ASTM C1460-20

(Specification)Standard Specification for Shielded Transition Couplings for Use with Dissimilar DWV Pipe and Fittings Above Ground

Standard Specification for Shielded Transition Couplings for Use with Dissimilar DWV Pipe and Fittings Above Ground

ABSTRACT

This specification deals with the performance of shielded transition couplings to join dissimilar DWV pipe and fittings above ground. All steel parts made from round stock shall be 300 series stainless steel. The elastomeric gasket shall consist of one piece and shall have an inside center stop-ring spaced equal distance from the ends. The clamp assembly shall be tested to withstand the stated installation torque. The following shall also be done: deflection test, shear test, and unrestrained hydrostatic joint test.

SCOPE

1.1 This specification covers the performance of shielded transition couplings to join dissimilar DWV pipe and fittings above ground up to and including 15-in. pipe and fittings. This standard is intended to cover reducing couplings used to join pipes and fittings of different sizes, materials, and different outside diameters.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.4 The following precaution comment pertains only to the test method portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1460 −20

Standard Specification for

Shielded Transition Couplings for Use with Dissimilar DWV

1

Pipe and Fittings Above Ground

This standard is issued under the fixed designation C1460; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A644 Terminology Relating to Iron Castings

C564 Specification for Rubber Gaskets for Cast Iron Soil

1.1 This specification covers the performance of shielded

Pipe and Fittings

transition couplings to join dissimilar DWV pipe and fittings

above ground up to and including 15-in. pipe and fittings. This

3. Terminology

standard is intended to cover reducing couplings used to join

3.1 Definitions—The following definitions used in this

pipes and fittings of different sizes, materials, and different

specification are found in Terminology A644: elastomeric,

outside diameters.

thermoset, and thermoplastic.

1.2 The values stated in inch-pound units are to be regarded

3.2 Definitions of Terms Specific to This Standard:

as standard. The values given in parentheses are mathematical

3.2.1 center stop, n—an integral part of the gasket centered

conversions to SI units that are provided for information only

on the axial length of the gasket intended to limit the insertion

and are not considered standard.

depth of the pipe to be coupled.

1.3 Thecommitteewithjurisdictionoverthisstandardisnot

3.2.2 clamp assembly, n—that portion of the coupling ex-

aware of any comparable standards published by other orga-

cluding the gasket.

nizations.

3.2.3 coupling, n—the complete assembly.

1.4 The following precaution comment pertains only to the

test method portion, Section 7, of this specification. This 3.2.4 dissimilar DWV pipe and fittings, n—pipe and fittings

made of different materials or different outside diameters, or

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user both.

of this standard to establish appropriate safety, health, and

3.2.5 fitting, n—parts of a pipeline other than straight pipes,

environmental practices and determine the applicability of

valves, or couplings.

regulatory limitations prior to use.

3.2.6 gasket, n—the elastomeric portion of the coupling.

1.5 This international standard was developed in accor-

3.2.7 joint, n—the point of assembly consisting of the

dance with internationally recognized principles on standard-

coupling and the joined pipes or fittings, or both.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 3.2.8 shield, n—an external metallic protective device de-

mendations issued by the World Trade Organization Technical signed to protect the sealing gasket from external elements that

Barriers to Trade (TBT) Committee. could cause failure of the sealing assembly.

4. Materials and Manufacture

2. Referenced Documents

2

4.1 Physical properties of gaskets shall be in accordance

2.1 ASTM Standards:

with Table 1 of Specification C564, using the durometer

A493 Specification for Stainless Steel Wire and Wire Rods

hardness column as specified by the manufacturer.

for Cold Heading and Cold Forging

4.2 Allsteelpartsmadefromroundstockshallbe300series

stainless steel and shall conform to the requirements of

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron

Specification A493 (excluding copper-bearing alloys).

Castings.

Current edition approved Nov. 1, 2020. Published December 2020. Originally

5. Elastomeric Gasket Requirements

approved in 2000. Last previous edition approved in 2017 as C1460 – 17. DOI:

10.1520/C1460-20.

