ASTM A342/A342M-99

(Test Method)Standard Test Methods for Permeability of Feebly Magnetic Materials

Standard Test Methods for Permeability of Feebly Magnetic Materials

SCOPE

1.1 These test methods cover three procedures for determination of the permeability [relative permeability] of materials having a permeability not exceeding 4.0.

1.2 The test methods covered are as follows:

1.2.1 Test Method 1 is suitable for materials with permeabilities between 1.0 and 4.0.

1.2.2 Test Method 2 is suitable for measuring the permeability of paramagnetic materials having a permeability less than 1.05.

1.2.3 Test Method 3 is a suitable means of measuring the permeability of a material as "less than" or "greater than" that of calibrated standard inserts designated for use in a Low-Mu Permeability Indicator.

1.3 The values stated in either customary (absolute (or practical) cgs-emu and inch-pound) units or SI units are to be regarded separately as standard. Within this test method, the SI units are shown in brackets except for the sections concerning calculations where there are separate sections for the respective unit systems. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation:A342/A342M–99

Standard Test Methods for

Permeability of Feebly Magnetic Materials

ThisstandardisissuedunderthefixeddesignationA342/A342M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 These test methods cover three procedures for determi- 2.1 ASTM Standards:

nation of the permeability [relative permeability] of materials A 341 Test Method for Direct Current Magnetic Properties

having a permeability not exceeding 4.0. of Materials Using dc Permeameters and the Ballistic Test

1.2 The test methods covered are as follows: Methods

1.2.1 Test Method 1 is suitable for materials with perme-

TEST METHOD NO. 1, FLUXMETRIC METHOD

abilities between 1.0 and 4.0.

1.2.2 Test Method 2 is suitable for measuring the perme-

3. Significance and Use of Test Method 1

ability of paramagnetic materials having a permeability less

3.1 Thistestmethodissuitableforspecificationacceptance,

than 1.05.

design purposes, service evaluation, regulatory statutes, manu-

1.2.3 Test Method 3 is a suitable means of measuring the

facturing control, and research and development.

permeability of a material as “less than” or “greater than” that

3.2 Because of the restrictions on the specimen shape and

of calibrated standard inserts designated for use in a Low-Mu

3 size, this test method is most often used to evaluate semifin-

Permeability Indicator.

ished product before fabrication of parts.

1.3 The values stated in either customary (cgs-emu and

inch-pound) units or SI units are to be regarded separately as

4. Apparatus

standard. Within this test method, the SI units are shown in

4.1 Power Supply—Asource of dc current for the electrical

brackets except for the sections concerning calculations where

circuit shown in Fig. 1. Electronic power supplies are prefer-

there are separate sections for the respective unit systems. The

able although the use of storage batteries is permitted.

values stated in each system are not exact equivalents; there-

4.2 Test Fixture—Atest fixture consisting of a magnetizing

fore, each system shall be used independently of the other.

solenoid with a set of test coils mounted midway between the

Combining values from the two systems may result in noncon-

ends of the solenoid for measuring magnetic induction and an

formance with this specification.

air flux balancing resistor, fluxmeter, and associated circuitry

1.4 This standard does not purport to address all of the

conforming to the following requirements:

safety concerns, if any, associated with its use. It is the

4.2.1 Magnetizing Solenoid, C , having a minimum length

responsibility of the user of this standard to establish appro-

of30cm[300mm]andaratiooflengthtoequivalentdiameter

priate safety and health practices and determine the applica-

of four or more. The magnetizing winding shall be uniformly

bility of regulatory limitations prior to use.

wound and be capable of producing a uniform field of at least

300Oe[24kA/m]overthelengthofthetestspecimenwithout

overheating.

