ASTM C627-93(2007)

(Test Method)Standard Test Method for Evaluating Ceramic Floor Tile Installation Systems Using the Robinson-Type Floor Tester

Standard Test Method for Evaluating Ceramic Floor Tile Installation Systems Using the Robinson-Type Floor Tester

SIGNIFICANCE AND USE

This test method provides a standardized procedure for evaluating performance of ceramic floor tile installations under conditions similar to actual specific usages. It can be used to make comparisons between customary basic installation methods, to establish the influence of minor changes in a particular installation method, and to judge the merit of proposed novel methods.

SCOPE

1.1 This test method covers the evaluation of ceramic floor tile installation systems, using the Robinson-type floor tester.

1.2 This test method is intended solely for evaluating complete ceramic floor tile installation systems for failure under loads and not for evaluating particular characteristics of ceramic tile, such as abrasion resistance. This test method does not claim to provide meaningful results for other than evaluating complete ceramic floor tile installation systems.

1.3 The values stated in inch-pound units are to be regarded as the standard. The metric (SI) units in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C627 – 93 (Reapproved 2007)

Standard Test Method for

Evaluating Ceramic Floor Tile Installation Systems Using

1

the Robinson-Type Floor Tester

This standard is issued under the fixed designation C627; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope subjecting them to one or more tests on the Robinson floor

tester, and evaluating the results in a prescribed manner.

1.1 This test method covers the evaluation of ceramic floor

2

Descriptionoftheinstallationmethodmustspecificallyinclude

tile installation systems, using the Robinson -type floor tester.

all variables, for example, the type of materials and mixture

1.2 This test method is intended solely for evaluating

proportions of substratum, setting material, and tile grout; type

complete ceramic floor tile installation systems for failure

of tile, installation technique, and cure.

under loads and not for evaluating particular characteristics of

ceramic tile, such as abrasion resistance. This test method does

4. Significance and Use

not claim to provide meaningful results for other than evalu-

4.1 This test method provides a standardized procedure for

ating complete ceramic floor tile installation systems.

evaluating performance of ceramic floor tile installations under

1.3 The values stated in inch-pound units are to be regarded

conditions similar to actual specific usages. It can be used to

as the standard. The metric (SI) units in parentheses are for

make comparisons between customary basic installation meth-

information only.

ods, to establish the influence of minor changes in a particular

1.4 This standard does not purport to address all of the

installation method, and to judge the merit of proposed novel

safety concerns, if any, associated with its use. It is the

methods.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use.

5.1 Foundation for Tester—The foundation for the tester

2. Referenced Documents shall consist of a nominally 4-ft (1220-mm) square and 1-ft

3 (300-mm) thick cement slab with two 15- by 15-in. (380- by

2.1 ASTM Standards:

1

380-mm) bearing plates with four 12 ⁄2-in. (318-mm) high tie

C144 Specification for Aggregate for Masonry Mortar

rods cast into the center of the foundation and with an 8-in.

