ASTM F1565-00(2019)

(Specification)Standard Specification for Pressure-Reducing Valves for Steam Service

Standard Specification for Pressure-Reducing Valves for Steam Service

ABSTRACT

This specification covers self-contained, internally operated, globe style, pressure-reducing valves for use in steam service. In these valves, the downstream pressure feedback is sensed by a spring-loaded diaphragm to position a pilot valve—the pilot valve uses the inlet steam pressure to position the main valve plug via an operating piston. The valves shall be of the following compositions: Composition B made with 1.25% chromium, 0.5% molybdenum and Composition B made with carbon steel. All materials shall be selected to prevent corrosion, galling, seizing, and excessive wear or erosion where applicable. Clearances shall prevent interference as a result of the thermal expansion. Cadmium plating is prohibited. Components of these valves shall include body, bonnet, bottom cover, internal trim, cylinder liner, piston, gaskets, diaphragm, springs, and bolts. Valves will be operated, maintained, and repaired on board ships and shall emphasize simplicity, maintainability, ruggedness, and reliability. Design shall permit access for adjustment and repair when working from either side of the valve and without requiring removal of the valve body from the line. Each production valve shall be subjected to the following tests: nondestructive test, hydrostatic test, seat tightness test, and external leakage test.

SCOPE

1.1 This specification covers self-contained, internally operated, globe style, pressure-reducing valves for use in steam service. In these valves, the downstream pressure feedback is sensed by a spring-loaded diaphragm to position a pilot valve—the pilot valve uses the inlet steam pressure to position the main valve plug by means of an operating piston.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1565 −00 (Reapproved 2019) An American National Standard

Standard Specification for

Pressure-Reducing Valves for Steam Service

This standard is issued under the fixed designation F1565; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A217/A217M Specification for Steel Castings, Martensitic

Stainless and Alloy, for Pressure-Containing Parts, Suit-

1.1 This specification covers self-contained, internally

able for High-Temperature Service

operated,globestyle,pressure-reducingvalvesforuseinsteam

A515/A515M Specification for Pressure Vessel Plates, Car-

service. In these valves, the downstream pressure feedback is

bon Steel, for Intermediate- and Higher-Temperature Ser-

sensed by a spring-loaded diaphragm to position a pilot

vice

valve—the pilot valve uses the inlet steam pressure to position

A516/A516M Specification for Pressure Vessel Plates, Car-

the main valve plug by means of an operating piston.

bon Steel, for Moderate- and Lower-Temperature Service

1.2 The values stated in inch-pound units are to be regarded

A547 Specification for Steel Wire, Alloy, Cold-Heading

as standard. No other units of measurement are included in this

Quality, for Hexagon-Head Bolts (Withdrawn 1989)

standard. 4

2.2 ASME Standards:

1.3 This international standard was developed in accor-

B1.1 Unified Screw Threads

dance with internationally recognized principles on standard-

B16.5 Pipe Flanges and Flanged Fittings

ization established in the Decision on Principles for the

B16.34 Valves—Flanged, Threaded, and Welding End

Development of International Standards, Guides and Recom-

B18.2.1 Square, Hex, Heavy Hex, and Askew Head Bolts

mendations issued by the World Trade Organization Technical

and Hex, Heavy Hex, Hex Flange, Lobed Head, and Lag

Barriers to Trade (TBT) Committee.

