ASTM D6158-18

(Specification)Standard Specification for Mineral Hydraulic Oils

Standard Specification for Mineral Hydraulic Oils

ABSTRACT

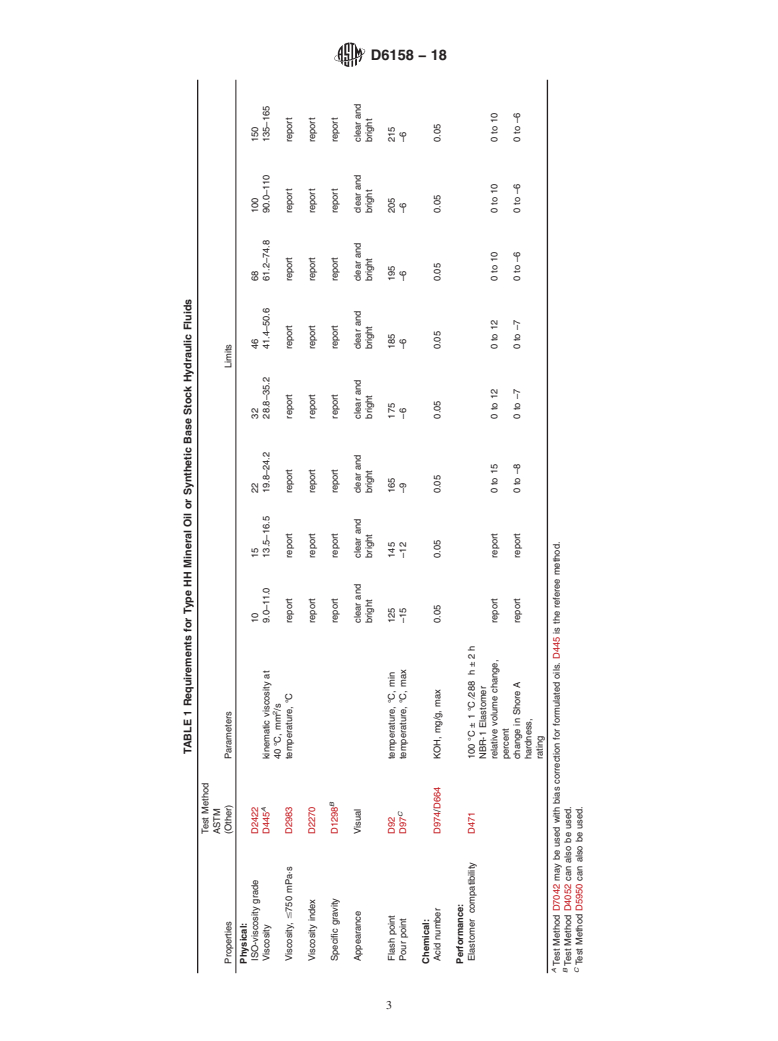

This specification covers the standard for mineral oils used in hydraulic systems which require refined base oil (Class HH), refined mineral base oil with rust and oxidation inhibitors (Class HL) or refined mineral base oil with rust and oxidation inhibitors plus antiwear characteristics (Class HM). This specification only covers lubricating oils before they are installed in the hydraulic system and does not include all hydraulic oils. Requirements for the mineral oils shall include, but not limited to, viscosity, specific gravity, appearance, flash point, chemical acid number, corrosion, water separation, elastomer compatibility, air release, and thermal stability.

SCOPE

1.1 This specification covers mineral and synthetic oils of the types API groups I, II, III, and IV used in hydraulic systems, where the performance requirements demand fluids with one of the following characteristics:

1.1.1 A refined base oil or synthetic base stock (Class HH),

1.1.2 A refined mineral base oil or synthetic base stock with rust and oxidation inhibitors (Class HL),

1.1.3 A refined mineral base oil or synthetic base stock with rust and oxidation inhibitors plus anti-wear characteristics (Class HM),

1.1.4 A refined mineral base oil or synthetic base stock with rust and oxidation inhibitors, anti-wear characteristics, and increased viscosity index higher than 140 (Class HV),

1.1.5 A refined mineral base oil or synthetic base stock with rust and oxidation inhibitors plus anti-wear characteristics meeting a higher performance level than an HM fluid to address higher demanding hydraulic systems (Class HMHP), and

1.1.6 A refined mineral base oil with rust or synthetic base stock and oxidation inhibitors, anti-wear characteristics, and increased viscosity index higher than 140 meeting a higher performance level than an HV fluid to address higher demanding hydraulic systems (Class HVHP).

1.2 This specification defines the requirements of mineral oil-based or synthetic-based hydraulic fluids that are compatible with most existing machinery components when there is adequate maintenance.

1.3 This specification defines only new lubricating oils before they are installed in the hydraulic system.

1.4 This specification defines specific types of hydraulic oils. It does not include all hydraulic oils. Some oils that are not included may be satisfactory for certain hydraulic applications. Certain equipment or conditions of use may permit or require a wider or narrower range of characteristics than those described herein.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5.1 Exception—In X1.3.9 on Wear Protection, the values of pump pressure are in MPa, and the psi follows in brackets as a reference point immediately recognized by a large part of the industry.

1.6 The following safety hazard caveat pertains to the test methods referenced in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D6158 −18

Standard Specification for

1

Mineral Hydraulic Oils

This standard is issued under the fixed designation D6158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This specification covers mineral and synthetic oils of

standard.

the types API groups I, II, III, and IV used in hydraulic

1.5.1 Exception—In X1.3.9 on Wear Protection, the values

systems, where the performance requirements demand fluids

ofpumppressureareinMPa,andthepsifollowsinbracketsas

with one of the following characteristics:

a reference point immediately recognized by a large part of the

1.1.1 Arefined base oil or synthetic base stock (Class HH),

industry.

