ASTM E1657-98(2011)

(Practice)Standard Practice for Testing Variable-Wavelength Photometric Detectors Used in Liquid Chromatography

Standard Practice for Testing Variable-Wavelength Photometric Detectors Used in Liquid Chromatography

SIGNIFICANCE AND USE

Although it is possible to observe and measure each of the several characteristics of a detector under different and unique conditions, it is the intent of this practice that a complete set of detector specifications should be obtained under the same operating conditions. It should also be noted that to completely specify a detector's capability, its performance should be measured at several sets of conditions within the useful range of the detector. The terms and tests described in this practice are sufficiently general that they may be used regardless of the ultimate operating parameters.

Linearity and response time of the recorder or other readout device used should be such that they do not distort or otherwise interfere with the performance of the detector. This requires adjusting the gain, damping, and calibration in accordance with the manufacturer's directions. If additional electronic filters or amplifiers are used between the detector and the final readout device, their characteristics should also first be established.

SCOPE

1.1 This practice covers the testing of the performance of a variable-wavelength photometric detector (VWPD) used as the detection component of a liquid-chromatographic (LC) system operating at one or more wavelengths in the range 190 to 800 nm. Many of the measurements are made at 254 nm for consistency with Practice E685. Measurements at other wavelengths are optional.

1.2 This practice is intended to describe the performance of the detector both independently of the chromatographic system (static conditions) and with flowing solvent (dynamic conditions).

1.3 For general liquid chromatographic procedures, consult Refs (1-9).

1.4 For general information concerning the principles, construction, operation, and evaluation of liquid-chromatography detectors, see Refs (10, 11) in addition to the sections devoted to detectors in Refs (1-7).

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1657 − 98 (Reapproved 2011)

Standard Practice for

Testing Variable-Wavelength Photometric Detectors Used in

Liquid Chromatography

This standard is issued under the fixed designation E1657; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E685Practice for Testing Fixed-Wavelength Photometric

Detectors Used in Liquid Chromatography

1.1 This practice covers the testing of the performance of a

variable-wavelengthphotometricdetector(VWPD)usedasthe

3. Terminology

detection component of a liquid-chromatographic (LC) system

operating at one or more wavelengths in the range 190 to 800 3.1 Definitions:

nm. Many of the measurements are made at 254 nm for

3.1.1 absorbance calibration—the procedure that verifies

consistency with Practice E685. Measurements at other wave-

that the absorbance scale is correct within 65%.

lengths are optional.

3.1.2 drift—the average slope of the noise envelope ex-

1.2 This practice is intended to describe the performance of

pressed in absorbance units per hour (AU/h) as measured over

thedetectorbothindependentlyofthechromatographicsystem

a period of 1 h.

(static conditions) and with flowing solvent (dynamic condi-

3.1.3 dynamic—under conditions of a flow rate of 1.0

tions).

mL/min.

1.3 For general liquid chromatographic procedures, consult

3.1.4 linear range—of a VWPD,therangeofconcentrations

Refs (1-9).

