ASTM D893-97

(Test Method)Standard Test Method for Insolubles In Used Lubricating Oils

Standard Test Method for Insolubles In Used Lubricating Oils

SCOPE

1.1 This test method covers the determination of pentane and toluene insolubles in used lubricating oils.

1.2 Procedure A covers the determination of insolubles without the use of coagulant in the pentane. It provides an indication of the materials that can readily be separated from the oil-solvent mixtures by centrifuging.

1.3 Procedure B covers the determination of insolubles in oils containing detergents and employs a coagulant for both the pentane and toluene insolubles. In addition to the materials separated by using Procedure A, this coagulation procedure separates some finely divided materials that may be suspended in the oil. Note 1-Results obtained by Procedures A and B should not be compared since they usually give different values. The same procedure should be employed when comparing values obtained periodically on an oil in use or when comparing results determined by two or more laboratories.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.> For specific precautionary statements, see 7.3, 7.4, 7.5, 7.6, 9.1, and 9.7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 893 – 97

METRIC

Standard Test Method for

Insolubles In Used Lubricating Oils

This standard is issued under the fixed designation D 893; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

This test method has been adopted for use by government agencies to replace Method D 3121 of Federal Test Method Standard No.

791b.

1. Scope Petroleum Products

D 4175 Terminology Relating to Petroleum, Petroleum

1.1 This test method covers the determination of pentane

Products, and Lubricants

and toluene insolubles in used lubricating oils.

D 4177 Practice for Automatic Sampling of Petroleum and

1.2 Procedure A covers the determination of insolubles

Petroleum Products

without the use of coagulant in the pentane. It provides an

indication of the materials that can readily be separated from

3. Terminology

the oil-solvent mixtures by centrifuging.

3.1 Definitions:

1.3 Procedure B covers the determination of insolubles in

3.1.1 coagulate, v—to cause to become viscous or thick-

oils containing detergents and employs a coagulant for both the

ened into a coherent mass.

pentane and toluene insolubles. In addition to the materials

3.1.2 coagulated pentane insolubles, n—in used oil analy-

separated by using Procedure A, this coagulation procedure

sis, separated matter that results when a coagulant is added to

separates some finely divided materials that may be suspended

a solution of used oil in pentane.

in the oil.

3.1.2.1 Discussion—The addition of a coagulant will aid in

1.4 The values stated in acceptable SI units are to be

separating finely divided materials that may have been held in

regarded as the standard.

suspension because of the dispersant characteristics of the oil.

NOTE 1—Results obtained by Procedures A and B should not be

3.1.3 coagulated toluene insolubles, n—in used oil analysis,

compared since they usually give different values. The same procedure

coagulated and separated matter not soluble in pentane or

should be employed when comparing values obtained periodically on an

toluene.

oil in use or when comparing results determined by two or more

3.1.4 pentane insolubles, n— in used oil analysis, separated

laboratories.

matter resulting when a used oil is mixed with pentane.

1.5 This standard does not purport to address all of the

3.1.4.1 Discussion—In this test method, the separation is

safety concerns, if any, associated with its use. It is the

effected by centrifugation.

responsibility of the user of this standard to establish appro-

3.1.5 toluene insolubles, n— in used oil analysis, the

priate safety and health practices and determine the applica-

portion of pentane insolubles not soluble in toluene.

bility of regulatory limitations prior to use. For specific

3.1.6 used oil, n—any oil that has been in a piece of

precautionary statements, see 7.7, 7.8, 7.9, 9.1, and 9.7.

equipment (for example, an engine, gearbox, transformer, or

turbine), whether operated or not.

2. Referenced Documents

3.1.6.1 Discussion—In this test method, the oil can be any

2.1 ASTM Standards:

oil that has been used for lubrication.

D 1193 Specification for Reagent Water

3.2 Definitions of Terms Specific to This Standard:

D 4057 Practice for Manual Sampling of Petroleum and

3.2.1 insoluble resins, n— in used oil analysis, separated

matter soluble in toluene but not pentane.

3.2.1.1 Discussion—Insoluble resins can be calculated for

This test method is under the jurisdiction of ASTM Committee D-2 on

either Procedue A or B by subtracting the toluene insolubles

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

from the pentane insolubles.

D02.06 on Analysis of Lubricants.

