ASTM C199-22

(Test Method)Standard Test Method for Pier Test for Refractory Mortars

Standard Test Method for Pier Test for Refractory Mortars

SIGNIFICANCE AND USE

3.1 This test method is used to estimate the application temperature limits of a refractory mortar and will establish its classification.

3.2 This test method will be regarded as a pass or fail test because the results are based on observations of whether the mortar flowed from the joints as a result of the heat treatment used.

3.3 Results obtained by this test method will not agree with those obtained in service when heating is done from only one side.

3.4 This test method is not applicable for testing nonaqueous mortars.

SCOPE

1.1 This test method covers the determination of refractoriness of all types of refractory mortar by heating a pier of brick laid up with the test mortar to learn whether the prescribed heat treatment causes the mortar to flow out of the joints.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C199 − 22

Standard Test Method for

1

Pier Test for Refractory Mortars

This standard is issued under the fixed designation C199; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.2 This test method will be regarded as a pass or fail test

because the results are based on observations of whether the

1.1 This test method covers the determination of refractori-

mortar flowed from the joints as a result of the heat treatment

ness of all types of refractory mortar by heating a pier of brick

used.

laid up with the test mortar to learn whether the prescribed heat

treatment causes the mortar to flow out of the joints. 3.3 Results obtained by this test method will not agree with

those obtained in service when heating is done from only one

1.2 The values stated in inch-pound units are to be regarded

side.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 3.4 This test method is not applicable for testing nonaque-

and are not considered standard.

ous mortars.

1.3 This standard does not purport to address all of the

4. Apparatus

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 Brick—Three 9-in. (228-mm) straight fireclay or high-

priate safety, health, and environmental practices and deter-

alumina brick, conforming to the following respective require-

mine the applicability of regulatory limitations prior to use.

ments for refractories:

1.4 This international standard was developed in accor-

A

Class of Mortar to be Tested PCE, Not Lower Than Cone No.

dance with internationally recognized principles on standard-

High-alumina 36

ization established in the Decision on Principles for the

Super-duty 33

Development of International Standards, Guides and Recom-

1

High-duty 31 ⁄2

mendations issued by the World Trade Organization Technical Medium-duty 29

Barriers to Trade (TBT) Committee.

A

See Test Method C24.

2. Referenced Documents

4.2 Spacing Rods—Nine joint-thickness spacing rods made

3

2 of ⁄32-in. (2-mm) diameter drill rod, cut into 6-in. (152-mm)

2.1 ASTM Standards:

lengths.

C24 Test Method for Pyrometric Cone Equivalent (PCE) of

Fireclay and High-Alumina Refractory Materials

4.3 Drying Oven, to accommodate five 9-in. (228-mm)

C113 Test Method for Reheat Change of Refractory Brick

straight brick standing on end, for use at 220 to 230 °F (105 to

110 °C).

3. Significance and Use

4.4 Furnace, capable of heating the test pier uniformly at

3.1 This test method is used to estimate the application

one of four temperatures, the highest being 3100 °F (1705 °C).

temperature limits of a refractory mortar and will establish its

classification.

5. Sampling

5.1 The sample of mortar evaluated will be a prepared test

sample of about 10 lb (4.5 kg). If a larger quantity is presented,

1

This test method is under the jurisdiction of ASTM Committee C08 on

ranging in size up to a commercial container, it must be

Refractories and is the direct responsibility of Subcommittee C08.01 on Strength.

reduced in size to about 10 lb (4.5 kg) for evaluation. To do

Current edition approved Feb. 1, 2022. Published February 2022. Originally

this, the contents of the container shall be thoroughly mixed in

approved in 1945. Last previous edition approved in 2016 as C199 – 84 (2016).

DOI: 10.1520/C0199-22.

the container, or transferred without loss to a clean impervious

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

receptacle of larger size and mixed thoroughly to a uniform

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

consistency. A 10-lb (4.5-kg) test sample shall then be taken

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and sealed in a metal or glass container.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C199 − 22

