ASTM D7680-10(2019)

(Practice)Standard Practice for Preparing Prints of Paste Printing Inks by a Motor-Driven Printability Tester

Standard Practice for Preparing Prints of Paste Printing Inks by a Motor-Driven Printability Tester

SIGNIFICANCE AND USE

5.1 It is generally recognized that the best method for evaluating printing properties of ink-substrate combinations is by actual printing. this practice provides a convenient method for preparing repeatable laboratory prints at realistic conditions of printing speed, printing pressure and ink film thickness.

5.2 This practice is useful for quality control, specification acceptance between producer and user, product development and research. Printed samples have found widespread applications for color matching, gloss-ink holdout and other appearance properties, permanency, abrasion, drying time and many other tests of interest to the printing ink, paper and allied industries.

SCOPE

1.1 This practice describes the procedure for preparing laboratory prints of paste printing inks using a motor-driven printability tester.

1.2 This practice covers printability testers of four different designs, referred to as Tester A, B, C, and D. These testers feature “push-button” control of printing speed and pressure and facilitate measurement of exact ink film thickness.

1.3 This practice is intended primarily for lithographic and letterpress inks that dry by oxidation or penetration. With appropriate drying or curing equipment, it is also applicable to other systems such as heat-set or energy curable.

1.4 This practice is applicable to the preparation of single-color solid-area prints by dry offset (also know as letterset) or by letterpress on any flat surface including paper, paperboard, plastic film, textiles, and metal.

1.5 The values stated in SI units are to be regarded as the standard. The only other unit of measurement used is fpm.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7680 − 10 (Reapproved 2019)

Standard Practice for

Preparing Prints of Paste Printing Inks by a Motor-Driven

Printability Tester

This standard is issued under the fixed designation D7680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice describes the procedure for preparing

D528Test Method for Machine Direction of Paper and

laboratory prints of paste printing inks using a motor-driven

Paperboard (Withdrawn 2010)

printability tester.

D1475Test Method for Density of Liquid Coatings, Inks,

1.2 This practice covers printability testers of four different

and Related Products

designs, referred to as Tester A, B, C, and D. These testers

D5039TestMethodsforIdentificationofWireSideofPaper

feature “push-button” control of printing speed and pressure

(Withdrawn 2009)

and facilitate measurement of exact ink film thickness.

D6073Test Method for Relative Setting of Heatset Printing

1.3 This practice is intended primarily for lithographic and Inks

letterpress inks that dry by oxidation or penetration. With

D7189Test Method for Relative Mileage of News Ink on

appropriate drying or curing equipment, it is also applicable to Newsprint

other systems such as heat-set or energy curable.

D7305TestMethodforReflectionDensityofPrintedMatter

2.2 Other Standards:

1.4 This practice is applicable to the preparation of single-

ISO 187Paper, board and pulps—Standard atmosphere for

color solid-area prints by dry offset (also know as letterset) or

conditioning and testing and procedure for monitoring the

by letterpress on any flat surface including paper, paperboard,

atmosphere and conditioning of samples

plastic film, textiles, and metal.

ISO/DIS 2835–1Graphic technology—Laboratory prepara-

1.5 The values stated in SI units are to be regarded as the

tion test prints–Part 1: Paste inks

standard. The only other unit of measurement used is fpm.

ISO 2846–1Graphic technology—Specification for color

and transparency of printing ink sets–Part 1: Inks for

1.6 This standard does not purport to address all of the

heat-set web offset lithographic printing

safety concerns, if any, associated with its use. It is the

ISO 2846–2Graphic technology—Specification for color

responsibility of the user of this standard to establish appro-

and transparency of printing ink sets–Part 2: Inks for

priate safety, health, and environmental practices and deter-

coldset offset lithographic printing

mine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

3.1 Symbols:

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

fpm = feet per minute

mendations issued by the World Trade Organization Technical

(fpm ÷ 200 = m/s)

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Standards volume information, refer to the standard’s Document Summary page on

Related Coatings, Materials, and Applications and is the direct responsibility of the ASTM website.

