ASTM D6396-99

(Test Method)Standard Test Method for Testing of Pipe Thread Sealants on Pipe Tees

Standard Test Method for Testing of Pipe Thread Sealants on Pipe Tees

SCOPE

1.1 This test method covers procedures used to assemble, evaluate and test pipe thread sealants.

1.2 Test procedures included in this test method are cure speed versus temperature, primer cure, instant seal/sealability, heat aging, solvent rsistance, hot strength, steam resistance, and specimen preparation for high pressure testing.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6396 – 99

Standard Test Method for

Testing of Pipe Thread Sealants on Pipe Tees

This standard is issued under the fixed designation D 6396; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method covers procedures used to assemble, 5.1 Many of the tests that have been employed in the past to

evaluate and test pipe thread sealants. evaluate thread sealant products have not consistently targeted

1.2 Test procedures included in this test method are cure the most significant product features of a thread sealant. For

speed versus temperature, primer cure, instant seal/sealability, instance, one of a thread sealant’s primary performance fea-

heat aging, solvent resistance, hot strength, steam resistance, tures is its ability to maintain a seal under a range of

and specimen preparation for high pressure testing. conditions. The procedures in this test method assess the

1.3 The values stated in inch-pound units are to be regarded important characteristic properties of a thread sealant.

as the standard. The SI units given in parentheses are for 5.2 Because of the variability of the test specimens and the

information only. techniques employed by each operator, the assembly and test

1.4 This standard does not purport to address all of the procedures and the testing apparatus have been designed to

safety concerns, if any, associated with its use. It is the reduce the variability of the test results.

responsibility of the user of this standard to establish appro-

6. Apparatus

priate safety and health practices and determine the applica-

6.1 Torque Testing Device, of suitable capacity, for testing

bility of regulatory limitations prior to use.

assemblies.

2. Referenced Documents

NOTE 1—Using automated torque testers to test the assemblies gener-

2.1 ASTM Standards:

ally produces more reproducible results.

D 907 Terminology of Adhesives

6.2 Torque Wrench, of suitable capacity, for providing

D 1599 TestMethodforShort-TimeHydraulicFailurePres-

3 installation torque.

sure of Plastic Pipe, Tubing, and Fittings

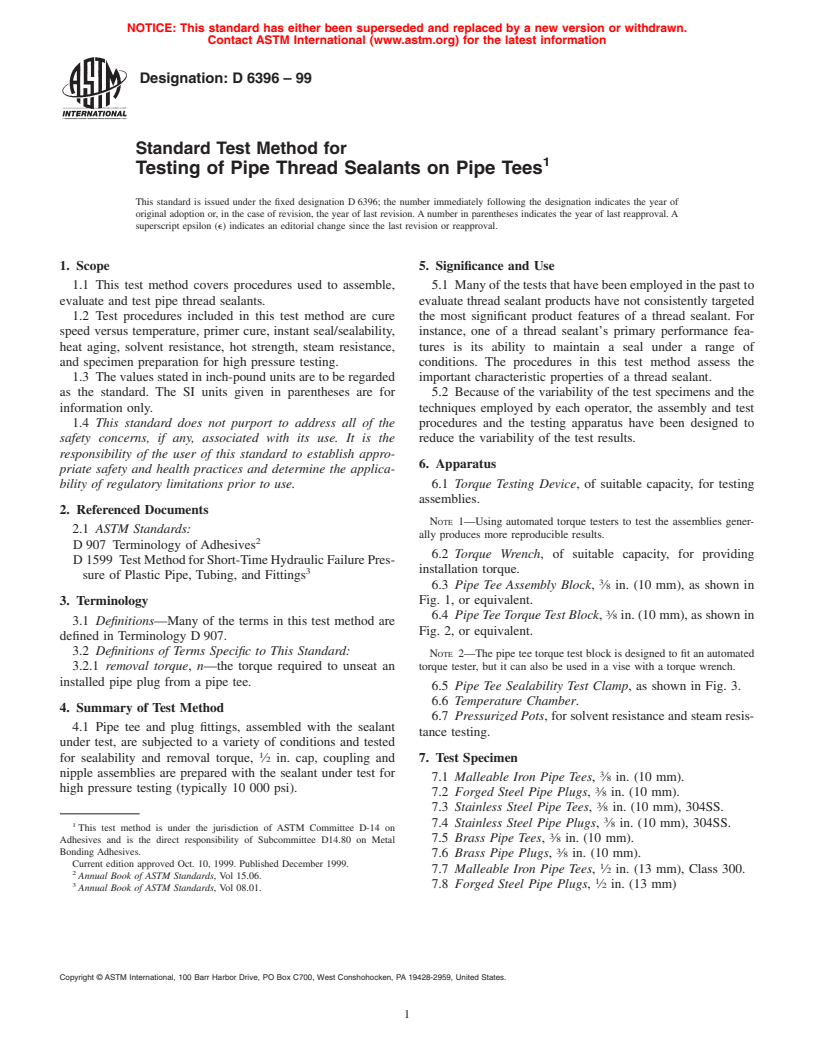

6.3 Pipe Tee Assembly Block, ⁄8 in. (10 mm), as shown in

Fig. 1, or equivalent.

