ASTM E466-96

(Practice)Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

SCOPE

1.1 This practice covers the procedure for the performance of axial force controlled fatigue tests to obtain the fatigue strength of metallic materials in the fatigue regime where the strains are predominately elastic, both upon initial loading and throughout the test. This practice is limited to the fatigue testing of axial unnotched and notched specimens subjected to a constant amplitude, periodic forcing function in air at room temperature. This practice is not intended for application in axial fatigue tests of components or parts. Note 1-The following documents, although not directly referenced in the text, are considered important enough to be listed in this practice: E739 Practice for Statistical Analysis of Linear or Linearized Stress-Life (S-N) and Strain-Life (e-N) Fatigue Data STP 566 Handbook of Fatigue Testing STP 588 Manual on Statistical Planning and Analysis for Fatigue Experiments STP 731 Tables for Estimating Median Fatigue Limits 2. Referenced Documents ASTM Standards:

E 3* Methods of Preparation of Metallographic Specimens

E 467* Practice for Verification of Constant Amplitude Dynamic Loads on Displacements in an Axial Load Fatigue Testing System

E 468* Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Material

E 739* Practice for Statistical Analysis of Linear or Linearized Stress-Life (S-N) and Strain-Life (e-N) Fatigue Data

E 606* Practice for Strain-Controlled Fatigue Testing

E 1012* Practice for Verification of Specimen Alignment Under Tensile Loading

E 1150* Definitions of Terms Relating to Fatigue

General Information

Relations

Standards Content (Sample)

Designation: E 466 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Conducting Force Controlled Constant Amplitude Axial

1

Fatigue Tests of Metallic Materials

This standard is issued under the fixed designation E 466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice covers the procedure for the performance 3.1 Definitions:

of axial force controlled fatigue tests to obtain the fatigue 3.1.1 The terms used in this practice shall be as defined in

strength of metallic materials in the fatigue regime where the Definitions E 1150.

strains are predominately elastic, both upon initial loading and

4. Significance and Use

throughout the test. This practice is limited to the fatigue

4.1 The axial force fatigue test is used to determine the

testing of axial unnotched and notched specimens subjected to

a constant amplitude, periodic forcing function in air at room effect of variations in material, geometry, surface condition,

stress, and so forth, on the fatigue resistance of metallic

temperature. This practice is not intended for application in

axial fatigue tests of components or parts. materials subjected to direct stress for relatively large numbers

of cycles. The results may also be used as a guide for the

NOTE 1—The following documents, although not directly referenced in

selection of metallic materials for service under conditions of

the text, are considered important enough to be listed in this practice:

repeated direct stress.

E 739 Practice for Statistical Analysis of Linear or Linearized Stress-

4.2 In order to verify that such basic fatigue data generated

Life (S-N) and Strain-Life (e-N) Fatigue Data

2

STP 566 Handbook of Fatigue Testing using this practice is comparable, reproducible, and correlated

STP 588 Manual on Statistical Planning and Analysis for Fatigue

among laboratories, it may be advantageous to conduct a

3

Experiments

round-robin-type test program from a statistician’s point of

4

STP 731 Tables for Estimating Median Fatigue Limits

view. To do so would require the control or balance of what are

often deemed nuisance variables; for example, hardness, clean-

2. Referenced Documents

liness, grain size, composition, directionality, surface residual

2.1 ASTM Standards:

stress, surface finish, and so forth. Thus, when embarking on a

5

E 3 Methods of Preparation of Metallographic Specimens

program of this nature it is essential to define and maintain

E 467 Practice for Verification of Constant Amplitude Dy-

consistency a priori, as many variables as reasonably possible,

namic Loads on Displacements in an Axial Load Fatigue

with as much economy as prudent. All material variables,

5

Testing System

testing information, and procedures used should be reported so

E 468 Practice for Presentation of Constant Amplitude Fa-

that correlation and reproducibility of results may be attempted

5

tigue Test Results for Metallic Material

in a fashion that is considered reasonably good current test

E 739 Practice for Statistical Analysis of Linear or Linear-

practice.