Subcommittee D01.56 on Printing Inks. The last approved version of this historical standard is referenced on

Current edition approved Jan. 1, 2019. Published January 2019. Originally www.astm.org.

approved in 2010. Last previous edition approved in 2010 as D7680 – 10. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D7680-10R19. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7680 − 10 (2019)

cylinder presses. Printing speed and pressure are set simply by

kgf = kilograms of force

turning appropriate dials except on Tester D, where they are

(kgf = 9.81 N)

computer-controlled.

kp = kilopascals of pressure

6.1.2 Inking System,consistingofthreerollersonwhichthe

(kp = 9.81 N)

m/s = meters per second ink is distributed. the bottom two rollers, at least one of which

(m/s × 200 = fpm) oscillates, are metal, while the top roller is of synthetic

composition.Atoprollerofspecialcompositionisrequiredfor

3.2 Symbols for Ink Film Thickness Calculations:

glycol-based and energy curable inks. As seen in Table 1 and

A = printed area on the substrate, cm Fig. 1a and Fig. 1c, Testers A and C contain built-in inking

S

D = density of the ink, g/cm systems, while Fig. 2 illustrates the separate inking systems

IFT = ink film thickness on the plate, µm

that are required for Testers B and D. Several inking systems

P

IFT = ink film thickness on the substrate, µm

arethermostated,animportantfeatureforrunningheatsetinks.

S

µm = micrometers

All are engineered so as to provide multiple inking stations,

W = weight of inked plate after printing, g

A

each of which contains a device to support the disk during the

W = weight of inked plate before printing, g

B

inking process.

W = weight of ink carried on the plate, g

P

6.1.3 Printing Disk,toserveastheprintingplate.Asseenin

W = weight of the clean uninked plate, g

PO

Table 1, disks are 2 to 7 cm wide and ~ 20 cm in circumfer-

W = weight of ink on the substrate, g

S

2 ence. They are constructed of light-weight polished aluminum

W = weight of ink on the substrate per unit area, g/m

SA

or rubber-covered aluminum or as a core with an aluminum or

rubber covering. If rubber disks are used, it it recommended to

4. Summary of Practice

procure two or more so as to minimize waiting time after

4.1 Thedesignatedprintingspeedandpressurearepreseton

cleanup.

the print maker of the printability tester.Aspecified volume of

NOTE 1—Disks of other sizes and surface coverings are available. For

ink is metered to the rollers of the inking system and

the purpose of this practice, the discussion is limited to those listed in

distributedfor15to25sforheatsetandnewsinks,60sormore

Table 1.

forotherinks.Theprintingdiskisinkedforthesameperiodof

6.1.4 Carrier, a “sled” on which flexible substrates are

time, installed on the print maker, and a print made on the

mountedformakingprintsonthetwoflat-bedtesters,AandC.

designated substrate.

Carriers are constructed of stiff plastic with a rubber coating.

4.2 Theprintsaredriedbyappropriatemeansandmeasured

Heavy cardboard and metal specimens may possibly be run

forreflectiondensityinordertoverifythatthetargetvaluehas

without benefit of a carrier. When disks of different widths are

been achieved.

being used with thin substrates, separate carriers are required

4.3 If required by the test, the inked disk is weighted before so that indentation from the narrower disk does not mar the

and after printing and the exact ink film thickness on the

appearance of prints made subsequently with the wider disk.

substrate is computed.

6.2 Ink Pipette, consisting of a metal cylinder and plunger,

4.4 After a suitable lapse of time, the prints are subjected to

2 mL capacity, accurate to a minimum of 0.01 mL.

the intended end use test(s). Results are compared to those of

6.3 Timer, with clear 1 s divisions.

reference prints prepared in the identical fashion.

6.4 Tongs or Rubber Gloves (optional), for handling the

disk when making gravimetric measurements.

5. Significance and Use

6.5 Analytical Balance (optional),accurateto0.0001gwith

5.1 It is generally recognized that the best method for

150 g capacity to accommodate the printing disk described in

evaluating printing properties of ink-substrate combinations is

6.1.3.

by actual printing. this practice provides a convenient method

forpreparingrepeatablelaboratoryprintsatrealisticconditions

6.6 Accelerated Drying Equipment (optional) such as a

of printing speed, printing pressure and ink film thickness.

source of heat as in Test Method D6073, or energy-curing, as

needed.