C150 Specification for Portland Cement

(203-mm) square and 1-ft (300-mm) deep opening in the exact

2.2 ASTM Adjuncts:

2 center. The top surface of this slab shall be smooth, level, and

Robinson-type Floor Tester

4 flat with the maximum deviation from a true plane not to

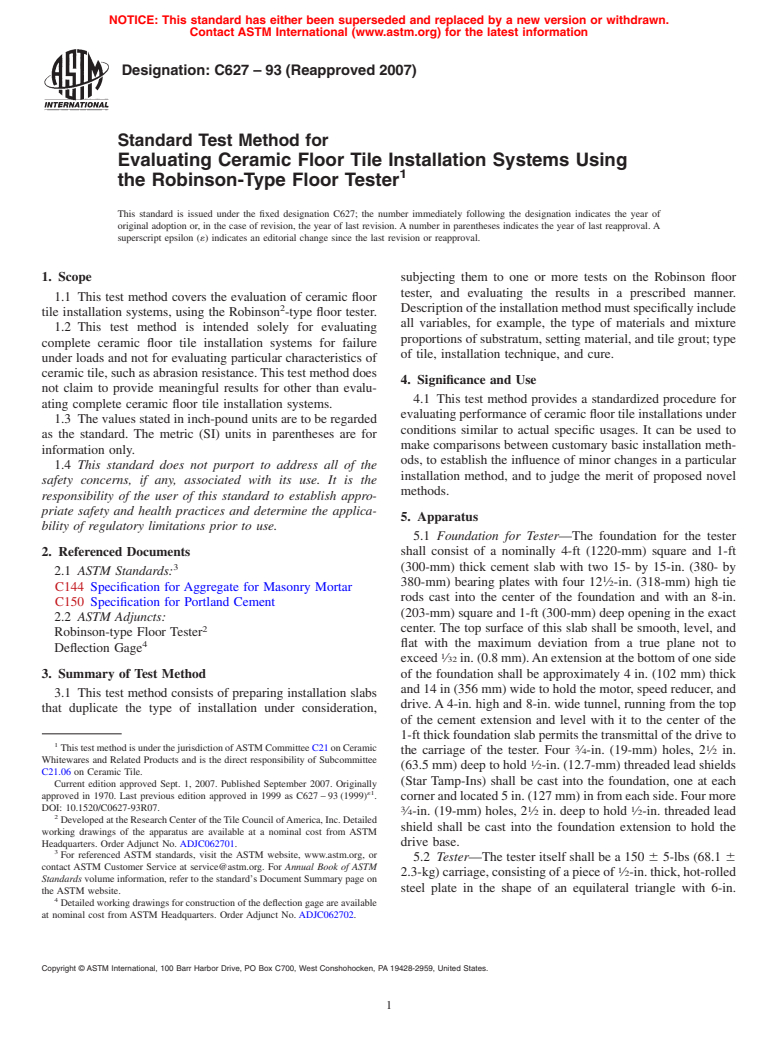

Deflection Gage

1

exceed ⁄32 in. (0.8 mm).An extension at the bottom of one side

3. Summary of Test Method of the foundation shall be approximately 4 in. (102 mm) thick

and 14 in (356 mm) wide to hold the motor, speed reducer, and

3.1 This test method consists of preparing installation slabs

drive.A4-in. high and 8-in. wide tunnel, running from the top

that duplicate the type of installation under consideration,

of the cement extension and level with it to the center of the

1-ft thick foundation slab permits the transmittal of the drive to

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic 3 1

the carriage of the tester. Four ⁄4-in. (19-mm) holes, 2 ⁄2 in.

Whitewares and Related Products and is the direct responsibility of Subcommittee

1

(63.5 mm) deep to hold ⁄2-in. (12.7-mm) threaded lead shields

C21.06 on Ceramic Tile.

(Star Tamp-Ins) shall be cast into the foundation, one at each

Current edition approved Sept. 1, 2007. Published September 2007. Originally

´1

approved in 1970. Last previous edition approved in 1999 as C627 – 93 (1999) .

cornerandlocated5in.(127mm)infromeachside.Fourmore

DOI: 10.1520/C0627-93R07.

3 1 1

⁄4-in. (19-mm) holes, 2 ⁄2 in. deep to hold ⁄2-in. threaded lead

2

Developed at the Research Center of theTile Council ofAmerica, Inc. Detailed

shield shall be cast into the foundation extension to hold the

working drawings of the apparatus are available at a nominal cost from ASTM

Headquarters. Order Adjunct No. ADJC062701. drive base.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 Tester—The tester itself shall be a 150 6 5-lbs (68.1 6

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

2.3-kg) carriage, consisting of a piece of ⁄2-in. thick, hot-rolled

Standards volume information, refer to the standard’s Document Summary page on

steel plate in the shape of an equilateral triangle with 6-in.

the ASTM website.

4

Detailed working drawings for co

...

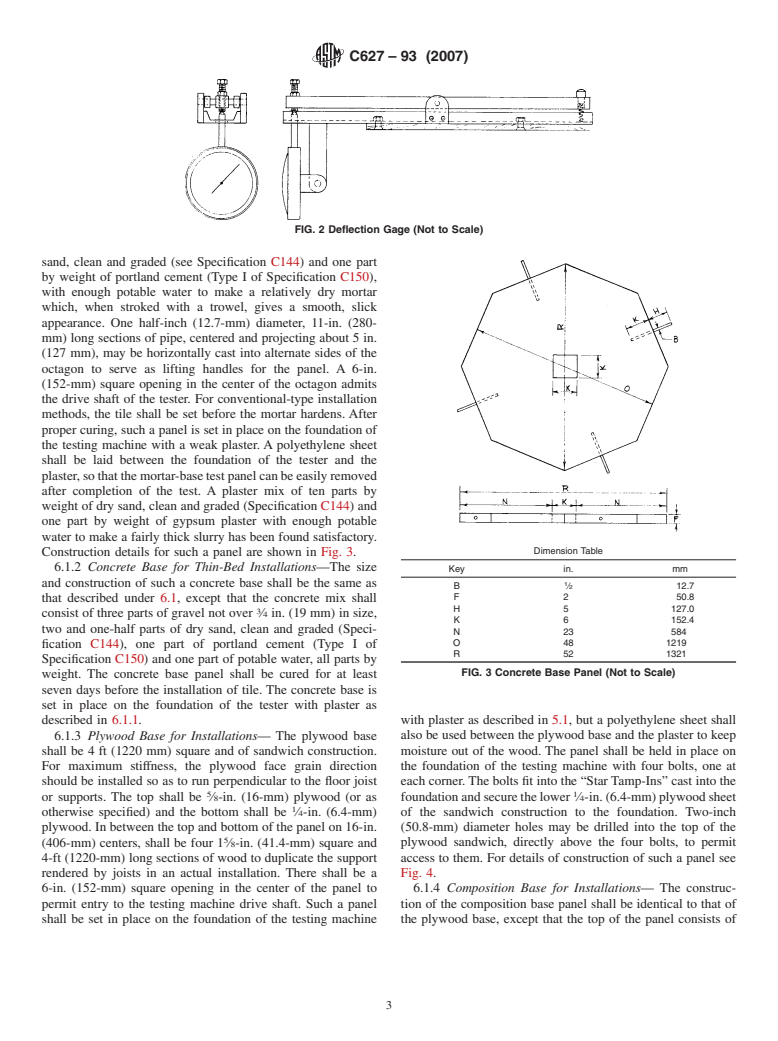

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.