These test methods are under the jurisdiction of ASTM Committee A06 on

4.2.2 Test Coil, B ,usedformeasuringinduction,shallhave

Magnetic Properties and are the direct responsibility of Subcommittee A06.01 on

a cross-sectional area not greater than ten times that of the test

Test Methods.

specimen. The test coil should have sufficient turns (>1000) to

Current edition approved Oct. 10, 1999. Published January 2000. Originally

published as A342–49. Last previous edition A342–95.

provideadequateresolutionandshouldbenolongerthan20%

Test Methods 1 and 2 actually measure magnetic susceptibility. The perme-

of the test specimen length.

ability (µ) [relative permeability ( µ )] is related to the susceptibility (k)bythe

r

4.2.3 Compensating Coil, B8 , of the same length, cross-

equations:

sectionalarea,andnumberofturnsascoil B andconnectedto

µ=1+4pk (cgs-emu)

µ =1+ k (SI)

r

it in series opposition.

The term permeability has been retained in these test methods because of its

4.2.4 Air Flux Compensating Resistor, R8 —This resistor is

B

widespread commercial and technological usage.

used in conjunction with coil B8 of Fig. 1 to help it

Low-Mu Permeability Indicator, manufactured by Severn Engineering Co., 1

Inc., 555 Stage Rd., Suite 1A, Auburn, AL 36830, http://

www.severnengineering.com, has been found suitable. Indicators can be returned

for recalibration. Annual Book of ASTM Standards, Vol 03.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

A342/A342M–99

FIG. 1 Circuit Diagram for Method No. 1

compensatefortheairfluxenclosedbycoil B inorderthatthe the test and adjusting the compensating resistor to obtain the

intrinsic induction may be measured directly. minimum output from the flux sensing coils.

6.3 Place the test specimen in position in coil B

4.2.5 Electronic Fluxmeter, F—used to measure magnetic , adjust the

induction. Alternatively, the magnetizing fixture may be con- magnetic field strength to the desired test value, then reverse

nected to a dc hysteresigraph. the magnetizing current and record the fluxmeter reading.

4.2.6 Magnetic Field Strength Sensor (optional)—if the Optionally, the B versus H curve can be recorded on a

magnetic field strength cannot be accurately determined from hysteresigraph.

the magnetizing current, then either a Hall effect sensor or

7. Calculation (Customary Units)

H-coil connected to the fluxmeter shall be used.

7.1 Convert the fluxmeter reading to intrinsic induction B

i

5. Test Specimens and calculate the permeability as follows:

5.1 The test specimens shall consist of straight bars, rods, B

i

µ 51 1 (1)

H

wires, or strips of uniform cross section. Multiple pieces of the

same test lot may be used to increase the specimen cross-

sectional area when needed. The cross-sectional area shall be

where:

2 2

not less than 0.2 cm [20 mm ]. The length shall be not less

µ = permeability of the test specimen;

than 10 cm [100 mm] and the ratio of length to diameter or

B = intrinsic induction of the test specimen, G; and

i

equivalent diameter (that is, the diameter of a circle having an

H = magnetic field strength, Oe.

area equal to the cross-sectional area of the specimen) shall be

8. Calculation (SI Units)

as follows:

Permeability Dimensional Ratio 8.1 The output from the fluxmeter is the magnetic polariza-

tion J. The relative permeability is calculated as follows:

Under 1.5 10 or greater

1.5 to 2.0, incl. 15 or greater

J

µ 51 1 (2)

2.0 to 4.0 30 or greater

r

G H

m

5.2 This test method can be used with smaller dimension-

where:

ratio test specimens when used for comparing to similar

µ = relative permeability of the test specimen;

r

specimens for quality control purposes.

J = magnetic polarization, T;

−7

G =4p310 H/m; and

m

6. Procedure

H = magnetic field strength, A/m.

6.1 Measure the thickness and width or diameter of the test

9. Precision and Bias of Test Method 1

specimens and calculate the cross-sectional area in square

centimetres [square millimetres]. 9.1 Theprecisionandbiasofthistestmethodhavenotbeen

6.2 Before inserting the test specimen in the solenoid, established by interlaboratory study.

obtain an exact balance to nullify the effect of air flux in coil 9.2 The measured permeabilities will be less than their true

B by reversing the highest magnetizing current to be used in values due to the demagnetizing field arising from the sample

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

A342/A342M–99

dimensional ratio. This leads not only to an overestimation of between the pole faces shall be 1.9 cm [19 mm]. The

themagneticfieldstrengthbutalsoreducesthefluxlinkagesin magnetizing winding shall be so wound as to produce a

the B-coil. Provided the sample and coil dimensional ratios are magnetic field strength of at least 1000 Oe [80 kA/m] between

as specified in 4.2.2 and 5.1, the largest negative error in µ−1 the pole pieces without overheating.