5.2 This practice is useful for quality control, specification

acceptance between producer and user, product development

6.7 Reflection Densitometer or Spectrodensitometer (op-

and research. Printed samples have found widespread applica-

tional) conforming to Test Method D7305.

tions for color matching, gloss-ink holdout and other appear-

6.8 Weight per Volume Cup (optional) for measuring ink

ance properties, permanency, abrasion, drying time and many

density in accordance with Test Method D1475.

other tests of interest to the printing ink, paper and allied

industries.

7. Materials

6. Apparatus

7.1 If the test sample is a printing ink:

7.1.1 Reference Ink,ofthesametype,rheologyandcoloras

6.1 Printability Tester having the following components:

6.1.1 Print Maker, a motorized printing press that can be the test ink and having known printing properties.

accommodated on a laboratory bench.As noted in Table 1 and 7.1.2 Standard Substrate, as specified in the test method or

Fig.1,TestersAandCareflat-bedpresses,TestersBandDare as agreed upon between producer and user.

D7680 − 10 (2019)

A

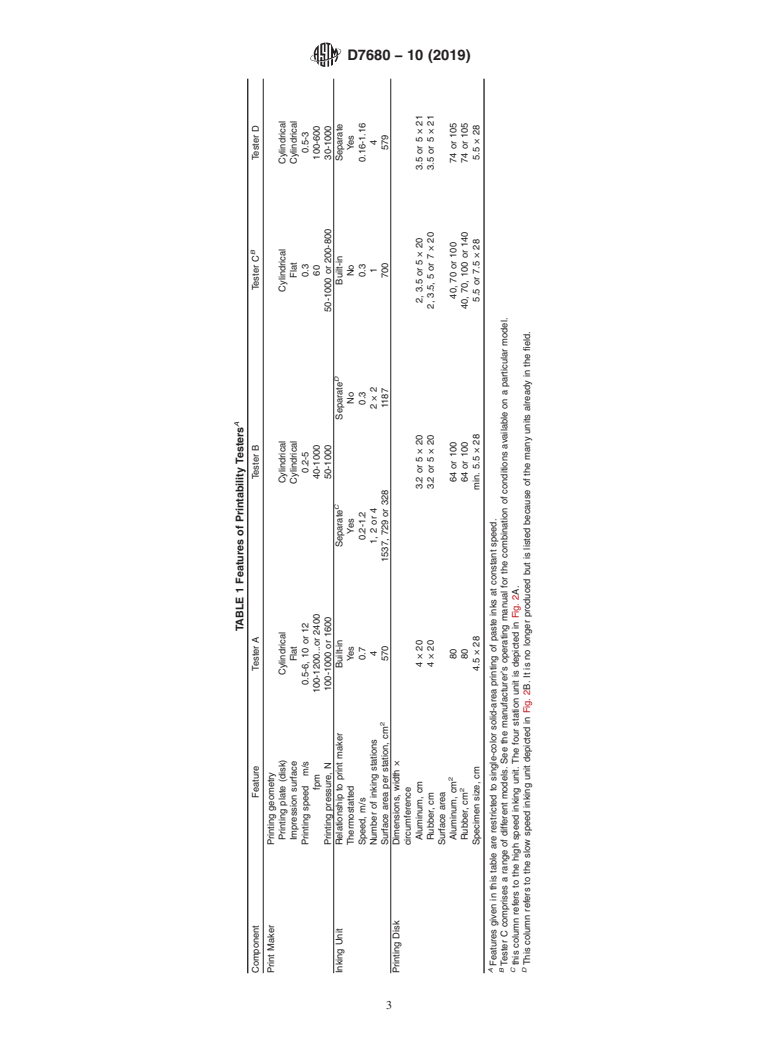

TABLE 1 Features of Printability Testers

B

Component Feature Tester A Tester B Tester C Tester D

Print Maker Printing geometry

Printing plate (disk) Cylindrical Cylindrical Cylindrical Cylindrical

Impression surface Flat Cylindrical Flat Cylindrical

Printing speed m/s 0.5-6, 10 or 12 0.2-5 0.3 0.5-3

fpm 100-1200.or 2400 40-1000 60 100-600

Printing pressure, N 100-1000 or 1600 50-1000 50-1000 or 200-800 30-1000

C D

Inking Unit Relationship to print maker Built-in Separate Separate Built-in Separate

