ASTM D3322-82(2001)

(Practice)Standard Practice for Testing Primers and Primer Surfacers Over Preformed Metal

Standard Practice for Testing Primers and Primer Surfacers Over Preformed Metal

SCOPE

1.1 This practice covers the selection and use of procedures for testing primers and primer surfacers. The test methods included are listed in Table 1.

1.2 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3322–82 (Reapproved2001)

Standard Practice for

Testing Primers and Primer Surfacers Over Preformed

Metal

This standard is issued under the fixed designation D 3322; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

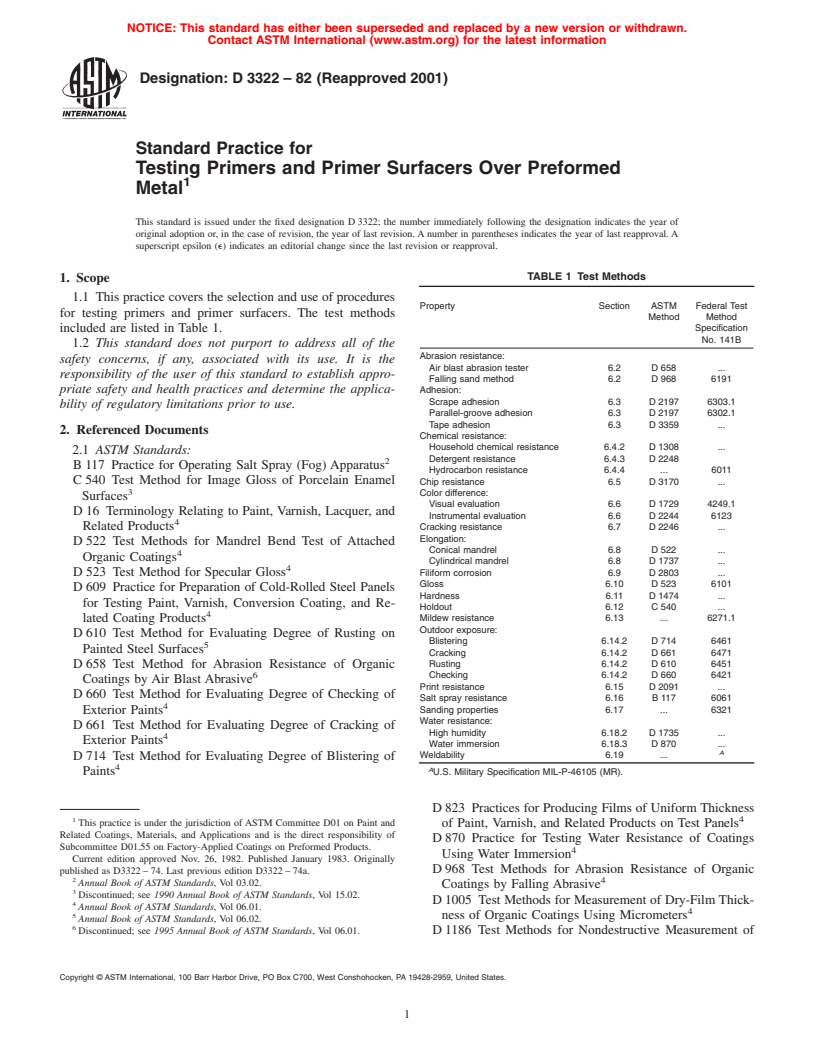

TABLE 1 Test Methods

1. Scope

1.1 This practice covers the selection and use of procedures

Property Section ASTM Federal Test

for testing primers and primer surfacers. The test methods

Method Method

included are listed in Table 1. Specification

No. 141B

1.2 This standard does not purport to address all of the

Abrasion resistance:

safety concerns, if any, associated with its use. It is the

Air blast abrasion tester 6.2 D 658 .

responsibility of the user of this standard to establish appro-

Falling sand method 6.2 D 968 6191

priate safety and health practices and determine the applica- Adhesion:

Scrape adhesion 6.3 D 2197 6303.1

bility of regulatory limitations prior to use.

Parallel-groove adhesion 6.3 D 2197 6302.1

Tape adhesion 6.3 D 3359 .

2. Referenced Documents

Chemical resistance:

Household chemical resistance 6.4.2 D 1308 .

