ASTM F30-96(2002)

(Specification)Standard Specification for Iron-Nickel Sealing Alloys

Standard Specification for Iron-Nickel Sealing Alloys

ABSTRACT

This specification covers the characteristics and requirements for iron-nickel alloys intended primarily for sealing to glass in electronic applications. The alloys shall conform to chemical composition, surface finish, temper, grain size, and thermal expansion requirements as stated herein.

SCOPE

1.1 This specification covers iron-nickel alloys that are intended primarily for sealing to glass in electronic applications.

Note 1—Some of these alloys may be used for sealing to ceramics, but this specification in its present form is not intended to cover material for metal-to-ceramic seals.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. The hazard statement pertains only to the test method sections, Sections 10 and 12.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 30 – 96 (Reapproved 2002)

Standard Specification for

Iron-Nickel Sealing Alloys

ThisstandardisissuedunderthefixeddesignationF30;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Polarimetric Methods

1.1 This specification covers iron-nickel alloys that are

3. Ordering Information

intended primarily for sealing to glass in electronic applica-

3.1 Orders for material under this specification shall include

tions.

the following information:

NOTE 1—Some of these alloys may be used for sealing to ceramics, but

3.1.1 Size,

this specification in its present form is not intended to cover material for

3.1.2 Temper (Section 6),

metal-to-ceramic seals.

3.1.3 Surface finish (Section 8),

1.2 The values stated in inch-pound units are to be regarded

3.1.4 Marking and packaging (Section 16), and

as the standard. The values given in parentheses are for

3.1.5 Certification if required.

information only.

4. Chemical Composition

1.3 This standard does not purport to address the safety

concerns, if any, associated with its use. It is the responsibility

4.1 The material shall conform to the requirements as to

of the user of this standard to establish appropriate safety and

chemical composition prescribed in Table 1.

health practices and determine the applicability of regulatory

5. Surface Lubricants

limitations prior to use. The hazard statement pertains only to

the test method sections, Sections 10 and 12.

5.1 All lubricants used in processing shall be thoroughly

removed. Protective coatings present on the material as

2. Referenced Documents

shipped shall be readily removable by any of the common

2.1 ASTM Standards:

organic degreasing solvents.

E 18 Test Methods for Rockwell Hardness and Rockwell

6. Temper

Superficial Hardness of Metallic Materials

E 29 Practice for Using Significant Digits in Test Data to

6.1 The desired temper of the material shall be specified on

Determine Conformance with Specification

the purchase order. Unless otherwise specified, wire, rod, bar,

E 112 Test Methods for Determining Average Grain Size

and tubing shall be given a final bright anneal by the manu-

E 228 Test Method for Linear Thermal Expansion of Solid

facturer. Strip and sheet shall be annealed properly to develop

Materials with a Vitreous Silica Dilatometer

deep drawing properties. For deep drawing the hardness shall

F 14 Practice for Making and Testing Reference Glass-

not exceed Rockwell B82 for material 0.100 in. (2.54 mm) and

Metal Bead-Seal

less in thickness, and B85 for material over 0.100 in. thick

F 140 Practice for Making Reference Glass-Metal Butt

when determined in accordance with Test Methods E 18.

Seals and Testing for Expansion Characteristics by Polari-

7. Grain Size

metric Methods

F 144 Practice for Making Reference Glass-Metal Sand-

7.1 Strip and sheet for deep drawing applications shall have

wich Seal and Testing for Expansion Characteristics by

an average grain size not larger thanASTM No. 5 (Note 2) and

no more than 10 % of the grains shall be larger than No. 5

when measured in accordance with Test Methods E 112. For

This specification is under the jurisdiction of ASTM Committtee F01 on

materials less than 0.005 in. (0.13 mm) in thickness the grain

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

Materials. size shall be such that there are no less than 4 grains across the

Current edition approvedJune 10, 1996, Published August 1996. Originally

thickness.

published as F 30 – 77. Last previous edition F 30 - 90.

Annual Book of ASTM Standards, Vol 03.01.

NOTE 2—This corresponds to a grain size of 0.065 mm or 16 grains/

Annual Book of ASTM Standards, Vol 14.02.

in. of image of 1003.

Annual Book of ASTM Standards, Vol 15.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 30 – 96 (2002)

TABLE 1 Chemical Requirements

10. Test for Thermal Expansion

Composition, %

10.1 Determine the thermal expansion characteristics with a

42 Alloy 46 Alloy 48 Alloy 52 Alloy

precision dilatometer after heating the specimen as follows:

UNS UNS UNS 51 Alloy UNS

10.1.1 Heat the specimen in a hydrogen atmosphere for 1 h

K94100 K94600 K94800 N14052

at 900°C and then cool it from 900 to 200°C at a rate not

A

Nickel, nominal 41 46 48 51.5 50.5

exceeding 5°C/min.

Manganese, max 0.80 0.80 0.80 0.60 0.60

Silicon, max 0.30 0.30 0.30 0.30 0.30 10.1.2 The thermal expansion properties are determined in

Carbon, max 0.05 0.05 0.05 0.05 0.05

accordance with Test Method E 228.