Thermostatted Yes Yes No No Yes

Speed, m/s 0.7 0.2-1.2 0.3 0.3 0.16-1.16

Number of inking stations 4 1, 2 or 4 2 × 2 1 4

Surface area per station, cm 570 1537, 729 or 328 1187 700 579

Printing Disk Dimensions, width ×

circumference

Aluminum, cm 4 × 20 3.2 or 5 × 20 2, 3.5 or 5 × 20 3.5 or 5 × 21

Rubber, cm 4 × 20 3.2 or 5 × 20 2, 3.5, 5 or 7 × 20 3.5 or 5 × 21

Surface area

Aluminum, cm 80 64 or 100 40, 70 or 100 74 or 105

Rubber, cm 80 64 or 100 40, 70, 100 or 140 74 or 105

Specimen size, cm 4.5 × 28 min. 5.5 × 28 5.5 or 7.5 × 28 5.5 × 28

A

Features given in this table are restricted to single-color solid-area printing of paste inks at constant speed.

B

Tester C comprises a range of different models. See the manufacturer’s operating manual for the combination of conditions available on a particular model.

C

this column refers to the high speed inking unit. The four station unit is depicted in Fig. 2A.

D

This column refers to the slow speed inking unit depicted in Fig. 2B. It is no longer produced but is listed because of the many units already in the field.

D7680 − 10 (2019)

FIG. 2 Inking Systems for Use with Testers B and D

FIG. 1 Printability Testers Covered in this Practice

7.2 If the test sample is a substrate:

D7680 − 10 (2019)

7.2.1 Reference Substrate, of the same type as the test ink to the pipette, using the spatula to force the ink in while

substrate and having known printing properties. slowlypullingbacktheram.Wipeexcessmaterialoffthetipof

7.2.2 Standard Ink, as specified in the test method or as the pipette.

agreed upon between producer and user.

9.2 Substrates:

7.3 Target Value(s) for reflection density or gravimetric-

9.2.1 Cutthenumberofspecimensrequiredforboththetest

based end result or both.

and reference prints. Three are recommended for most pur-

poses; up to ten or more may be needed for special tests.

7.4 Was up Solvent, such as mineral spirits or other com-

Specimen sizes (4.5 to 7.5 by 28 cm) are listed at the end of

patible with the printing ink system and the composition

Table 1.

surfaces.

NOTE 2—Multiple replicates are advisable because of the likelihood of

7.5 Rags or Wipers, clean, absorbent, lint-free.

nonuniformity in substrate properties. For example samples taken from a

7.6 Plastic Sheet, large enough to cover the instrument(s).

ream of commercially supplied paper can be assumed to be cut from as

many as seven or more reels, each with slightly different properties. For

7.7 Manufacturer’s Operating Manual, for the specific in-

this reason, studies of a research nature are best conducted with samples

strument model.

cut from a single reel.

9.2.2 Specimens should be free of wrinkles, creases, water-

8. Hazards

marks and other types of contamination and consistent as to

8.1 WARNING—Since solvents may be hazardous to the

side and direction. Mark each specimen with the side (felt or

skin and eyes, wear rubber gloves and safety glasses during

wire, which may be determined by Test Method D5039) and

cleanup to avoid solvent contact with skin and eyes. In case of

machine direction (in or across, as determined byTest Method

contact, wash skin and eyes for 15 min with water and call a

D528). Handle specimens only by the edge, as touching the

physician. See supplier’s Material Safety Data Sheets for

surface with bare fingers may cause localized changes in

further information on each solvent used.

absorbency.