Screws

2.3 Federal Specification:

2. Referenced Documents

FED-STD-H 28 Screw-Thread Standards for Federal Ser-

2.1 ASTM Standards:

vices

A105/A105M Specification for Carbon Steel Forgings for

2.4 Military Standards and Specifications:

Piping Applications

MIL-V-3 Valves, Fittings, and Flanges (Except for Systems

A182/A182M Specification for Forged or Rolled Alloy and

Indicated Herein); Packaging of

Stainless Steel Pipe Flanges, Forged Fittings, and Valves

MIL-S-901 Shock Tests, H.I. (High Impact); Shipboard

and Parts for High-Temperature Service

Machinery, Equipment and Systems, Requirements for

A193/A193M Specification for Alloy-Steel and Stainless

MIL-R-2765 Rubber Sheet Strip, Extruded, and Molded

Steel Bolting for High Temperature or High Pressure

Shapes, Synthetic, Oil Resistant

Service and Other Special Purpose Applications

MIL-P-15024 Plates, Tags and Bands for Identification of

A194/A194M Specification for Carbon Steel, Alloy Steel,

Equipment

and Stainless Steel Nuts for Bolts for High Pressure or

MIL-P-15024/5 Plates, Identification

High Temperature Service, or Both

MIL-R-17131 Rods and Powders, Welding, Surfacing

A216/A216M SpecificationforSteelCastings,Carbon,Suit-

MIL-G-24716 Gaskets, Metallic-Flexible Graphite, Spiral

able for Fusion Welding, for High-Temperature Service

Wound

MIL-I-45208 Inspection Systems Requirements

MIL-STD-167-1 Mechanical Vibrations of Shipboard

Equipment (Type I—Environmental and Type II—

1 Internally Excited)

This specification is under the jurisdiction of ASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved May 1, 2019. Published June 2019. Originally The last approved version of this historical standard is referenced on

approved in 1994. Last previous edition approved in 2013 as F1565 – 00 (2013). www.astm.org.

DOI: 10.1520/F1565-00R19. Available from American Society of Mechanical Engineers (ASME), ASME

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.asme.org.

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1565 − 00 (2019)

NAVSEA T9074–AQ-GIB-010/271 Nondestructive Testing

Requirements for Metals

NAVSEAS9074–AR-GIB-010/278 FabricationWeldingand

Inspections and Casting Inspection and Repair for

Machinery, Piping and Pressure Vessels in Ships of the

United States Navy

MIL-STD-798 Nondestructive Testing, Welding, Quality

Control, Material Control and Identification and Hi-Shock

Test Requirements for Piping System Components for

Naval Shipboard Use

MS 16142 Boss, Gasket Seal Straight Thread Tube Fitting,

Standard Dimensions for

3. Terminology

3.1 Definitions:

3.1.1 accuracy of regulation, n—the amount by which the

downstream pressure may vary when the valve is set at any

pressure within the required set pressure limit and is subjected

to any combination of inlet pressure, flow demand, and

ambient temperature variations, within the specified limits.

3.1.2 design pressure and temperature, n—the maximum

pressure and temperature the valve should be subjected to

under any condition. These are the pressure and temperature

upon which the strength of the pressure-containing envelope is

based.

3.1.3 hydrostatic test pressure, n—the maximum test pres-

sure that the valve is required to withstand without damage.

Valve operation is not required during application of this test

pressure, but after the pressure has been removed, the valve

must meet all performance requirements.

