ASTM D4502-92(2011)

(Test Method)Standard Test Method for Heat and Moisture Resistance of Wood-Adhesive Joints

Standard Test Method for Heat and Moisture Resistance of Wood-Adhesive Joints

SIGNIFICANCE AND USE

This test method can serve as a useful tool for durability assessment and service life forecasting.

This test method can be used to measure the effects of heat and moisture and the effect of their interaction on adhesives and bonded joints. Knowledge of these effects is useful to an adhesive formulator or manufacturer. Moist heat aging is particularly useful for determining the effects of acidic adhesive systems on the hydrolysis of wood adherends.

This test method provides a means of comparing the rate of degradation of an unknown adhesive-adherend combination to the rate of degradation of a known combination in thermal or hydrolytic aging environments. Such a comparison can be useful to adhesive manufacturers for introducing a new product to the market and for helping designers selecting adhesives.

This test method does not duplicate any natural service environment, but it does provide a means of estimating the service life of joints in similar environments. Service-life estimates are useful to designers of bonded structures or structures using bonded products.

Service-life estimates rely on the assumption that the chemical degradation mechanism is the same at the elevated aging temperatures as at the service temperature. However, this may not be true in every case. This possibility, together with the variability in specimen preparation, in the aging exposures, and in the strength measurements, require that caution be used in accepting the estimate of service life.

SCOPE

1.1 The purpose of this test method is to estimate the resistance of adhesive-bonded joints to thermal and hydrolytic degradation.

1.2 This test method is primarily for wood-to-wood joints but may be applied to joints of wood to other materials.

1.3 The effects of chemicals such as fire retardants, preservatives, and extractives in the wood upon joint degradation resistance can be estimated.

1.4 This test method does not account for the effects of stress, the other principal degrading factor, nor does it account for cyclic or variable temperature or moisture levels.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4502 − 92 (Reapproved 2011)

Standard Test Method for

Heat and Moisture Resistance of Wood-Adhesive Joints

This standard is issued under the fixed designation D4502; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 IEEE Standard:

IEEENo.1GeneralPrinciplesforTemperatureLimitsinthe

1.1 The purpose of this test method is to estimate the

Rating of Electrical Equipment

resistance of adhesive-bonded joints to thermal and hydrolytic

degradation.

3. Terminology

1.2 This test method is primarily for wood-to-wood joints

3.1 Definitions

but may be applied to joints of wood to other materials.

3.1.1 For definitions of terms used in this test method, refer

to Terminology D907.

1.3 The effects of chemicals such as fire retardants,

3.2 shear strength, n—in an adhesive joint, the maximum

preservatives, and extractives in the wood upon joint degrada-

average stress when a force is applied parallel to the joint.

tion resistance can be estimated.

3.2.1 Discussion—In most adhesive test methods, the shear

1.4 This test method does not account for the effects of

strength is actually the maximum average stress at failure of

stress, the other principal degrading factor, nor does it account

the specimen, not necessarily the true maximum stress in the

for cyclic or variable temperature or moisture levels.

material.

1.5 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 The degradation of adhesive joints is a physicochemical

responsibility of the user of this standard to establish appro-

process. The speed of degradation is related to the levels of

priate safety and health practices and determine the applica-

temperature, moisture (and other chemicals), and physical

bility of regulatory limitations prior to use.

stress to which the joint is exposed. This test method is based

on the principles of chemical kinetics and uses theArrehenius

2. Referenced Documents

temperature dependence relationship to estimate the long-term

2.1 ASTM Standards:

effects of heat and moisture at the service temperature.

D897Test Method forTensile Properties ofAdhesive Bonds

4.2 Specimens whose unaged properties have been esti-

D905Test Method for Strength Properties of Adhesive

mated by control tests are subjected to an accelerated thermal

Bonds in Shear by Compression Loading

or hydrolytic aging environment in groups. Aging is acceler-

D907Terminology of Adhesives

ated by using elevated temperature. Periodically, a group of

D2304Test Method for Thermal Endurance of Rigid Elec-

specimens is removed from the aging environment and tested.

trical Insulating Materials

The estimated property after aging and the time of aging are

D2307 Test Method for Thermal Endurance of Film-

recorded.Afterseveralgroupshavebeentestedinthismanner,

Insulated Round Magnet Wire

the rate of property loss in the aging environment can be

D2339Test Method for Strength Properties ofAdhesives in

estimated. This basic experiment is repeated at several other

Two-PlyWood Construction in Shear byTension Loading

elevated temperatures, and the rates of property loss at those

temperatures estimated. The rate of property loss relationship

to temperature is estimated. This relationship can be extrapo-

lated to lower service temperatures for estimating service life.