5.1 The elastomeric gasket shall consist of one piece in

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

accordance with the physical requirements of 4.1.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.1 The elastomeric gasket shall have an inside center

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. stop-ring spaced equal distance from the ends to serve as a stop

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1460−20

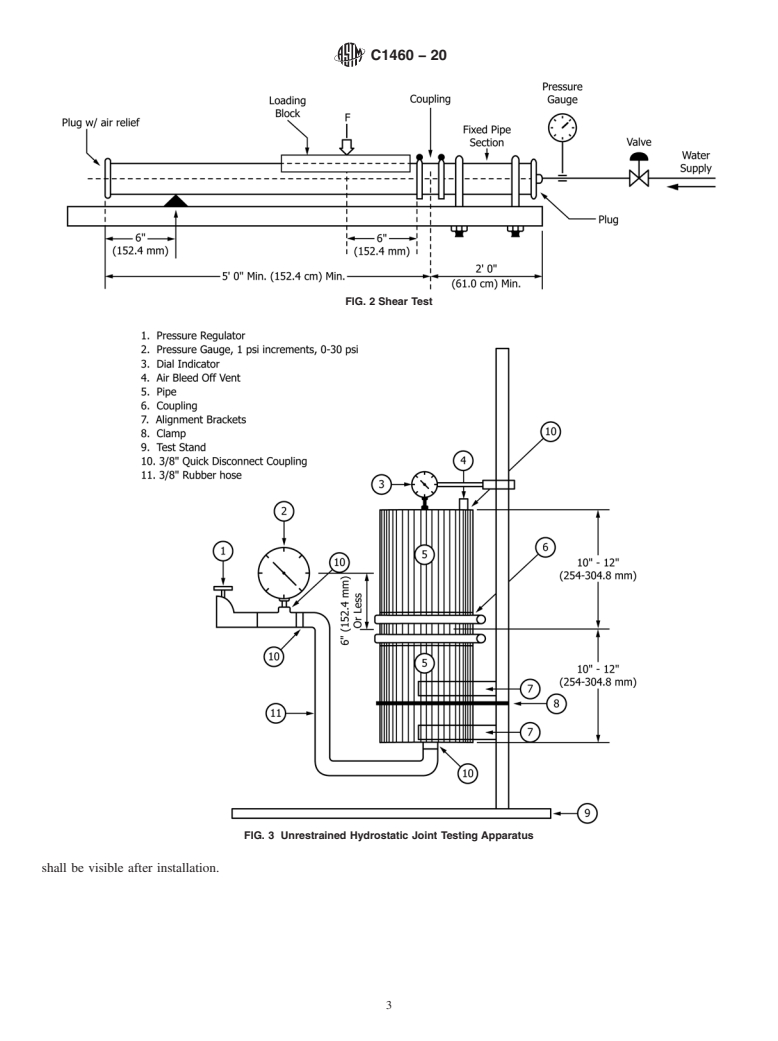

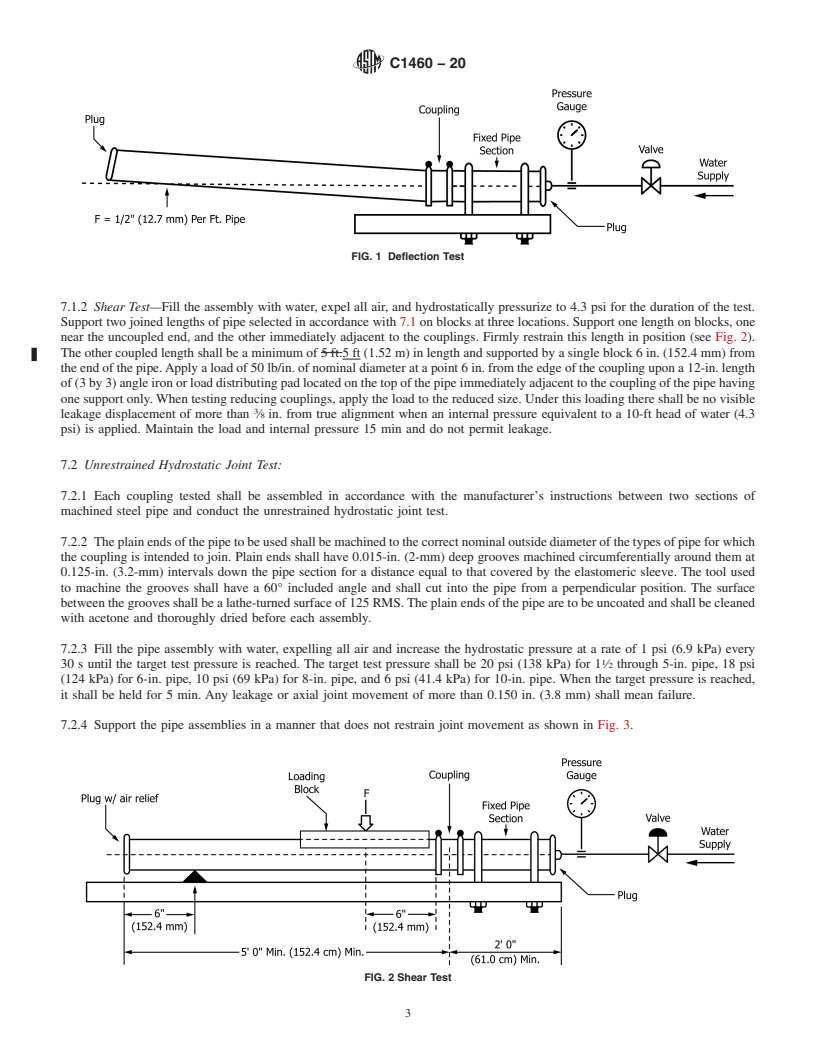

between the pipe/fitting ends that does not create an enlarge- adjacent to the coupling of the pipe having one support only.

ment chamber or recess with a ledge, shoulder, or reduction of When testing reducing couplings, apply the load to the reduced

pipe area or offer an obstruction to flow. A gasket without an size. Under this loading

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1460 − 17 C1460 − 20

Standard Specification for

Shielded Transition Couplings for Use with Dissimilar DWV

1

Pipe and Fittings Above Ground

This standard is issued under the fixed designation C1460; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the performance of shielded transition couplings to join dissimilar DWV pipe and fittings above

ground up to and including 10-in.15-in. pipe and fittings. This standard is intended to cover reducing couplings used to join pipes

and fittings of different sizes, materials, and different outside diameters.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.4 The following precaution comment pertains only to the test method portion, Section 7, of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A493 Specification for Stainless Steel Wire and Wire Rods for Cold Heading and Cold Forging

A644 Terminology Relating to Iron Castings

C564 Specification for Rubber Gaskets for Cast Iron Soil Pipe and Fittings

3. Terminology

