ASTM E1476-04(2010)

(Guide)Standard Guide for Metals Identification, Grade Verification, and Sorting

Standard Guide for Metals Identification, Grade Verification, and Sorting

SIGNIFICANCE AND USE

A major concern of metals producers, warehouses, and users is to establish and maintain the identity of metals from melting to their final application. This involves the use of standard quality assurance practices and procedures throughout the various stages of manufacturing and processing, at warehouses and materials receiving, and during fabrication and final installation of the product. These practices typically involve standard chemical analyses and physical tests to meet product acceptance standards, which are slow. Several pieces from a production run are usually destroyed or rendered unusable through mechanical and chemical testing, and the results are used to assess the entire lot using statistical methods. Statistical quality assurance methods are usually effective; however, mixed grades, off-chemistry, and nonstandard physical properties remain the primary causes for claims in the metals industry. A more comprehensive verification of product properties is necessary. Nondestructive means are available to supplement conventional metals grade verification techniques, and to monitor chemical and physical properties at selected production stages, in order to assist in maintaining the identities of metals and their consistency in mechanical properties.

Nondestructive methods have the potential for monitoring grade during production on a continuous or statistical basis, for monitoring properties such as hardness and case depth, and for verifying the effectiveness of heat treatment, cold-working, and the like. They are quite often used in the field for solving problems involving off-grade and mixed-grade materials.

The nondestructive methods covered in this guide provide both direct and indirect responses to the sample being evaluated. Spectrometric analysis instruments respond to the presence and percents of alloying constituents. The electromagnetic (eddy current) and thermoelectric methods, on the other hand, are among those that respond to properties in t...

SCOPE

1.1 This guide is intended for tutorial purposes only. It describes the general requirements, methods, and procedures for the nondestructive identification and sorting of metals.

1.2 It provides guidelines for the selection and use of methods suited to the requirements of particular metals sorting or identification problems.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1476 −04(Reapproved 2010)

Standard Guide for

1

Metals Identification, Grade Verification, and Sorting

This standard is issued under the fixed designation E1476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F355TestMethodforImpactAttenuationofPlayingSurface

Systems and Materials

1.1 This guide is intended for tutorial purposes only. It

F1156Terminology Relating to Product Counterfeit Protec-

describes the general requirements, methods, and procedures

3

tion Systems (Withdrawn 2001)

for the nondestructive identification and sorting of metals.

1.2 It provides guidelines for the selection and use of

3. Terminology

methods suited to the requirements of particular metals sorting

3.1 Definitions—Terms used in this guide are defined in the

or identification problems.

standards cited in Section 2 and in current technical literature

1.3 This standard does not purport to address all of the

or dictionaries; however, because a number of terms that are

safety concerns, if any, associated with its use. It is the

used generally in nondestructive testing have meanings or

responsibility of the user of this standard to establish appro-

carry implications unique to metal sorting, they appear with

priate safety and health practices and determine the applica-

explanation in Appendix X1.

bility of regulatory limitations prior to use. For specific

precautionary statements, see Section 10.

4. Significance and Use

4.1 A major concern of metals producers, warehouses, and

2. Referenced Documents

users is to establish and maintain the identity of metals from

2

2.1 ASTM Standards:

melting to their final application. This involves the use of

E158Practice for Fundamental Calculations to Convert

standardqualityassurancepracticesandproceduresthroughout

Intensities into Concentrations in Optical Emission Spec-

the various stages of manufacturing and processing, at ware-

3

trochemical Analysis (Withdrawn 2004)

