ASTM C1667-15(2023)

(Test Method)Standard Test Method for Using Heat Flow Meter Apparatus to Measure the Center-of-Panel Thermal Transmission Properties of Vacuum Insulation Panels

Standard Test Method for Using Heat Flow Meter Apparatus to Measure the Center-of-Panel Thermal Transmission Properties of Vacuum Insulation Panels

SIGNIFICANCE AND USE

5.1 Heat flow meter apparatus are being used to measure the center-of-panel portion of a vacuum insulation panel, which typically has a very high value of thermal resistivity (that is, equal to or greater than 90 m-K/W). As described in Specification C1484, the center-of-panel thermal resistivity is used, along with the panel geometry and barrier material thermal conductivity, to determine the effective thermal resistance of the evacuated panel.

5.2 Using a heat flow meter apparatus to measure the thermal resistivity of non-homogenous and high thermal resistance specimens is a non-standard application of the equipment, and shall only be performed by qualified personnel with understanding of heat transfer and error propagation. Familiarity with the configuration of both the apparatus and the vacuum insulation panel is necessary.

5.3 The center-of-panel thermal transmission properties of evacuated panels vary due to the composition of the materials of construction, mean temperature and temperature difference, and the prior history. The selection of representative values for the thermal transmission properties of an evacuated panel for a particular application must be based on a consideration of these factors and will not apply necessarily without modification to all service conditions.

SCOPE

1.1 This test method covers the measurement of steady-state thermal transmission through the center of a flat rectangular vacuum insulation panel using a heat flow meter apparatus.

1.2 Total heat transfer through the non-homogenous geometry of a vacuum insulation panel requires the determination of several factors, as discussed in Specification C1484. One of those factors is the center-of-panel thermal resistivity. The center-of-panel thermal resistivity is an approximation of the thermal resistivity of the core evacuated region.

1.3 This test method is based upon the technology of Test Method C518 but includes modifications for vacuum insulation panel applications as outlined in this test method.2

1.4 This test method shall be used in conjunction with Practice C1045 and Practice C1058.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1667 − 15 (Reapproved 2023)

Standard Test Method for

Using Heat Flow Meter Apparatus to Measure the Center-of-

Panel Thermal Transmission Properties of Vacuum

Insulation Panels

This standard is issued under the fixed designation C1667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the measurement of steady-state

C168 Terminology Relating to Thermal Insulation

thermal transmission through the center of a flat rectangular

C518 Test Method for Steady-State Thermal Transmission

vacuum insulation panel using a heat flow meter apparatus.

Properties by Means of the Heat Flow Meter Apparatus

1.2 Total heat transfer through the non-homogenous geom-

C740 Guide for Evacuated Reflective Insulation In Cryo-

etry of a vacuum insulation panel requires the determination of

genic Service

several factors, as discussed in Specification C1484. One of

C1045 Practice for Calculating Thermal Transmission Prop-

those factors is the center-of-panel thermal resistivity. The

erties Under Steady-State Conditions

center-of-panel thermal resistivity is an approximation of the

C1058 Practice for Selecting Temperatures for Evaluating

thermal resistivity of the core evacuated region.

and Reporting Thermal Properties of Thermal Insulation

C1484 Specification for Vacuum Insulation Panels

1.3 This test method is based upon the technology of Test

E691 Practice for Conducting an Interlaboratory Study to

Method C518 but includes modifications for vacuum insulation

Determine the Precision of a Test Method

panel applications as outlined in this test method.

E177 Practice for Use of the Terms Precision and Bias in

1.4 This test method shall be used in conjunction with ASTM Test Methods

Practice C1045 and Practice C1058.

3. Terminology

1.5 The values stated in SI units are to be regarded as

3.1 Definitions—Terminology C168 applies to terms used in

standard. No other units of measurement are included in this

this specification.

standard.