,

as a result of demagnetizing effects will be−3% for µ−1< 11.2.2 Balance—Abalance capable of weighing up to 50 g

0.5. with a sensitivity of 0.1 mg. Any magnetic material in the

balance should be 12.7 cm [127 mm] or more above the

TEST METHOD NO. 2, PERMEABILITY OF

electromagnet. The space surrounding the sample shall be

PARAMAGNETIC MATERIALS

closed by a shield of nonmagnetic material to protect the

sample from air currents during measurements.

10. Significance and Use of Test Method 2

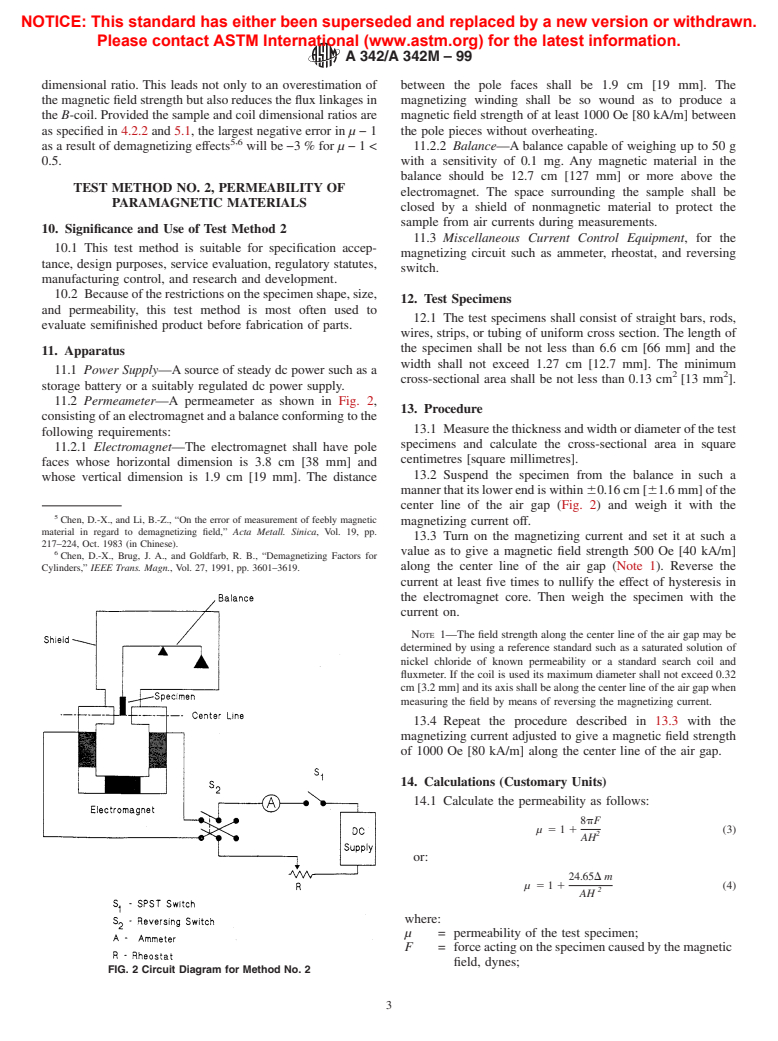

11.3 Miscellaneous Current Control Equipment, for the

10.1 This test method is suitable for specification accep-

magnetizing circuit such as ammeter, rheostat, and reversing

tance, design purposes, service evaluation, regulatory statutes,

switch.

manufacturing control, and research and development.

10.2 Becauseoftherestricti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.