ASTM F2013-05

(Test Method)Standard Test Method for Determination of Residual Acetaldehyde in Polyethylene Terephthalate Bottle Polymer Using an Automated Static Head-Space Sampling Device and a Capillary GC with a Flame Ionization Detector

Standard Test Method for Determination of Residual Acetaldehyde in Polyethylene Terephthalate Bottle Polymer Using an Automated Static Head-Space Sampling Device and a Capillary GC with a Flame Ionization Detector

SIGNIFICANCE AND USE

This test method is of particular use as a quality control tool for a molding or synthesis operation. Acetaldehyde is a volatile degradation product generated during melt processing of PET. Thus, it becomes trapped in the sidewalls of a molded article and desorbs slowly into the contents packaged therein. In some foods and beverages AA can impart an off-taste that is undesirable, thus, it is important to know its concentration in PET articles that are to be used in food contact applications.

The desorption conditions of 150 C for 60 min are such that no measurable AA is generated by the sample during the desorption process.

SCOPE

1.1 This test method covers a gas chromatographic procedure for the determination of the ppm residual acetaldehyde (AA) present in poly(ethylene terephthalate) (PET) homo-polymers and co-polymers which are used in the manufacture of beverage bottles. This includes sample types of both amorphous and solid-stated pellet and preform samples, as opposed to the bottle test, Test Method D 4509, an acetaldehyde test requiring 24 h of desorption time at 23°C into the bottle headspace and then the concentration of the headspace quantified by a similar GC method.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2013–05

Standard Test Method for

Determination of Residual Acetaldehyde in Polyethylene

Terephthalate Bottle Polymer Using an Automated Static

Head-Space Sampling Device and a Capillary GC with a

1

Flame Ionization Detector

This standard is issued under the fixed designation F2013; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers a gas chromatographic proce- 4.1 Aspecified size (800 to 1000 µm) of granulated sample

dure for the determination of the ppm residual acetaldehyde is weighed into a 20-mL head-space vial, sealed, and then

(AA) present in poly(ethylene terephthalate) (PET) homo- heated at 150°C for 60 min. After heating, the gas above the

polymers and co-polymers which are used in the manufacture sealed sample of PET polymer is injected onto a capillary GC

of beverage bottles. This includes sample types of both column. The acetaldehyde is separated, and the ppm of

amorphous and solid-stated pellet and preform samples, as acetaldehyde is calculated.

opposedtothebottletest,TestMethodD4509,anacetaldehyde

5. Significance and Use

test requiring 24 h of desorption time at 23°C into the bottle

headspace and then the concentration of the headspace quan- 5.1 This test method is of particular use as a quality control

tool for a molding or synthesis operation. Acetaldehyde is a

tified by a similar GC method.

1.2 This standard does not purport to address all of the volatile degradation product generated during melt processing

of PET. Thus, it becomes trapped in the sidewalls of a molded

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- article and desorbs slowly into the contents packaged therein.

In some foods and beveragesAAcan impart an off-taste that is

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. undesirable, thus, it is important to know its concentration in

PET articles that are to be used in food contact applications.

2. Referenced Documents

5.2 The desorption conditions of 150 C for 60 min are such

2

2.1 ASTM Standards: that no measurable AA is generated by the sample during the

D4509 Test Methods for Determining the 24-Hour Gas desorption process.

(AIR) SpaceAcetaldehyde Content of Freshly Blown PET

3 6. Sources of Error

Bottles

6.1 Abias is known to exist if the ratio of sample mass (mg)

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method to head-space vial volume (mL) exceeds a value of ten.

6.2 Acetaldehyde is very volatile and must be handled

3. Terminology

carefullytoavoidsamplelossduringthecalibrationprocedure.

3.1 The terms employed in this test method are commonly Storing the standard vials in a refrigerator is a must to

used in normal laboratory practice and require no special minimize the error due to volatility.

comment. 6.3 Failuretoachieveatightsealonthehead-spacevialwill

result in the loss of acetaldehyde during storage and desorp-

tion, producing a false low value.

