ASTM F1150-88(1995)

(Specification)Standard Specification for Commercial Food Waste Pulper and Waterpress Assembly

Standard Specification for Commercial Food Waste Pulper and Waterpress Assembly

SCOPE

1.1 This specification covers commercial pulping and waterpress assemblies intended for grinding of food scraps, paper, cardboard, and disposable plastic food-service ware.

1.2 The values as stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 13, of this specification: 1.4 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1150 – 88 (Reapproved 1995)

Standard Specification for

Commercial Food Waste Pulper and Waterpress Assembly

This standard is issued under the fixed designation F 1150; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 513 Specification for Electric-Resistance-Welded Carbon

and Alloy Steel Mechanical Tubing

1.1 This specification covers commercial pulping and wa-

A 519 Specification for Seamless Carbon and Alloy Steel

terpress assemblies intended for grinding of food scraps, paper,

Mechanical Tubing

cardboard, and disposable plastic food-service ware.

A 532 Specification for Abrasion-Resistant Cast Iron

1.2 The values as stated in inch-pound units are to be

A 554 Specification for Welded Stainless Steel Mechanical

regarded as the standard. The values in parentheses are given

Tubing

for information only.

A 582 Specification for Free Machining Stainless and Heat-

1.3 The following safety hazards caveat pertains only to the

Resisting Steel Bars; Hot-Rolled or Cold-Finished

test method portion, Section 13, of this specification:

A 681 Specification for Alloy Tool Steels

1.4 This standard does not purport to address all of the

B 43 Specification for Seamless Red Brass Pipe, Standard

safety concerns, if any, associated with its use. It is the

Sizes

responsibility of the user of this standard to establish appro-

B 75 Specification for Seamless Copper Tube

priate safety and health practices and determine the applica-

D 2000 Classification System for Rubber Products in Auto-

bility of regulatory limitations prior to use.

motive Applications

2. Referenced Documents D 2287 Specification for NonRigid Vinyl Chloride Polymer

and Copolymer Molding and Extrusion Compounds

2.1 ASTM Standards:

D 3915 Specification for Poly(Vinyl Chloride) (PVC) and

A 6 Specification for General Requirements for Rolled

Related Plastic Pipe and Fitting Compounds

Steel Plates, Shapes, Sheet Piling, and Bars for Structural

D 3951 Practice for Commercial Packaging

Use

E 674 Specification for Industrial Perforated Plate and

A 29 Specification for General Requirements for Steel Bars,

Screens (Round Opening Series)

Carbon and Alloy, Hot-Wrought and Cold-Finished

F 104 Classification System for NonMetallic Gasket Mate-

A 120 Specification for Pipe, Steel, Black and Hot-Dipped,

rials

Zinc-Coated (Galvanized), Welded and Seamless, for Or-

F 437 Specification for Threaded Chlorinated Poly(Vinyl

dinary Uses

Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80

A 126 Specification for Gray Iron Castings for Valves,

F 439 Specifications for Socket-Type Chlorinated Poly(Vi-

Flanges, and Pipe Fittings

nyl Chloride) (CPVC) Plastic Pipe Fittings (Schedule 80)

A 167 Specification for Stainless and Heat-Resisting

F 441 Specification for Chlorinated Poly(Vinyl Chloride)

Chromium-Nickel Steel Plate, Sheet, and Strip

(CPVC) Plastic Pipe, Schedules 40 and 80

A 269 Specification for Seamless and Welded Austenitic

F 442 Specification for Chlorinated Poly(Vinyl Chloride)

Stainless Steel Tubing for General Service

(CPVC) Plastic Pipe, (SDR-PR)

A 276 Specification for Stainless Steel and Heat-Resisting

F 443 Specification for Bell-End Chlorinated Poly(Vinyl

Steel Bars and Shapes

Chloride) (CPVC) Pipe, Schedule 40

A 436 Specification for Austenitic Gray Iron Castings

2.2 Underwriters Laboratory Standards:

A 505 Specification for General Requirements for Steel and

UL 430 Waste Disposers

Strip, Alloy, Hot-Rolled and Cold-Rolled

Annual Book of ASTM Standards, Vol 02.01.

This specification is under the jurisdiction of ASTM Committee F-26 on Food

Annual Book of ASTM Standards, Vol 09.01.

Service Equipment and is the direct responsibility of Subcommittee F26.04 on

Annual Book of ASTM Standards, Vol 08.02.

Mechanical Preparation Equipment.

Annual Book of ASTM Standards, Vol 08.04.

