ASTM A982/A982M-10(2020)

(Specification)Standard Specification for Steel Forgings, Stainless, for Compressor and Turbine Airfoils

Standard Specification for Steel Forgings, Stainless, for Compressor and Turbine Airfoils

ABSTRACT

This specification covers stainless steel forgings for compressor and turbine bucket, blade, and airfoil applications. The stainless steel shall be made by the melting process and either the closed impression die or the open die forging processes may be utilized. Two complete heat treatments, consisting of an austenize, quench, and temper, are permitted. When heat treatment for mechanical properties is followed by straightening, a stress-relieving heat treatment is required. The forgings shall be subjected to tension, impact, hardness, and non-destructive tests. All forgings shall be free of cracks, seams, laps, shrinkage, and similar discontinuities.

SCOPE

1.1 This specification covers stainless steel forgings for compressor and turbine bucket, blade, and airfoil applications.

1.2 This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies the applicable M designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A982/A982M −10 (Reapproved 2020)

Standard Specification for

Steel Forgings, Stainless, for Compressor and Turbine

Airfoils

This standard is issued under the fixed designationA982/A982M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E562Test Method for Determining Volume Fraction by

Systematic Manual Point Count

1.1 This specification covers stainless steel forgings for

compressor and turbine bucket, blade, and airfoil applications.

3. Ordering Information

1.2 This specification is expressed in both inch-pound units

3.1 In addition to the ordering information required by

and in SI units; however, unless the purchase order or contract

Specification A788/A788M, the purchaser shall include a

specifies the applicable M designation (SI units), the inch-

sketchorwrittendescriptionoftheforgingwiththeinquiryand

pound units shall apply.The values stated in either inch-pound

order.

units or SI units are to be regarded separately as standard.

4. General Requirements

Within the text, the SI units are shown in brackets. The values

stated in each system are not necessarily exact equivalents;

4.1 Materials supplied to this specification shall conform to

therefore, to ensure conformance with the standard, each the requirements of Specification A788/A788M, which out-

system shall be used independently of the other, and values

lines additional ordering information, manufacturing

from the two systems shall not be combined. requirements, testing and retesting methods and procedures,

marking, certification, product analysis variations and addi-

1.3 This international standard was developed in accor-

tional supplementary requirements.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4.2 If the requirements of this specification are in conflict

Development of International Standards, Guides and Recom-

with the requirements of Specification A788/A788M, the

mendations issued by the World Trade Organization Technical

requirements of this specification shall prevail.

Barriers to Trade (TBT) Committee.

5. Manufacture

2. Referenced Documents

5.1 MeltingProcess—AllmeltingprocessesofSpecification

2.1 ASTM Standards: A788/A788M are permitted unless Supplementary Require-

ment S1 is invoked by the purchaser.

A275/A275MPracticeforMagneticParticleExaminationof

Steel Forgings

5.2 Forging Process—Either the closed impression die or

A788/A788MSpecification for Steel Forgings, General Re-

the open die forging processes may be utilized unless the

quirements

purchaser specifies one or the other.

E112Test Methods for Determining Average Grain Size

5.2.1 Forging Temperature—The maximum part tempera-

E292Test Methods for Conducting Time-for-Rupture Notch

ture during forging shall be 2150°F [1175°C].

Tension Tests of Materials

5.3 HeatTreatment—Heattreatingallforgingsisrequiredin

E381Method of Macroetch Testing Steel Bars, Billets,

accordance with Table 1 to develop the required mechanical

Blooms, and Forgings

properties.

5.3.1 Number of Heat Treatments—Two complete heat

treatments, consisting of an austenitize, quench, and temper,

are permitted. Purchaser approval is required prior to any

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee additional heat treatments.

A01.06 on Steel Forgings and Billets.

5.3.2 Temperature Variation—Heat treating temperatures

Current edition approved March 1, 2020. Published March 2020. Originally

shall be controlled in the range of 625°F [614°C].

published in 1998. Last previous edition approved in 2015 as A982/A982M–10

(2015). DOI: 10.1520/A0982_A0982M–10R20.

5.4 Stress Relief—When heat treatment for mechanical

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

properties is followed by straightening, a stress-relieving heat

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

treatmentisrequiredatatemperaturemeetingtherequirements

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. of Table 1.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A982/A982M − 10 (2020)

TABLE 1 Heat Treatment, °F [°C]

Grade A Grade B Grade C Grade D Grade E Grade F

Classes1&2 Class1 Class1 Class2 Classes1&2 Class1 Class2 Class1

Austenitizing 1725-1775 1600-1750 1825-1875 1725-1875 1875-1925 2075-2125 1725-1775 1875-1925

[940-970] [870-955] [995-1025] [940-1025] [1025-1050] [1135-1165] [940-970] [1025-1050]

Quenching Air or liquid Air or liquid Air or liquid Air or liquid Air or liquid Air or liquid Air or liquid Air or liquid

Single tempering 1050 min 1050 min 1050 min 1050 min 1150 min 1250 min 1100 min .

[565 min] [565 min] [565 min] [565 min] [620 min] [675 min] [595 min]

Double tempering . . . . . . 1025 min 1025 min . . . .

