ASTM D5438-00

(Practice)Standard Practice for Collection of Floor Dust for Chemical Analysis

Standard Practice for Collection of Floor Dust for Chemical Analysis

SCOPE

1.1 This practice covers a procedure for the collection of a sample of dust from carpets and bare floors that can be analyzed for lead, pesticides, or other chemical compounds and elements.

1.2 This practice is applicable to a variety of carpeted and bare floor surfaces. It has been tested for level loop and plush pile carpets and bare wood floors, specifically.

1.3 This practice is not intended for the collection and evaluation of dust for the presence of asbestos fibers.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5438 – 00

Standard Practice for

Collection of Floor Dust for Chemical Analysis

This standard is issued under the fixed designation D 5438; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope larger, embedded in carpet pile and normally removable by

household vacuum cleaners.

1.1 This practice covers a procedure for the collection of a

3.1.2 surface dust—soil and other particulate matter, ap-

sample of dust from carpets and bare floors that can be

proximately 5-µm equivalent aerodynamic diameter and larger,

analyzedforlead,pesticides,orotherchemicalcompoundsand

adhering to floor surfaces and normally removable by house-

elements.

hold vacuum cleaners.

1.2 This practice is applicable to a variety of carpeted and

bare floor surfaces. It has been tested for level loop and plush

4. Summary of Practice

pile carpets and bare wood floors, specifically.

4.1 The sampling method described in this practice is taken

1.3 This practice is not intended for the collection and

6,7,8 9

from work published in Roberts, et al, and Stamper, et al.

evaluation of dust for the presence of asbestos fibers.

4.2 Particulate matter is withdrawn from the carpet or bare

1.4 The values stated in SI units are to be regarded as the

floor by means of a flowing air stream passing through a

standard.

sampling nozzle at a specific velocity and flow rate and

1.5 This standard does not purport to address all of the

separated mechanically by a cyclone. The cyclone collects

safety concerns, if any, associated with its use. It is the

efficiently particles approximately 5-µm mean aerodynamic

responsibility of the user of this standard to establish appro-

diameter and larger.The sampling system allows for height, air

priate safety and health practices and determine the applica-

flow, and suction adjustments to reproduce systematically a

bility of regulatory limitations prior to use.

specific air velocity for the removal of particulate matter from

2. Referenced Documents carpeted and bare floor surfaces, so that these sampling

conditions can be repeated.

2.1 ASTM Standards:

D 422 Test Method for Particle-Size Analysis of Soils

NOTE 1—Side-by-side comparison of the HVS3 and a conventional

D 1356 Terminology Relating to Sampling and Analysis of upright vacuum cleaner revealed that both collected particles down to at

least 0.2 µm and that the HVS3 was more efficient at collecting particles

Atmospheres

smaller than 20 µm than conventional vacuum cleaners. If desired, a

E 1 Specification for ASTM Thermometers

fine-particlefiltermaybeaddeddownstreamofthecyclonetocollect99.9

E 337 Test Method for Measuring Humidity with a Psy-

% of particles above 0.2 µm aerodynamic mean diameter.

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

peratures)

F 608 TestMethodforEvaluationofCarpet-EmbeddedDirt

Removal Effectiveness of Household Vacuum Cleaners

Roberts, J. W., Budd, W. T., Ruby, M. G., Stamper, V. R., Camann, D. E.,

Fortman, R. C., Sheldon, L. S., and Lewis, R. G., “A Small High Volume Surface

3. Terminology Sampler HVS3 for Pesticides, and Other Toxic Substances in House Dust,” Paper

No. 91-150.2, 84th Annual Meeting, Air & Waste Management Association,

3.1 Definitions—For definitions of terms used in this prac-

Vancouver, British Columbia, June 16–21, 1991.

tice, refer to Terminology D 1356. Roberts, J. W., and Ruby, M. G., “Development of a High Volume Surface

Sampler for Pesticides,” U.S. Environmental Protection Agency Report No. EPA

3.1.1 carpet-embedded dust—soilandotherparticulatemat-

600/4-88/036, Research Triangle Park, NC, January 1989.

ter, approximately 5-µm equivalent aerodynamic diameter and

Roberts, J. W., Han, W., and Ruby, M. G., “Evaluation of Dust Samplers for

Bare Floors and Upholstery,” Battelle Subcontract No. 46534(g21733808)-00

03EQ, EPAPrime Contract No. 68-00-0007, U.S. EPA,AREAL, Office of Research

and Development, 1993.