Current edition approved July 25, 1988. Published September 1988.

2 12

Annual Book of ASTM Standards, Vol 01.04. Annual Book of ASTM Standards, Vol 15.09.

3 13

Annual Book of ASTM Standards, Vol 01.05. Annual Book of ASTM Standards, Vol 14.02.

4 14

Discontinued. See Annual Book of ASTM Standards, Vol 01.01. Annual Book of ASTM Standards, Vol 09.02.

5 15

Annual Book of ASTM Standards, Vol 01.02. Annual Book of ASTM Standards, Vol 08.04.

6 16

Annual Book of ASTM Standards, Vol 01.03. Available from Underwriters Laboratories, Inc., 333 Pfingsten Road, North-

Annual Book of ASTM Standards, Vol 01.01. brook, IL 60062.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1150

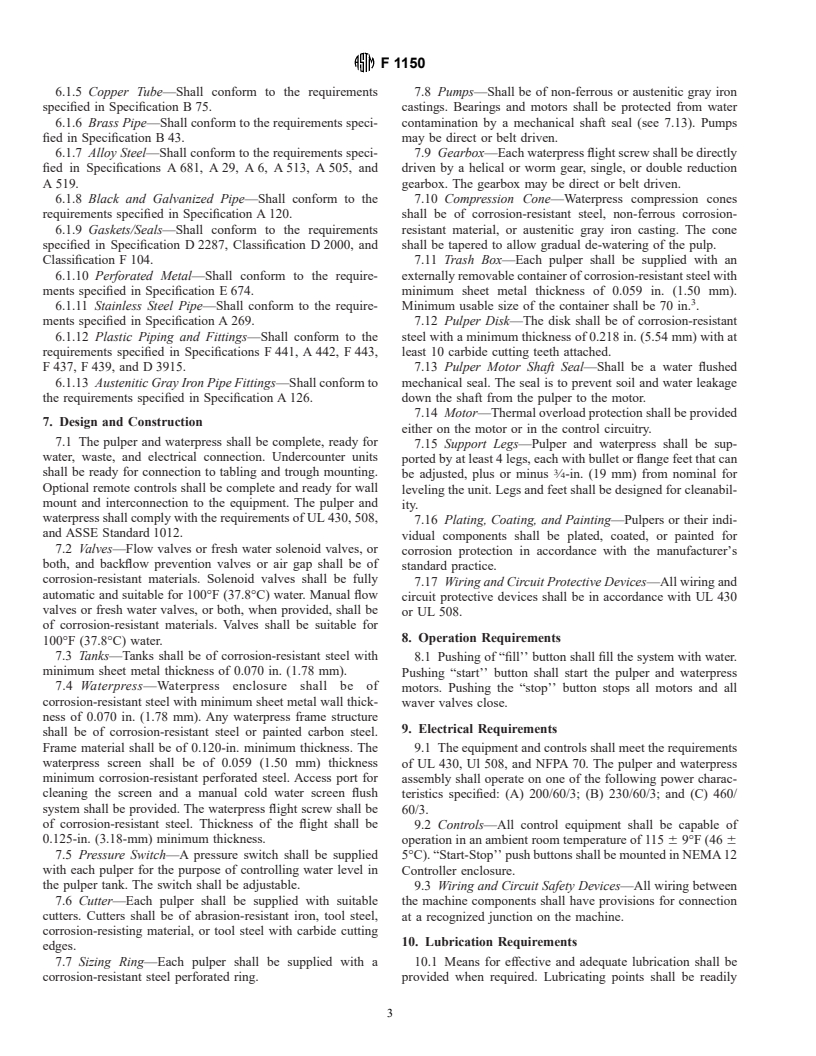

TABLE 1 Type, Size, and Options

UL 508 Electrical Industrial Control Equipment

2.3 National Fire Protection Agency Standard: Type Pulper with Waterpress A B

Size Pulper Diameter

NFPA No. 70 National Electric Code

24 30 24 30

Options Inches—Maximum

2.4 Other Publication:

Pulper Motor HP 5 7.5 5 7.5

ASSE Standard No. 1012 Backflow Preventers with Inter- Waterpress Motor HP 2 3 2 3

1 Automatic Shutdown Timer 3 3 3 3

mediate Atmospheric Vent

2 18 In. Higher than Standard

Waterpress 3 3 3 3

3. Terminology

3 Tray Flush (Recirculated

Water) 3 3 3 3

3.1 General—Commercial pulpers with waterpresses are

4 Trough Flush (Recirculated) 2 2 3 3

intended for grinding food waste, food service paper and

5 Single Feed Through

Connection 2 2 3 3

cardboard products, food service plastic products, documents

6 Double Feed Through

including computer printouts, general office and retail store

Connection 2 2 3 3

paper, and cardboard waste. Materials are ground in a water-

7 Feed Hood with Tray 4 4 3 3

filled tank (pulper) to produce a slurry which is then passed to

(1) Pulper cover plate supplied in lieu of feed hood.

the waterpress to be de-watered. Pulpers are not intended to be

(2) Pulper and waterpress type not compatible with optional feature.

