ASTM C1681-23

(Test Method)Standard Test Method for Evaluating the Tear Resistance of a Sealant Under Constant Strain

Standard Test Method for Evaluating the Tear Resistance of a Sealant Under Constant Strain

SIGNIFICANCE AND USE

5.1 This test method is intended to determine if a joint that is subjected to a mechanically induced cut will resist tear propagation during normal joint movement.

Note 1: A sealant with a high resistance to tear propagation may perform better than a sealant with a low resistance to tear propagation.

SCOPE

1.1 This test method evaluates the impact of an induced tear on a sealant specimen that is dimensioned, cured according to the guidelines in Test Method C719 and then subjected to a constant strain. It is effective in differentiating between sealants that are used in dynamic joints subject to abrasion, punctures, tears, or combination thereof.

1.2 Since this test method is for the evaluation of tear propagation, an adhesive failure to the substrates provides no usable data regarding tear propagation. This would be considered a failed test and that data would be discarded, or at least separated from the other data from specimens that did not experience an adhesive failure.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This standard is similar in concept to European Technical Approval Guidelines (ETAG) 002, Part 1, Section 5.1.4.6.4—Resistance To Tearing.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1681 − 23

Standard Test Method for

Evaluating the Tear Resistance of a Sealant Under Constant

1

Strain

This standard is issued under the fixed designation C1681; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C719 Test Method for Adhesion and Cohesion of Elasto-

meric Joint Sealants Under Cyclic Movement (Hockman

1.1 This test method evaluates the impact of an induced tear

Cycle)

on a sealant specimen that is dimensioned, cured according to

the guidelines in Test Method C719 and then subjected to a

3. Terminology

constant strain. It is effective in differentiating between seal-

3.1 Definitions—Refer to Terminology C717 for definitions

ants that are used in dynamic joints subject to abrasion,

of terms used in this standard, including but not limited to the

punctures, tears, or combination thereof.

following: adhesive failure, casting spacers, cohesive failure,

1.2 Since this test method is for the evaluation of tear

separators, standard conditions.

propagation, an adhesive failure to the substrates provides no

usable data regarding tear propagation. This would be consid-

4. Summary of Test Method

ered a failed test and that data would be discarded, or at least

4.1 Test specimens are fabricated and cured in accordance

separated from the other data from specimens that did not

with Test Method C719. At the end of the 21-day cure period,

experience an adhesive failure.

