ASTM E661-88(1997)

(Test Method)Standard Test Method for Performance of Wood and Wood-Based Floor and Roof Sheathing Under Concentrated Static and Impact Loads

Standard Test Method for Performance of Wood and Wood-Based Floor and Roof Sheathing Under Concentrated Static and Impact Loads

SCOPE

1.1 This test method covers procedures for determining the resistance to deflection and damage of floor and roof sheathing used in site-built construction subjected to concentrated static loads as well as impact loads from nonrigid blunt objects. It is applicable to wood and wood-based panels and boards, but is not intended to cover profiled metal decks, nor precast or cast-in-place slabs. Surface indentation is not evaluated separately from deflection.

1.2 Three applications are covered: roof sheathing, subfloors, and single floors. Roof sheathing is tested in both a dry and a wet condition, while subfloors and single floors are both tested in a dry condition, as well as a condition of having dried out after being wet. These moisture conditions are those commonly experienced with site-built construction. Note 1-Where it is anticipated that sheathing will be subjected only to dry conditions during construction and use, or else to greater moisture exposure than is indicated in 6.3.2, the corresponding exposure conditions may be modified by agreement between the interested parties. For example, shop-built construction may be tested dry only, although the possibility of exposure to high humidity or leaks and flooding during use should be considered.

1.3 The values stated in metric (SI) units are to be regarded as the standard.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:E661–88(Reapproved1997)

Standard Test Method for

Performance of Wood and Wood-Based Floor and Roof

Sheathing Under Concentrated Static and Impact Loads

This standard is issued under the fixed designation E 661; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

During construction and occupancy of a building, floor and roof sheathing are subjected to

concentrated loads that frequently govern the thickness required. Static loads may simulate either foot

traffic, or loads from fixtures, when applied through loading disks of appropriate size. Impact loads

will occur during construction and also in service.

Roof sheathing and subflooring are likely to be critical in strength or stiffness, or both, under foot

traffic and construction loads, while single-layer floors are generally critical under fixture loads, foot

traffic, and in-service impact loads. Subfloors, like single floors, must also support fixture loads, but

they will have an additional layer of material, such as underlayment above, which will help to

distribute concentrated loads.

1. Scope 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers procedures for determining the

responsibility of the user of this standard to establish appro-

resistance to deflection and damage of floor and roof sheathing

priate safety and health practices and determine the applica-

used in site-built construction subjected to concentrated static

bility of regulatory limitations prior to use.

loads as well as impact loads from nonrigid blunt objects. It is

applicable to wood and wood-based panels and boards, but is

2. Referenced Documents

not intended to cover profiled metal decks, nor precast or

2.1 ASTM Standards:

cast-in-place slabs. Surface indentation is not evaluated sepa-

D 1517 Definitions of Terms Relating to Leather

rately from deflection.

E 575 Practice for Reporting Data from Structural Tests of

1.2 Three applications are covered: roof sheathing, sub-

Building Constructions, Elements, Connections, and As-

floors, and single floors. Roof sheathing is tested in both a dry

semblies

and a wet condition, while subfloors and single floors are both

2.2 Federal Standards:

tested in a dry condition, as well as a condition of having dried

Fed. Spec. V-T-291E(1) Linen Thread

out after being wet. These moisture conditions are those

commonly experienced with site-built construction.

3. Summary of Test Method

NOTE 1—Whereitisanticipatedthatsheathingwillbesubjectedonlyto

3.1 Roof and floor sheathing specimens are subjected to

dry conditions during construction and use, or else to greater moisture

concentrated loads applied through a 76-mm (3-in.) or a

exposure than is indicated in 6.3.2, the corresponding exposure conditions

25-mm (1-in.) diameter loading disk, depending on the in-

may be modified by agreement between the interested parties. For

tended use and the properties to be evaluated. They are also

example, shop-built construction may be tested dry only, although the

subjectedtotheimpactofashot-filleddropbag.Specimensare

possibility of exposure to high humidity or leaks and flooding during use

should be considered. tested in a horizontal position, mounted on fully supported

framingmembersandwithloadsappliedtothetopsurfacenear

1.3 The values stated in metric (SI) units are to be regarded

anedge,oratalocationdeterminedtobemorevulnerable.Any

as the standard.

support framing may be used that is representative of the

anticipated service, as the framing is not considered a major

test variable.