2.1 ASTM Standards:

Detergent resistance 6.4.3 D 2248

B 117 Practice for Operating Salt Spray (Fog) Apparatus

Hydrocarbon resistance 6.4.4 . 6011

C 540 Test Method for Image Gloss of Porcelain Enamel Chip resistance 6.5 D 3170 .

Color difference:

Surfaces

Visual evaluation 6.6 D 1729 4249.1

D 16 Terminology Relating to Paint, Varnish, Lacquer, and

Instrumental evaluation 6.6 D 2244 6123

Related Products Cracking resistance 6.7 D 2246 .

Elongation:

D 522 Test Methods for Mandrel Bend Test of Attached

Conical mandrel 6.8 D 522 .

Organic Coatings

Cylindrical mandrel 6.8 D 1737 .

Filiform corrosion 6.9 D 2803 .

D 523 Test Method for Specular Gloss

Gloss 6.10 D 523 6101

D 609 Practice for Preparation of Cold-Rolled Steel Panels

Hardness 6.11 D 1474 .

for Testing Paint, Varnish, Conversion Coating, and Re-

Holdout 6.12 C 540 .

lated Coating Products Mildew resistance 6.13 . 6271.1

Outdoor exposure:

D 610 Test Method for Evaluating Degree of Rusting on

Blistering 6.14.2 D 714 6461

Painted Steel Surfaces

Cracking 6.14.2 D 661 6471

D 658 Test Method for Abrasion Resistance of Organic Rusting 6.14.2 D 610 6451

6 Checking 6.14.2 D 660 6421

Coatings by Air Blast Abrasive

Print resistance 6.15 D 2091 .

D 660 Test Method for Evaluating Degree of Checking of

Salt spray resistance 6.16 B 117 6061

Sanding properties 6.17 . 6321

Exterior Paints

Water resistance:

D 661 Test Method for Evaluating Degree of Cracking of

High humidity 6.18.2 D 1735 .

Exterior Paints

Water immersion 6.18.3 D 870 .

A

Weldability 6.19 .

D 714 Test Method for Evaluating Degree of Blistering of

A

Paints U.S. Military Specification MIL-P-46105 (MR).

D 823 Practices for Producing Films of Uniform Thickness

1 4

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

of Paint, Varnish, and Related Products on Test Panels

Related Coatings, Materials, and Applications and is the direct responsibility of

D 870 Practice for Testing Water Resistance of Coatings

Subcommittee D01.55 on Factory-Applied Coatings on Preformed Products.

Using Water Immersion

Current edition approved Nov. 26, 1982. Published January 1983. Originally

D 968 Test Methods for Abrasion Resistance of Organic

published as D3322 – 74. Last previous edition D3322 – 74a.

Annual Book of ASTM Standards, Vol 03.02.

Coatings by Falling Abrasive

Discontinued; see 1990 Annual Book of ASTM Standards, Vol 15.02.

D 1005 Test Methods for Measurement of Dry-Film Thick-

Annual Book of ASTM Standards, Vol 06.01.

ness of Organic Coatings Using Micrometers

Annual Book of ASTM Standards, Vol 06.02.

Discontinued; see 1995 Annual Book of ASTM Standards, Vol 06.01. D 1186 Test Methods for Nondestructive Measurement of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3322

Dry Film Thickness of Nonmagnetic Coatings Applied to 141B/6321 Sanding Characteristics

a Ferrous Base 2.3 U.S. Military Specification:

D 1308 Test Method for Effect of Household Chemicals on MIL-P-46105

Clear and Pigmented Organic Finishes

3. Terminology

D 1400 Test Method for Nondestructive Measurement of

3.1 Definitions:

DryFilmThicknessofNonconductiveCoatingsAppliedto

a Nonferrous Metal Base 3.1.1 primer—the first of two or more coats of paint,

varnish, or lacquer system (same as in Terminology D 16).

D 1474 Test Methods for Indentation Hardness of Organic

Coatings 3.1.2 primer surfacer—a pigmented coating for filling mi-

nor irregularities which is sanded to obtain a smooth uniform

D 1640 Test Methods for Drying, Curing, or Film Forma-

tion of Organic Coatings at Room Temperature surface preparatory to applying finish coats. A primer surfacer

is not usually applied over a primer.

D 1729 Practice for Visual Appraisal of Colors and Color

Differences of Diffusely Illuminated Opaque Materials

4. Significance and Use

D 1730 Practices for Preparation of Aluminum and

4.1 Primers and primer surfacers may be used over many

Aluminum-Alloy Surfaces for Painting

different surfaces top coated with one or more of a variety of

D 1731 Practices for Preparation of Hot-Dip Aluminum

coatings and subjected to many kinds of wear and exposure.