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

4.3 This test method employs a smaller version of the Test

Adhesives.

MethodD905blockshearspecimen,butothershearstrengthor

Current edition approved Jan. 1, 2011. Published January 2011. Originally

approved in 1985. Last previous edition approved in 2004 as D4502–92(2004).

tensile strength specimens may also be used.

DOI: 10.1520/D4502-92R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

the ASTM website. 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4502 − 92 (2011)

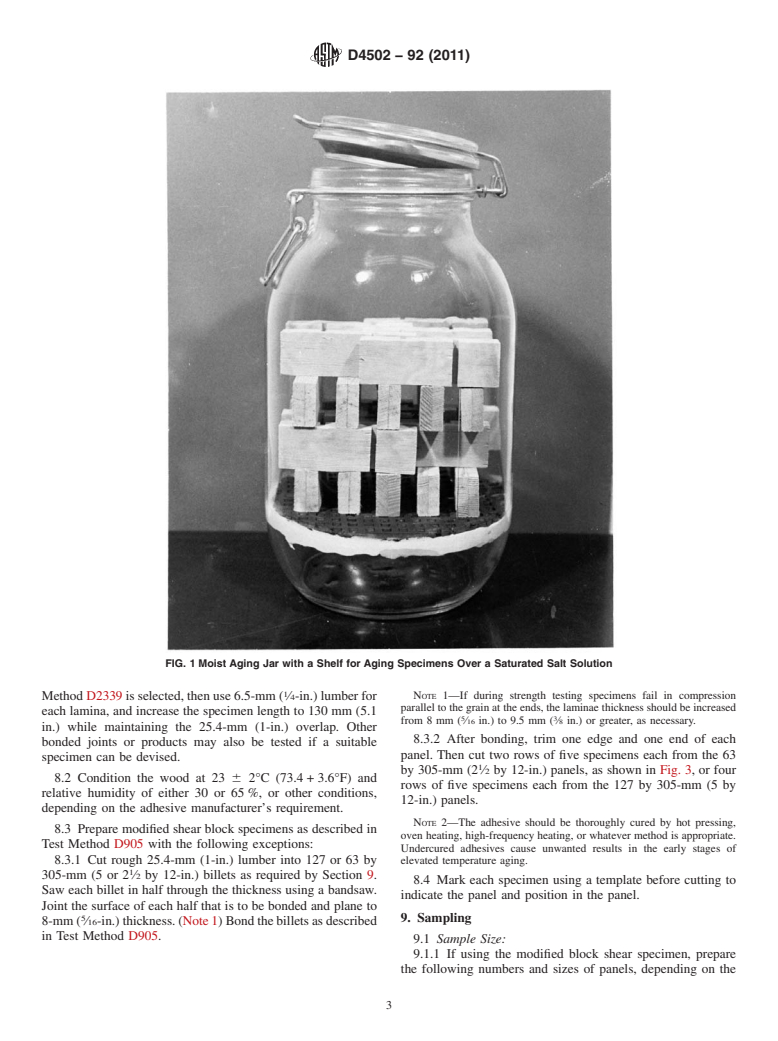

5. Significance and Use providesaledgetosupporttheplatform.Theplatformmustbe

perforated to permit free-flow of water vapor. It may be cut

5.1 Thistestmethodcanserveasausefultoolfordurability

from any material that is resistant to corrosion, heat, and

assessment and service life forecasting.

moisture. Perforated high-density hardboard has proven satis-

5.1.1 This test method can be used to measure the effects of

factory. The platform must be cut in half to pass through the

heat and moisture and the effect of their interaction on

neck of the jar.An aging jar with platform is shown in Fig. 1.

adhesives and bonded joints. Knowledge of these effects is

The jars must be placed in an aging oven, such as described in

useful to an adhesive formulator or manufacturer. Moist heat

5.1, to achieve the required temperature.

agingisparticularlyusefulfordeterminingtheeffectsofacidic

adhesive systems on the hydrolysis of wood adherends. 6.4 Water Baths—Constant-level water baths capable of

5.1.2 This test method provides a means of comparing the controltowithin0.5°Cofthedesiredtemperaturearerequired.

rate of degradation of an unknown adhesive-adherend combi- The baths must be able to contain 100 specimens.