1 9

This practice is under the jurisdiction of ASTM Committee D22 on Sampling Stamper, V. R., Roberts, J. W., and Ruby, M. G., “Development of a High

and Analysis of Atmospheres and is the direct responsibility of Subcommittee Volume Small Surface Sampler for Pesticide and Toxics in House Dust,” Research

D22.05 on Indoor Air. Triangle Institute Report No. RTI/171-01/02F, Research Triangle Park, NC, June

Current edition approved March 10, 2000. Published June 2000. Originally 1990.Includedinsupportingdata,whichareonfileatASTMHeadquarters.Request

published as D 5438 – 93. Last previous edition D 5438 – 94. RR:D22-1010.

2 10

Annual Book of ASTM Standards, Vol 04.08. Willis, R. D., “SEM Characterization of House Dusts Collected by Conven-

Annual Book of ASTM Standards, Vol 11.03. tional Vacuum and the HVS3 Sampler.” Report to the U.S. EPA under Contract

Annual Book of ASTM Standards, Vol 14.03. 68–D5–0049, Research Triangle Park, NC, ManTech Environmental Technology,

Annual Book of ASTM Standards, Vol 15.07. Inc., 1995.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5438–00

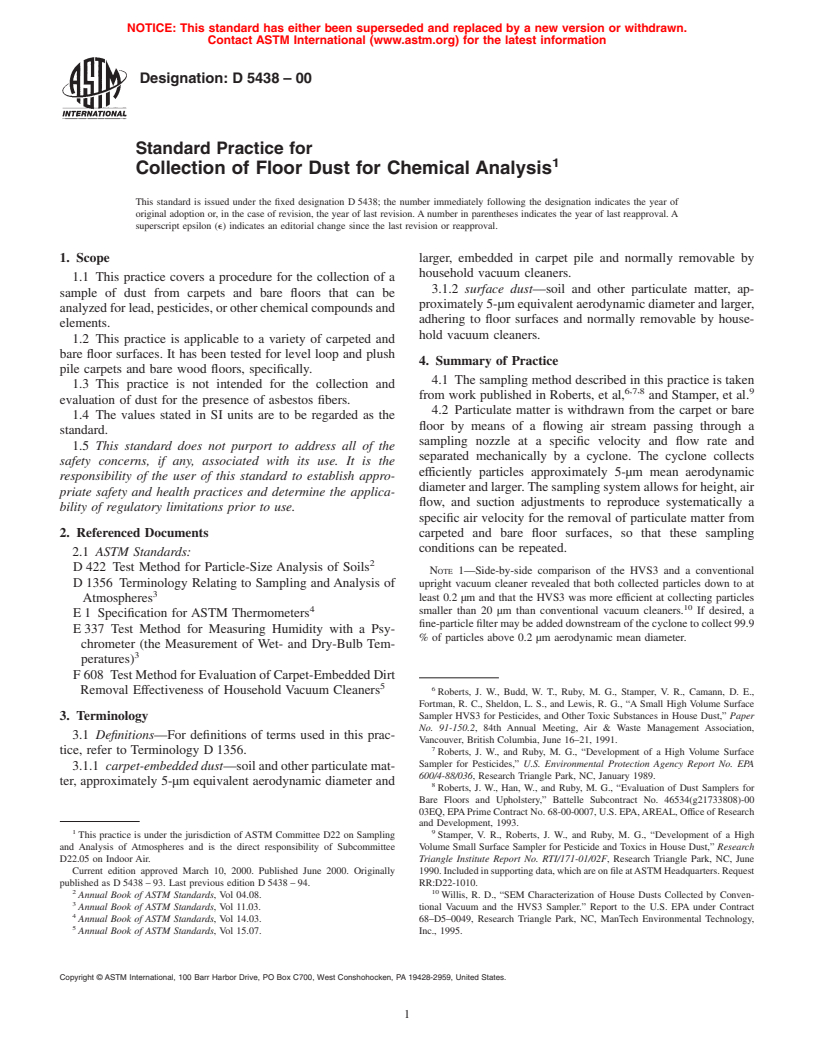

4.3 The particulate matter in the air stream is collected in a 7.1.1 The dimensions of the sampling apparatus (nozzle

catch bottle attached to the bottom of the collection cyclone. size, cyclone diameter, cyclone inlet diameter, etc.) are inter-