housesandmaterialsreceiving,andduringfabricationandfinal

E305Practice for Establishing and Controlling Atomic

installation of the product. These practices typically involve

Emission Spectrochemical Analytical Curves

standard chemical analyses and physical tests to meet product

E322Test Method for Analysis of Low-Alloy Steels and

acceptance standards, which are slow. Several pieces from a

CastIronsbyWavelengthDispersiveX-RayFluorescence

production run are usually destroyed or rendered unusable

Spectrometry

through mechanical and chemical testing, and the results are

E566Practice for Electromagnetic (Eddy-Current) Sorting

usedtoassesstheentirelotusingstatisticalmethods.Statistical

of Ferrous Metals

quality assurance methods are usually effective; however,

E572TestMethodforAnalysisofStainlessandAlloySteels

mixed grades, off-chemistry, and nonstandard physical proper-

by X-ray Fluorescence Spectrometry

ties remain the primary causes for claims in the metals

E703Practice for Electromagnetic (Eddy-Current) Sorting

industry. A more comprehensive verification of product prop-

of Nonferrous Metals

erties is necessary. Nondestructive means are available to

E977Practice for Thermoelectric Sorting of Electrically

supplement conventional metals grade verification techniques,

Conductive Materials

and to monitor chemical and physical properties at selected

production stages, in order to assist in maintaining the identi-

1

ties of metals and their consistency in mechanical properties.

This guide is under the jurisdiction ofASTM Committee E07 on Nondestruc-

tiveTesting and is the direct responsibility of Subcommittee E07.10 on Specialized

4.2 Nondestructive methods have the potential for monitor-

NDT Methods.

inggradeduringproductiononacontinuousorstatisticalbasis,

Current edition approved June 1, 2010. Published November 2010. Originally

approved in 1992. Last previous edition approved in 2004 as E1476-04. DOI:

formonitoringpropertiessuchashardnessandcasedepth,and

10.1520/E1476-04R10.

forverifyingtheeffectivenessofheattreatment,cold-working,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and the like. They are quite often used in the field for solving

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on problems involving off-grade and mixed-grade materials.

the ASTM website.

3

4.3 The nondestructive methods covered in this guide pro-

The last approved version of this historical standard is referenced on

www.astm.org. vide both direct and indirect responses to the sample being

Copyright © ASTM International,

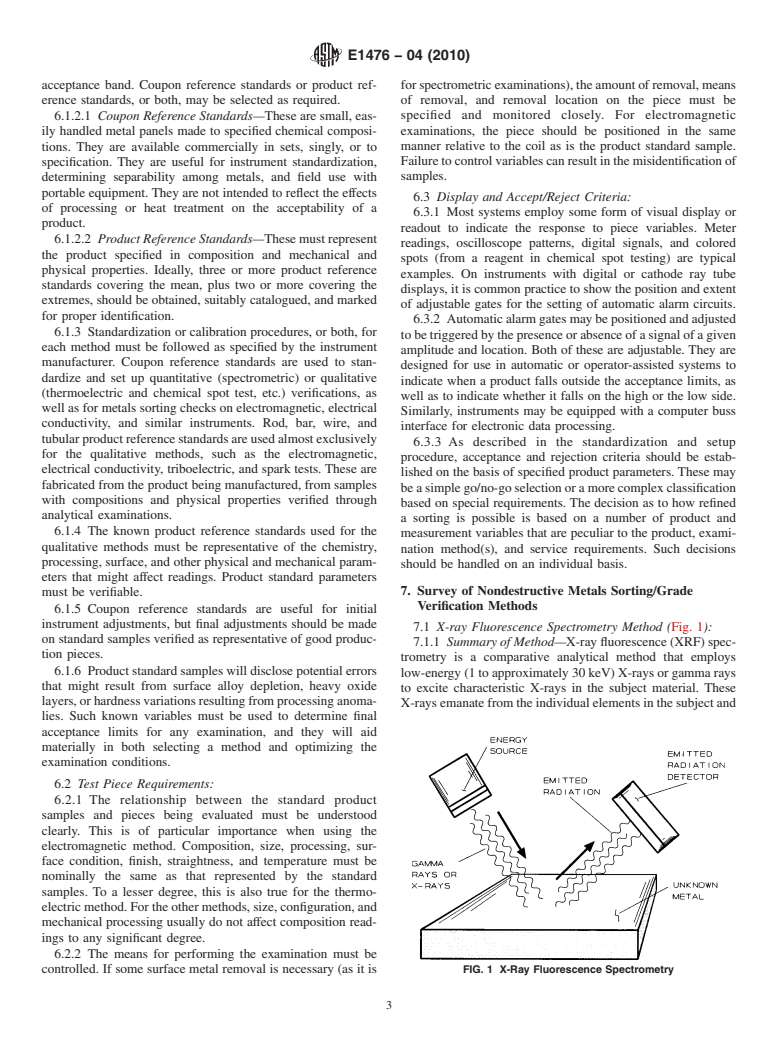

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.