This test method is under the jurisdiction of ASTM Committee E6 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.11

on Horizontal and Vertical Structures/Structural Performance of Completed Struc- Annual Book of ASTM Standards, Vol 15.04.

tures. Annual Book of ASTM Standards, Vol 04.07.

Current edition approved May 27, 1988. Published September 1988. Originally Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

published as E 661 – 78. Last previous edition E 661 – 78. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E661–88 (1997)

4. Significance and Use measuring the load within 61 % accuracy. Load shall be

applied through a ball-and-socket joint to assure even applica-

4.1 The procedures outlined will provide data that can be

tion.

usedtoevaluatethestructuralperformance,underconcentrated

5.1.3 Loading Disks—Two steel disks are required, one

loads, of roof and floor sheathing, separate from the effects of

havingadiameterof25mm(1in.),representingaconcentrated

the framing, under simulated conditions representative of those

load, and one of 76 mm (3 in.) representing foot traffic, each

in actual service.

with a thickness of at least 13 mm (0.50 in.). The edge of the

4.2 The procedures are intended to be applied to roof or

loading disk contacting the test specimen shall be rounded to a

floor sheathing materials installed directly to framing.They are

radius not exceeding 1.5 mm (0.06 in.).

not intended for the evaluation of the framed assembly as a

whole. 5.1.4 Deflection Gage,mountedonarigidtripodwhoselegs

rest on the sheathing immediately above the framing members

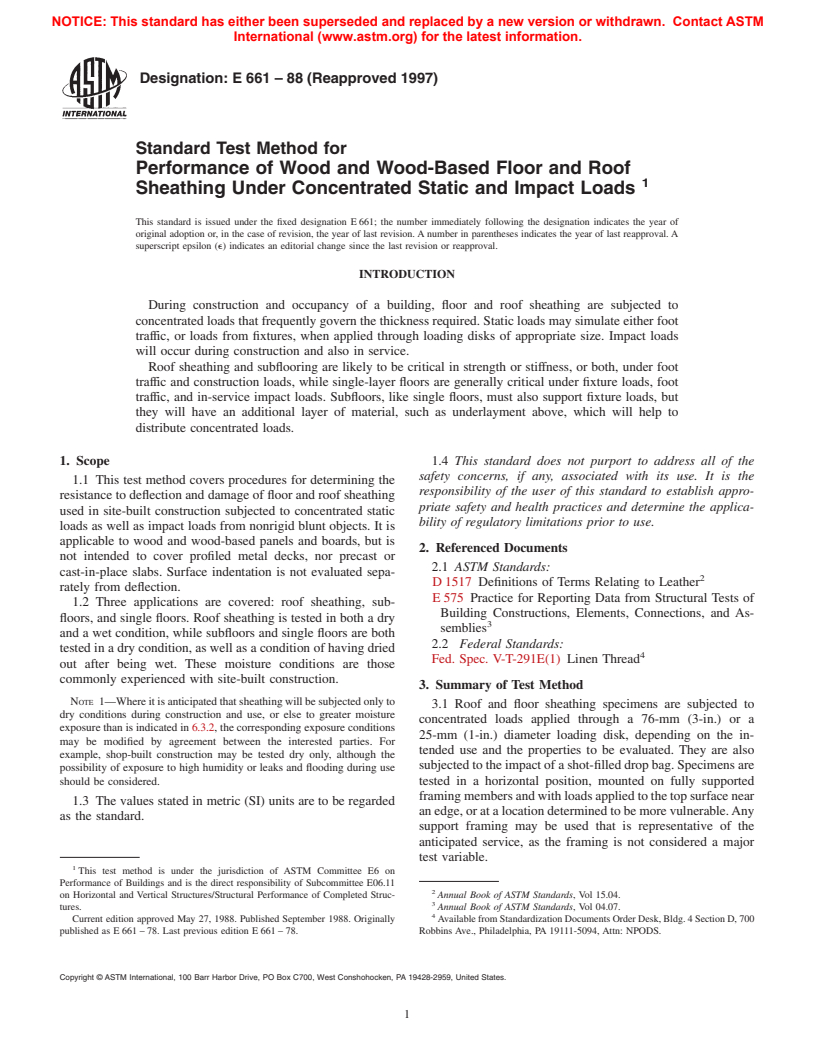

5. Apparatus that are adjacent to the load point (Fig. 1). The deflection gage

should have a range exceeding the maximum anticipated

5.1 Concentrated Load—Theapparatusfortheconcentrated

deflection, have a maximum error of 61 %, and be graduated

load test shall conform to the following requirements (see Fig.

to 0.02 mm (0.001 in.).

1):

5.2 Impact Load—The apparatus for the impact load test

5.1.1 Supports—The framing members shall be supported

shall conform to the requirements of 5.1.1-5.1.4. In addition,

in order not to deflect under the applied loads. The support

the following equipment shall be used:

system shall include provisions for rigidly restraining the ends

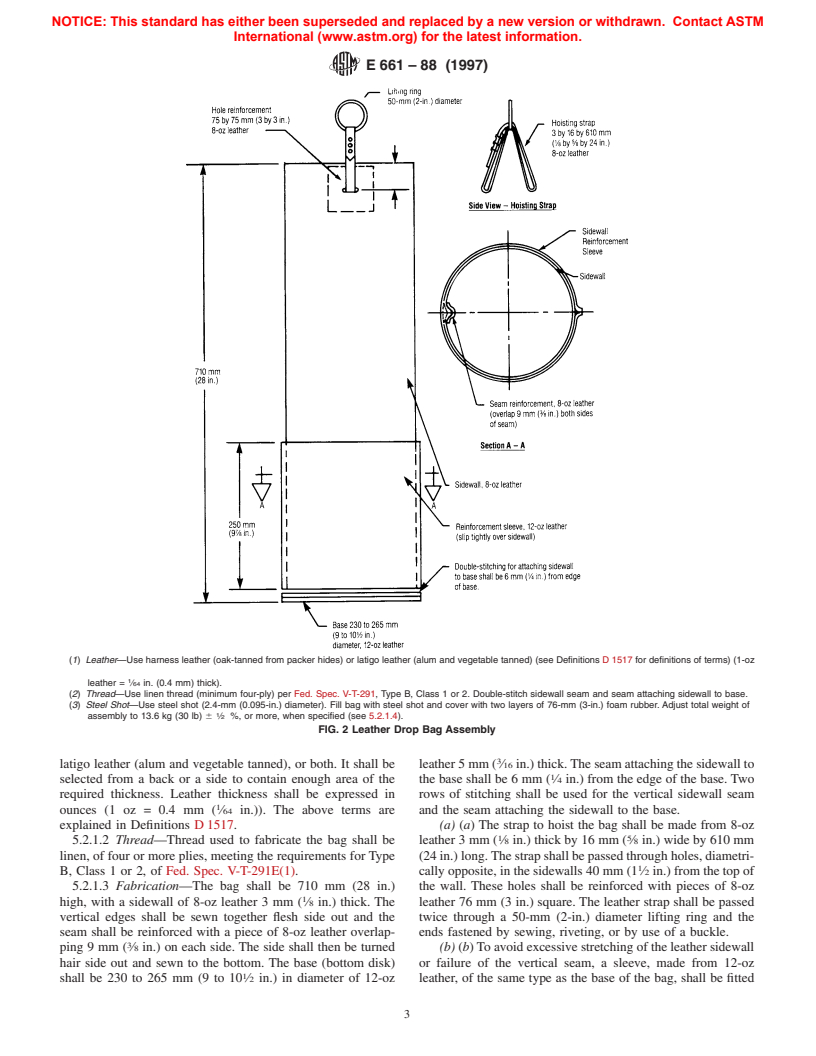

5.2.1 Drop Bag—The bag shall be constructed as in 5.2.1.1-

of the framing members, as with blocking and clamps, to

5.2.1.3 (see Fig. 2).

prevent rotation or vertical movement during testing.