This catch bottle shall be capped for storage of the sample and dependent. The flow rate must produce a sufficient velocity

transported to the laboratory for analysis. both at the sampled surface and in the cyclone. The cyclone

must have a cut diameter of 5 µm at the same velocity that will

5. Significance and Use

provide a horizontal velocity of 40 cm/s at 10 mm from the

5.1 This practice may be used to collect dust from carpeted nozzle in the carpet material, or 5 mm from the nozzle on bare

or bare floor surfaces for gravimetric or chemical analysis.The

floors. The fundamental principles of this device have been

6,7,8

collected sample is substantially unmodified by the sampling discussed in detail in Roberts, et al.

procedure.

FIG. 1 Floor Dust Sampler Using a Commercial Vacuum Cleaner as the Suction Source

5.2 This practice provides for a reproducible dust removal 7.1.2 Nozzle—The edges and corners of the sampling

rate from level loop and plush carpets, as well as bare floors. It nozzleshallberoundedtopreventcatchingthecarpetmaterial.

has the ability to achieve relatively constant removal efficiency The nozzle must be constructed to allow for sufficient suction

to separate loose particles from the carpet or bare floor and

at different loadings of surface dust.

5.3 This practice also provides for the efficient capture of carry them to the cyclone. It must have an adjustment mecha-

semivolatile organic chemicals associated with the dust. The nism to establish the nozzle lip parallel to the surface and to

test system can be fitted with special canisters downstream of achieve the proper suction velocity and pressure drop across

the cyclone for the capture of specific semivolatile organic the nozzle. A nozzle 12.4 cm long and 1 cm wide, with a

chemicals that may volatilize from the dust particles during 13-mm flange and tapered to the nozzle tubing at no more than

collection. 30°, will yield the appropriate velocities when operated as

5.4 This practice does not describe procedures for evalua- specified in Section 11.

tion of the safety of floor surfaces or the potential human

7.1.3 Gaskets—Gaskets in joints should be of a material

exposure to carpet dust. It is the user’s responsibility to

appropriate to avoid sample contamination.

evaluate the data collected by this practice and make such

7.1.4 Cyclone—The cyclone shall be of a specific size such

determinations in the light of other available information.

that a given air flow allows for separation of the particles 5-µm

mean aerodynamic diameter and larger. The cyclone must be

6. Interferences

made of aluminum or stainless steel, and the catch bottle must

6.1 There are no known interferences to the determination

be made of clear glass or fluorinated ethylene propylene (FEP)

of dust loadings covered by this practice.

to avoid contamination and allow the operator to see the

sample.

7. Apparatus

7.1.5 Flow Control System—The flow control system shall

7.1 Sampling Apparatus, which may be acquired commer-

allow for substantial volume adjustment. The suction source

cially (as shown in Fig. 1) or constructed as follows:

must be capable of drawing 12 L/s (26.5 CFM) through the

system with no restrictions other than the nozzle, cyclone, and

flowcontrolsystemconnected.Anuprightcommercialvacuum

The sampling device used in the development and performance evaluation of

cleaner with a 7 amp or greater motor capable of pulling a

this test method was manufactured by CS-3, Inc., P.O. Box 1461, Sandpoint, ID

83864, which is the sole source of supply of the sampler known to the committee

vacuum of 6.5 kPa may be used for this purpose.

atthistime.Ifyouareawareofalternativesuppliers,pleaseprovidethisinformation

7.1.6 Flow Measuring and Suction Gages— Two vacuum

to the Committee on Standards, ASTM Headquarters, 100 Barr Harbor Dr., West

gages are required — one with a range of 0 to 3.7 kPa (0–15

Conshohocken, PA 19428. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend. in. water) is used for setting flow rate and another with a range

D5438–00

of 0 to 2.5 kPa (0–10 in. water) is used to set the pressure drop is, temperature gage) used for testing purposes should be

across the vacuum nozzle. calibrated against a primary standard.