3. Terminology

6.4 Pipe Tee Torque Test Block, ⁄8 in. (10 mm), as shown in

3.1 Definitions—Many of the terms in this test method are

Fig. 2, or equivalent.

defined in Terminology D 907.

3.2 Definitions of Terms Specific to This Standard:

NOTE 2—The pipe tee torque test block is designed to fit an automated

3.2.1 removal torque, n—the torque required to unseat an torque tester, but it can also be used in a vise with a torque wrench.

installed pipe plug from a pipe tee.

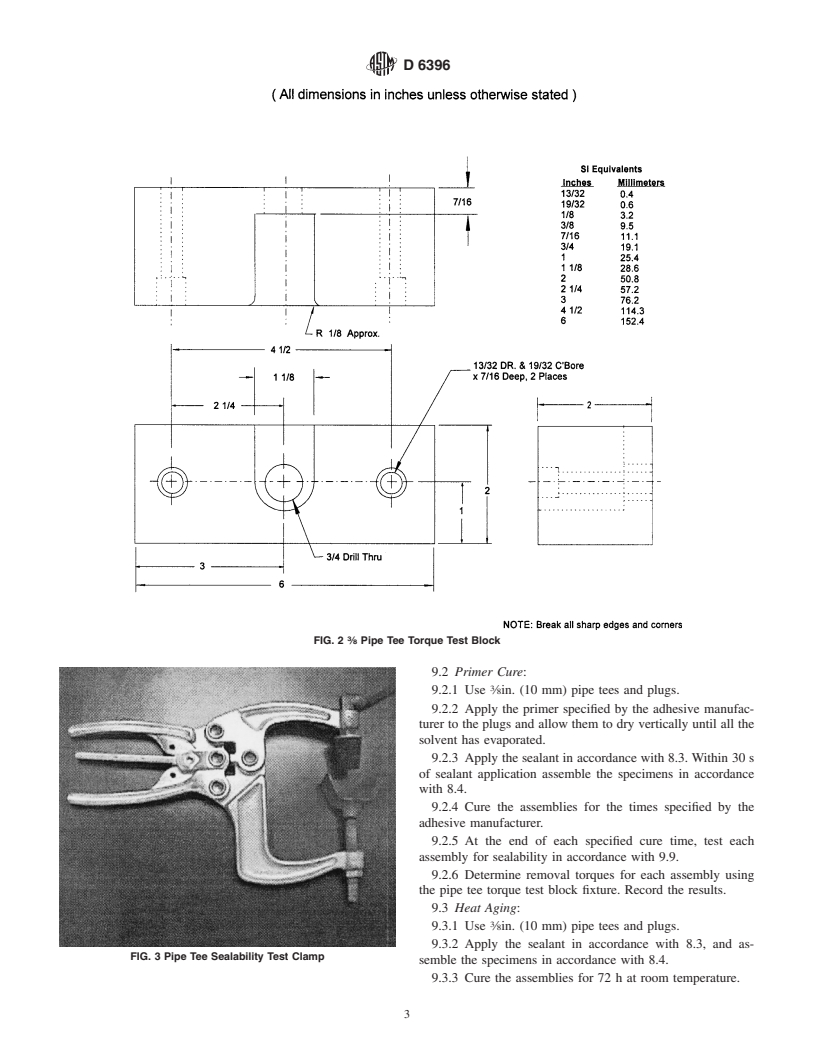

6.5 Pipe Tee Sealability Test Clamp, as shown in Fig. 3.

6.6 Temperature Chamber.

4. Summary of Test Method

6.7 Pressurized Pots, for solvent resistance and steam resis-

4.1 Pipe tee and plug fittings, assembled with the sealant

tance testing.

under test, are subjected to a variety of conditions and tested

for sealability and removal torque, ⁄2 in. cap, coupling and 7. Test Specimen

nipple assemblies are prepared with the sealant under test for

7.1 Malleable Iron Pipe Tees, ⁄8 in. (10 mm).

high pressure testing (typically 10 000 psi). 3

7.2 Forged Steel Pipe Plugs, ⁄8 in. (10 mm).

7.3 Stainless Steel Pipe Tees, ⁄8 in. (10 mm), 304SS.

1 7.4 Stainless Steel Pipe Plugs, ⁄8 in. (10 mm), 304SS.

