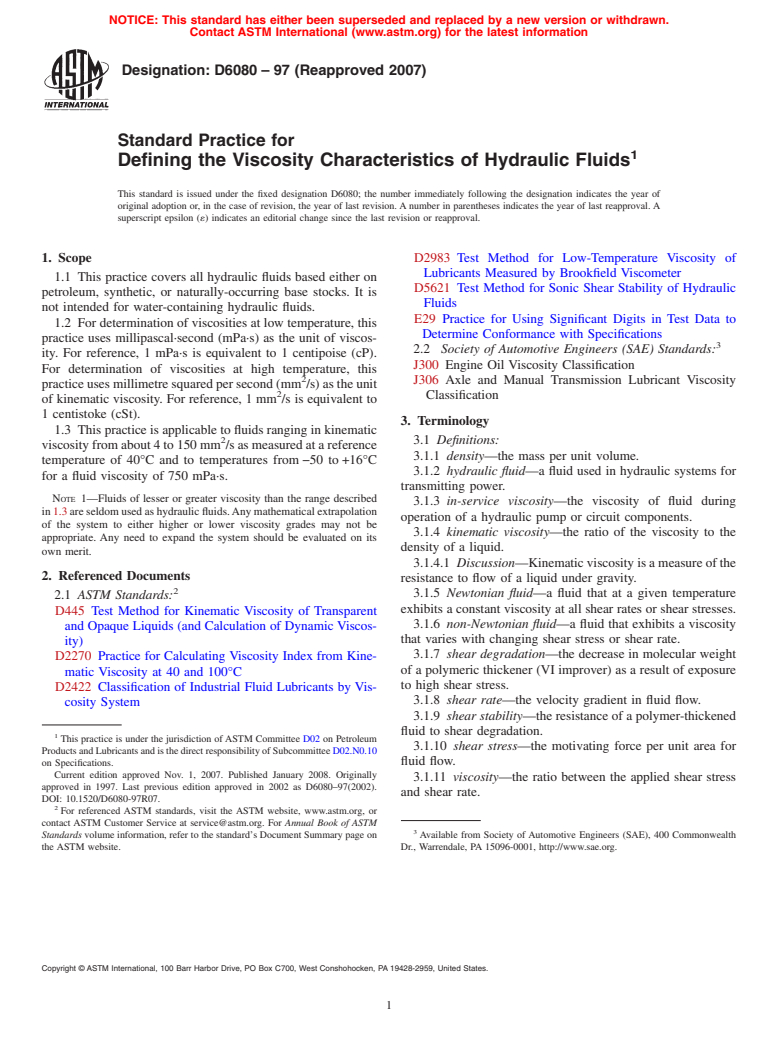

TABLE 1 Low Temperature Viscosity Grades for Hydraulic Fluid

5.2 This practice is not intended to be a replacement for

Classifications

Classification D2422. Rather, it is an enhancement intended to

Temperature,° C, for Brookfield Viscosity

provide a better description of the viscosity characteristics of

A

of 750 mPa·s

Viscosity Grade

lubricants used as hydraulic fluids.

min max

5.3 This practice implies no evaluation of hydraulic oil

L5 . −50

quality other than its viscosity and shear stability under the

L7 −49 −42

conditions specified. L10 −41 −33

L15 −32 −23

5.4 While it is not intended for other functional fluids, this

L22 −22 −15

practice may be useful in high-shear-stress applications where L32 −14 − 8

L46 −7 −2

viscosity index (VI) improvers are used to extend the useful

L68 − 1 4

operating temperature range of the fluid.

L100 5 10

L150 11 16

5.5 This practice does not apply to other lubricants for

A

The temperature range for a given L-grade is approximately equivalent to that

which viscosity classification systems already exist, for ex-

for an ISO grade of the same numerical designation and having a viscosity index

ample,SAEJ300forautomotiveengineoilsandSAEJ306for

of 100, that is, the temperature range for the L10 grade is approximately the same

axle and manual transmission lubricants. as that for an ISO VG 10 grade with a viscosity index of 100.