Chromium, max 0.25 0.25 0.25 0.25 0.25

BBBBB 10.2 The thermal expansion match between the alloy and a

Cobalt, max

Phosphorus, max 0.025 0.025 0.025 0.0250 0.025 glass may be evaluated by testing the assembly in accordance

Sulfur, max 0.025 0.025 0.025 0.0250 0.025

with Practices F 14, F 140, or F 144.

Aluminum, max 0.10 0.10 0.10 0.100 0.10

Iron remainder remainder remainder remainder remainder

11. Dimensions and Permissible Variations

A

The nickel contents listed are nominal. The nickel contents of the alloys shall

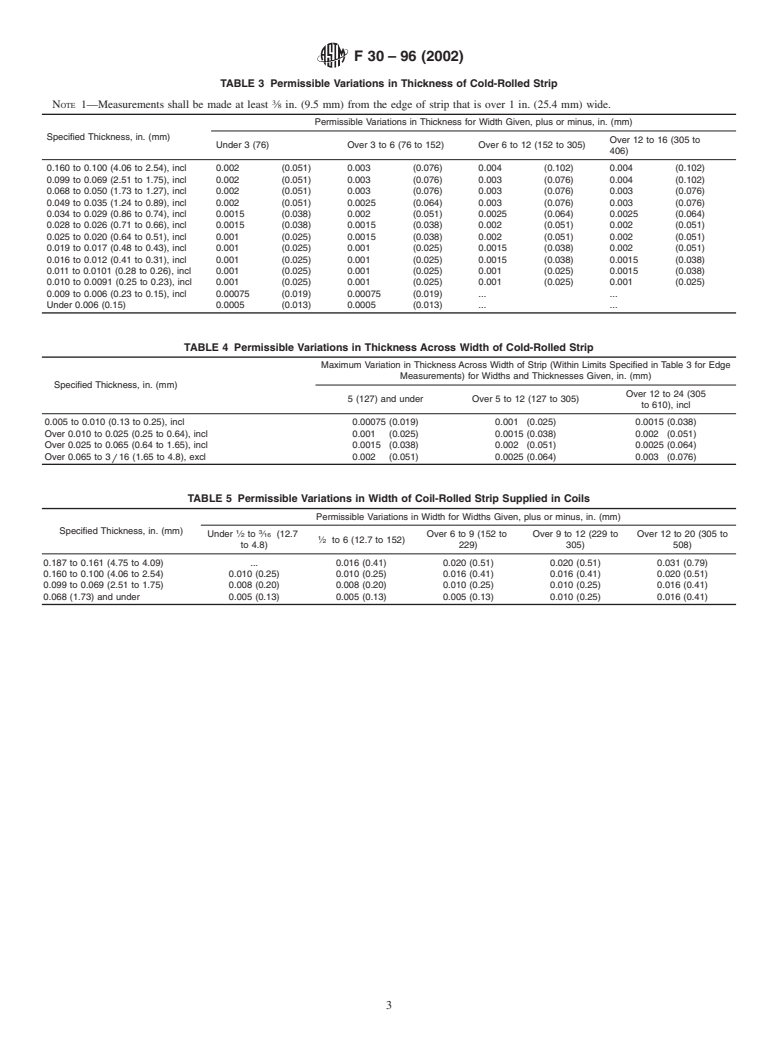

11.1 Cold-Rolled Strip—Cold-rolled strip shall conform to

be adjusted by the manufacturer so that the alloys meet the requirements for

the permissible variations in dimensions prescribed in Table 3,

thermalexpansion.The52Alloyisspecificallyintendedtomatchlead(Pb)sealing

glasses.

Table 4, and Table 5.

B

Cobalt is present as an incidental element and shall be reported separately.

11.2 Round Wire and Rod—Wire and rod shall conform to

the permissible variations in dimension prescribed in Table 6.

11.3 Cold-DrawnTubing—Cold-drawn tubing, available ei-

8. Surface Finish

ther as seamless or welded, shall conform to the permissible

8.1 The standard surface finishes available shall be those

variations prescribed in Table 7.

resulting from the following operations:

12. Rounding Results

8.1.1 Hot-rolling,

8.1.2 Forging,

12.1 Observed or calculated values obtained from analysis,

8.1.3 Centerless grinding (rod), measurements, or tests shall be rounded in accordance with

8.1.4 Belt polishing,

Practice E 29, to the nearest unit in the last right place of

8.1.5 Cold rolling, and drawing, and figures used in expressing the specified limit.

8.1.6 Wire drawing.

13. General Requirements

13.1 Thematerialshallbecommerciallysmooth,uniformin

9. Thermal Expansion Characteristics

cross section, in composition, and in temper; it shall be free

9.1 The average linear coefficients of thermal expansion

from scale, corrosion, porosity, cracks, seams, scratches, sliv-

shall be within the limits specified in Table 2.

ers, and other defects as best commercial practice will permit.

14. Packaging and Package Marking

A

TABLE 2 Thermal Expansion Requirements

14.1 Packaging shall be subject to agreement between the

Average Linear

purchaser and the seller.

Coefficient of

Temperature

14.2 The material as furnished under this specification shall

UNS Number Alloy No. Thermal

Range, °C

Expansion,µ

beidentifiedbythenameorsymbolofthemanufacturerandby

m/m·°C

melt number. The lot size for determining compliance with the

K94100 42 30

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.