This test method is under the jurisdiction of ASTM Committee D-14 on

7.5 Brass Pipe Tees, ⁄8 in. (10 mm).

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

Bonding Adhesives.

7.6 Brass Pipe Plugs, ⁄8 in. (10 mm).

Current edition approved Oct. 10, 1999. Published December 1999.

7.7 Malleable Iron Pipe Tees, ⁄2 in. (13 mm), Class 300.

Annual Book of ASTM Standards, Vol 15.06.

3 7.8 Forged Steel Pipe Plugs, ⁄2 in. (13 mm)

Annual Book of ASTM Standards, Vol 08.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6396

FIG. 1 ⁄8 Pipe Tee Assembly Block

1 1

7.9 Hex Reducing Coupling, ⁄2 in. (13 mm) FNPT by ⁄8 in. 8.4.2 Remove excess sealant to avoid excess specimen

(3 mm) FNPT, 316 stainless steel. weight loss that may be caused by charred sealant flaking off

7.10 Cap, ⁄2 in. (13 mm) pipe cap. during initial heat exposure and in steam resistance tests.

7.11 Hex Long Nipple, 316SS.

9. Procedure

8. Assembly

9.1 Cure Speed Versus Temperature:

8.1 Assemble not less than three assemblies for each test.

9.1.1 Use ⁄8in. (10 mm) pipe tees and plugs.

8.2 Degrease all pipe tees and plugs. Allow specimens to

9.1.2 Condition pipe tees and plugs in a temperature cham-

cool to room temperature prior to sealant application.

ber at the cure temperature specified by the adhesive manufac-

8.3 Apply sealant as follows:

turer for a minimum of 2 h.

8.3.1 Apply sealant uniformly to the second through the

NOTE 3—A temperature chamber is not needed for conditioning speci-

sixth threads of the male fitting for each test joint.

mens for curing at room temperature.

8.3.2 Ensure that the average height of the sealant reaches

the thread crown (major diameter), and that the sealant 9.1.3 Remove the specimens from the temperature chamber,

completely wets the thread roots. and immediately apply the sealant, which has been held at

8.3.3 Note any separation or visible defects with the prod- room temperature, in accordance with 8.3, and assemble the

ucts. Also note any problems with wettability or excessive specimens in accordance with 8.4.

running due to low viscosity or a low thixotropy level. 9.1.4 Cure the assemblies for the time and at the tempera-

8.4 Assemble test specimens as follows: ture specified by the adhesive manufacturer.

8.4.1 Using a torque wrench and the pipe tee assembly 9.1.5 After the specified cure time period, determine re-

block fixture, install two sealant coated pipe plugs for each moval torques for each assembly using the pipe tee torque test

pipe tee. Install with the application of 240 in.–lbs (27.1 N·m) block fixture, within 30 s of removal from the temperature

of torque. chamber. Record the results.

D 6396

FIG. 2 ⁄8 Pipe Tee Torque Test Block

9.2 Primer Cure:

9.2.1 Use ⁄8in. (10 mm) pipe tees and plugs.

9.2.2 Apply the primer specified by the adhesive manufac-

turer to the plugs and allow them to dry vertically until all the

solvent has evaporated.

9.2.3 Apply the sealant in accordance with 8.3. Within 30 s

of sealant application assemble the specimens in accordance

with 8.4.

9.2.4 Cure the assemblies for the times specified by the

adhesive manufacturer.

9.2.5 At the end of each specified cure time, test each

assembly for sealability in accordance with 9.9.

9.2.6 Determine removal torques for each assembly using

the pipe tee torque test block fixture. Record the results.

9.3 Heat Aging:

9.3.1 Use ⁄8in. (10 mm) pipe tees and plugs.

9.3.2 Apply the sealant in accordance with 8.3, and as-

FIG. 3 Pipe Tee Sealability Test Clamp

semble the specimens in accordance with 8.4.

9.3.3 Cure the assemblies for 72 h at room temperature.

D 6396

9.3.4 Test each assembly for sealability in accordance with 9.6.1 Use ⁄2in. (13 mm) pipe tees and plugs. Ensure that the

9.9. All assemblies used for heat aging must be leak-free. pipe tees are Class 300 (see Note 5).

9.3.5 Place assemblies in a temperature chamber for the 9.6.2 Apply the sealant in accordance with 8.3, and as-

time and temperature specified by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.