of a test substance in a test solvent over which the ratio of

1.4 For general information concerning the principles,

response of the detector versus concentration of test substance

construction, operation, and evaluation of liquid-

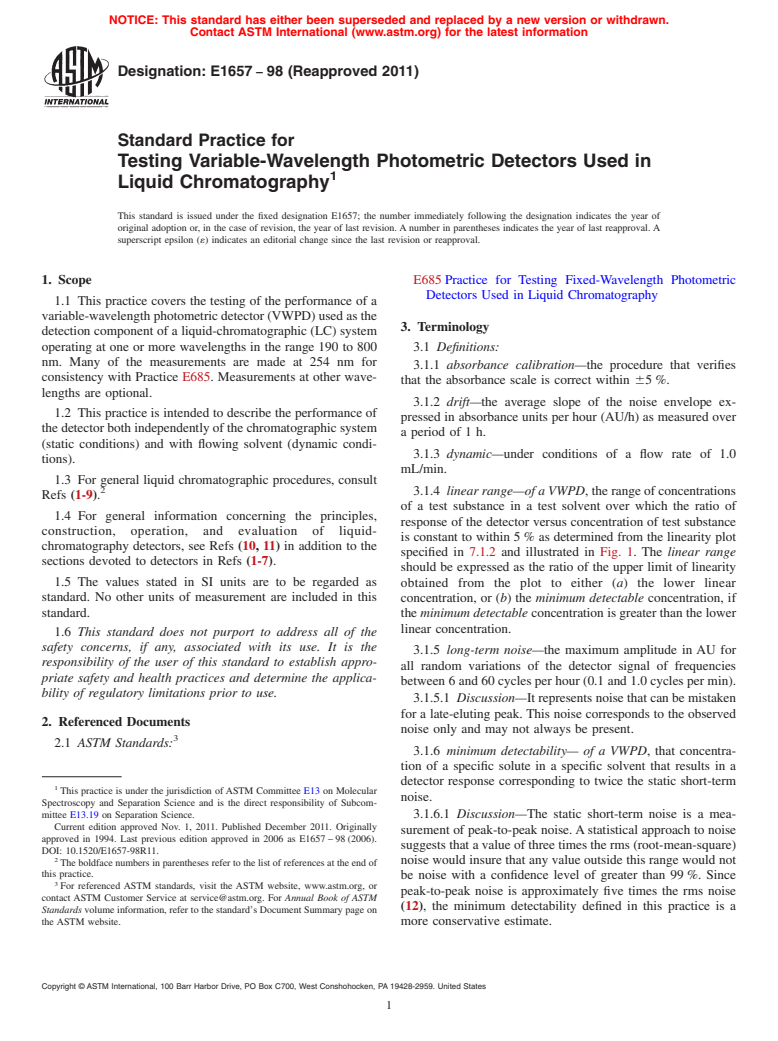

is constant to within 5% as determined from the linearity plot

chromatography detectors, see Refs (10, 11) in addition to the

specified in 7.1.2 and illustrated in Fig. 1. The linear range

sections devoted to detectors in Refs (1-7).

should be expressed as the ratio of the upper limit of linearity

1.5 The values stated in SI units are to be regarded as obtained from the plot to either (a) the lower linear

standard. No other units of measurement are included in this

concentration, or (b) the minimum detectable concentration, if

standard.

the minimum detectableconcentrationisgreaterthanthelower

linear concentration.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.5 long-term noise—the maximum amplitude in AU for

responsibility of the user of this standard to establish appro-

all random variations of the detector signal of frequencies

priate safety and health practices and determine the applica-

between6and60cyclesperhour(0.1and1.0cyclespermin).

bility of regulatory limitations prior to use.

3.1.5.1 Discussion—Itrepresentsnoisethatcanbemistaken

for a late-eluting peak. This noise corresponds to the observed

2. Referenced Documents

noise only and may not always be present.

2.1 ASTM Standards:

3.1.6 minimum detectability— of a VWPD, that concentra-

tion of a specific solute in a specific solvent that results in a

detector response corresponding to twice the static short-term

This practice is under the jurisdiction ofASTM Committee E13 on Molecular

noise.

Spectroscopy and Separation Science and is the direct responsibility of Subcom-

mittee E13.19 on Separation Science.

3.1.6.1 Discussion—The static short-term noise is a mea-

Current edition approved Nov. 1, 2011. Published December 2011. Originally

surement of peak-to-peak noise.Astatistical approach to noise

approved in 1994. Last previous edition approved in 2006 as E1657–98(2006).

suggeststhatavalueofthreetimestherms(root-mean-square)

DOI: 10.1520/E1657-98R11.

noise would insure that any value outside this range would not

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this practice.

be noise with a confidence level of greater than 99%. Since

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

peak-to-peak noise is approximately five times the rms noise

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(12), the minimum detectability defined in this practice is a

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. more conservative estimate.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1657 − 98 (2011)

under the same operating conditions. It should also be noted

that to completely specify a detector’s capability, its perfor-

mance should be measured at several sets of conditions within

the useful range of the detector. The terms and tests described

in this practice are sufficiently general that they may be used

regardless of the ultimate operating parameters.

