ASTM D823-18(2022)

(Practice)Standard Practices for Producing Films of Uniform Thickness of Paint, Coatings and Related Products on Test Panels

Standard Practices for Producing Films of Uniform Thickness of Paint, Coatings and Related Products on Test Panels

SIGNIFICANCE AND USE

4.1 This practice should be used for those coatings that are designed for spray applications of objects in the factory or in the field. It is particularly important that it be used in the evaluation of metallic coatings for appearance properties, such as gloss and color.

4.2 Coatings applied by this test method may exhibit a slight orange-peel or spray wave.

SCOPE

1.1 Five practices are given for preparing films of uniform thickness of coatings on test panels. These practices are:

Practice A—Automated Spray Machine Application

Practice B—Motor-Driven Dip Coater Application

Practice C—Motor-Driven Blade Film Application

Practice D—Hand-Held Spray Gun Application

Practice E—Hand-Held Blade Film Application

1.2 The use of wire-wound drawdown bars as described in Practice D4147 may also be an appropriate method for producing films of uniform coating thickness.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D823 − 18 (Reapproved 2022)

Standard Practices for

Producing Films of Uniform Thickness of Paint, Coatings

and Related Products on Test Panels

This standard is issued under the fixed designation D823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Related Coating Products

D1005 Test Method for Measurement of Dry-Film Thick-

1.1 Five practices are given for preparing films of uniform

ness of Organic Coatings Using Micrometers

thickness of coatings on test panels. These practices are:

D1212 Test Methods for Measurement of Wet Film Thick-

Practice A—Automated Spray Machine Application

ness of Organic Coatings

Practice B—Motor-Driven Dip Coater Application

D3924 Specification for Standard Environment for Condi-

Practice C—Motor-Driven Blade Film Application

tioning and Testing Paint, Varnish, Lacquer, and Related

Practice D—Hand-Held Spray Gun Application

Materials

Practice E—Hand-Held Blade Film Application

D4147 Practice for Applying Coil Coatings Using Wire-

1.2 The use of wire-wound drawdown bars as described in

Wound Drawdown Bars

Practice D4147 may also be an appropriate method for

D4285 Test Method for Indicating Oil or Water in Com-

producing films of uniform coating thickness.

pressed Air

1.3 The values stated in SI units are to be regarded as the D4414 Practice for Measurement of Wet Film Thickness by

Notch Gages

standard. The values given in parentheses are for information

only. D7091 Practice for Nondestructive Measurement of Dry

Film Thickness of Nonmagnetic Coatings Applied to

1.4 This standard does not purport to address all of the

Ferrous Metals and Nonmagnetic, Nonconductive Coat-

safety concerns, if any, associated with its use. It is the

ings Applied to Non-Ferrous Metals

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

PRACTICE A—AUTOMATED SPRAY MACHINE

mine the applicability of regulatory limitations prior to use.

APPLICATION

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3. Summary of Practices

ization established in the Decision on Principles for the

3.1 A liquid material is applied to a test panel by means of

Development of International Standards, Guides and Recom-

anautomatedspraymachineconsistingofamountedspraygun

mendations issued by the World Trade Organization Technical

and a panel holder. This machine can (1) move the panel

Barriers to Trade (TBT) Committee.

holder, with test panel, at a uniform speed through the

atomized spray produced by a fixed spray gun, or (2)itcan

2. Referenced Documents

move the gun, with atomized spray, at a uniform speed past the

2.1 ASTM Standards:

test panel(s) mounted on a fixed panel holder. A machine

D609 Practice for Preparation of Cold-Rolled Steel Panels

equipped with a programmable system can index the spray gun

for Testing Paint, Varnish, Conversion Coatings, and

vertically for multiple passes and for multiple coats with

selective time delay.