3.2 Definitions of Terms Specific to This Standard:

1.6 This standard does not purport to address all of the

3.2.1 center-of-panel—the location at the center of the

safety concerns, if any, associated with its use. It is the

largest planar surface of the panel, equidistant from each pair

responsibility of the user of this standard to establish appro-

of opposite edges of that surface.

priate safety, health, and environmental practices and deter-

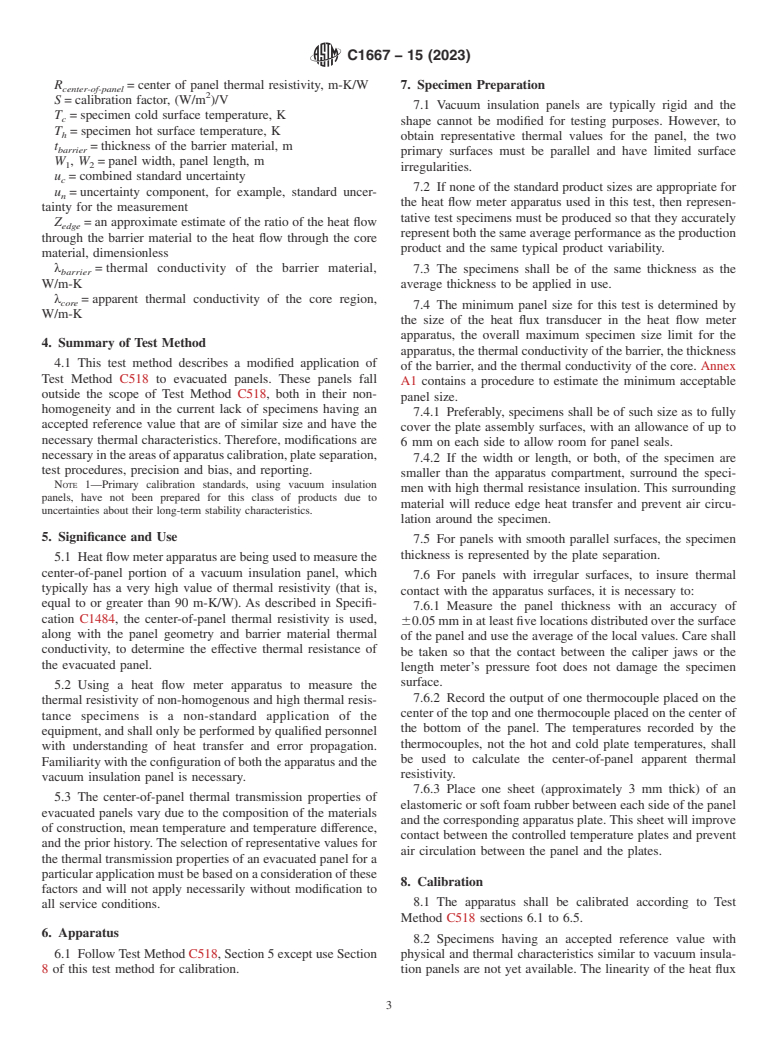

3.2.2 center-of-panel apparent thermal resistivity—the ther-

mine the applicability of regulatory limitations prior to use.

mal performance of vacuum insulation panels includes an edge

1.7 This international standard was developed in accor-

effect due to heat flow through the barrier material and this

dance with internationally recognized principles on standard-

shunting of heat around the evacuated volume of the panel

ization established in the Decision on Principles for the

becomes more prevalent with greater barrier thermal

Development of International Standards, Guides and Recom-

conductivity, as shown in Fig. 1. For panels larger than a

mendations issued by the World Trade Organization Technical

minimum size (as described in Annex A1), the center-of-panel

Barriers to Trade (TBT) Committee.

apparent thermal resistivity is a close approximation of the

intrinsic core thermal resistivity of the vacuum insulation

panel. The effective thermal performance of a panel will vary

This test method is under the jurisdiction of ASTM Committee C16 on Thermal

with the size and shape of the panel.

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurement.

Current edition approved Nov. 1, 2023. Published December 2023. Originally

approved in 2007. Last previous edition approved in 2015 as C1667 – 15. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/C1667-15R23. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

All references to particular sections of Test Method C518 within this document Standards volume information, refer to the standard’s Document Summary page on

refer to the 2010 edition of Test Method C518. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1667 − 15 (2023)

FIG. 1 Side View of a Vacuum Insulation Panel Showing Edge Heat Flow and the Center-of-Panel Region

3.2.2.1 Discussion—Thermal resistivity, the reciprocal of apparent thermal conductivity has been significantly reduced

apparent thermal conductivity, is used when discussing the by reduction of the internal gas pressure. The level of vacuum

center-of-panel thermal behavior. will depend on properties of the composite panel materials, and

the desired effective panel thermal resistance.