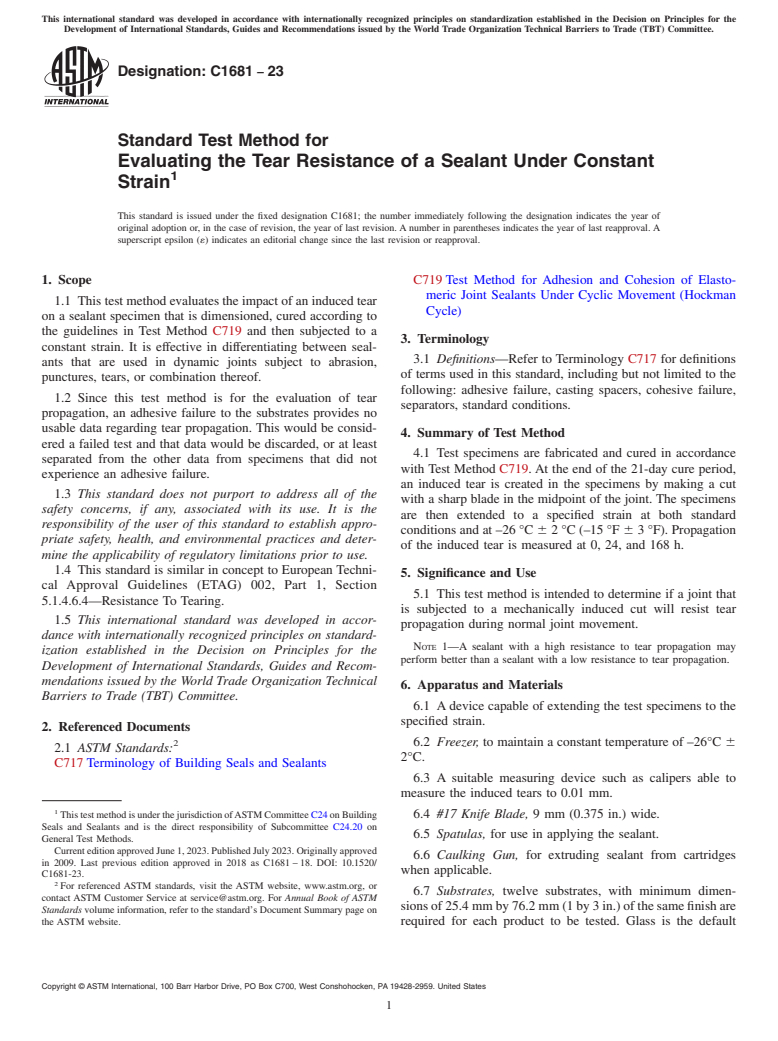

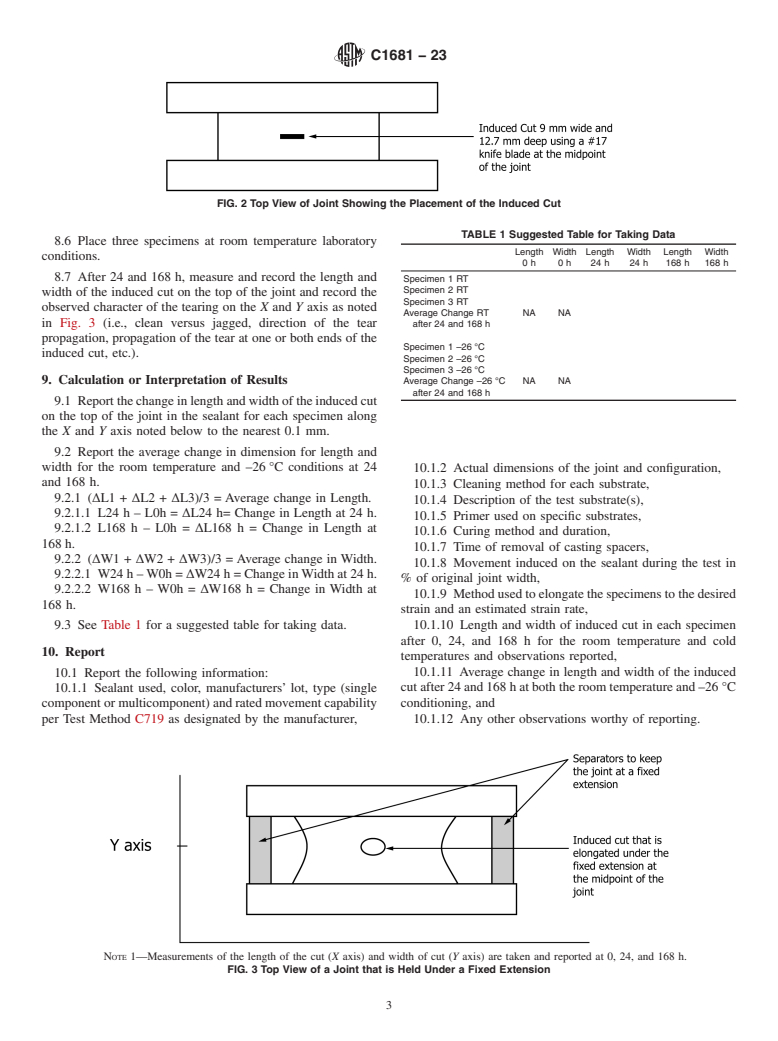

an induced tear is created in the specimens by making a cut

1.3 This standard does not purport to address all of the

with a sharp blade in the midpoint of the joint. The specimens

safety concerns, if any, associated with its use. It is the

are then extended to a specified strain at both standard

responsibility of the user of this standard to establish appro-

conditions and at –26 °C 6 2 °C (–15 °F 6 3 °F). Propagation

priate safety, health, and environmental practices and deter-

of the induced tear is measured at 0, 24, and 168 h.

mine the applicability of regulatory limitations prior to use.