3.2 The thickness of coating applied is controlled by the

These practices are under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, and Applications and are the direct responsibility traverse speed of the panel or gun, the fluid delivery rate of the

of Subcommittee D01.23 on Physical Properties of Applied Paint Films.

gun,thesprayguntipsize,theviscosityofthematerial,andthe

Current edition approved June 1, 2022. Published June 2022. Originally

amount of nonvolatile matter in the material.

approved in 1945. Last previous edition approved in 2018 as D823 – 18. DOI:

10.1520/D0823-18R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4. Significance and Use

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1 This practice should be used for those coatings that are

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. designed for spray applications of objects in the factory or in

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D823 − 18 (2022)

the field. It is particularly important that it be used in the spray gun. Reduce the material to a viscosity suitable for

evaluation of metallic coatings for appearance properties, such spraying using the coating manufacturer’s recommended thin-

as gloss and color. ner.

4.2 Coatingsappliedbythistestmethodmayexhibitaslight 7.3 Connect the container to the gun and test the spray gun

orange-peel or spray wave. operation while stationary, for correct spray pattern and uni-

formity by allowing a momentary spray to be deposited on a

5. Apparatus

piece of paper placed in the panel position. Adjust the air

pressure, material flow, and spray fan width controls until the

5.1 Test Panels, of any clean, planar rigid substrate with a

desired pattern and uniformity are obtained. Further refine-

uniform surface of a size that can be accommodated by the

ments may be made in the spray pattern by modifying the air

panel holder of the automated spray machine.

pressure, and the type and amount of thinner.

5.1.1 Whensteelpanelsareused,theyshouldbepreparedin

accordance with the appropriate method in Practice D609.

NOTE 4—The width of the spray pattern should be considerably wider

than the width of the test panel to assure spray uniformity on the test

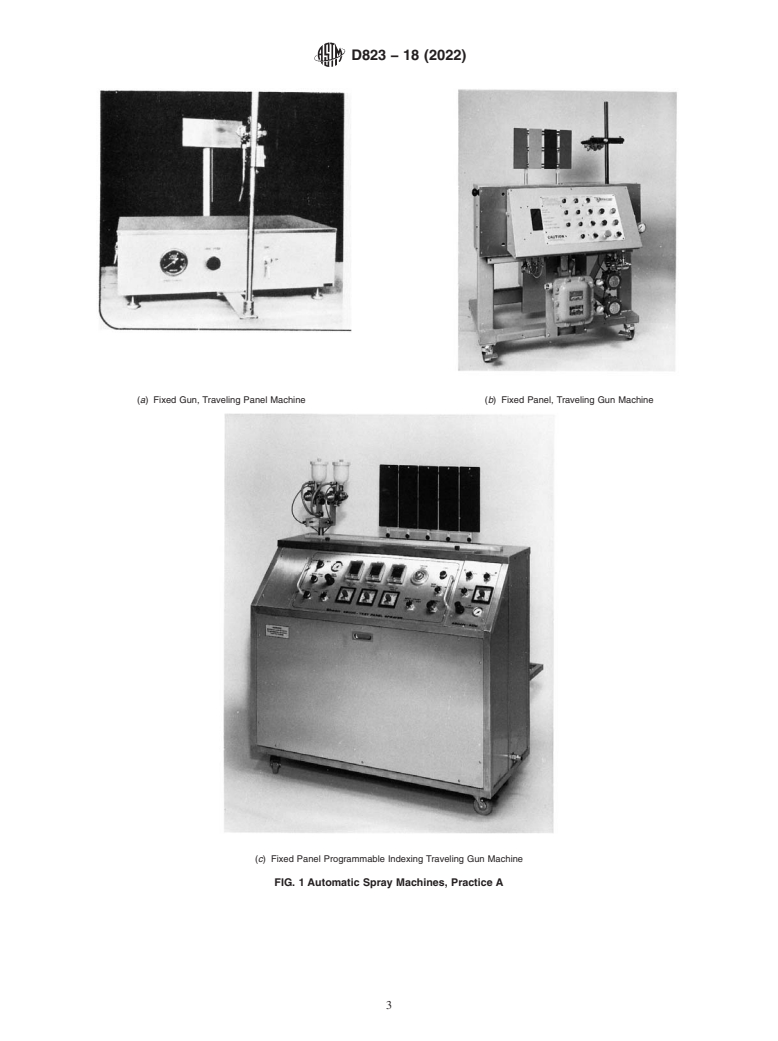

5.2 Automated Spray Machine, equipped with a panel

panel.

holder and a mounting for a spray gun. The machine shall be

7.4 Place a test panel on the panel holder and start the

designed to move the panel holder at a uniform speed past the

machine. Operate the spray gun so that it will begin spraying a

fixed gun mount or designed to move the gun mount at a

few inches before the test panel enters the spray pattern and

uniform speed past the fixed panel holder. The panel holder or

continue spraying a few inches after the test panel leaves the

the gun mount traverse speed shall be adjustable from

spray pattern.