3.2.3 core—the material placed within the evacuated vol-

ume of a vacuum insulation panel. This material may perform 3.2.6 panel barrier—the material that envelops the evacu-

any or all of the following functions: prevent panel collapse ated volume and is used to separate the evacuated volume from

due to atmospheric pressure, reduce radiation heat transfer, and the environment and to provide a long term barrier to gas and

reduce gas-phase conduction. The apparent thermal conductiv- vapor diffusion.

ity of the core, or λ , is defined as the apparent thermal

core

3.2.7 seal—any joint between two pieces of barrier material.

conductivity of the core material under the same vacuum that

3.3 Symbols and Units:

would occur within a panel, but without the barrier material.

A = area of the barrier perpendicular to the largest

barrier

This is the apparent thermal conductivity that would be

panel faces, m

measured in a vacuum chamber without the barrier material.

A = area of the largest panel face covering the core

core

3.2.4 effective panel thermal resistance (effective panel 2

material, m

R-value)—this value reflects the total panel resistance to heat 2

C = calibration standard conductance, W/m -K

flow, considering heat flow through the evacuated region and

E = heat flux transducer output, V

through the barrier material. Depending on the thermal con-

L = panel thickness, m

panel

ductivity of the barrier material and the size of the panel, the

L = thickness of a single layer of the calibra-

calibration standard

effective thermal resistance may be significantly less than the

tion standard material, m

product of the center-of-panel apparent thermal resistivity and

L = target total thickness of the calibra-

calibration standard, target

the panel thickness. The effective thermal resistance is based

tion standard material, m

on the edge-to-edge area covered by the vacuum insulation 2

q = heat flux through the panel, W/m

panel, that is, the entire panel. The effective thermal resistance

Q = heat flow through the barrier material, W

barrier

will also vary with the panel mean temperature.

Q = estimated heat flow at the transducer (as

center-of-panel

3.2.4.1 Discussion—Thermal resistance, the reciprocal of

calculated by the model), W

thermal conductance, is used when discussing the effective

Q = heat flow through the core region, W

core

thermal performance of the panel. This value includes the

R = thermal resistivity of the calibration

calibration standard

effect of the actual panel dimensions, including the panel

standard, m-K/W

thickness.

3.2.5 evacuated or vacuum insulations—insulation systems

For further discussion on heat flow mechanisms in evacuated insulations, see

whose gas phase thermal conductivity portion of the overall Practice C740 on Evacuated Reflective Insulation in Cryogenic Service.

C1667 − 15 (2023)

R = center of panel thermal resistivity, m-K/W 7. Specimen Preparation

center-of-panel

S = calibration factor, (W/m )/V

7.1 Vacuum insulation panels are typically rigid and the

T = specimen cold surface temperature, K

c

shape cannot be modified for testing purposes. However, to

T = specimen hot surface temperature, K

h

obtain representative thermal values for the panel, the two

t = thickness of the barrier material, m

barrier

primary surfaces must be parallel and have limited surface

W , W = panel width, panel length, m

1 2

irregularities.

u = combined standard uncertainty

c

7.2 If none of the standard product sizes are appropriate for

u = uncertainty component, for example, standard uncer-

n

the heat flow meter apparatus used in this test, then represen-

tainty for the measurement

tative test specimens must be produced so that they accurately

Z = an approximate estimate of the ratio of the heat flow

edge

represent both the same average performance as the production

through the barrier material to the heat flow through the core

product and the same typical product variability.

material, dimensionless

λ = thermal conductivity of the barrier material,

7.3 The specimens shall be of the same thickness as the

barrier

W/m-K average thickness to be applied in use.