3.1 Definitions—The following definitions used in this specification are found in Terminology A644: elastomeric,thermoset, and

thermoplastic.

3.2 Definitions of Terms Specific to This Standard:

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings.

Current edition approved Nov. 15, 2017Nov. 1, 2020. Published November 2017December 2020. Originally approved in 2000. Last previous edition approved in 20122017

as C1460 – 12.C1460 – 17. DOI: 10.1520/C1460-17.10.1520/C1460-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1460 − 20

3.2.1 center stop, n—an integral part of the gasket centered on the axial length of the gasket intended to limit the insertion depth

of the pipe to be coupled.

3.2.2 clamp assembly, n—that portion of the coupling excluding the gasket.

3.2.3 coupling, n—the complete assembly.

3.2.4 dissimilar DWV pipe and fittings, n—pipe and fittings made of different materials or different outside diameters, or both.

3.2.5 fitting, n—parts of a pipeline other than straight pipes, valves, or couplings.

3.2.6 gasket, n—the elastomeric portion of the coupling.

3.2.7 joint, n—the point of assembly consisting of the coupling and the joined pipes or fittings, or both.

3.2.8 shield, n—an external metallic protective device designed to protect the sealing gasket from external elements that could

cause failure of the sealing assembly.

4. Materials and Manufacture

4.1 Physical properties of gaskets shall be in accordance with Table 1 of Specification C564, using the durometer hardness column

as specified by the manufacturer.

4.2 All steel parts made from round stock shall be 300 series stainless steel and shall conform to the requirements of Specification

A493 (excluding copper bearing copper-bearing alloys).

5. Elastomeric Gasket Requirements

5.1 The elastomeric gasket shall consist of one piece in accordance with the physical requirements of 4.1.

5.1.1 The elastomeric gasket shall have an inside center stop-ring spaced equal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.