5.1.2 Loading Device—Any convenient means may be used 5.2.1.1 Leather—Theleatherusedinconstructionofthebag

for applying a compressive load up to ultimate, and for shall be harness leather (oak tanned from packer hides), or

FIG. 1 Concentrated Static Load Apparatus

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E661–88 (1997)

(1) Leather—Use harness leather (oak-tanned from packer hides) or latigo leather (alum and vegetable tanned) (see Definitions D 1517 for definitions of terms) (1-oz

leather = ⁄64 in. (0.4 mm) thick).

(2) Thread—Use linen thread (minimum four-ply) per Fed. Spec. V-T-291, Type B, Class 1 or 2. Double-stitch sidewall seam and seam attaching sidewall to base.

(3) Steel Shot—Use steel shot (2.4-mm (0.095-in.) diameter). Fill bag with steel shot and cover with two layers of 76-mm (3-in.) foam rubber. Adjust total weight of

assembly to 13.6 kg (30 lb) 6 ⁄2 %, or more, when specified (see 5.2.1.4).

FIG. 2 Leather Drop Bag Assembly

latigo leather (alum and vegetable tanned), or both. It shall be leather 5 mm ( ⁄16 in.) thick.The seam attaching the sidewall to

selected from a back or a side to contain enough area of the the base shall be 6 mm ( ⁄4 in.) from the edge of the base. Two

required thickness. Leather thickness shall be expressed in rows of stitching shall be used for the vertical sidewall seam

ounces (1 oz = 0.4 mm ( ⁄64 in.)). The above terms are and the seam attaching the sidewall to the base.

explained in Definitions D 1517. (a) (a) The strap to hoist the bag shall be made from 8-oz

1 5

5.2.1.2 Thread—Thread used to fabricate the bag shall be leather 3 mm ( ⁄8 in.) thick by 16 mm ( ⁄8 in.) wide by 610 mm

linen, of four or more plies, meeting the requirements for Type (24 in.) long.The strap shall be passed through holes, diametri-

B, Class 1 or 2, of Fed. Spec. V-T-291E(1). cally opposite, in the sidewalls 40 mm (1 ⁄2 in.) from the top of

5.2.1.3 Fabrication—The bag shall be 710 mm (28 in.) the wall. These holes shall be reinforced with pieces of 8-oz

high, with a sidewall of 8-oz leather 3 mm ( ⁄8 in.) thick. The leather 76 mm (3 in.) square. The leather strap shall be passed

vertical edges shall be sewn together flesh side out and the twice through a 50-mm (2-in.) diameter lifting ring and the

seam shall be reinforced with a piece of 8-oz leather overlap- ends fastened by sewing, riveting, or by use of a buckle.

ping 9 mm ( ⁄8 in.) on each side. The side shall then be turned (b) (b)To avoid excessive stretching of the leather sidewall

hair side out and sewn to the bottom. The base (bottom disk) or failure of the vertical seam, a sleeve, made from 12-oz

shall be 230 to 265 mm (9 to 10 ⁄2 in.) in diameter of 12-oz leather, of the same type as the base of the bag, shall be fitted

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E661–88 (1997)

to slip tightly over the lower portion of the bag. This sleeve redried condition after exposure to wet conditions, in accor-

should be 250 mm (9 ⁄8 in.) high. dance with 6.3.1 and 6.3.3. This sheathing may also be tested

5.2.1.4 Shot—The bag shall be loosely filled with steel shot under wet conditions in accordance with 6.3.2 (see Note 1).

approximately 2.4 mm (0.094 in.) in diameter. Two layers of 6.3.1 Dry Tests—Condition sheathing to either constant

76-mm (3-in.) thick foam rubber or similar padding shall be weight or moisture content or for at least 2 weeks, at 20 6 3°C

placed over the steel shot to prevent spillage during testing. (68 6 6°F) and 65 6 5 % relative humidity.