D6080 – 97 (2007)

6.3.2 For fluids which do not contain polymeric compo- 7.2 The low temperature grade determined in 6.1, Lyy,

nents, the viscosity index is determined on the new fluid using definesthelowestrecommendedfluidtemperatureatwhichthe

PracticeD2270.Theviscosityindexdesignationforthefluidis fluidmaybeusedinequipmentwithastart-up,underloadlimit

established by rounding this viscosity index to the nearest ten of 750 mPa·s, max.

units in accordance with Practice E29.

7.2.1 Thelowtemperaturelimitisdeterminedbycomparing

the Lyy designation with the corresponding temperature in

NOTE 2—The guidelines for rounding viscosity in 6.2.1 and 6.2.2 and

Table 1.

viscosity index in 6.3.1 and 6.3.2 are specific to this practice and should

not be confused with the larger number of significant figures that can be

7.2.2 Example 1a—For an oil with the designation:

reportedwhenTestMethodsD445andD2270areusedforotherpurposes.

ISO VG 46

L32-40 ,

6.3.3 If the viscosity index fails to meet the same designa-

tion consistently, that is, it varies between the lower values for

the low temperature grade is defined by L32. Reference to

one designation and the higher values for the next lower

Table 1 indicates that this oil has a viscosity of 750 mPa·s at a

designation (for example, it varies because of spread in base

temperature between−8 and−14°C. Hence, in equipment

stock or component specifications, or variability in kinematic

which has a low temperature start-up viscosity limit of 750

viscosity or shear stability measurements), the lower designa-

mPa·s, the oil in this example may be used down to at

tion must be used to ensure conformance with 6.5 below.

least−8°C.

6.4 For the sake of uniformity of nomenclature in identify-

7.2.3 Example 2a—For an oil with the designation:

ing the viscosity characteristics of hydraulic fluids, the follow-

ISO VG 68

ing designation shall be used:

L46-57

ISO VG xx

the low temperature grade is defined by L46. Reference to

Lyy-zz (VI)

Table 1 indicates that this oil has a viscosity of 750 mPa·s at a

where xx is the new oil viscosity grade as determined by

temperaturebetween−2and−7°C.Hence,inequipmentwhich

Classification D2422 (Table 2); Lyy is the low temperature

hasalowtemperaturestart-upviscositylimitof750mPa·s,the

viscositygradeasdeterminedin6.1;zzisthehightemperature

oil in this example may be used down to at least−2°C.

sheared viscosity designation as determined in 6.2; and VI is

7.2.4 This practice is not quantitative when a manufacturer

the viscosity index designation as determined in 6.3.

specifieslowerorhigherstart-upviscositylimits.However,the

6.4.1 If the new oil viscosity does not meet a grade

process described in 6.1 can be used to determine low

described by Classification D2422, the ISO VG xx portion of

temperaturelimitationscorrespondingtoanystart-upviscosity.

the designation does not apply. In such cases, the Lyy-zz (VI)

7.3 The high temperature designation determined in6.2 and

designation may still be used, and the use of any other

the viscosity index determined in 6.3, zz (VI), can be used in

descriptors for the new oil is at the discretion of the fluid

combination with the data in Figs. 1-4 to estimate high

marketer.

temperature operating limits (Fig. 1 and Fig. 2) and optimum

6.4.2 Examples of use of this practice are shown inTable 3.

operating temperatures (Fig. 3 and Fig. 4) for the fluid.

6.5 An oil blender may use any manufacturing control that

7.3.1 Fig. 1 and Fig. 2 apply directly to equipment which

seems appropriate to his operation. However, it is the respon-

hasminimumoperatingkinematicviscositylimitsof10and13

sibility of the blender to ensure that all production fully meets

mm /s, respectively.

the requirements for the viscosity designation on the container.

7.3.1.1 FindthevaluezzonthehorizontalaxislabeledHigh

7. Interpretation of Results

Temperature Viscosity Designation.