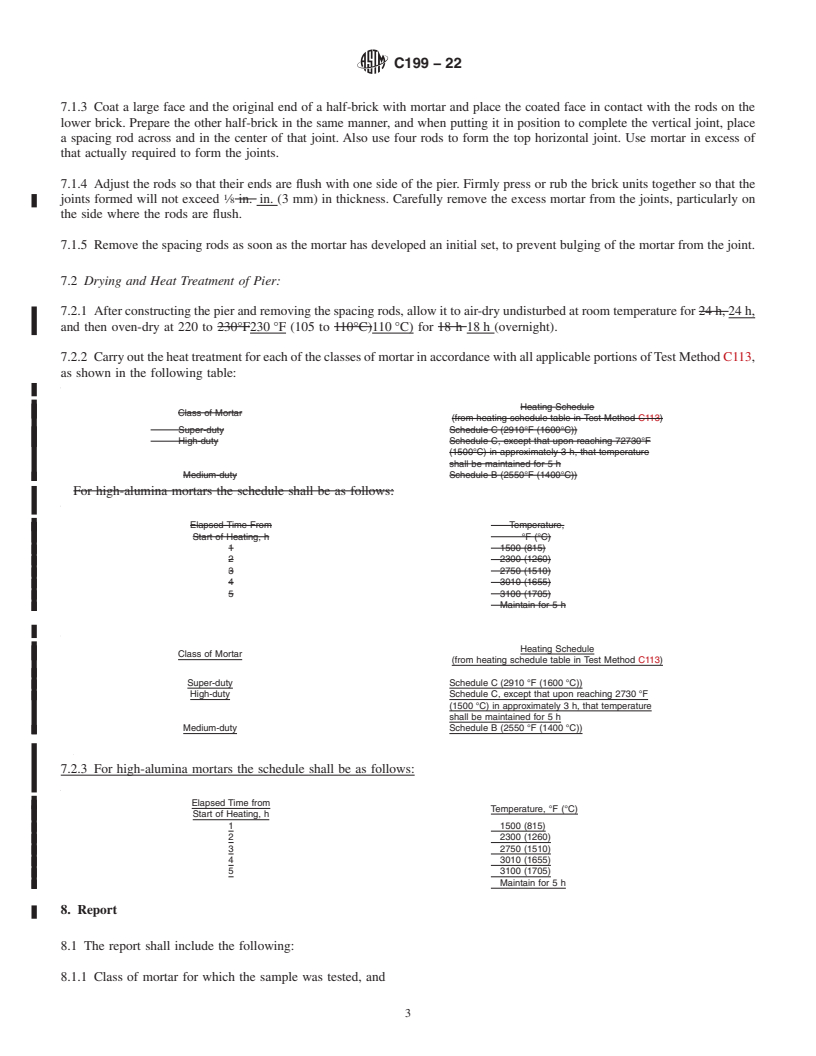

6. Test Specimens 7.2 Drying and Heat Treatment of Pier:

7.2.1 After constructing the pier and removing the spacing

6.1 The test mortar shall be of troweling consistency. When

rods, allow it to air-dry undisturbed at room temperature for

working with wet mortars not at this consistency small

2

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C199 − 84 (Reapproved 2016) C199 − 22

Standard Test Method for

1

Pier Test for Refractory Mortars

This standard is issued under the fixed designation C199; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of refractoriness of all types of refractory mortar by heating a pier of brick laid up

with the test mortar to learn whether the prescribed heat treatment causes the mortar to flow out of the joints.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C24 Test Method for Pyrometric Cone Equivalent (PCE) of Fireclay and High-Alumina Refractory Materials

C113 Test Method for Reheat Change of Refractory Brick

3. Significance and Use

3.1 This test method is used to estimate the application temperature limits of a refractory mortar and will establish its

classification.

3.2 This test method will be regarded as a pass or fail test because the results are based on observations of whether the mortar

flowed from the joints as a result of the heat treatment used.

3.3 Results obtained by this test method will not agree with those obtained in service when heating is done from only one side.

3.4 This test method is not applicable for testing nonaqueous mortars.

1

This test method is under the jurisdiction of ASTM Committee C08 on Refractories and is the direct responsibility of Subcommittee C08.01 on Strength.

Current edition approved June 1, 2016Feb. 1, 2022. Published June 2016February 2022. Originally approved in 1945. Last previous edition approved in 20112016 as

C199 – 84 (2016). (2011). DOI: 10.1520/C0199-84R16.10.1520/C0199-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C199 − 22

4. Apparatus

4.1 Brick—Three 9-in. (228-mm) straight fireclay or high-alumina brick, conforming to the following respective requirements for

refractories:

A

Class of Mortar to be Tested PCE, Not Lower than Cone No.

High-alumina 36

Super-duty 33

1

High-duty 31 ⁄2

Medium-duty 29

A

See Test Method C24.

A

Class of Mortar to be Tested PCE, Not Lower Than Cone No.

High-alumina 36

Super-duty 33

1

High-duty 31 ⁄2

Medium-duty 29

A

See Test Method C24.

3

4.2 Spacing Rods—Spacing Rods—Nine joint-thickness spacing rods made of ⁄32-in. (2-mm) diameter drill rod, cut into 6-in.

(152-mm) lengths.

4.3 Drying Oven, to accommodate five 9-in. (228-mm) straight brick standing on end, for use at 220 to 230°F230 °F (105 to

110°C).110 °C).

4.4 Furnace, capable of heating the test pier uniformly at one of four temperatures, the highest being 3100°F (1705°C).3100 °F

(1705 °C).

5. Sampling

5.1 The sample of mortar evaluated will be a prepared test sample of about 10 lb (4.5 kg). If a larger quantity is presented, ranging

in size up to a commercial container, it must be reduced in size to about 10 lb (4.5 kg) for evaluation. To do this, the contents of

the container shall be thoroughly mixed in the container, or transferred without loss to a clean impervious receptacle of larger size

and mixed thoroughly to a uniform consistency.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.