7.1.7 Optional filter holder assembly with appropriate fine 10.1.1 Pressure Gages—Pressure gages shall be calibrated

particle filter, such as a 25–cm micro-quartz-fibre, binderless, against an inclined manometer or other primary standard prior

acid-washed filter. to any field test. One means of checking a Magnehelic gage is

7.2 Other Equipment: to set a flow rate through the sampling system with a

7.2.1 Stopwatch. manometer and then switch to the Magnehelic gage. If the

7.2.2 Masking Tape and Marking Pen,foroutliningsections difference in the readings is more than 3 %, the gage is leaking

for sampling. orisinneedofrepairorcalibration.Thisshouldbedoneattwo

7.2.3 Clean Aluminum Foil and Clean Glass or FEP Jars, different flow rates when checking the gage.

for the collection and storage of samples. 10.1.2 The cyclone flow measurement is calibrated with a

7.2.4 Thermometer (see Specification E 1). laminar flow element, spirometer, or roots meter. See the

7.2.5 Relative Humidity Meter (see Test Method E 337). appendix for cyclone calibration with a laminar flow element.

7.2.6 Shaker Sieve, as specified in Test Method D 422, with 10.2 Pretest Preparation:

100 mesh-screen above the pan to separate the fine dust below 10.2.1 Each catch bottle to be used shall be clean and

150 µm. inspected for any contamination.The bottles should be marked

7.2.7 Analytical Balance, sensitive to at least 0.1 mg and with masking tape and a marking pen for identification of the

having a weighing range from 0.1 mg to 1000 g. test site, time, and date.

10.2.2 Thesamplingtrainshallbeinspectedtoensurethatit

8. Reagents and Materials

has been cleaned and assembled properly.

8.1 Purity of Reagents—Reagent grade chemicals shall be

10.2.3 The sampling train shall be leak-checked prior to

used in all tests. Unless otherwise indicated, it is intended that sampling. This can be accomplished by placing a mailing

all reagents shall conform to the specifications of the Commit-

envelope or a piece of cardboard beneath the nozzle and

tee onAnalytical Reagents of theAmerican Chemical Society, switching on the suction source. The flow Magnehelic gage

where such specifications are available.

should read 5 Pa (0.02 in. H O) or less to ensure that the

8.2 Methanol is required for sampling train cleaning after system is leak free. If any leakage is detected, the system shall

sample collection.

be inspected for the cause and corrected before use.

11. Sampling

9. Sampling Strategy

11.1 Sampling a Carpeted Floor:

9.1 The overall sampling strategy should be designed to

11.1.1 Pre-Test Survey—Immediately prior to testing, com-

address the goals of the study. Users should consider factors

plete a data form recording all requested information and

such as foot traffic volume, types of activities, proximity to

sketch the area to be sampled. (See Fig. 2 for a sample data

potential sources, etc. The sampling strategy should be de-

form.)

scribed in the sampling report so it can be taken into consid-

erationwhenreadersarecomparingloadingsorconcentrations, 11.1.2 Select a sampling area according to the established

protocol for your sampling campaign. This should be deter-

or both, to those obtained from other studies. The ideal

sampling location(s) for the beginning of the test procedure are mined prior to testing.

11.1.3 A typical sampling procedure may use measuring

an area that conforms with the protocol for the user’s overall

sampling strategy. For example, when sampling in a home for tapesplacedonthecarpetsothattheyareparalleltoeachother

and on either side of the portion of carpet to be sampled (Fig.

child exposure assessment, protocol may require the selection

of a carpeted area for sampling where small children play or 3).Themeasuringtapesshouldbebetween0.5and1.5-mapart

and extended as far as practical. They should be taped to the

are likely to play.

carpet with masking tape every 30 cm.

10. Pretest Preparation and Calibration

11.1.4 Place the sampler in one corner of the sampling area

10.1 Calibration—The sampling system described in this andadjusttheflowrateandpressuredropaccordingtothetype

practice does not have any calibrated flow devices other than ofcarpet(see11.8).Thetwofactorsthataffecttheefficiencyof

the sampling system are the flow rate and pressure drop at the

the cyclone and the Magnehelic gages. The cyclone used for

the separation of the particles must be designed to give proper nozzle.Thepressuredropatthenozzleisafunctionoftheflow

rate and distance between the surface and the nozzle flange.

separation at varying flow rates throughout the sampling range

of the system. The pressure gages and any other devices (that 11.1.5 Clean the wheels and nozzle lip with a clean labora-

tory tissue immediately before sampling. Begin sampling by

moving the nozzle between the ends of the two measuring

A filter holder for circular 25–cm particle filters

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.