3.1.4 lockup pressure, n—the outlet pressure delivered by a

pressure-reducing valve under shutoff conditions (that is, when

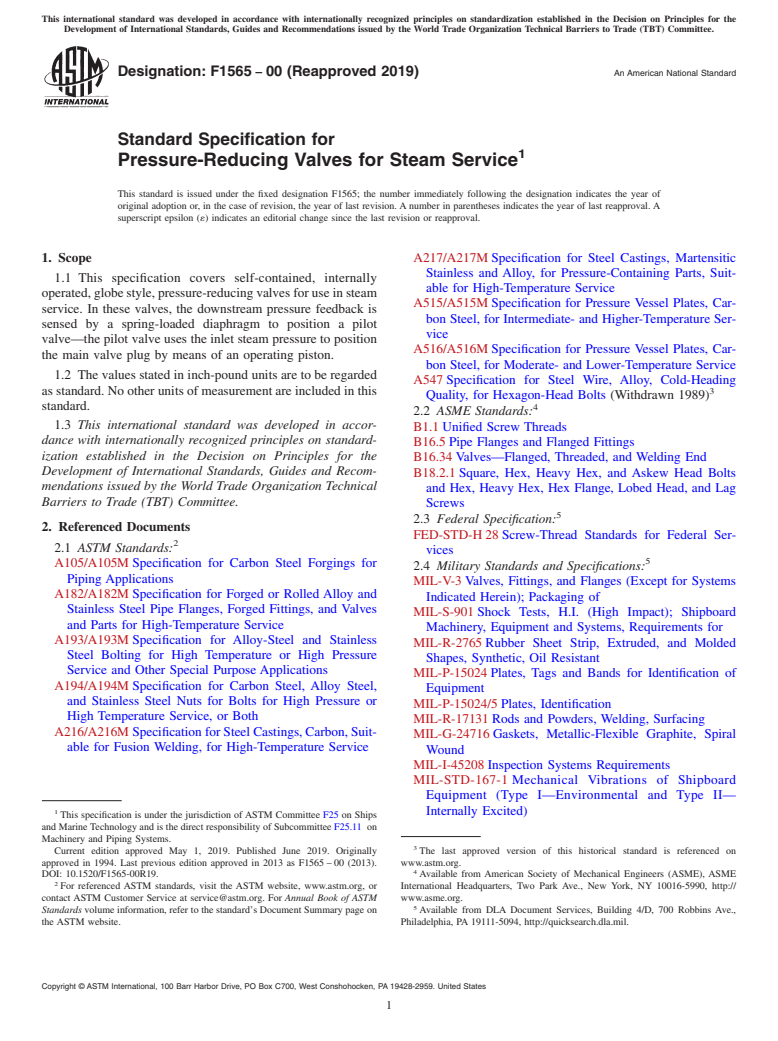

NOTE 1—Pictorial representations are for illustrative purpose only and

the flow demand is reduced to a point where it is equal to or

do not imply design.

less than the allowable leakage as defined in 8.3).

FIG. 1 Pressure-Reducing Valve (External Pressure Sensing)

3.1.5 nominal pressure, n—the approximate maximum pres-

sure to which the valve will be subjected in service under

4.3 Pressure Ratings—These shall conform toASME Class

normal conditions.

150, Class 300, Class 600, or Class 1500.

3.1.6 set pressure, n—the downstream pressure which the

valve is set to maintain under a given set of operating

5. Ordering Information

conditions (that is, inlet pressure and flow). Ideally, the valve

5.1 Ordering documentation for valves under this specifica-

should be set at downstream pressure approximately equal to

tion shall include the following information, as required, to

the mid-point of the set pressure limits (defined in 3.1.7).

describe the equipment adequately.

3.1.7 set pressure limits (range of set pressure adjustment),

5.1.1 ASTM designation and year of issue.

n—the range of set pressure over which the valve can be

5.1.2 Valve specification code (see 6.1.14).

adjusted while meeting the specified performance require-

5.1.3 Composition and pressure rating required (see Section

ments.

4).

5.1.4 Trim materials where specific requirement is known

4. Classification

(see Table 1, Footnote B, Note 2).

4.1 Valves shall be of the following compositions and

5.1.5 Whether internal or external reduced pressure sensing

pressure ratings, as specified (see Section 5 and 6.1.7). The

line is required (see 6.1.2.1).

pressure-temperatureratingsshownbelowareapplicabletothe

5.1.6 Accuracy of regulation required if other than listed in

pressure-containing components of the valve. See Fig. 1 and

7.2.

Fig. 2.

5.1.7 Minimum and maximum inlet steam pressures (psig)

1 1

4.1.1 Composition B—1 ⁄4 % chromium, ⁄2 % molybdenum

(see 7.3 and S1.5).

[maximum temperature 1000°F (see 6.1.7)].

5.1.8 Maximum inlet steam temperature (°F) (see S1.5).

4.2 Composition D—carbon steel [maximum temperature 5.1.9 Range of set pressure adjustment for valves, if other

775°F (see 6.1.7)]. than listed in 7.4.