[550 min] [550 min]

Aging . . . . . . . . . . . . . . . . . . . . . 1135-1165

[615-630]

Stress Relieving 1025 min 1025 min 1000 min 1000 min 1100 min 1200 min 1050 min 1100 min

[550 min] [550 min] [540 min] [540 min] [595 min] [650 min] [565 min] [595 min]

5.4.1 QuenchingafterStressRelief—Wateroroilquenching 7.1.1.3 Test Locations—One tension test specimen and one

of stress-relieved forgings is prohibited. set of three impact test specimens shall be machined from the

center portion of the air foil vane section.

6. Chemical Composition

7.1.2 Forging Hardness Testing:

7.1.2.1 Batch Type Furnaces—A minimum of 10% of the

6.1 Thesteelshallconformtotherequirementsforchemical

forgings in each lot shall be hardness tested.

composition prescribed in Table 2.

7.1.2.2 Continuous Type Furnaces—Samples for hardness

7. Mechanical Properties

testing shall be taken from every other tray or push.

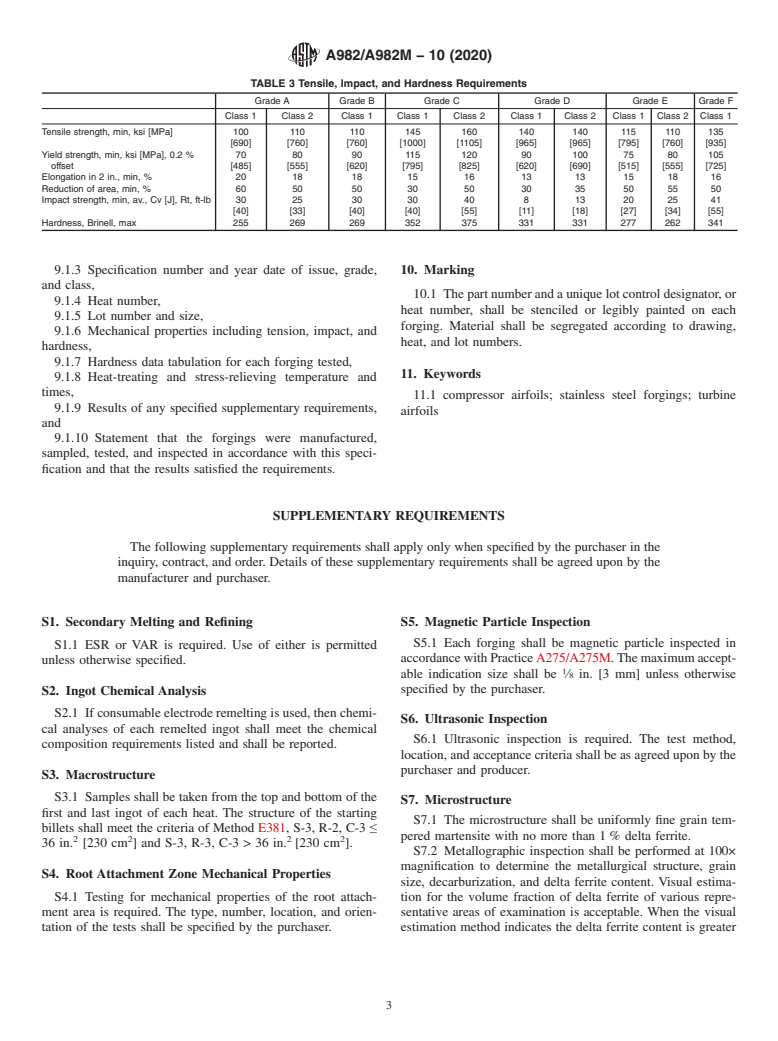

7.1 Tension, Impact, and Hardness Tests—All testing shall

8. Nondestructive Examination

be performed after heat treatment and stress relief, as appli-

cable.The test specimens shall meet the requirements of Table

8.1 General Requirements—All forgings shall be free of

3.

cracks, seams, laps, shrinkage, and similar discontinuities.

7.1.1 Number of Tests—A minimum of two forgings from

8.2 NondestructiveTests—Nondestructivetestingandcorre-

each lot shall be randomly selected for longitudinal tensile,

sponding acceptance criteria shall be as specified by the

impact, and hardness testing. Hardness values of the tension

purchaser.

test specimen shall be reported with the tensile data.

7.1.1.1 Lot Size—A lot shall consist of all forgings of the

9. Certification and Reports

same size from one electric furnace heat of steel and heat

9.1 All tests required by this specification shall be made by

treated either in the same charge in either a batch furnace or a

the manufacturer and reported on a certificate of test to the

continuous type furnace.

purchaser. Each test certificate shall include the following

7.1.1.2 Continuous Heat Treating Furnaces—Test forgings

items:

shallbetakenfromeachofthefirstandlastpushortraytoexit

9.1.1 Purchase order number,

the furnace. Additional forgings shall be taken so that the

maximum time between samples is 4 h. 9.1.2 Forging identification number,

TABL

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.