4.2 Linearity and response time of the recorder or other

readout device used should be such that they do not distort or

otherwise interfere with the performance of the detector. This

requires adjusting the gain, damping, and calibration in accor-

dance with the manufacturer’s directions. If additional elec-

tronicfiltersoramplifiersareusedbetweenthedetectorandthe

final readout device, their characteristics should also first be

established.

5. Noise and Drift

5.1 Test Conditions—Pure, degassed methanol shall be

used in the sample cell. Air or nitrogen shall be used in the

reference cell if there is one. Nitrogen is preferred where the

presenceofhigh-voltageequipmentmakesitlikelythatthereis

FIG. 1 Example of Linearity Plot for a Variable-Wavelength De-

ozone in the air. Protect the entire system from temperature

tector

fluctuations because these will lead to detectable drift.

5.1.1 The detector should be located at the test site and

3.1.7 response time (speed of output)— the detector, the turned on at least 24 h before the start of testing. Insufficient

time required for the detector output to change from 10% to warm-upmayresultindriftinexcessoftheactualvalueforthe

detector. The detector wavelength should be set to 254 nm.

90% of the new equilibrium value when the composition of

the mobile phase is changed in a stepwise manner, within the

5.2 Methods of Measurement:

linear range of the detector.

5.2.1 Connect a suitable device (see Note 1) between the

3.1.7.1 Discussion—Because the detector volume is very

pumpandthedetectortoprovideatleast75kPa(500psi)back

small and the transport rate is not diffusion dependent, the

pressure at 1.0 mL/min flow of methanol. Connect a short

response time is generally fast enough to be unimportant. It is

length(about100mm)of0.25-mm(0.01-in.)internal-diameter

generally comparable to the response time of the recorder and

stainless steel tubing to the outlet tube of the detector to retard

dependent on the response time of the detector electrometer

bubble formation. Connect the recorder to the proper detector

and on the recorder amplifier. Factors that affect the observed

output channels.

response time include the true detector response time, elec-

NOTE 1—Suggested devices include (a)2to4mof 0.1-mm (0.004-in.)

tronic filtering, and system band-broadening.

internal-diameter stainless steel tubing, (b) about 250 mm of 0.25 to 0.5

3.1.8 short-term noise—the maximum amplitude, peak to

mm(0.01to0.02-in.)internal-diameterstainlesssteeltubingcrimpedwith

peak, inAU for all random variations of the detector signal of pliersorcutters,or(c)aconstantback-pressurevalvelocatedbetweenthe

pump and the injector.

a frequency greater than one cycle per minute.

3.1.8.1 Discussion—Itdeterminesthesmallestsignaldetect-

5.2.2 Repeatedly rinse the reservoir and chromatographic

ablebyaVWPD,limitstheprecisionattainableinquantitation

system, including the detector, with degassed methanol to

of trace-level samples, and sets the lower limit on linearity.

remove from the system all other solvents, any soluble

This noise corresponds to the observed noise only.

material, and any entrained gasses. Fill the reservoir with

methanolandpumpthissolventthroughthesystemforatleast

3.1.9 static—under conditions of no flow.

30 min to complete the system cleanup.

3.1.10 wavelength accuracy—the deviation of the observed

5.2.3 Air or nitrogen is used in the reference cell, if any.

wavelength maximum from the maximum of a known test

Ensure that the cell is clean, free of dust, and completely dry.

substance.