1

This test method is under the jurisdiction ofASTM Committee F02 on Flexible

6.4 Failure to grind the sample to the appropriate particle

Barrier Materials and is the direct responsibility of Subcommittee F02.15 on

Chemical/Safety Properties. size may lead to a false low value for residual AA due to the

Current edition approved April 1, 2005. Published September 2005. Originally

increased path length for desorption.

approvedin2000aspublishedasF2013–00.Lastpreviouseditionapprovedin2001

6.5 Samples submitted for “residual AA measurement”

as F2013–01. DOI: 10.1520/F2013-05.

2

should be stored in a freezer until they are tested. Failure to do

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

so can result in lower than expected results.

Standards volume information, refer to the standard’s Document Summary page on

6.6 Excessive grinding of samples can cause residual AA

the ASTM website.

3 contained therein to be desorbed. Extensive excessive grinding

Withdrawn. The last approved version of this historical standard is referenced

can lead to actual melting of the polymer and AA generation.

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

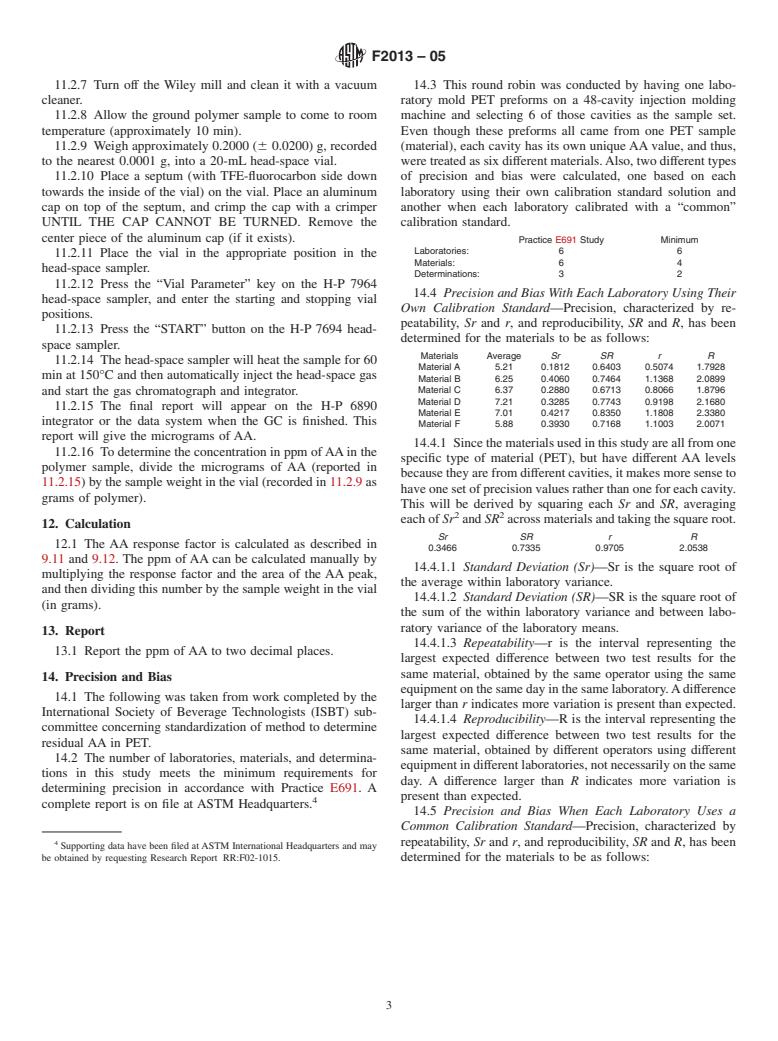

F2013–05

NOTE 3—Due to the error associated with the certified standard,

Samples which have been ch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.