nation to the rate of degradation of a known combination in

6.5 Testing Machine—The testing machine shall have a

thermal or hydrolytic aging environments. Such a comparison

capacity of not less than 3000 kg (6210 lbf) in compression.

can be useful to adhesive manufacturers for introducing a new

The machine shall be capable of maintaining a uniform rate of

product to the market and for helping designers selecting

loading such that the load may be applied with a continuous

adhesives.

motion of the movable head to the maximum load at a rate of

5.1.3 This test method does not duplicate any natural

10.0 6 5 mm/min (0.40 in./min) with a permissible variation

serviceenvironment,butitdoesprovideameansofestimating

of+0.5%.

the service life of joints in similar environments. Service-life

6.6 Shearing Tool—A shearing tool similar to the tool

estimates are useful to designers of bonded structures or

pictured in Test Method D905 is satisfactory. The tool must

structures using bonded products.

have a self-aligning seat to ensure uniform lateral distribution

5.2 Service-life estimates rely on the assumption that the

of the load.

chemical degradation mechanism is the same at the elevated

agingtemperaturesasattheservicetemperature.However,this

7. Materials

may not be true in every case. This possibility, together with

7.1 Adhesive to Be Tested:

thevariabilityinspecimenpreparation,intheagingexposures,

7.2 Joints—Wood for wood-to-wood joints or joints of

and in the strength measurements, require that caution be used

wood to metal or plastic shall be free of defects such as knots,

in accepting the estimate of service life.

cracks, short-grain and sharp-grain deviations, or any discol-

6. Apparatus

orations or soft spots indicative of decay. Generally, a high-

density uniform-textured wood is desirable so that the maxi-

6.1 Aging Ovens—Ovens are required that are capable of

mum stress will be placed on the adhesive joint during testing.

control within 62 % of specified exposure temperature

The standard shall be hard maple (Acer saccharum or Acer

throughout the chamber for extended periods of time (60.5°C

nigrum) having a minimum specific gravity of 0.65 (based on

control is desirable). The ovens must be capable of operating

oven-dry weight and volume). Other species may be used

at temperatures from 60 to 175°C. The oven must have an

whereevaluationoftheadhesive’sperformanceincontactwith

internal capacity for up to 100 specimens well-spaced and

that species is a specific requirement.

supported on racks to allow free air flow.

7.3 Saturated Salt Solutions—A constant relative humidity

6.2 Environmental Chambers—Chambers for moist-heat

at a given temperature can be maintained in sealed aging jars

aging must be capable of 60.5°C temperature and 0.5%

byasaturatedaqueoussolutionincontactwithanexcessofthe

relative humidity control uniformly throughout the chamber.

solid phase of a specific salt. Tables are available that show

The chamber must be capable of operating at temperatures

relative humidities at given temperatures for many salts.

from 60 to 90°C and relative humidity from 60 to 80%. The

Sodium chloride is recommended. A saturated solution of

chamber must have the capacity for up to 100 specimens

sodiumchloridewillproducearelativehumidityof73to76%

well-spaced and supported on racks to allow free air flow.

overthetemperaturerangefrom40to100°C.Thistranslatesto

6.3 Moist Aging Jars—Heat-resistant glass jars are required

wood moisture content in the approximate range from 9 to

to expose specimens to constant relative humidity and tem-

13%.

perature over saturated salt solutions. Wide-neck canning jars

⁄2 L (1 gal), rubber gaskets, and clamp lids

with volumes of 3

8. Test Specimens

haveprovensatisfactoryattemperaturesof100°C(212°F)and

8.1 A modified block shear specimen (Fig. 2) is suggested.

below. The jars must have a platform inside (without legs) to

ThespecimenissimilartothespecimenofTestMethodD905,

support specimens above the saturated salt solution. A 6-mm

but its smaller size allows more specimens to fit in the aging

( ⁄4-in.) diameter bead of silicone sealant around the inside

chambers. Other specimens such as used inTest Method D897

surface of the jar and about 5 cm (2 in.) above the bottom

orTestMethodD2339arealsosatisfactory.IfatypefromTest

Millett,M.A.,Western,L.J.,andBooth,J.J.,“AcceleratedAgingofCellulosic

Materials: Design andApplication of a Heating Chamber,” TAPPI, Vol 50, No. 11, Dean, J.A., ed., Lange’s Handbook of Chemistry, 12th ed., McGraw-Hill Book

1967, pp 74A–80A. Co., Inc., 1978.