8.2 Use local exhaust/ventilation during solvent cleanup.

9.2.3 The side and direction used for making the prints

dependsontheanticipatedenduse.Unlessotherwisespecified,

8.3 Never let a vehicle or ink dry completely on the surface

specimens for testing inks should be cut so that the longer

of the rollers or disks.

directionisinthemachinedirectionandfeltsideup.Papersare

8.4 Be careful not to cause any damage during the cleaning

frequently tested on both sides and, if intended for sheet-fed

process or by leaving the rollers and disks in contact when not

printing, in both directions. Paperboard is tested only on the

in use.

printing side and across the machine direction.

9. Test Specimens

10. Conditioning

9.1 Printing Ink:

10.1 The transfer and absorbency properties of printing ink

9.1.1 Printing ink samples should be press-ready. Because

are highly sensitive to temperature, while those of paper and

ofthesmallsurfaceareasoftheinkingstationsshowninTable

other celluloic substrates are sensitive to relative humidity. For

1, and as can be surmised from the data in Table 2 (to be

those reasons, reproducible printing requires that the test and

discussedinmoredetailin12.4.2),verylittleink,lessthanone

reference samples be conditioned. ISO 187 specifies 23 6 1°C

mL, is usually sufficient to make prints of the required number

temperature and 50 6 2% rela

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7680 − 10 D7680 − 10 (Reapproved 2019)

Standard Practice for

Preparing Prints of Paste Printing Inks by a Motor-Driven

Printability Tester

This standard is issued under the fixed designation D7680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the procedure for preparing laboratory prints of paste printing inks using a motor-driven printability

tester.

1.2 This practice covers printability testers of four different designs, referred to as Tester A, B, C, and D. These testers feature

“push-button” control of printing speed and pressure and facilitate measurement of exact ink film thickness.

1.3 This practice is intended primarily for lithographic and letterpress inks that dry by oxidation or penetration. With appropriate

drying or curing equipment, it is also applicable to other systems such as heat-set or energy curable.

1.4 This practice is applicable to the preparation of single-color solid-area prints by dry offset (also know as letterset) or by

letterpress on any flat surface including paper, paperboard, plastic film, textiles, and metal.

1.5 The values stated in SI units are to be regarded as the standard. The only other unit of measurement used is fpm.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D528 Test Method for Machine Direction of Paper and Paperboard (Withdrawn 2010)

D1475 Test Method for Density of Liquid Coatings, Inks, and Related Products

D5039 Test Methods for Identification of Wire Side of Paper (Withdrawn 2009)

D6073 Test Method for Relative Setting of Heatset Printing Inks

D7189 Test Method for Relative Mileage of News Ink on Newsprint

D7305 Test Method for Reflection Density of Printed Matter

2.2 Other Standards:

ISO 187 Paper, board and pulps—Standard atmosphere for conditioning and testing and procedure for monitoring the

atmosphere and conditioning of samples

ISO/DIS 2835–1 Graphic technology—Laboratory preparation test prints–Part 1: Paste inks

ISO 2846–1 Graphic technology—Specification for color and transparency of printing ink sets–Part 1: Inks for heat-set web

offset lithographic printing

ISO 2846–2 Graphic technology—Specification for color and transparency of printing ink sets–Part 2: Inks for coldset offset

lithographic printing

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.56 on Printing Inks.

Current edition approved Dec. 1, 2010Jan. 1, 2019. Published February 2011January 2019. Originally approved in 2010. Last previous edition approved in 2010 as D7680

– 10. DOI: 10.1520/D7680-10.10.1520/D7680-10R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7680 − 10 (2019)

3. Terminology

3.1 Symbols:

fpm = feet per minute

(fpm ÷ 200 = m/s)

kgf = kilograms of force

(kgf = 9.81 N)

kp = kilopascals of pressure

(kp = 9.81 N)

m/s = meters per second

(m/s × 200 = fpm)

