ASTM F3056-14(2021)

(Specification)Standard Specification for Additive Manufacturing Nickel Alloy (UNS N06625) with Powder Bed Fusion

Standard Specification for Additive Manufacturing Nickel Alloy (UNS N06625) with Powder Bed Fusion

ABSTRACT

This specification defines the requirements for additive manufacturing of nickel alloy (UNS N06625) using full-melt powder bed fusion such as electron beam melting and laser melting. The standard may be used by purchasers and producers of additively manufactured UNS N06625 components to specify the requirements and ensure component properties, and by users to obtain components that will satisfy the minimum acceptance requirements. The standard covers terminology and classification as well as the requirements with respect to ordering information, manufacturing plan, feedstock, thermal processing, chemical composition, microstructure, mechanical properties, hot isostatic pressing, dimensions and permissible variations, retests, inspection, rejection, certification, product marking and packaging, maintenance of a quality program, and the significance of numerical limits.

SCOPE

1.1 This specification covers additively manufactured UNS N06625 components using full-melt powder bed fusion such as electron beam melting and laser melting. The components produced by these processes are used typically in applications that require mechanical properties similar to machined forgings and wrought products. Components manufactured to this specification are often, but not necessarily, post processed via machining, grinding, electrical discharge machining (EDM), polishing, and so forth to achieve desired surface finish and critical dimensions.

1.2 This specification is intended for the use of purchasers or producers, or both, of additively manufactured UNS N06625 components for defining the requirements and ensuring component properties.

1.3 Users are advised to use this specification as a basis for obtaining components that will meet the minimum acceptance requirements established and revised by consensus of the members of the committee.

1.4 User requirements considered more stringent may be met by the addition to the purchase order of one or more supplementary requirements, which may include, but are not limited to, those listed in Supplementary Requirements S1–S16.

1.5 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F3056 −14 (Reapproved 2021)

Standard Specification for

Additive Manufacturing Nickel Alloy (UNS N06625) with

Powder Bed Fusion

This standard is issued under the fixed designation F3056; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This specification covers additively manufactured UNS

mendations issued by the World Trade Organization Technical

N06625componentsusingfull-meltpowderbedfusionsuchas

Barriers to Trade (TBT) Committee.

electron beam melting and laser melting. The components

produced by these processes are used typically in applications

2. Referenced Documents

thatrequiremechanicalpropertiessimilartomachinedforgings

2.1 ASTM Standards:

and wrought products. Components manufactured to this

B213 Test Methods for Flow Rate of Metal Powders Using

specification are often, but not necessarily, post processed via

the Hall Flowmeter Funnel

machining, grinding, electrical discharge machining (EDM),

B214 Test Method for Sieve Analysis of Metal Powders

polishing, and so forth to achieve desired surface finish and

B243 Terminology of Powder Metallurgy

critical dimensions.

B311 Test Method for Density of Powder Metallurgy (PM)

1.2 This specification is intended for the use of purchasers

Materials Containing Less Than Two Percent Porosity

orproducers,orboth,ofadditivelymanufacturedUNSN06625

B769 Test Method for Shear Testing of Aluminum Alloys

components for defining the requirements and ensuring com-

B880 Specification for General Requirements for Chemical

ponent properties.

Check Analysis Limits for Nickel, Nickel Alloys and

1.3 Users are advised to use this specification as a basis for

Cobalt Alloys

obtaining components that will meet the minimum acceptance B964 Test Methods for Flow Rate of Metal Powders Using

requirements established and revised by consensus of the

the Carney Funnel

members of the committee. D3951 Practice for Commercial Packaging

E3 Guide for Preparation of Metallographic Specimens

1.4 User requirements considered more stringent may be

E8/E8M Test Methods for Tension Testing of Metallic Ma-

met by the addition to the purchase order of one or more

terials

supplementary requirements, which may include, but are not

E9 Test Methods of Compression Testing of Metallic Mate-

limited to, those listed in Supplementary Requirements

rials at Room Temperature

S1–S16.

E10 Test Method for Brinell Hardness of Metallic Materials

1.5 Units—The values stated in SI units are to be regarded

E11 Specification for Woven Wire Test Sieve Cloth and Test

as the standard. No other units of measurement are included in

Sieves

this standard.