Surfaces for Painting

4.2 The selection of the tests to be used for any given

D 1732 Practices for Preparation of Magnesium Alloy Sur-

product or system must be governed by experience and by the

faces for Painting

requirement agreed upon between the producer and the user.

D 1733 Method of Preparation of Aluminum Alloy Panels

for Testing Paint, Varnish, Lacquer, and Related Products

5. Panel Preparation

D 1735 Practice for Testing Water Resistance of Coatings

5.1 Treatment of Substrate—Preparation of test panels

Using Water Fog Apparatus

shouldincludeanycleaningtreatmentagreeduponbetweenthe

D 1737 Test Method for Elongation of Attached Organic

purchaser and the seller or one of the following ASTM

Coatings with Cylindrical Mandrel Apparatus

Practices: D609, D1730, D1731, D1732, D2201; Guide

D 2091 Test Method for Print Resistance of Lacquers

D 2092; and Method D 1733.

D 2092 Guide for Treatment of Zinc-Coated (Galvanized)

5.2 Substrate, Film Thickness, and Application Means—

Steel Surfaces for Painting

Conduct performance tests on the specified substrate on

D 2197 Test Methods for Adhesion of Organic Coatings by

coatings having a film thickness agreed upon between the

Scrape Adhesion

purchaser and the seller. Primers are generally applied to a dry

D 2201 Practice for Preparation of Zinc–Coated and Zin-

film thickness of 0.3 to 1.5 mil (8 to 38 µm) and primer

c–Alloy–Coated Steel Panels forTesting Paint and Related

surfacers to film thickness of 0.7 to 2.0 mil (17 to 50 µm).

Coating Products

Unless otherwise agreed upon, apply primers and primer

D 2244 Test Method for Calculation of Color Differences

surfacers in accordance with Practices D 823.

from Instrumentally Measured Color Coordinates

5.3 Measurement of Film Thickness—Since the properties

D 2246 Test Method for Finishes on Primed Metallic Sub-

of the primer or primer surfacer can vary considerably with the

strates for Humidity-Thermal Cycle Cracking

thickness of the coating, it is important to know the film

D 2248 Practice for Detergent Resistance of Organic Fin-

thickness. Measure the film thickness in accordance with Test

ishes

Methods D 1400, D 1005, or D 1186.

D 2454 Practice for Determining the Effect of Overbaking

5.4 Drying of Primer or Primer Surfacer:

on Organic Coatings

5.4.1 Before tests are run, air dry or bake the primer or

D 2803 Guide for Filiform Corrosion Resistance of Organic

primer surfacer according to the schedule and temperature and

Coatings on Metal

age as agreed upon between the purchaser and the seller.

D 3170 Test Method for Chipping Resistance of Coatings

5.4.2 Overbake the primer or primer surfacer to determine

D 3359 Test Methods for Measuring Adhesion by Tape

the time/temperature effect on the physical and chemical

Test

properties. Do this in accordance with Practice D 2454.

D 3456 Practice for Determining by Exterior Exposure

5.4.3 It may be desirable for some reason (handling, stack-

Tests the Susceptibility of Paint Films to Microbiological

ing, etc.) to determine the various stages and rates of film

Attack

formation in the drying or curing of primers and primer

2.2 Federal Test Methods:

surfacers at room temperatures. Do this as described in Test

141B/6011 Immersion Resistance

Method D 1640.

141B/6271.1 Mildew Resistance

6. Physical Properties of The Dry Film

6.1 Primers and primer surfacers are usually (but not al-

Annual Book of ASTM Standards, Vol 02.05.

Discontinued; see 1980 Annual Book of ASTM Standards, Part 27.

ways) topcoated.Therefore, many of the following tests should

Discontinued; see 1988 Annual Book of ASTM Standards, Vol 06.01.

be run on the complete system (substrate/primer or primer

Discontinued; see 1991 Annual Book of ASTM Standards, Vol 06.01.

surfacer/topcoat). Some of the tests however are for the

Available from Standardization Documents Order Desk, Bldg. 4 Section D,

700 Robbins Ave., Philadelphia, PA 19111-5094. untopcoated primer or primer surfacer. The properties required

D3322

of a primer or primer surfacer depend on the intended end use topcoat, a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.