1.4 This standard is similar in concept to European Techni-

5. Significance and Use

cal Approval Guidelines (ETAG) 002, Part 1, Section

5.1 This test method is intended to determine if a joint that

5.1.4.6.4—Resistance To Tearing.

is subjected to a mechanically induced cut will resist tear

1.5 This international standard was developed in accor-

propagation during normal joint movement.

dance with internationally recognized principles on standard-

NOTE 1—A sealant with a high resistance to tear propagation may

ization established in the Decision on Principles for the

perform better than a sealant with a low resistance to tear propagation.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

6. Apparatus and Materials

Barriers to Trade (TBT) Committee.

6.1 A device capable of extending the test specimens to the

specified strain.

2. Referenced Documents

6.2 Freezer, to maintain a constant temperature of –26°C 6

2

2.1 ASTM Standards:

2°C.

C717 Terminology of Building Seals and Sealants

6.3 A suitable measuring device such as calipers able to

measure the induced tears to 0.01 mm.

1

This test method is under the jurisdiction of ASTM Committee C24 on Building 6.4 #17 Knife Blade, 9 mm (0.375 in.) wide.

Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on

6.5 Spatulas, for use in applying the sealant.

General Test Methods.

Current edition approved June 1, 2023. Published July 2023. Originally approved

6.6 Caulking Gun, for extruding sealant from cartridges

in 2009. Last previous edition approved in 2018 as C1681 – 18. DOI: 10.1520/

when applicable.

C1681-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.7 Substrates, twelve substrates, with minimum dimen-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sions of 25.4 mm by 76.2 mm (1 by 3 in.) of the same finish are

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. required for each product to be tested. Glass is the default

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1681 − 23

substrate, however as mentioned in the scope, this is not an compound. In the case of a pourable-type compound, use

adhesion test, therefore

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1681 − 18 C1681 − 23

Standard Test Method for

Evaluating the Tear Resistance of a Sealant Under Constant

1

Strain

This standard is issued under the fixed designation C1681; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method evaluates the impact of an induced tear on a sealant specimen that is dimensioned, cured according to the

guidelines in Test Method C719 and then subjected to a constant strain. It is effective in differentiating between sealants that are

used in dynamic joints subject to abrasion, punctures, tears, or combination thereof.

1.2 Since this test method is for the evaluation of tear propagation, an adhesive failure to the substrates provides no usable data

regarding tear propagation. This would be considered a failed test and that data would be discarded, or at least separated from the

other data from specimens that did not experience an adhesive failure.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

This standard is similar in concept to European Technical Approval Guidelines (ETAG) 002, Part 1, Section 5.1.4.6.4—Resistance

To Tearing.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

C719 Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants Under Cyclic Movement (Hockman Cycle)

3. Terminology

3.1 Definitions—Refer to Terminology C717 for definitions of terms used in this standard, including but not limited to the

following: adhesive failure, casting spacers, cohesive failure, separators, standard conditions.

1

This test method is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on General

Test Methods.

Current edition approved Jan. 1, 2018June 1, 2023. Published January 2018July 2023. Originally approved in 2009. Last previous edition approved in 20142018 as

C1681C1681 – 18.-14. DOI: 10.1520/C1681-18.10.1520/C1681-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1681 − 23

4. Summary of Test Method

4.1 Test specimens are fabricated and cured in accordance with Test Method C719. At the end of the 21-day cure period, an

induced tear is created in the specimens by making a cut with a sharp blade in the midpoint of the joint. The specimens are then

extended to a specified strain at both standard conditions and at –26 6 2°C (–15 6 3°F).–26 °C 6 2 °C (–15 °F 6 3 °F).

Propagation of the induced tear is measured at 0, 24, and 168 h.

5. Significance and Use

5.1 This test method is intended to determine if a joint that is subjected to a mechanically induced cut will resist tear propagation

during normal joint movement. A sealant with a high resistance to tear propagation will typically perform better than a sealant with

a low resistance to tear propagation.

NOTE 1—A sealant with a high resistance to tear propagation may perform better than a sealant with a low resistance to tear propagation.

6. Apparatus and Materials

6.1 A device capable of extending the test specimens to the specified strain.

6.2 Freezer, to maintain a constant temperature of –26°C 6 2°C.

6.3 A suitable measuring device such as calipers able to measure the induced tears to 0.01 mm.

6.4 #17 Knife Blade, 9 mm (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.