5.2.4 To perform the static test, cease pumping and allow

3.1.11 wavelength precision—a measure of the ability of a

thechromatographicsystemtostabilizeforatleast1hatroom

VWPD to return to the same spectral position as measured by

temperature without flow. Set the attenuator at maximum

the reproducibility of absorbance values when the detector is

sensitivity (lowest attenuation), that is, the setting for the

reset to a wavelength maximum of a known test substance.

smallest value of absorbance units full-scale (AUFS). Adjust

the response time as close as possible to 2 s for a VWPD that

4. Significance and Use

has a variable response time (see Note 2). Record the response

4.1 Although it is possible to observe and measure each of

the several characteristics of a detector under different and

unique conditions, it is the intent of this practice that a

Distilled-in-glass or liquid-chromatography grade. Complete freedom from

complete set of detector specifications should be obtained particles may require filtration, for example, through a 0.45-µm membrane filter.

E1657 − 98 (2011)

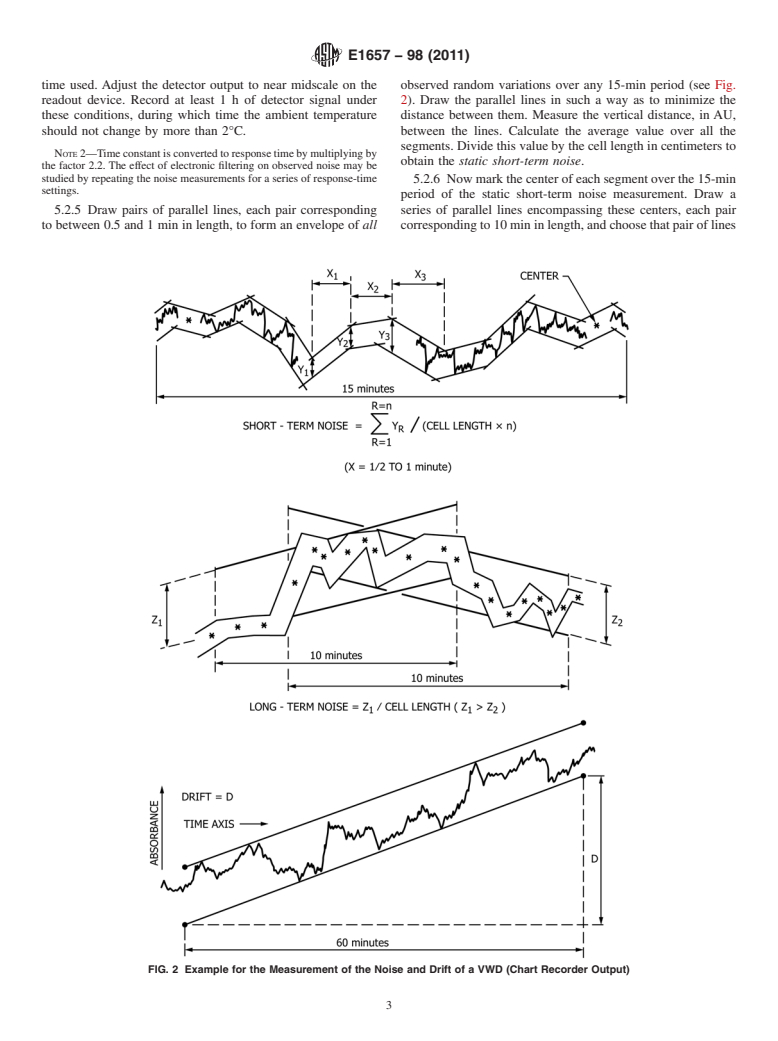

time used. Adjust the detector output to near midscale on the observed random variations over any 15-min period (see Fig.

readout device. Record at least1hof detector signal under 2). Draw the parallel lines in such a way as to minimize the

these conditions, during which time the ambient temperature distance between them. Measure the vertical distance, in AU,

should not change by more than 2°C. between the lines. Calculate the average value over all the

segments.Dividethisvaluebythecelllengthincentimetersto

NOTE2—Timeconstantisconvertedtoresponsetimebymultiplyingby

obtain the static short-term noise.

the factor 2.2. The effect of electronic filtering on observed noise may be

studied by repeating the noise measurements for a series of response-time

5.2.6 Nowmarkthecenterofeachsegmentoverthe15-min

settings.

period of the static short-term noise measurement. Draw a

5.2.5 Draw pairs of parallel lines, each pair corresponding series of parallel lines encompassing these centers, each pair

to between 0.5 and 1 min in length, to form an envelope of all correspondingto10mininlength,andchoosethatpairoflines

FIG. 2 Example for the Measurement of the Noise and Drift of a VWD (Chart Recorder Output)

E1657 − 98 (2011)

procedure verifies that the detector is properly aligned and

meets the manufacturer’s specifications for wavelength accu-

racy and precision.