F1565 − 00 (2019)

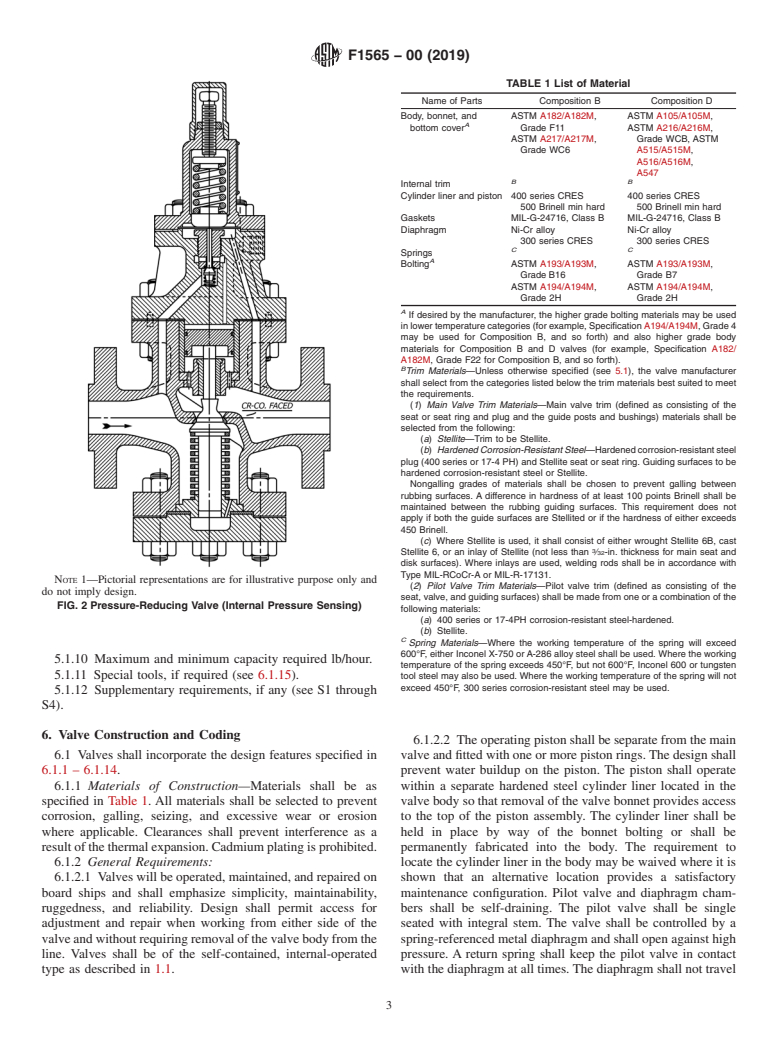

TABLE 1 List of Material

Name of Parts Composition B Composition D

Body, bonnet, and ASTM A182/A182M, ASTM A105/A105M,

A

bottom cover Grade F11 ASTM A216/A216M,

ASTM A217/A217M, Grade WCB, ASTM

Grade WC6 A515/A515M,

A516/A516M,

A547

BB

Internal trim

Cylinder liner and piston 400 series CRES 400 series CRES

500 Brinell min hard 500 Brinell min hard

Gaskets MIL-G-24716, Class B MIL-G-24716, Class B

Diaphragm Ni-Cr alloy Ni-Cr alloy

300 series CRES 300 series CRES

CC

Springs

A

Bolting ASTM A193/A193M, ASTM A193/A193M,

Grade B16 Grade B7

ASTM A194/A194M, ASTM A194/A194M,

Grade 2H Grade 2H

A

If desired by the manufacturer, the higher grade bolting materials may be used

inlowertemperaturecategories(forexample,SpecificationA194/A194M,Grade4

may be used for Composition B, and so forth) and also higher grade body

materials for Composition B and D valves (for example, Specification A182/

A182M, Grade F22 for Composition B, and so forth).

B

Trim Materials—Unless otherwise specified (see 5.1), the valve manufacturer

shall select from the categories listed below the trim materials best suited to meet

the requirements.

(1) Main Valve Trim Materials—Main valve trim (defined as consisting of the

seat or seat ring and plug and the guide posts and bushings) materials shall be

selected from the following:

(a) Stellite—Trim to be Stellite.

(b) HardenedCorrosion-ResistantSteel—Hardenedcorrosion-resistantsteel

plug (400 series or 17-4 PH) and Stellite seat or seat ring. Guiding surfaces to be

hardened corrosion-resistant steel or Stellite.