1.1.2 Arefined mineral base oil or synthetic base stock with

1.6 The following safety hazard caveat pertains to the test

rust and oxidation inhibitors (Class HL),

methods referenced in this specification. This standard does

1.1.3 Arefined mineral base oil or synthetic base stock with

not purport to address all of the safety concerns, if any,

rust and oxidation inhibitors plus anti-wear characteristics

associated with its use. It is the responsibility of the user of this

(Class HM),

standard to establish appropriate safety, health, and environ-

1.1.4 Arefined mineral base oil or synthetic base stock with

mental practices and determine the applicability of regulatory

rust and oxidation inhibitors, anti-wear characteristics, and

limitations prior to use.

increased viscosity index higher than 140 (Class HV),

1.7 This international standard was developed in accor-

1.1.5 Arefined mineral base oil or synthetic base stock with

dance with internationally recognized principles on standard-

rust and oxidation inhibitors plus anti-wear characteristics

ization established in the Decision on Principles for the

meeting a higher performance level than an HM fluid to

Development of International Standards, Guides and Recom-

address higher demanding hydraulic systems (Class HMHP),

mendations issued by the World Trade Organization Technical

and

Barriers to Trade (TBT) Committee.

1.1.6 A refined mineral base oil with rust or synthetic base

stock and oxidation inhibitors, anti-wear characteristics, and

2. Referenced Documents

increased viscosity index higher than 140 meeting a higher

performance level than an HV fluid to address higher demand- 2

2.1 ASTM Standards:

ing hydraulic systems (Class HVHP).

D92 Test Method for Flash and Fire Points by Cleveland

1.2 This specification defines the requirements of mineral Open Cup Tester

D97 Test Method for Pour Point of Petroleum Products

oil-based or synthetic-based hydraulic fluids that are compat-

ible with most existing machinery components when there is D130 Test Method for Corrosiveness to Copper from Petro-

leum Products by Copper Strip Test

adequate maintenance.

D445 Test Method for Kinematic Viscosity of Transparent

1.3 This specification defines only new lubricating oils

and Opaque Liquids (and Calculation of Dynamic Viscos-

before they are installed in the hydraulic system.

ity)

1.4 This specification defines specific types of hydraulic

D471 Test Method for Rubber Property—Effect of Liquids

oils.Itdoesnotincludeallhydraulicoils.Someoilsthatarenot

D664 Test Method for Acid Number of Petroleum Products

included may be satisfactory for certain hydraulic applications.

by Potentiometric Titration

Certain equipment or conditions of use may permit or require

D665 Test Method for Rust-Preventing Characteristics of

a wider or narrower range of characteristics than those de-

Inhibited Mineral Oil in the Presence of Water

scribed herein.

D892 Test Method for Foaming Characteristics of Lubricat-

ing Oils

1

This specification is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

2

Subcommittee D02.N0 on Hydraulic Fluids. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2018. Published October 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1997. Last previous edition approved in 2016 as D6158 – 16. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6158-18. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6158 − 16 D6158 − 18

Standard Specification for

1

Mineral Hydraulic Oils

This standard is issued under the fixed designation D6158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers mineral and synthetic oils of the types API groups I, II, III, and IV used in hydraulic systems,

where the performance requirements demand fluids with one of the following characteristics:

1.1.1 A refined base oil or synthetic base stock (Class HH),

1.1.2 A refined mineral base oil or synthetic base stock with rust and oxidation inhibitors (Class HL),

1.1.3 A refined mineral base oil or synthetic base stock with rust and oxidation inhibitors plus anti-wear characteristics (Class

HM),

1.1.4 A refined mineral base oil or synthetic base stock with rust and oxidation inhibitors, anti-wear characteristics, and

increased viscosity index higher than 140 (Class HV),

1.1.5 A refined mineral base oil or synthetic base stock with rust and oxidation inhibitors plus anti-wear characteristics meeting

a higher performance level than an HM fluid to address higher demanding hydraulic systems (Class HMHP), and

1.1.6 A refined mineral base oil with rust or synthetic base stock and oxidation inhibitors, anti-wear characteristics, and

increased viscosity index higher than 140 meeting a higher performance level than an HV fluid to address higher demanding

hydraulic systems (Class HVHP).

1.2 This specification defines the requirements of mineral oil-based or synthetic-based hydraulic fluids that are compatible with

most existing machinery components when there is adequate maintenance.

1.3 This specification defines only new lubricating oils before they are installed in the hydraulic system.

1.4 This specification defines specific types of hydraulic oils. It does not include all hydraulic oils. Some oils that are not

included may be satisfactory for certain hydraulic applications. Certain equipment or conditions of use may permit or require a

wider or narrower range of characteristics than those described herein.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5.1 Exception—In X1.3.9 on Wear Protection, the values of pump pressure are in MPa, and the psi follows in brackets as a

reference point immediately recognized by a large part of the industry.

1.6 The following safety hazard caveat pertains to the test methods referenced in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory

limitationlimitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D92 Test Method for Flash and Fire Points by Cleveland Open Cup Tester

D97 Test Method for Pour Point of Petroleum Products

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

1

This specification is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.N0D02.N0.10 on Hydraulic FluidsSpecifications.

Current edition approved Jan. 15, 2016Oct. 1, 2018. Published February 2016October 2018. Originally approved in 1997. Last previous edition approved in 20142016

as D6158 – 14.D6158 – 16. DOI: 10.1520/D6158-16.10.1520/D6158-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, W

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.