3.2 Symbols for ink film thickness calculations:Ink Film Thickness Calculations:

A = printed area on the substrate, cm

S

D = density of the ink, g/cm

IFT = ink film thickness on the plate, μm

P

IFT = ink film thickness on the substrate, μm

S

μm = micrometers

W = weight of inked plate after printing, g

A

W = weight of inked plate before printing, g

B

W = weight of ink carried on the plate, g

P

W = weight of the clean uninked plate, g

PO

W = weight of ink on the substrate, g

S

W = weight of ink on the substrate per unit area, g/m

SA

4. Summary of Practice

4.1 The designated printing speed and pressure are preset on the print maker of the printability tester. A specified volume of ink

is metered to the rollers of the inking system and distributed for 15 to 25 s for heatset and newsinks, 60 s or more for other inks.

The printing disk is inked for the same period of time, installed on the print maker, and a print made on the designated substrate.

4.2 The prints are dried by appropriate means and measured for reflection density in order to verify that the target value has

been achieved.

4.3 If required by the test, the inked disk is weighted before and after printing and the exact ink film thickness on the substrate

is computed.

4.4 After a suitable lapse of time, the prints are subjected to the intended end use test(s). Results are compared to those of

reference prints prepared in the identical fashion.

5. Significance and Use

5.1 It is generally recognized that the best method for evaluating printing properties of ink-substrate combinations is by actual

printing. this practice provides a convenient method for preparing repeatable laboratory prints at realistic conditions of printing

speed, printing pressure and ink film thickness.

5.2 This practice is useful for quality control, specification acceptance between producer and user, product development and

research. Printed samples have found widespread applications for color matching, gloss-ink holdout and other appearance

properties, permanency, abrasion, drying time and many other tests of interest to the printing ink, paper and allied industries.

6. Apparatus

6.1 Printability Tester having the following components:

6.1.1 Print Maker, a motorized printing press that can be accommodated on a laboratory bench. As noted in Table 1 and Fig.

1, Testers A and C are flat-bed presses, Testers B and D are cylinder presses. Printing speed and pressure are set simply by turning

appropriate dials except on Tester D, where they are computer-controlled.

6.1.2 Inking System, consisting of three rollers on which the ink is distributed. the bottom two rollers, at least one of which

oscillates, are metal, while the top roller is of synthetic composition. A top roller of special composition is required for glycol-based

and energy curable inks. As seen in Table 1 and Fig. 1a and Fig. 1c, Testers A and C contain built-in inking systems, while Fig.

2 illustrates the separate inking systems that are required for Testers B and D. Several inking systems are thermostated, an

important feature for running heatset inks. All are engineered so as to provide multiple inking stations, each of which contains a

device to support the disk during the inking process.

6.1.3 Printing Disk, to serve as the printing plate. As seen in Table 1, disks are 2 to 7 cm wide and ~ 20 cm in circumference.

They are constructed of light-weight polished aluminum or rubber-covered aluminum or as a core with an aluminum or rubber

covering. If rubber disks are used, it it recommended to procure two or more so as to minimize waiting time after cleanup.

D7680 − 10 (2019)

