ASTM G17-07(2020)

(Test Method)Standard Test Method for Penetration Resistance of Pipeline Coatings (Blunt Rod)

Standard Test Method for Penetration Resistance of Pipeline Coatings (Blunt Rod)

SIGNIFICANCE AND USE

3.1 Since pipeline coatings are subjected to concentrated pressures exerted by the weight of the pipe and the backfill, this test is intended primarily for determining the resistance of the coating to penetration or deformation under controlled conditions.

3.1.1 Deformation of a compressible coating does not signify a potential weakness in underground burial service, if the coating is not penetrated. Deformation cannot be compared to penetration into and through a coating.

SCOPE

1.1 This accelerated test method is used to determine the relative resistance of steel pipeline coatings to penetration or deformation by a blunt rod under a specified load. The test method is intended to apply to the testing of all types of nonmetallic pipeline coatings subjected to various temperatures.

1.2 The values stated in SI units to three significant decimals are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G17 − 07 (Reapproved 2020)

Standard Test Method for

Penetration Resistance of Pipeline Coatings (Blunt Rod)

This standard is issued under the fixed designation G17; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope coating is not penetrated. Deformation cannot be compared to

penetration into and through a coating.

1.1 This accelerated test method is used to determine the

relative resistance of steel pipeline coatings to penetration or

4. Apparatus

deformation by a blunt rod under a specified load. The test

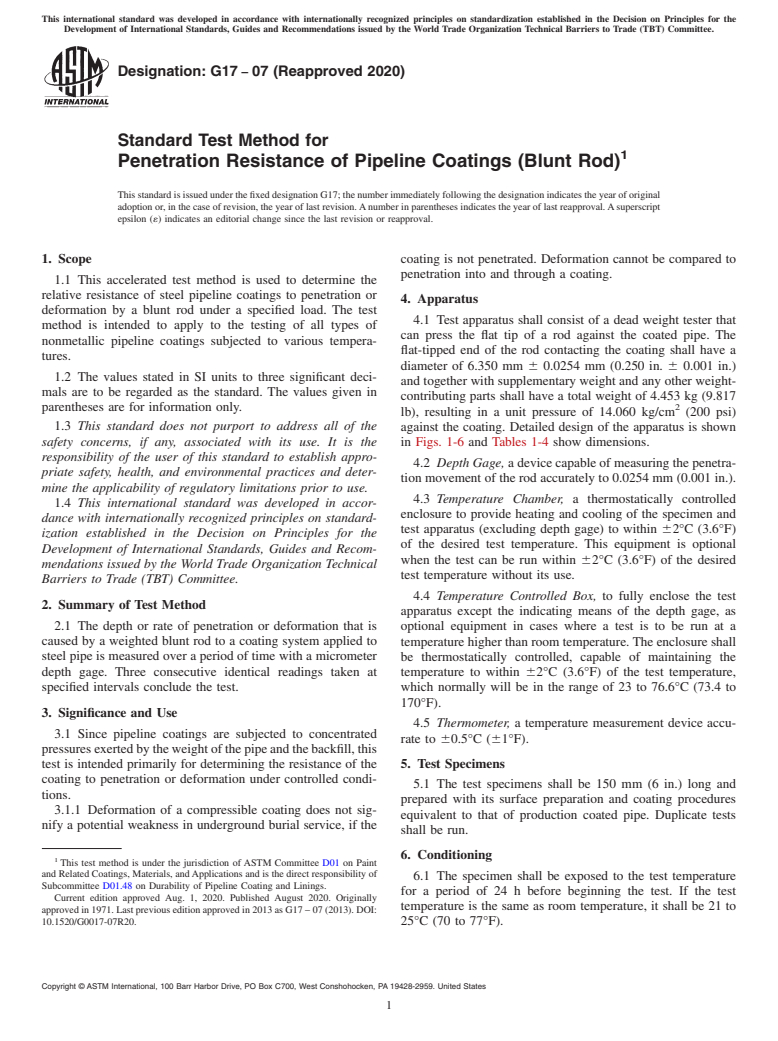

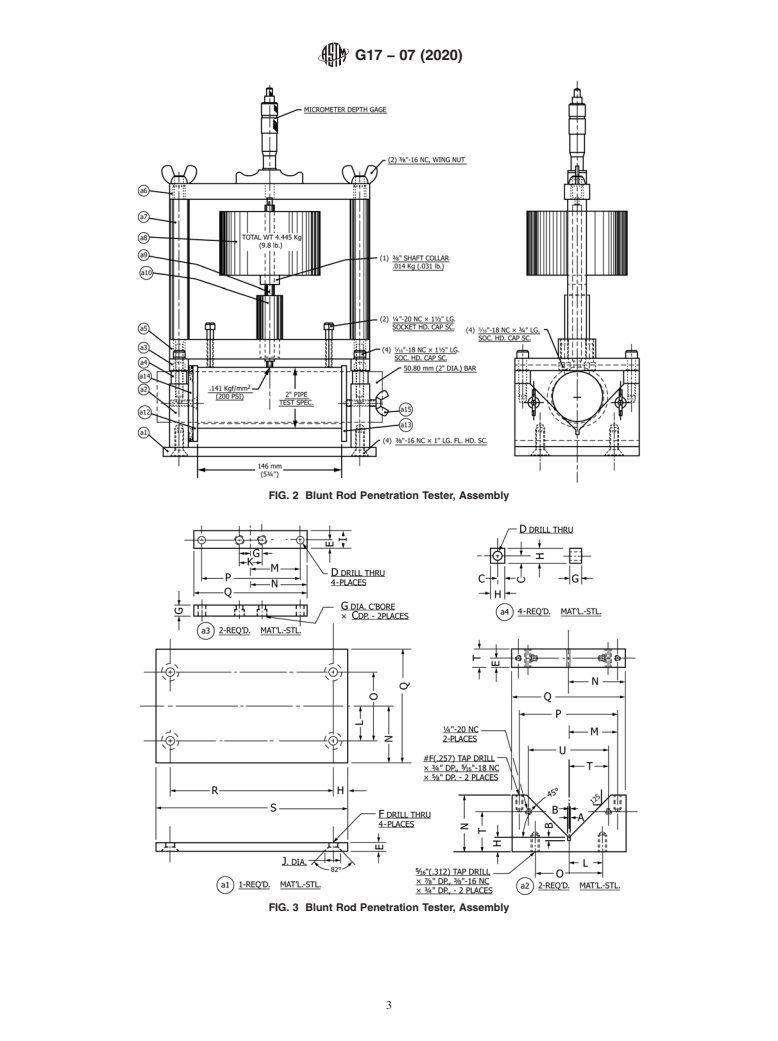

4.1 Test apparatus shall consist of a dead weight tester that

method is intended to apply to the testing of all types of

can press the flat tip of a rod against the coated pipe. The

nonmetallic pipeline coatings subjected to various tempera-

flat-tipped end of the rod contacting the coating shall have a

tures.

diameter of 6.350 mm 6 0.0254 mm (0.250 in. 6 0.001 in.)

1.2 The values stated in SI units to three significant deci-

and together with supplementary weight and any other weight-

mals are to be regarded as the standard. The values given in

contributing parts shall have a total weight of 4.453 kg (9.817

parentheses are for information only.

lb), resulting in a unit pressure of 14.060 kg/cm (200 psi)

1.3 This standard does not purport to address all of the against the coating. Detailed design of the apparatus is shown

safety concerns, if any, associated with its use. It is the

in Figs. 1-6 and Tables 1-4 show dimensions.

responsibility of the user of this standard to establish appro-

4.2 Depth Gage, a device capable of measuring the penetra-

priate safety, health, and environmental practices and deter-

tion movement of the rod accurately to 0.0254 mm (0.001 in.).

mine the applicability of regulatory limitations prior to use.