Current edition approved Dec. 10, 1997. Published February 1998. Originally

issued as D 893 – 67. Last previous edition D 893 – 92.

Annual Book of ASTM Standards, Vol 11.01. 3

Annual Book of ASTM Standards, Vol 05.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D893–97

4. Summary of Test Method

4.1 Procedure A— A representative sample of used lubri-

cating oil is mixed with pentane and centrifuged. The oil

solution is decanted and the precipitate washed twice with

pentane, dried, and weighed to give the pentane insolubles. For

toluene insolubles a separate sample of the oil is mixed with

pentane and then centrifuged. The precipitate is washed twice

with pentane, once with toluene-alcohol solution, and once

with toluene. The insoluble material is then dried and weighed

to give the insolubles.

4.2 Procedure B— A representative sample of used lubri-

cating oil is mixed with pentane-coagulant solution and cen-

trifuged. The precipitate is washed twice with pentane, dried,

and weighed to give coagulated pentane insolubles. For coagu-

lated toluene insolubles a separate sample of the oil is mixed

with pentane-coagulant solution and centrifuged. The precipi-

tate is washed twice with pentane, once with toluene-alcohol

solution, and once with toluene. The insoluble material is then

dried and weighed to give coagulated toluene insolubles.

5. Significance and Use

5.1 Pentane insolubles can include oil-insoluble materials

and some oil-insoluble resinous matter originating from oil or

additive degradation, or both.

5.2 Toluene insoluble materials can come from (1) external

contamination, (2) fuel carbon and highly carbonized materials

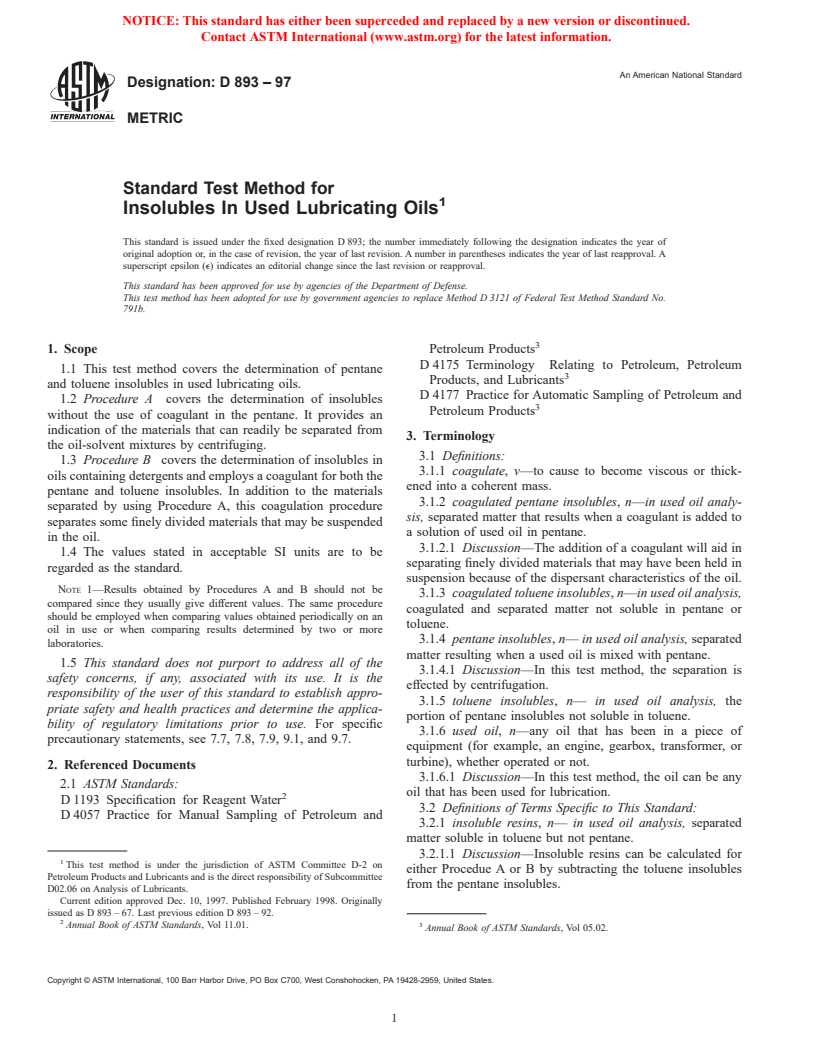

FIG. 1 ASTM Cone-Shaped Centrifuge Tube

from degradation of fuel, oil, and additives, or (3) engine wear

and corrosion materials.