A

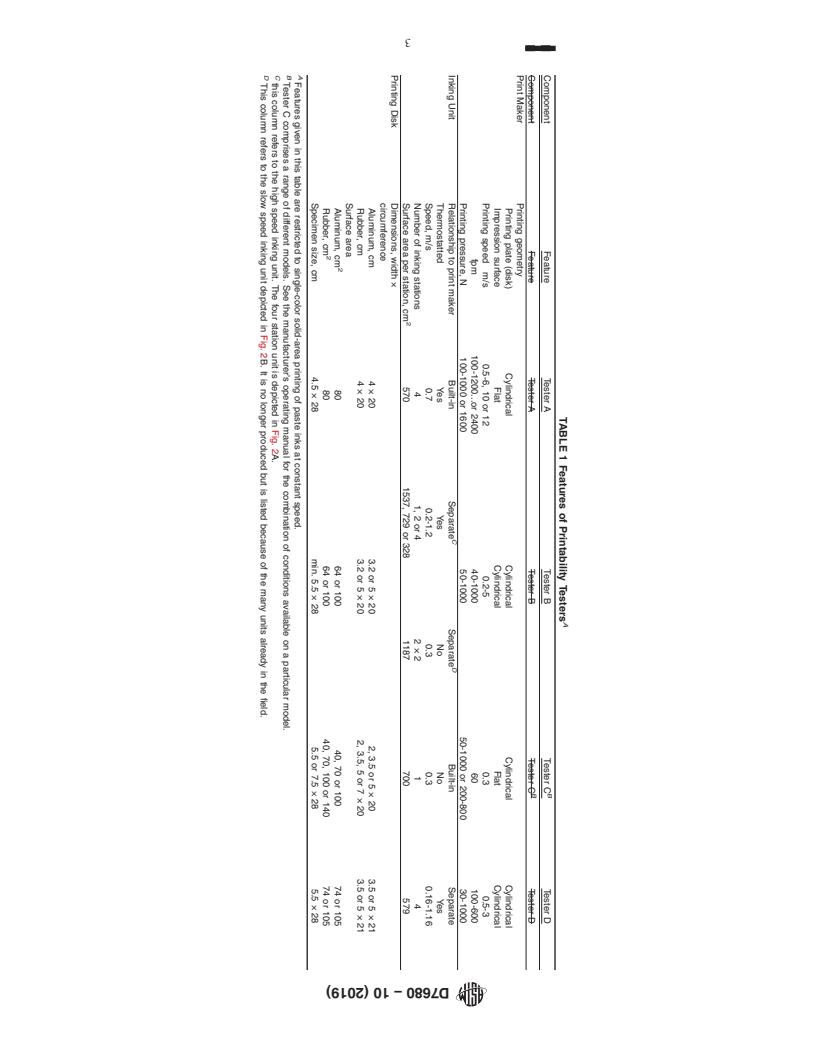

TABLE 1 Features of Printability Testers

B

Component Feature Tester A Tester B Tester C Tester D

B

Component Feature Tester A Tester B Tester C Tester D

Print Maker Printing geometry

Printing plate (disk) Cylindrical Cylindrical Cylindrical Cylindrical

Impression surface Flat Cylindrical Flat Cylindrical

Printing speed m/s 0.5-6, 10 or 12 0.2-5 0.3 0.5-3

fpm 100-1200.or 2400 40-1000 60 100-600

Printing pressure, N 100-1000 or 1600 50-1000 50-1000 or 200-800 30-1000

C D

Inking Unit Relationship to print maker Built-in Separate Separate Built-in Separate

Thermostatted Yes Yes No No Yes

Speed, m/s 0.7 0.2-1.2 0.3 0.3 0.16-1.16

Number of inking stations 4 1, 2 or 4 2 × 2 1 4

Surface area per station, cm 570 1537, 729 or 328 1187 700 579

Printing Disk Dimensions, width ×

circumference

Aluminum, cm 4 × 20 3.2 or 5 × 20 2, 3.5 or 5 × 20 3.5 or 5 × 21

Rubber, cm 4 × 20 3.2 or 5 × 20 2, 3.5, 5 or 7 × 20 3.5 or 5 × 21

Surface area

Aluminum, cm 80 64 or 100 40, 70 or 100 74 or 105

Rubber, cm 80 64 or 100 40, 70, 100 or 140 74 or 105

Specimen size, cm 4.5 × 28 min. 5.5 × 28 5.5 or 7.5 × 28 5.5 × 28

A

Features given in this table are restricted to single-color solid-area printing of paste inks at constant speed.

B

Tester C comprises a range of different models. See the manufacturer’s operating manual for the combination of conditions available on a particular model.

C

this column refers to the high speed inking unit. The four station unit is depicted in Fig. 2A.

D

This column refers to the slow speed inking unit depicted in Fig. 2B. It is no longer produced but is listed because of the many units already in the field.

D7680 − 10 (2019)

FIG. 1 Printability Testers Covered in this Practice

D7680 − 10 (2019)

FIG. 2 Inking Systems for Use with Testers B and D

NOTE 1—Disks of other sizes and surface coverings are available. For the purpose of this practice, the discussion is limited to those listed in Table

1.