λ = apparent thermal conductivity of the core region,

core

7.4 The minimum panel size for this test is determined by

W/m-K

the size of the heat flux transducer in the heat flow meter

apparatus, the overall maximum specimen size limit for the

4. Summary of Test Method

apparatus, the thermal conductivity of the barrier, the thickness

4.1 This test method describes a modified application of

of the barrier, and the thermal conductivity of the core. Annex

Test Method C518 to evacuated panels. These panels fall

A1 contains a procedure to estimate the minimum acceptable

outside the scope of Test Method C518, both in their non-

panel size.

homogeneity and in the current lack of specimens having an

7.4.1 Preferably, specimens shall be of such size as to fully

accepted reference value that are of similar size and have the

cover the plate assembly surfaces, with an allowance of up to

necessary thermal characteristics. Therefore, modifications are

6 mm on each side to allow room for panel seals.

necessary in the areas of apparatus calibration, plate separation,

7.4.2 If the width or length, or both, of the specimen are

test procedures, precision and bias, and reporting.

smaller than the apparatus compartment, surround the speci-

NOTE 1—Primary calibration standards, using vacuum insulation

men with high thermal resistance insulation. This surrounding

panels, have not been prepared for this class of products due to

material will reduce edge heat transfer and prevent air circu-

uncertainties about their long-term stability characteristics.

lation around the specimen.

5. Significance and Use

7.5 For panels with smooth parallel surfaces, the specimen

thickness is represented by the plate separation.

5.1 Heat flow meter apparatus are being used to measure the

center-of-panel portion of a vacuum insulation panel, which

7.6 For panels with irregular surfaces, to insure thermal

typically has a very high value of thermal resistivity (that is,

contact with the apparatus surfaces, it is necessary to:

equal to or greater than 90 m-K/W). As described in Specifi-

7.6.1 Measure the panel thickness with an accuracy of

cation C1484, the center-of-panel thermal resistivity is used,

60.05 mm in at least five locations distributed over the surface

along with the panel geometry and barrier material thermal

of the panel and use the average of the local values. Care shall

conductivity, to determine the effective thermal resistance of

be taken so that the contact between the caliper jaws or the

the evacuated panel.

length meter’s pressure foot does not damage the specimen

surface.

5.2 Using a heat flow meter apparatus to measure the

7.6.2 Record the output of one thermocouple placed on the

thermal resistivity of non-homogenous and high thermal resis-

center of the top and one thermocouple placed on the center of

tance specimens is a non-standard application of the

the bottom of the panel. The temperatures recorded by the

equipment, and shall only be performed by qualified personnel

thermocouples, not the hot and cold plate temperatures, shall

with understanding of heat transfer and error propagation.

be used to calculate the center-of-panel apparent thermal

Familiarity with the configuration of both the apparatus and the

resistivity.

vacuum insulation panel is necessary.

7.6.3 Place one sheet (approximately 3 mm thick) of an

5.3 The center-of-panel thermal transmission properties of

elastomeric or soft foam rubber between each side of the panel

evacuated panels vary due to the composition of the materials

and the corresponding apparatus plate. This sheet will improve

of construction, mean temperature and temperature difference,

contact between the controlled temperature plates and prevent

and the prior history. The selection of representative values for

air circulation between the panel and the plates.

the thermal transmission properties of an evacuated panel for a

particular application must be based on a consideration of these

8. Calibration

factors and will not apply necessarily without modification to

8.1 The apparatus shall be calibrated according to Test

all service conditions.

Method C518 sections 6.1 to 6.5.

6. Apparatus

8.2 Specimens having an accepted reference value with

6.1 Follow Test Method C518, Section 5 except use Section physical and thermal characteristics similar to vacuum insula-

8 of this test method for calibration. tion panels are not yet available. The linearity of the heat flux

C1667 − 15 (2023)

transducers at very low levels of heat flux must be verified T 2 T

~ !

h c

S 5 (3)

using another method. The apparatus calibration must include 1

E ×

(

the addition of at least one of the modified calibration C

Layers

procedures described in 8.5 and 8.6, that is Modified Calibra-

8.5.4 For each heat flux transducer, evaluate the variation in

tion Procedure A or B. As described in 8.7, the two modified

S as a function of heat flux. Determine whether the variation is

procedures can be combined if necessary to meet uncertainty

acceptable and include this value as an element of the

goals. Although each method magnifies an element of experi-

measurement uncertainty in the reported error analysis.

mental error (as discussed below), it is necessary to augment

the standard Test Method C518 calibration for this particular

NOTE 6—Any change in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.