TABLE 1 Calibration Tolerances of Cone-Shaped Centrifuge Tube

5.3 A significant change in pentane insolubles, toluene

Smallest Scale Maximum Scale

insolubles (with or without coagulant) and insoluble resins

Range, mL

Division, mL Error, mL

indicates a change in oil which could lead to lubrication system

0 to 0.1 0.05 60.02

problems.

Over 0.1 to 0.3 0.05 60.03

5.4 Insolubles measured can also assist in evaluating the

Over 0.3 to 0.5 0.05 60.05

Over 0.5 to 1.0 0.1 60.05

performance characteristics of a used oil or in determining the

Over 1.0 to 2.0 0.1 60.10

cause of equipment failure.

Over 2.0 to 3.0 0.2 60.10

Over 3.0 to 5.0 0.5 60.20

Over 5.0 to 10.0 1.0 60.50

6. Apparatus

Over 10 to 25 5.0 61.0

Over 25 to 100 25.0 61.0

6.1 Centrifuge Tube, cone-shaped, conforming to the di-

mensions given in Fig. 1, and made of thoroughly annealed

glass. The graduations, numbered as shown in Fig. 1, shall be

clear and distinct and the mouth constricted in shape for

Speed, rpm 5 1337 =rcf/d (1)

closure with a cork. Scale error tolerances and smallest

graduations between various calibration marks are given in

where:

Table 1 and apply to calibrations made with air-free water at

rcf = relative centrifugal force, and

20°C.

d = diameter swing, mm, measured between tips of

6.2 Centrifuge, meeting all safety requirements for normal

opposite tubes when in rotating position.

use and capable of whirling two or more filled centrifuge tubes

Table 2 shows the relationship between the diameter of

at a speed that can be controlled to give a relative centrifugal

force (rcf) between 600 and 700 at the tips of the tubes. The

TABLE 2 Rotation Speeds for Centrifuges of Various Diameters

revolving head, trunnion rings, and trunnion cups, including

of Swing

the rubber cushion, shall be soundly constructed to withstand

A

Diameter of Swing, mm rpm at 600 rcf rpm at 700 rcf

the maximum centrifugal force capable of being delivered by

483 1490 1610

the power source. The trunnion cups and cushions shall firmly

508 1450 1570

support the tubes when the centrifuge is in motion. The

533 1420 1530

centrifuge shall be enclosed by a metal shield or case strong

559 1390 1500

enough to eliminate danger if any breakage occurs. Calculate

A

Measured in millimetres between tips of opposite tubes when in rotating

the speed of the rotating head as follows: position.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D893–97

swing, ref and rpm. transfer all traces of sediment from the original container to the

6.3 Oven, explosion-proof, capable of maintaining a tem- bottle by violent agitation of portions of the sample in the

perature of 105 6 3°C. original container. After complete suspension of all sediment,

6.4 Balance, having a sensitivity of 0.5 mg for weighing the strain the sample or a convenient aliquot through a 150-μm

100-mL beaker and centrifuge tube, and a balance having a (No. 100) sieve to remove large contaminating particles.

sensitivity of 0.1 g for weighing the oil sample.

NOTE 7—As used oil may change appreciably in storage, samples

should be tested as soon as possible after removal from the lubricating

7. Reagents and Solvents

system and the dates of sampling and testing should be noted.

7.1 Purity of Reagents—Reagent grade chemicals shall be

9. Procedure A for Pentane and Toluene Insolubles

used in all tests. Unless otherwise indicated, it is intended that

Without Coagulant

all reagents shall conform to the specifications of the Commit-

Pentane Insolubles

tee on Analytical Reagents of the American Chemical Society,

9.1 Dry a clean centrifuge tube for 30 min at 105 6 3°C,

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of cool in a desiccator, and weigh to the nearest 1 mg. Weigh 10.0

6 0.1 g of the prepared sample of used oil into the tube and fill

sufficiently high purity to permit its use without lessening the

accuracy of the determination. to the 100-mL mark with pentane (Warning—See Note 5).

Stopper the tube and shake until the mixture is homogeneous.

7.2 Purity of Water— Unless otherwise indicated references

to water sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.