D7680 − 10 (2019)

6.1.4 Carrier, a “sled” on which flexible substrates are mounted for making prints on the two flat-bed testers, A and C. Carriers

are constructed of stiff plastic with a rubber coating. Heavy cardboard and metal specimens may possibly be run without benefit

of a carrier. When disks of different widths are being used with thin substrates, separate carriers are required so that indentation

from the narrower disk does not mar the appearance of prints made subsequently with the wider disk.

6.2 Ink Pipette, consisting of a metal cylinder and plunger, 2 mL capacity, accurate to a minimum of 0.01 mL.

6.3 Timer, with clear 1 s divisions.

6.4 Tongs or Rubber Gloves (optional), for handling the disk when making gravimetric measurements.

6.5 Analytical Balance (optional), accurate to 0.0001 g with 150 g capacity to accommodate the printing disk described in 6.1.3.

6.6 Accelerated Drying Equipment (optional) such as a source of heat as in Test Method D6073, or energy-curing, as needed.

6.7 Reflection Densitometer or Spectrodensitometer (optional) conforming to Test Method D7305.

6.8 Weight per Volume Cup (optional) for measuring ink density in accordance with Test Method D1475.

7. Materials

7.1 If the test sample is a printing ink:

7.1.1 Reference Ink, of the same type, rheology and color as the test ink and having known printing properties.

7.1.2 Standard Substrate, as specified in the test method or as agreed upon between producer and user.

7.2 If the test sample is a substrate:

7.2.1 Reference Substrate, of the same type as the test substrate and having known printing properties.

7.2.2 Standard Ink, as specified in the test method or as agreed upon between producer and user.

7.3 Target Value(s) for reflection density or gravimetric-based end result or both.

7.4 Was up Solvent, such as mineral spirits or other compatible with the printing ink system and the composition surfaces.

7.5 Rags or Wipers, clean, absorbent, lint-free.

7.6 Plastic Sheet, large enough to cover the instrument(s).

7.7 Manufacturer’s Operating Manual, for the specific instrument model.

8. Hazards

8.1 WARNING—Since solvents may be hazardous to the skin and eyes, wear rubber gloves and safety glasses during cleanup

to avoid solvent contact with skin and eyes. In case of contact, wash skin and eyes for 15 min with water and call a physician.

See supplier’s Material Safety Data Sheets for further information on each solvent used.

8.2 Use local exhaust/ventilation during solvent cleanup.

8.3 Never let a vehicle or ink dry completely on the surface of the rollers or disks.

8.4 Be careful not to cause any damage during the cleaning process or by leaving the rollers and disks in contact when not in

use.

9. Test Specimens

9.1 Printing Ink:

9.1.1 Printing ink samples should be press-ready. Because of the small surface areas of the inking stations shown in Table 1,

and as can be surmised from the data in Table 2 (to be discussed in more detail in 12.4.2), very little ink, less than one mL, is

usually sufficient to make prints of the required number of replicates.

9.1.2 Make sure the test specimen is free of bubbles, skin and other contamination. Prior to transferring to the ink pipette, it

may be useful to place a small quantity on a clean glass plate and gently work up with a small spatula without aerating. Add ink

to the pipette, using the spatula to force the ink in while slowly pulling back the ram. Wipe excess material off the tip of the pipette.

9.2 Substrates:

9.2.1 Cut the number of specimens required for both the test and reference prints. Three are recommended for most purposes;

up to ten or more may be needed for special tests. Specimen sizes (4.5 to 7.5 by 28 cm) are listed at the end of Table 1.

NOTE 2—Multiple replicates are advisable because of the likelihood of nonuniformity in substrate properties. For example samples taken from a ream

of commercially supplied paper can be assumed to be cut from as many as seven or more reels, each with slightly different properties. For this reason,

studies of a research nature are best conducted with samples cut from a single reel.

9.2.2 Specimens should be free of wrinkles, creases, watermarks and other types of contamination and consistent as to side and

direction. Mark each specimen with the side (felt or wire, which may be determined by Test Method D5039

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.