E18 Test Methods for Rockwell Hardness of Metallic Ma-

1.6 This standard does not purport to address all of the

terials

safety concerns, if any, associated with its use. It is the

E21 TestMethodsforElevatedTemperatureTensionTestsof

responsibility of the user of this standard to establish appro-

Metallic Materials

priate safety, health, and environmental practices and deter-

E23 Test Methods for Notched Bar Impact Testing of Me-

mine the applicability of regulatory limitations prior to use.

tallic Materials

1.7 This international standard was developed in accor-

E29 Practice for Using Significant Digits in Test Data to

dance with internationally recognized principles on standard-

Determine Conformance with Specifications

E238 Test Method for Pin-Type Bearing Test of Metallic

Materials

ThistestmethodisunderthejurisdictionofASTMCommitteeF42onAdditive

Manufacturing Technologies and is the direct responsibility of Subcommittee

F42.05 on Materials and Processes. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2021. Published November 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ɛ1

approved in 2014. Last previous edition approved in 2014 as F3056-14 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F3056-14R21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3056−14 (2021)

E354 Test Methods for Chemical Analysis of High- ISO 6507-1 Metallic materials—Vickers hardness test—Part

Temperature,Electrical,Magnetic,andOtherSimilarIron, 1: Test method

Nickel, and Cobalt Alloys ISO 6508 Metallic materials—Rockwell hardness test—Part

E384 Test Method for Microindentation Hardness of Mate- 1: Test method (scales A, B, C, D, E, F, G, H, K, N, T)

rials ISO 6892-1 Metallic materials—Tensile testing at ambient

E399 Test Method for Linear-Elastic Plane-Strain Fracture temperature

Toughness of Metallic Materials ISO 6892-2 Metallic materials—Tensile testing—Part 2:

E407 Practice for Microetching Metals and Alloys Method of test at elevated temperature

E466 Practice for Conducting Force Controlled Constant ISO 9001 Quality management system—Requirements

Amplitude Axial Fatigue Tests of Metallic Materials ISO 9044 Industrial woven wire cloth—Technical require-

E606 Test Method for Strain-Controlled Fatigue Testing ments and testing

E647 Test Method for Measurement of Fatigue Crack ISO 12108 Metallic materials—Fatigue testing—Fatigue

Growth Rates crack growth method

E1019 Test Methods for Determination of Carbon, Sulfur, ISO 12111 Metallic materials—Fatigue testing—Strain-

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt controlled thermomechanical fatigue testing method

Alloys by Various Combustion and Inert Gas Fusion ISO 12135 Metallic materials—Unified method of test for

Techniques the determination of quasistatic fracture toughness

E1417 Practice for Liquid Penetrant Testing ISO 12737 Metallic materials—Determination of plane-

E1450 Test Method for Tension Testing of StructuralAlloys strain fracture toughness (withdrawn)

in Liquid Helium ISO 13485 Medical devices—Quality management

E1473 Test Methods for Chemical Analysis of Nickel, Co- systems—Requirements for regulatory purposes

balt and High-Temperature Alloys ISO 19819 Metallic materials—Tensile testing in liquid

E1820 Test Method for Measurement of Fracture Toughness helium

E1941 Test Method for Determination of Carbon in Refrac-

2.5 Military Standard:

toryandReactiveMetalsandTheirAlloysbyCombustion

MIL-C-24615A Military Specification, Castings, Nickel-

Analysis

Chromium-Molybdenum, Columbium Alloy

E2368 Practice for Strain Controlled Thermomechanical

2.6 SAE Standards:

Fatigue Testing

AMS 2269 Chemical Check Analysis Limits Nickel, Nickel

F629 Practice for Radiography of Cast Metallic Surgical

Alloys, and Cobalt Alloys

Implants

AMS 5599 Nickel Alloy, Corrosion and Heat-Resistant,

F2792 Terminology for Additive Manufacturing Technolo-

Sheet, Strip, and Plate 62Ni-21.5Cr-9.0Mo-3.7Cb (Nb)

gies (Withdrawn 2015)

Solution Heat Treated

F2924 Specification for Additive Manufacturing Titanium-6

AMS 2774 Heat Treatment Wrought Nickel Alloy and Co-

Aluminum-4 Vanadium with Powder Bed Fusion

balt Alloy Parts

2.2 ISO/ASTM Standards:

AS 9100 Quality Systems—Aerospace—Model for Quality

52915 Specification forAdditive Manufacturing File Format

Assurance in Design, Development, Production, Installa-

(AMF) Version 1.1

tion and Servicing

52921 Terminology for Additive Manufacturing—

2.7 ASME Standard:

Coordinate Systems and Test Methodologies

ASME B46.1 Surface Texture

2.3 ASQ Standard:

2.8 NIST Standard:

ASQ C1 Specification of General Requirements for a Qual-

IR 7847 (March 2012) CODEN:NTNOEF

ity Program

3. Terminology

2.4 ISO Standards:

ISO 148-1 Metallic materials—Charpy pendulum impact

3.1 Definitions:

test—Part 1: Test method

3.1.1 Terminology relating to powder bed fusion in Speci-

ISO 1099 Metallic materials—Fatigue testing—Axial force-

fication F2924 shall apply.