5

ized Stress-Life (S-N) and Strain-Life (e-N) Fatigue Data

4.3 The results of the axial force fatigue test are suitable for

5

E 606 Practice for Strain-Controlled Fatigue Testing

application to design only when the specimen test conditions

E 1012 Practice for Verification of Specimen Alignment

realistically simulate service conditions or some methodology

5

Under Tensile Loading

of accounting for service conditions is available and clearly

5

E 1150 Definitions of Terms Relating to Fatigue

defined.

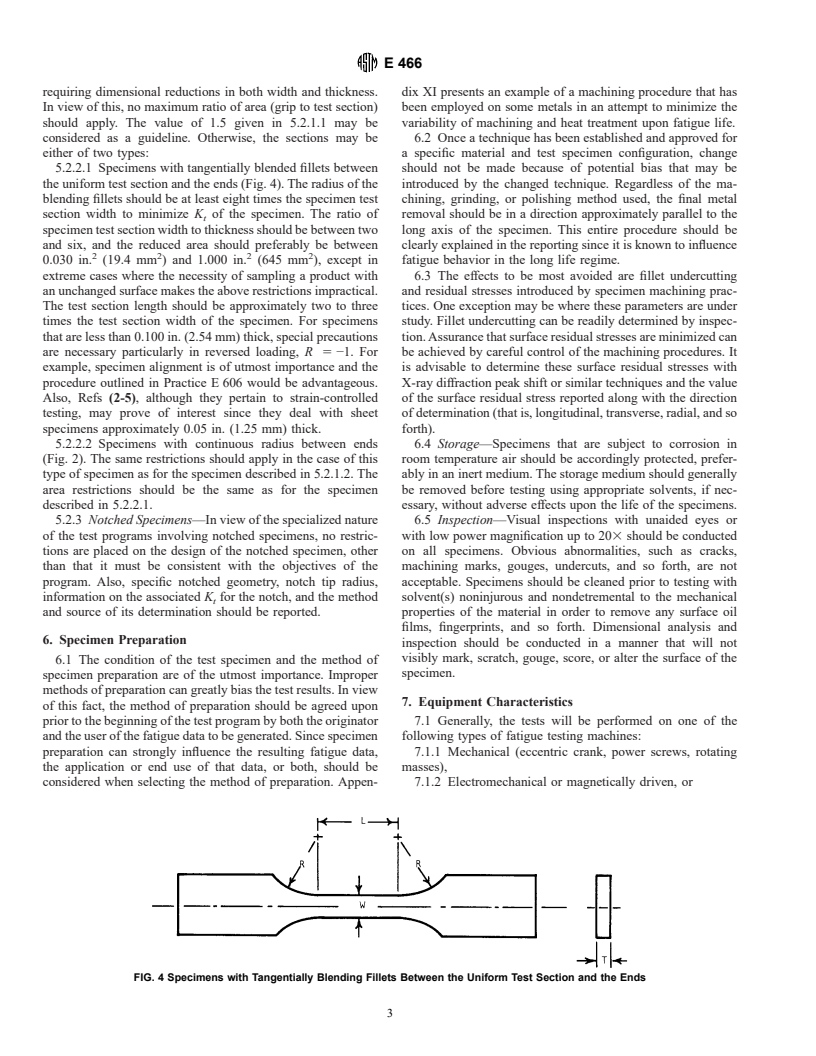

5. Specimen Design

1

This practice is under the jurisdiction of ASTM Committee E-8 on Fatigue and

5.1 The type of specimen used will depend on the objective

Fracture and is the direct responsibility of Subcommittee E08.05on Cyclic Defor-

of the test program, the type of equipment, the equipment

mation and Fatigue Crack Formation.

Current edition approved Feb. 10, 1996. Published April 1996. Originally

capacity, and the form in which the material is available.

published as E 466 – 72 T. Last previous edition E 466 – 95.

However, the design should meet certain general criteria

2

Handbook of Fatique Testing, ASTM STP 566, ASTM, 1974.

3

outlined below:

Little, R. E., Manual on Statistical Planning and Analysis, ASTM STP 588,

ASTM, 1975. 5.1.1 The design of the specimen should be such that failure

4

Little, R. E., Tables for Estimating Median Fatigue Limits, ASTM STP 731,

occurs in the test section (reduced area as shown in Fig. 1 and

ASTM, 1981.

Fig. 2). The acceptable ratio of the areas (test section to grip

5

Annual Book of ASTM Standards, Vol 03.01.

1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.