7.5 to 30 m (25 to 100 ft)/min. Examples of automated spray

machines are shown in Fig. 1.

7.5 Measure the wet film thickness in accordance with Test

Methods D1212 or Practice D4414. Additional passes may be

NOTE 1—Some automated spray machines provide additional features

that can improve the uniformity of film preparation. Some examples are: made until the desired wet film thickness has been achieved.

az-barpanelholder;indexingofthepanelholderatrightanglestothegun

7.6 Remove the coated panel and bake, force-dry, or air-dry

to provide uniform lapping; and automatic control of number of passes,

it, in accordance with its type, in a vertical position in a

time between passes, and lapping distance.

dust-free atmosphere (if required), as described in Specifica-

5.3 Spray Gun, any that will provide a uniform fan-type

tion D3924.

spray pattern at least 150 mm (6 in.) in width is satisfactory.

7.7 Measure the dry film thickness of the coating in accor-

The gun may be triggered manually or automatically.

dance with Test Methods D1005 or Practice D7091, whichever

5.4 Air Pressure Gage, covering the range of 0 to 690 kPa

is appropriate.

(0 to 100 psi).

5.5 Air Pressure Regulator.

8. Report

5.6 Air Supply, water and oil-free, under pressure.

8.1 Report the following information:

8.1.1 Type of coating material,

6. Preparation of Apparatus

8.1.2 Type and amount of thinner added as a percentage by

6.1 Mount the spray gun on the automated spray machine.

weight or volume of the total mixed coating, if applicable,

Connect the air line hose from the regulator to the air pressure

8.1.3 Temperature of coating material,

gagewhichinturnisconnectedtotheairinletofthespraygun.

8.1.4 Wet film thickness,

8.1.5 Distance of test panel from gun tip,

6.2 Set the gun so that its tip is at the desired distance from

the test panel surface, usually in the range from 200 to 300 mm 8.1.6 Type of spray gun and spray tip size,

8.1.7 Air pressure,

(8 to 12 in.).

8.1.8 Number of spray passes,

6.3 With the gun trigger fully open, adjust the air regulator

8.1.9 Traverse speed,

to provide the desired reading on the air pressure gage.

8.1.10 Air temperature, relative humidity and temperature

NOTE 2—A suitable air pressure is usually from 275 to 520 kPa (40 to

of test panel at time of application, and

75 psi).

8.1.11 Mean and range of dry film thickness values ob-

6.4 Set the automated spray machine controls to provide the

tained.

desired traverse speed of the panel holder or the gun mount,

PRACTICE B—MOTOR-DRIVEN DIP COATER

whichever is pertinent to the type of machine being used.

APPLICATION

NOTE3—Suitabletraversespeedsforautomotivecoatingsusuallyrange

from 17.5 to 22.5 m/min (700 to 900 in./min).

9. Summary of Practice

7. Procedure

9.1 Amotor-driven device is employed to withdraw the test

panel from a container of the coating material at a desired

7.1 If compressed air is used to atomize the coating, verify

that the air is clean and dry according to Test Method D4285. uniform rate.

7.2 If recommended by the coating manufacturer, strain the 9.2 The wet film thickness of the applied coating is influ-

material to be sprayed into the container to be used with the encedbymanyvariablesincluding,butnotlimitedtothespeed

D823 − 18 (2022)

(a) Fixed Gun, Traveling Panel Machine (b) Fixed Panel, Traveling Gun Machine

(c) Fixed Panel Programmable Indexing Traveling Gun Machine

FIG. 1 Automatic Spray Machines, Practice A

D823 − 18 (2022)

because the smaller exposed surfaces of the liquid coating reduces volatile

of withdrawal, rheological characteristics of the coating at the

loss.

test temperature and the temperature of the test panel.