controlled method

3.1.2 Terminology relating to additive manufacturing in

ISO 4545 Metallic materials—Knoop hardness test—Part 2:

Terminology F2792 shall apply.

Verification and calibration of testing machines

ISO 6506-1 Metallic materials—Brinell hardness test—Part

1: Test method Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

dodssp.daps.dla.mil.

Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

The last approved version of this historical standard is referenced on PA 15096-0001, http://www.sae.org.

www.astm.org. Available from American Society of Mechanical Engineers (ASME), ASME

Available from American Society for Quality (ASQ), 600 N. Plankinton Ave., International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

Milwaukee, WI 53203, http://www.asq.org. www.asme.org.

5 9

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Available from National Institute of Standards and Technology (NIST), 100

4th Floor, New York, NY 10036, http://www.ansi.org. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

F3056−14 (2021)

Location, orientation on the build platform, number of test specimens for

3.1.3 Terminology relating to coordinate systems in Termi-

each machine qualification build cycle, and relationship between speci-

nology 52921 shall apply.

men test results and component quality shall be agreed upon between

3.1.4 Terminology relating to powder metallurgy in Termi-

component supplier and purchaser.

nology B243 shall apply.

6.1.2 Feedstock that meets the requirements of Section 7;

6.1.3 The machine identification, including machine soft-

4. Classification

ware version, manufacturing control system version (if

4.1 Unless otherwise specified herein, all classifications

automated), build chamber environment, machine

shall meet the requirements in each section of this standard.

conditioning, and calibration information of the qualified

4.1.1 Class A components shall be stress relieved or an-

machine;

nealed per Section 12.

6.1.4 Predetermined process as substantiated by the quali-

4.1.2 Class B components shall be annealed per Section 12.

fication procedure;

4.1.3 Class C components shall be hot isostatically pressed

6.1.5 Safeguards to ensure traceability of the digital files,

per Section 13.

including design history of the components;

4.1.4 Class D—Not Used.

6.1.6 All the steps necessary to start the build process,

4.1.5 For Class E components, all thermal post processing

including build platform selection, machine cleaning, and

shall be optional.

powder handling;

4.1.6 Class F—Not Used.

6.1.7 The requirements for approving machine operators;

6.1.8 Logging of machine build data files, upper and lower

5. Ordering Information

limits of the parameters affecting component quality and other

5.1 Orders for components compliant with this specification

process validation controls;

shall include the following to describe the requirements ad-

6.1.9 The number of components per build cycle, their

equately:

orientation and location on the build platform, and support

5.1.1 This specification designation,

structures, if required;

5.1.2 Description or part number of product desired,

6.1.10 Process steps including, but not limited to, Section 8;

5.1.3 Quantity of product desired,

6.1.11 Post-processingprocedure,includingsequenceofthe

5.1.4 Classification,

post-processing steps and the specifications for each step;

5.1.5 SI or SAE units,

6.1.12 Thermal processing including stress relieve, furnace

5.1.5.1 Discussion—The STL file format used by many

anneal, hot isostatic pressing, and heat treat; and

powder bed fusion machines does not contain units of mea-

6.1.13 Inspection requirements as agreed between the pur-

surementasmetadata.WhenonlySTLfilesareprovidedbythe

chaser and component supplier, including any supplementary

purchaser, ordering information should specify the units of the

requirements.

component along with the electronic data file. More informa-

7. Feedstock

tion about data files can be found in ISO/ASTM 52915.

5.1.6 Dimensions and tolerances (Section 14),

7.1 The feedstock for this specification shall be metal

5.1.7 Mechanical properties (Section 11),

powder, as defined in ASTM B243, that has the powder type,

5.1.8 Methods for chemical analysis (Section 9),

size distribution, shape, tap density, and flow rate acceptable

5.1.9 Sampling methods (Section S16),

for the process as determined by the component supplier.