(3) Indicates available option for given type pulper with waterpress.

used for grinding glass, china, metal, wood, clam, or oyster

(4) Standard for Type A.

shells. Any small pieces of metal inadvertently placed in the

pulper, such as cardboard box staples, aluminum refreshment 5.1.2 Classification of size and type (see Section 4).

cans, or tin food cans, shall be removable from the outside of

5.1.3 Electrical power supply voltage range (see 9.1).

the pulper tank. 5.1.4 Electrical controls when specified to be remote from

3.2 Definitions of Terms Specific to This Standard:

the unit (see 9.3).

3.2.1 pulper—the pulper tank has a motor driven grinding 5.1.5 Optional automatic shutdown timer when specified

disk to grind and cut waste material, and mixes this material

(see Section 4).

with water to produce a slurry that is pumped to the waterpress 5.1.6 Spare and maintenance parts required.

through a sizing screen. Pulpers may consist of the following

5.1.7 Optional tray flush uses recycled water from the

principle parts: tank, motor, grinding disk, particle sizing ring, waterpress when specified (see Section 4).

trash box, legs, feed chute, stationary, and rotating cutters.

5.1.8 Optional waterpress for high profile pulp discharge 18

3.3 waterpress—the waterpress de-waters the slurry gener- in. above standard height optional when specified (see Section

ated in the pulper by use of a tapered compression cone and

4).

perforated screen, then discharges the pulp down a chute to a 5.1.9 Optional trough flush when specified (see Section 4).

waste container. Water removed during this process is pumped

5.1.10 Optional single feed trough connections on when

to the pulper tank in order to conserve fresh water use.

specified (see Section 4).

Waterpresses may consist of the following parts: shell, helical

5.1.11 Optional double feed trough connections when speci-

transport screw, perforated screen, gearbox, motor, compres-

fied (see Section 4).

sion cone, discharge housing, chute, and pump.

5.1.12 Optional feed hood with tray for Type B (see Section

4).

4. Classification

5.1.13 Designate special features required for installation,

such as location of controls, location of feed-hood and trough

4.1 General—Pulper and waterpress assemblies shall be of

openings, waterpress discharge location, and location for cold

the following type, size, and options as specified.

water and drain connections.

4.2 Type, Size, and Options (See Table 1):

4.2.1 Type A—Free-standing pulper and waterpress assem-

6. Materials

bly with tray assembly and flanged feet.

6.1 Unless otherwise specified, pulpers and waterpresses

4.2.2 Type B—Undercounter pulper for 34-in. (86-cm) high

shall be fabricated of materials specified in documents refer-

counter and waterpress with feed hood and bullet feet.

enced in Section 2. Materials used shall be free from defects

4.3 All equipment of the same model designation and

which would adversely affect the performance or maintainabil-

options on the same purchase order shall have component

ity of individual components or the overall assembly. Unit shall

interchangeability for serviceability.

be manufactured for cleanability.

6.1.1 Corrosion-Resistant Steel—Shall conform to the re-

5. Ordering Information

quirements of any 300 series steel specified in Specification

5.1 Purchasers should select the preferred options permitted

A 167, Specification A 554, Specification A 276, and Specifi-

in this specification and include the following information in

cation A 582.

procurement documents:

6.1.2 Corrosion-Resisting Material—Corrosion-resisting

5.1.1 Title, number, and date of this standard.

material is other than corrosion resistant steel that is equivalent

in the pulper and waterpress application.

6.1.3 Abrasion-Resistant Cast Iron—Shall conform to the

Available from the National Fire Protection Agency, Batterymarch Park,

requirements specified in Specification A 532.

Quincy, MA 02269.

6.1.4 Austenitic Gray Iron—Shall conform to the require-

Available from American Society of Sanitary Engineering, P.O. Box 9712, Bay

Village, OH 44140. ments specified in Specification A 436.

F 1150

6.1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.