ASTM E10-07a

(Test Method)Standard Test Method for Brinell Hardness of Metallic Materials

Standard Test Method for Brinell Hardness of Metallic Materials

SIGNIFICANCE AND USE

The Brinell hardness test is an indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, or other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

Brinell hardness tests are considered satisfactory for acceptance testing of commercial shipments, and have been used extensively in industry for this purpose.

Brinell hardness testing at a specific location on a part may not represent the physical characteristics of the whole part or end product.

SCOPE

1.1 This test method covers the determination of the Brinell hardness of metallic materials by the Brinell indentation hardness principle. This standard provides the requirements for a Brinell testing machine and the procedures for performing Brinell hardness tests.

1.2 This standard includes additional requirements in four annexes:Verification of Brinell Hardness Testing MachinesBrinell Hardness Standardizing MachinesStandardization of Brinell Hardness IndentersStandardization of Brinell Hardness Test Blocks

1.3 This standard includes nonmandatory information in an appendix which relates to the Brinell hardness test:Table of Brinell Hardness NumbersExamples of Procedures for Determining Brinell Hardness Uncertainty

1.4 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information and much of the discussion in this standard refers to forces in kgf units.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State Highway

Designation: E 10 – 07a and Transportation Officials Standard

AASHTO No.: T70–86

Standard Test Method for

1

Brinell Hardness of Metallic Materials

ThisstandardisissuedunderthefixeddesignationE 10;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Determine Conformance with Specifications

E74 Practice of Calibration of Force-Measuring Instru-

1.1 This test method covers the determination of the Brinell

ments for Verifying the Force Indication of Testing Ma-

hardness of metallic materials by the Brinell indentation

chines

hardnessprinciple.Thisstandardprovidestherequirementsfor

E 140 Hardness ConversionTables for Metals Relationship

a Brinell testing machine and the procedures for performing

Among Brinell Hardness, Vickers Hardness, Rockwell

Brinell hardness tests.

Hardness, Superficial Hardness, Knoop Hardness, and

1.2 This standard includes additional requirements in four

Scleroscope Hardness

annexes:

E 384 Test Method for Microindentation Hardness of Ma-

Verification of Brinell Hardness Testing Machines Annex A1

terials

Brinell Hardness Standardizing Machines Annex A2

Standardization of Brinell Hardness Indenters Annex A3

2.2 American Bearings Manufacturer Association Stan-

Standardization of Brinell Hardness Test Blocks Annex A4

dard:

3

1.3 This standard includes nonmandatory information in an

ABMA 10-1989 Metal Balls

appendix which relates to the Brinell hardness test: 2.3 ISO Standards:

Table of Brinell Hardness Numbers Appendix X1 ISO/IEC 17011 ConformityAssessment—General Require-

Examples of Procedures for Determining Appendix X2

ments for Accreditation Bodies Accrediting Conformity

Brinell Hardness Uncertainty

4

Assessment Bodies

1.4 At the time the Brinell hardness test was developed, the

ISO/IEC 17025 General Requirements for the Competence

4

force levels were specified in units of kilograms-force (kgf).

of Calibration and Testing

Although this standard specifies the unit of force in the

3. Terminology and Equations

International System of Units (SI) as the Newton (N), because

of the historical precedent and continued common usage of kgf

3.1 Definitions:

units,forcevaluesinkgfunitsareprovidedforinformationand

3.1.1 calibration—determination of the values of the sig-

much of the discussion in this standard refers to forces in kgf nificant parameters by comparison with values indicated by a

units.

reference instrument or by a set of reference standards.

1.5 This standard does not purport to address all of the 3.1.2 verification—checking or testing to assure conform-

safety concerns, if any, associated with its use. It is the

ance with the specification.

responsibility of the user of this standard to establish appro- 3.1.3 standardization—to bring in conformance with a

priate safety and health practices and determine the applica-

known standard through verification or calibration.

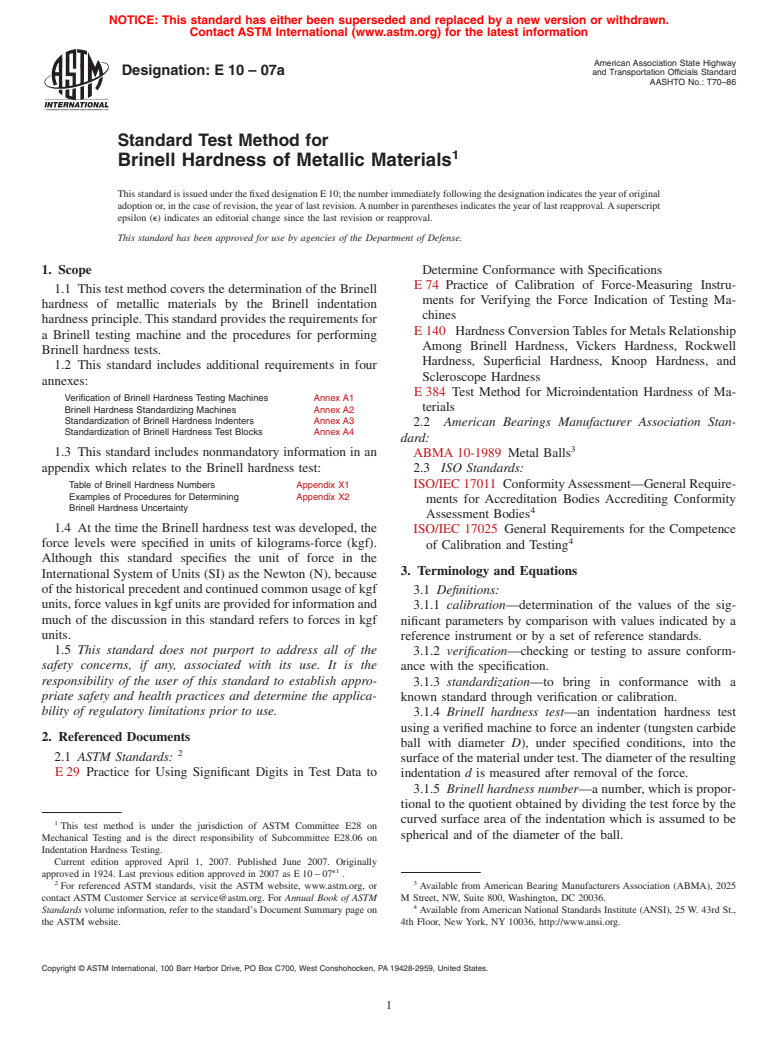

bility of regulatory limitations prior to use. 3.1.4 Brinell hardness test—an indentation hardness test

using a verified machine to force an indenter (tungsten carbide

2. Referenced Documents

ball with diameter D), under specified conditions, into the

2

2.1 ASTM Standards:

surface of the material under test.The diameter of the resulting

E29 Practice for Using Significant Digits in Test Data to

indentation d is measured after removal of the force.

3.1.5 Brinell hardness number—a number, which is propor-

tional to the quotient obtained by dividing the test force by the

curved surface area of the indentation which is assumed to be

1

This test method is under the jurisdiction of ASTM Committee E28 on

spherical and of the diameter of the ball.

Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on

Indentation Hardness Testing.

Current edition approved April 1, 2007. Published June 2007. Originally

e1

approved in 1924. Last previous edition approved in 2007 as E 10 – 07 .

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Bearing Manufacturers Association (ABMA), 2025

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM M Street, NW, Suite 800, Washington, DC 20036.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Pag

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.