Nongalling grades of materials shall be chosen to prevent galling between

rubbing surfaces. A difference in hardness of at least 100 points Brinell shall be

maintained between the rubbing guiding surfaces. This requirement does not

apply if both the guide surfaces are Stellited or if the hardness of either exceeds

450 Brinell.

(c) Where Stellite is used, it shall consist of either wrought Stellite 6B, cast

Stellite 6, or an inlay of Stellite (not less than ⁄32-in. thickness for main seat and

disk surfaces). Where inlays are used, welding rods shall be in accordance with

Type MIL-RCoCr-A or MIL-R-17131.

NOTE 1—Pictorial representations are for illustrative purpose only and

(2) Pilot Valve Trim Materials—Pilot valve trim (defined as consisting of the

do not imply design.

seat,valve,andguidingsurfaces)shallbemadefromoneoracombinationofthe

FIG. 2 Pressure-Reducing Valve (Internal Pressure Sensing)

following materials:

(a) 400 series or 17-4PH corrosion-resistant steel-hardened.

(b) Stellite.

C

Spring Materials—Where the working temperature of the spring will exceed

600°F, either Inconel X-750 orA-286 alloy steel shall be used. Where the working

5.1.10 Maximum and minimum capacity required lb/hour.

temperature of the spring exceeds 450°F, but not 600°F, Inconel 600 or tungsten

5.1.11 Special tools, if required (see 6.1.15).

tool steel may also be used. Where the working temperature of the spring will not

exceed 450°F, 300 series corrosion-resistant steel may be used.

5.1.12 Supplementary requirements, if any (see S1 through

S4).

6. Valve Construction and Coding

6.1.2.2 The operating piston shall be separate from the main

6.1 Valves shall incorporate the design features specified in valve and fitted with one or more piston rings.The design shall

6.1.1 – 6.1.14. prevent water buildup on the piston. The piston shall operate

6.1.1 Materials of Construction—Materials shall be as within a separate hardened steel cylinder liner located in the

specified in Table 1. All materials shall be selected to prevent valve body so that removal of the valve bonnet provides access

corrosion, galling, seizing, and excessive wear or erosion to the top of the piston assembly. The cylinder liner shall be

where applicable. Clearances shall prevent interference as a held in place by way of the bonnet bolting or shall be

resultofthethermalexpansion.Cadmiumplatingisprohibited. permanently fabricated into the body. The requirement to

6.1.2 General Requirements: locate the cylinder liner in the body may be waived where it is

6.1.2.1 Valves will be operated, maintained, and repaired on shown that an alternative location provides a satisfactory

board ships and shall emphasize simplicity, maintainability, maintenance configuration. Pilot valve and diaphragm cham-

ruggedness, and reliability. Design shall permit access for bers shall be self-draining. The pilot valve shall be single

adjustment and repair when working from either side of the seated with integral stem. The valve shall be controlled by a

valveandwithoutrequiringremovalofthevalvebodyfromthe spring-referenced metal diaphragm and shall open against high

line. Valves shall be of the self-contained, internal-operated pressure. A return spring shall keep the pilot valve in contact

type as described in 1.1. with the diaphragm at all times.The diaphragm shall not travel

F1565 − 00 (2019)

throughcenterduringanyphaseofoperation.Edgescontacting (1) Through-bolts or studs threaded the entire length and

the diaphragm shall be rounded to prevent wear and damage. fitted with a nut on each end. Threads on bolts, studs, and nuts

Condensate chamber or other suitable means shall be provided shall be Class 2 fit in accordance with ASME B1.1.

to preclude internal wetted springs from being exposed to (2) Studs with interference fit at the tap end sufficient to

preclude inadvertent backing out and a Class 2 fit at the nut

temperatures exceeding their material limitations. The reduced

pressure sensing line shall be internal or external as specified end.

(see 5.1). Bonnet and bottom cover shall be located by body guiding

(that is, a close tolerance fit between machined diameters on

6.1.3 Maintainability—Internal parts shall permit easy dis-

the body, bonnet, and bottom cover) rather than depending on

assemblyandreassemblywithstandardtoolsandshallprevent,

studs or bolts for location. Spiral wound gaskets shall be fully

as far as practical, the incorrect reassembly of parts. Position-

retained, and the joints shall have metal-to-metal take-up to

ing and alignment of all parts in assembly shall use positive

provide controlled compression of the gaskets. To ass

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.