Adjust the total weight of the drop bag and steel shot to the 6.3.2 Wet Tests—Expose sheathing to a continuous water

weight specified in Table 1, 6 ⁄2 %. This value shall be spray for 3 days, applied to the top surface of the sheathing at

verified before impact tests are conducted. For spans greater a rate such as to keep this surface continuously wet. Position

than 1220 mm (48 in.), the weight of the drop bag shall be as the sheathing so as to preclude water ponding on it, or

agreed upon between the interested parties. immersion of any portion.

5.2.2 Measuring Rod—A measuring rod, graduated in

NOTE 3—Asimplified spray tank may be used to support the sheathing

152-mm(6-in.)incrementsandequippedwithaslidingpointer,

in an approximately vertical position during exposure to the water spray.

shall be used to measure the drop height of the bag.

The tank should be fitted with drains so that water spray does not

accumulate, and the sheathing should be placed on blocks to elevate its

6. Test Specimens lower edge above the residual water in the tank bottom.

6.1 Select specimens that are representative of the product

6.3.3 Redried Tests—Expose sheathing to the 3-day water

beingevaluated,bothinaccordancewiththeinherentstructural

spray in accordance with 6.3.2 and then dry in accordance with

properties, including density, and in accordance with the

6.3.1.

thicknessandthicknesstolerancescharacteristicoftheproduct.

6.4 Fabrication of Test Specimens—Install the conditioned

Unless otherwise specified, the number of tests shall be such as

sheathing on framing as shown in Figs. 3 and 4, using the type

to develop the desired confidence level for each property

of framing, fastener schedule, and installation details as

measured, but conduct at least ten tests as a minimum for each

planned for use in service; consider this a part of the test

test condition evaluated.

conditions. After fabrication, test specimens promptly at am-

bient laboratory conditions.

NOTE 2—A specimen can usually be made from a single panel, or

assembled from a number of boards (see Figs. 3 and 4).

NOTE 4—Where sheathing is installed on wood framing, the framing

may be of any species and grade commonly used in construction that has

6.2 Specimen Size:

a specific gravity of 0.40 to 0.55, oven-dry basis, with a maximum

6.2.1 Length—The specimen length perpendicular to the

moisture content of 19 %. If nails are used, they may be double-headed to

main framing members shall conform to the center-to-center

simplify disassembly of the specimen upon completion of testing, provid-

spacing, S, anticipated in service (Figs. 3 and 4). Where

ing such nails will not damage the testing equipment. Framing may be

sheathing is continuous over more than one span, its length

reused for more than one test, provided it has not been significantly

shall be equal to the minimum number of spans permitted or

damaged by previous testing.

recommended for the product used and its intended applica-

7. Procedure

tion, multiplied by the center-to-center spacing of the framing

members.

7.1 Concentrated Static Load Tests—Apply the concen-

6.2.2 Width—The specimen width shall be at least 595 mm

trated static load at one location on the top surface of the

(23 ⁄2 in.). The specimen width shall conform to its nominal

sheathing, midway between framing members (see Fig. 3).

width when edges are fully supported. When edges are

7.1.1 If the edge of the sheathing is fully supported between

unsupported or partially supported, sheathing may be trimmed

main framing members, apply the concentrated load at mid-

to a width not less than 595 mm (23 ⁄2 in.).

width. If the edge is unsupported, or partially supported, as

6.2.3 Thickness—Measure thickness of all sheathing speci-

with clips or a tongue and groove joint, apply the load 65 mm

mens after conditioning in accordance with 6.3.1 and report.

(2 ⁄2 in.) in from the unsupported or partially supported edge as

6.2.4 Cut the sheathing to the required size prior to condi-

shown in Fig. 3.

tioning.

7.1.2 Specimens may be used for more than one test

6.3 Conditioning of Sheathing—Prior to static and impact

provided the test locations are at least 455 mm (18 in.) apart

testing, subject sheathing to wetting and drying to simulate

(measuredpara

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.