7.1 The designation determined for a hydraulic fluid as 7.3.1.2 Read vertically from the point defined by 7.3.1.1 to

described in 6.4 may be used in combination with a manufac- the curve corresponding to the viscosity index, VI, interpolat-

turer’s viscosity recommendations for specific equipment to ing, if necessary.

estimate an acceptable temperature range over which that fluid

7.3.1.3 Read horizontally from the point defined by 7.3.1.2

may be used in that equipment.

to the vertical axis labeled Temperature, °C, for a Kinematic

Viscosity of 10 (or 13) mm /s. This is the upper temperature

limit for fluid operation.

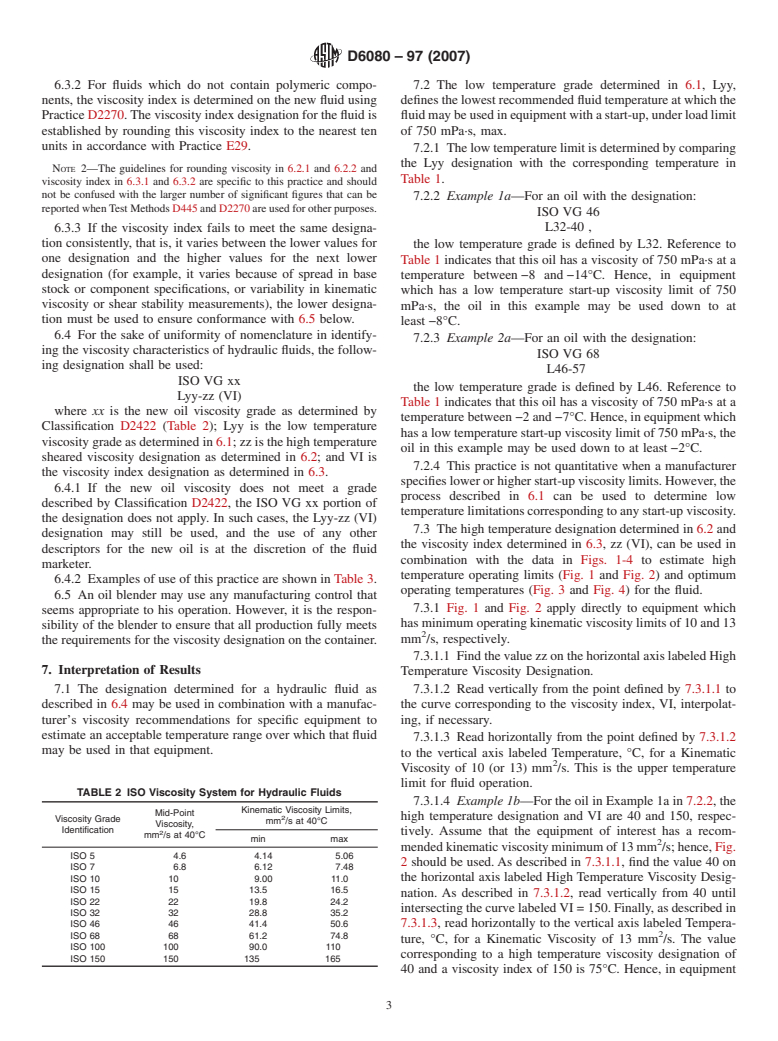

TABLE 2 ISO Viscosity System for Hydraulic Fluids

7.3.1.4 Example 1b—FortheoilinExample1ain7.2.2,the

Kinematic Viscosity Limits,

Mid-Point

high temperature designation and VI are 40 and 150, respec-

Viscosity Grade 2

mm /s at 40°C

Viscosity,

Identification

tively. Assume that the equipment of interest has a recom-

mm /s at 40°C

min max

mendedkinematicviscosityminimumof13mm /s;hence,Fig.

ISO 5 4.6 4.14 5.06

2 should be used.As described in 7.3.1.1, find the value 40 on

ISO 7 6.8 6.12 7.48

ISO 10 10 9.00 11.0 the horizontal axis label

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.