D4502 − 92 (2011)

FIG. 1 Moist Aging Jar with a Shelf for Aging Specimens Over a Saturated Salt Solution

NOTE 1—If during strength testing specimens fail in compression

MethodD2339isselected,thenuse6.5-mm( ⁄4-in.)lumberfor

paralleltothegrainattheends,thelaminaethicknessshouldbeincreased

each lamina, and increase the specimen length to 130 mm (5.1

5 3

from8mm( ⁄16 in.) to 9.5 mm ( ⁄8 in.) or greater, as necessary.

in.) while maintaining the 25.4-mm (1-in.) overlap. Other

8.3.2 After bonding, trim one edge and one end of each

bonded joints or products may also be tested if a suitable

panel. Then cut two rows of five specimens each from the 63

specimen can be devised.

by 305-mm (2 ⁄2 by 12-in.) panels, as shown in Fig. 3, or four

8.2 Condition the wood at 23 6 2°C (73.4+3.6°F) and

rows of five specimens each from the 127 by 305-mm (5 by

relative humidity of either 30 or 65%, or other conditions,

12-in.) panels.

depending on the adhesive manufacturer’s requirement.

NOTE 2—The adhesive should be thoroughly cured by hot pressing,

8.3 Prepare modified shear block specimens as described in

oven heating, high-frequency heating, or whatever method is appropriate.

Test Method D905 with the following exceptions:

Undercured adhesives cause unwanted results in the early stages of

8.3.1 Cut rough 25.4-mm (1-in.) lumber into 127 or 63 by elevated temperature aging.

305-mm (5 or 2 ⁄2 by 12-in.) billets as required by Section 9.

8.4 Mark each specimen using a template before cutting to

Saw each billet in half through the thickness using a bandsaw.

indicate the panel and position in the panel.

Joint the surface of each half that is to be bonded and plane to

9. Sampling

8-mm( ⁄16-in.)thickness.(Note1)Bondthebilletsasdescribed

in Test Method D905.

9.1 Sample Size:

9.1.1 If using the modified block shear specimen, prepare

the following numbers and sizes of panels, depending on the

D4502 − 92 (2011)

9.2.3 The distribution of specimens for subsequent data

analysis is summarized by the block experimental designs

shown in Table 4 for each of the experiments.

10. Procedure

10.1 Initial Strength:

10.1.1 Condition the control specimens to equilibrium

moisture content (EMC) at 23+2°C and 50 6 2% relative

humidity or other conditions as agreed upon by the parties

involved. One to four weeks may be required to reach EMC,

depending on the beginning moisture content.

10.1.2 Test the specimens (after they reach EMC) in the

shear tool with the universal test machine crosshead moving at

10+0.05 mm/min (0.400 6 0.002 in./min). Store the speci-

mens in a plastic bag, or remove them one at a time from the

conditioned environment during testing. Record the strength

and estimated percentage of wood failure for each specimen.

10.2 Service Life Estimate:

10.2.1 Aging temperatures are given inTable 4. For a given

temperature/moisture condition, mount five groups (10 speci-

mens per group) on suitable racks for dry aging, place in jars

for moist aging, or string each group on stainless steel wire for

wet aging.

10.2.2 Estimate five aging intervals that will produce ap-

proximately equal strength decrements to a total strength loss

of25to30%fromtheinitialstrengthforeachofthefiveaging

temperatures. Previous aging experience may not be available,

FIG. 2 Modified Block Shear Specimen

especially for new adhesives. If this is the case, use the

approximate times given in Table 5.

NOTE 3—Twenty-five percent strength loss is a convenient level. Any

type of experiment to be performed (service life, rate

amount of loss can be defined as failure as long as it is agreeable to the

comparison, or quality control):

partiesrequiringthistestanditisdefinedinthereport.Higherpercentages

of loss require longer exposure times.

Service life estimation 10 panels,

127 by 305 mm

10.2.3 Place the five groups (see Note 4) in the aging

Rate comparison:

exposure. At the end of the first aging interval, withdraw the

One adhesive/different exposures

(10 panels, 127 by 305 mm) first group of specimens, recondition to EMC, and test as

Two adhesives/same exposure

described in 10.1.1 and 10.1.2. Based on this test, project the

(10 panels, 63 by 305 mm)

time to reach 25% loss. If necessary, adjust the remaining

(for each adhesive)

Quality control (10 p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.