11.2 Test Panels, of any clean, rigid substrate with a

10. Significance and Use

uniform surface of a size that can be accommodated by the dip

10.1 This test method is limited to those materials that flow coater and the container.

out to smooth films when test panels are dipped into the 11.2.1 When steel panels are used they shall be prepared in

material and withdrawn.

accordance with the appropriate method in Practice D609.

NOTE 6—The test panels should not exceed 300 mm (12 in.) in length,

11. Apparatus

but the width may be varied up to 300 mm (12 in.) if a suitable

11.1 Dip Coater, consisting of a mechanism that will with-

counterweight is used and a dip tank of adequate size is provided. Use of

a multiple hook will permit dipping several panels at one time.

draw a panel from a container of the coating material at a

predetermined rate. Suitable apparatus, is shown in Fig. 2(a)

12. Procedure

and 2(b):

11.1.1 The apparatus shown in Fig. 2(a) uses a cord wound

12.1 Adjust the coating material to the desired viscosity

around a step-cone pulley on the shaft of a motor to provide

using thinner as necessary. Measure the temperature of the

panel withdrawal rate of 50, 75, and 100-mm (2, 3, and

material in the container at the time of application.

4-in.)/min. Prior to withdrawal, the panel, attached to the cord,

NOTE 7—The operating conditions (viscosity, percent of nonvolatile

is lowered by hand into the container holding the material.

matter, and rate of withdrawal) are specific for a given coating material

11.1.2 The apparatus shown in Fig. 2(b) uses a cord driven

and film thickness and need to be determined by trial. Subsequent

by a variable-speed device that can provide panel immersion

reproduction of the same operating conditions should yield a similar film

and withdrawal rates that are continuously variable from 65 to

thickness.

510 mm (2.5 to 20 in.)/min.

12.2 Place the prepared test panel on the hook attached to

NOTE 5—Rectangular containers (F-style can with lid cut off) are useful the cord and lower it into the container holding the coating

(a) Dip-Coater With Motor-Driven Step-Cone Pulley (b) Dip-Coater With Continuously Variable Speed Drive

FIG. 2 Dip-Coater, Practice B

D823 − 18 (2022)

material. Wind the cord once completely around the pulley of 13.1.5 Air temperature, relative humidity and temperature

the correct size to give the desired rate of withdrawal. of test panel surface at time of application, and

12.2.1 For the stepped-cone pulley apparatus, wind the cord 13.1.6 Mean and range of dry film thickness values ob-

once completely around the pulley of the correct size to give tained.

the desired weight of withdrawal.

PRACTICE C—MOTOR-DRIVEN BLADE FILM

12.2.2 For the continuously variable speed apparatus set the

APPLICATION

desired panel immersion and withdrawal rates on the control

panel.

14. Summary of Practice

12.3 Start the motor and withdraw the panel at the desired

14.1 Auniform film is produced by an applicator blade that

rate, with a smooth movement entirely free of vibration.

is pushed or pulled across the test panel at a uniform speed by

12.4 MeasurethewetfilmthicknessinaccordancewithTest

a motor-driven device.

Methods D1212 or Practice D4414.

14.2 The wet film thickness of the coating applied may be

12.5 Bake, force-dry, or air-dry the coated panel, in accor-

affected by the speed at which the applicator blade is moved,

dance with its type, in a vertical position in a dust-free

the clearance of the applicator blade, the design of the

atmosphere in accordance with Specification D3924. Measure

applicator blade, and the viscosity of the coating.

the dry film thickness of the coating in accordance with Test

Method D1005 or Practice D7091.

15. Significance and Use

12.6 If the coating thickness is too low, coat another panel

15.1 This test method is applicable to substrates consisting

using a slower rate of panel withdrawal. If the coating

of uniform rigid materials, such as metal or glass, and of

thickness is too high, coat another panel using a faster rate of

non-rigid materials, such as paper charts. The motor-driven

panel withdrawal.

film applicator may offer advantages over the use of hand-held

12.7 Continue in this manner until a test panel having the

film applicator blade, due to the constant speed of application.

desired film thickness is produced. Measure thickness on at

least three different areas of the test panel to determine coating

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.