6.2 Method of Measurement—Wavelength Accuracy—For

thedeterminationofthe wavelength accuracy of a VWPD, (13)

a solution of a compound with known absorbance maxima is

introduced into the cell. The measured maxima are compared

to the known maxima for the compound. There are several

acceptable compounds and solvents. The following procedure

is recommended (Note 3).

NOTE 3—The recommended procedure is covered under U.S. Patent

4836673. The American Society for Testing and Materials takes no

position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are

expressly advised that determination of the validity of any such patent

rights, and the risk of infringement of such rights, are entirely their own

responsibility. Alternative procedures will be considered.

6.2.1 Prepare the test solution. For example, dissolve2gof

FIG. 3 Example of Wavelength Accuracy Test Plot

6 7

erbiumperchloratehexahydrate in25mLwater. Thenominal

concentrationis0.14M.Filterthesolutionwithanappropriate

filter to ensure the sample is free of particles.

whose vertical distance apart is greatest (see Fig. 2). Divide

NOTE4—Thiscanbeconvenientlydonebyaddngwatertoa2gvialof

this distance in AU by the cell length in centimeters to obtain

erbiumperchloratehexahydratetodissolvethesolid.Transferthecontents

the static long-term noise.

to a 25 mL volumetric flask and make up to volume with water. While

5.2.7 Draw the pair of parallel lines that minimizes the

reasonable care should be observed in transferring the dissolved erbium

vertical distance separating these lines over the 1 h of mea-

perchlorate into the volumetric flask, the final solution is not used

surement (Fig. 2). The slope of either line is the static drift quantitatively.

expressed in AU/h.

6.2.2 Turn on the detector and allow it to warm up accord-

5.2.8 Set the pump to deliver 1.0 mL/min under the same

ing to the manufacturer’s recommendations. Thoroughly flush

conditions of tubing, solvent, and temperature as in 5.2.1 –

thedetectorcellwithwaterpreferablyfromthesamesourceas

5.2.3.Allow 15 min for the system to stabilize. Record at least

that to make up the test solution. (If using another test

1hofsignalundertheseflowingconditions,duringwhichtime

compound,besuretousethesamesolventasthetestsolution.)

the ambient temperature should not change by more than 2°C.

Set the detector wavelength to 250 nm. Zero the absorbance of

5.2.9 Draw pairs of parallel lines, measure the vertical

the detector. (Some detectors will automatically zero the

distances, and calculate the dynamic short-term noise follow-

detector after changing wavelengths.) Flush the cell with at

ing the procedure of 5.2.5.

least 1 mL of the erbium test solution. Record the absorbance

5.2.10 Make the measurement for the dynamic long-term

reading. Increase the wavelength by 1 nm. Flush the cell with

noise following the procedure outlined in 5.2.6.

at least 1 mL of water. Zero the absorbance of the detector.

5.2.11 Draw the pair of parallel lines as directed in 5.2.7.

Flush the cell with the erbium test solution and record the

The slope of these lines is the dynamic drift.

absorbance. Repeat the procedure in 0.5 to 1.0 nm increments

5.2.12 The actual noise of the system may be larger or

until reaching 260 nm.

smaller than the observed values, depending upon the method

6.2.3 Plot absorbance versus wavelength and determine the

of data collection, or signal monitoring of the detector, since

maximum absorbance. (See Fig. 3) Compare the calculated

observed noise is a function of the frequency, speed of

maximum to the maximum for erbium perchlorate of 255 nm

response, and bandwidth of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.