5.1.10 Post-processing sequence of operations,

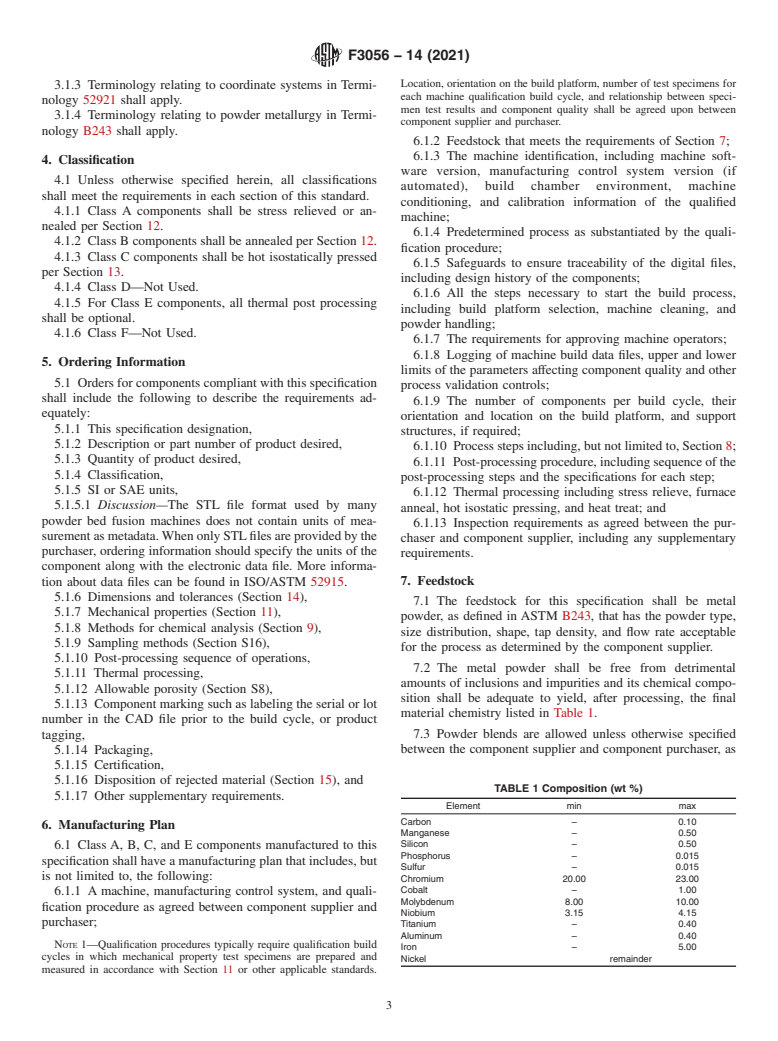

7.2 The metal powder shall be free from detrimental

5.1.11 Thermal processing,

amounts of inclusions and impurities and its chemical compo-

5.1.12 Allowable porosity (Section S8),

sition shall be adequate to yield, after processing, the final

5.1.13 Component marking such as labeling the serial or lot

material chemistry listed in Table 1.

number in the CAD file prior to the build cycle, or product

tagging, 7.3 Powder blends are allowed unless otherwise specified

between the component supplier and component purchaser, as

5.1.14 Packaging,

5.1.15 Certification,

5.1.16 Disposition of rejected material (Section 15), and

TABLE 1 Composition (wt %)

5.1.17 Other supplementary requirements.

Element min max

Carbon – 0.10

6. Manufacturing Plan

Manganese – 0.50

Silicon – 0.50

6.1 Class A, B, C, and E components manufactured to this

Phosphorus – 0.015

specification shall have a manufacturing plan that includes, but

Sulfur – 0.015

is not limited to, the following:

Chromium 20.00 23.00

Cobalt – 1.00

6.1.1 A machine, manufacturing control system, and quali-

Molybdenum 8.00 10.00

fication procedure as agreed between component supplier and

Niobium 3.15 4.15

purchaser;

Titanium – 0.40

Aluminum – 0.40

NOTE 1—Qualification procedures typically require qualification build

Iron – 5.00

cycles in which mechanical property test specimens are prepared and Nickel remainder

measured in accordance with Section 11 or other applicable standards.

F3056−14 (2021)

long as all powder used to create the powder blend meets the 8.3 Condition and finish of the components shall be agreed

requirements in Table 1 and lot numbers are documented and upon between the component supplier and purchaser.

maintained.

8.4 Post-processing operations may be used to achieve the

7.4 Used powder is allowed. The proportion of virgin desire

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.