4.3 Temperature Chamber, a thermostatically controlled

1.4 This international standard was developed in accor-

enclosure to provide heating and cooling of the specimen and

dance with internationally recognized principles on standard-

test apparatus (excluding depth gage) to within 62°C (3.6°F)

ization established in the Decision on Principles for the

of the desired test temperature. This equipment is optional

Development of International Standards, Guides and Recom-

when the test can be run within 62°C (3.6°F) of the desired

mendations issued by the World Trade Organization Technical

test temperature without its use.

Barriers to Trade (TBT) Committee.

4.4 Temperature Controlled Box, to fully enclose the test

2. Summary of Test Method

apparatus except the indicating means of the depth gage, as

2.1 The depth or rate of penetration or deformation that is

optional equipment in cases where a test is to be run at a

caused by a weighted blunt rod to a coating system applied to temperature higher than room temperature. The enclosure shall

steel pipe is measured over a period of time with a micrometer

be thermostatically controlled, capable of maintaining the

depth gage. Three consecutive identical readings taken at temperature to within 62°C (3.6°F) of the test temperature,

specified intervals conclude the test.

which normally will be in the range of 23 to 76.6°C (73.4 to

170°F).

3. Significance and Use

4.5 Thermometer, a temperature measurement device accu-

3.1 Since pipeline coatings are subjected to concentrated

rate to 60.5°C (61°F).

pressuresexertedbytheweightofthepipeandthebackfill,this

test is intended primarily for determining the resistance of the 5. Test Specimens

coating to penetration or deformation under controlled condi-

5.1 The test specimens shall be 150 mm (6 in.) long and

tions.

prepared with its surface preparation and coating procedures

3.1.1 Deformation of a compressible coating does not sig-

equivalent to that of production coated pipe. Duplicate tests

nify a potential weakness in underground burial service, if the

shall be run.

6. Conditioning

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

6.1 The specimen shall be exposed to the test temperature

Subcommittee D01.48 on Durability of Pipeline Coating and Linings.

for a period of 24 h before beginning the test. If the test

Current edition approved Aug. 1, 2020. Published August 2020. Originally

temperature is the same as room temperature, it shall be 21 to

approved in 1971. Last previous edition approved in 2013 as G17 – 07 (2013). DOI:

10.1520/G0017-07R20. 25°C (70 to 77°F).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G17 − 07 (2020)

C 5 M 2 M (1)

N F I

C 5 ~C /T! 3100

P N

where:

C = net change,

N

M = final measurement,

F

M = initial measurement,

I

C = percent change, and

P

T = film thickness.

9. Report

9.1 The report shall include the following:

9.1.1 Complete identification

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.