ASTM C1812/C1812M-15e1

(Practice)Standard Practice for Design of Journal Bearing Supports to be Used in Fiber Reinforced Concrete Beam Tests

Standard Practice for Design of Journal Bearing Supports to be Used in Fiber Reinforced Concrete Beam Tests

SIGNIFICANCE AND USE

4.1 The presence of friction in the supporting rollers used when testing a fiber-reinforced concrete beam will increase the apparent load resistance of the beam. Roller supports designed in accordance with this practice will provide a relatively low and consistent value of friction at the supports.

4.2 Two types of rollers are used to support a beam. One includes a cylindrical bearing that allows the roller assembly to rotate along an axis parallel to the longitudinal axis of the beam and thereby accommodate any warping introduced during specimen fabrication. The other roller does not include the cylindrical bearing.

4.3 The rollers are designed for use with 150 mm [6 in.] or 100 mm [4 in.] deep beams of square cross-section.

4.4 A method is provided for correcting the apparent load resistance measured using the roller with a known value of the effective coefficient of friction of the roller supports to obtain an estimate of the load resistance in the absence of friction.

SCOPE

1.1 This practice prescribes the design of journal-bearing type rollers to support each end of fiber-reinforced concrete beams tested using Test Method C1399/C1399M or Test Method C1609/C1609M. The roller design is intended to provide a consistent and relatively low value of effective coefficient of friction at the beam supports. The bearing design incorporates metal-on-metal sliding surfaces lubricated with grease.

Note 1: During the progress of a test, a crack or cracks open on the underside of the beam between the loaded third points causing the underside of each portion of the beam to move away from the center. The design is intended to provide for unlimited rotation of the roller at the point of contact with the test beam in response to this motion.

Note 2: The design of the supporting rollers is a significant factor in determining the magnitude of the arching forces that cause error in flexural test results.2 Improperly designed supporting rollers can influence the apparent flexural behavior of fiber-reinforced concrete beams.3 The effective coefficient of friction can be determined using a method similar to that described by Bernard.4

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C1812/C1812M − 15

Standard Practice for

Design of Journal Bearing Supports to be Used in Fiber

1

Reinforced Concrete Beam Tests

This standard is issued under the fixed designation C1812/C1812M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—The designation was corrected editorially in June 2016 to conform with the units statement (1.2).

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This practice prescribes the design of journal-bearing

bility of regulatory limitations prior to use.

type rollers to support each end of fiber-reinforced concrete

beams tested using Test Method C1399/C1399M or Test

2. Referenced Documents

Method C1609/C1609M. The roller design is intended to

5

2.1 ASTM Standards:

provide a consistent and relatively low value of effective

C125 Terminology Relating to Concrete and Concrete Ag-

coefficient of friction at the beam supports. The bearing design

gregates

incorporates metal-on-metal sliding surfaces lubricated with

C1399/C1399M Test Method for Obtaining Average

grease.

Residual-Strength of Fiber-Reinforced Concrete

NOTE 1—During the progress of a test, a crack or cracks open on the

C1609/C1609M Test Method for Flexural Performance of

underside of the beam between the loaded third points causing the

underside of each portion of the beam to move away from the center. The

Fiber-Reinforced Concrete (Using BeamWithThird-Point

design is intended to provide for unlimited rotation of the roller at the

Loading)

point of contact with the test beam in response to this motion.

D4950 Classification and Specification for Automotive Ser-

NOTE 2—The design of the supporting rollers is a significant factor in

vice Greases

determining the magnitude of the arching forces that cause error in

6

2

2.2 SAE International Standard:

flexural test results. Improperly designed supporting rollers can influence

3

the apparent flexural behavior of fiber-reinforced concrete beams. The

J 404 Chemical Composition of SAE Alloy Steels

effective coefficient of friction can be determined using a method similar

4

to that described by Bernard.

3. Terminology

1.2 Units—The values stated in either SI units or inch-

3.1 Definitions:

pound units are to be regarded separately as standard. The

3.1.1 For definitions of terms used in this practice, refer to

values stated in each system may not be exact equivalents;

Terminology C125.

therefore,eachsystemshallbeusedindependentlyoftheother.

3.2 Definitions of Terms Specific to This Standard:

Combining values from the two systems may result in non-

3.2.1 effective coeffıcient of friction, n—a dimensionless

conformance with the standard.

ratio of the horizontal force required to initiate rotation of the

roller support applied at the contact point between the roller

1.3 This standard does not purport to address all of the

and test beam divided by the normal force applied at the same

safety concerns, if any, associated with its use. It is the

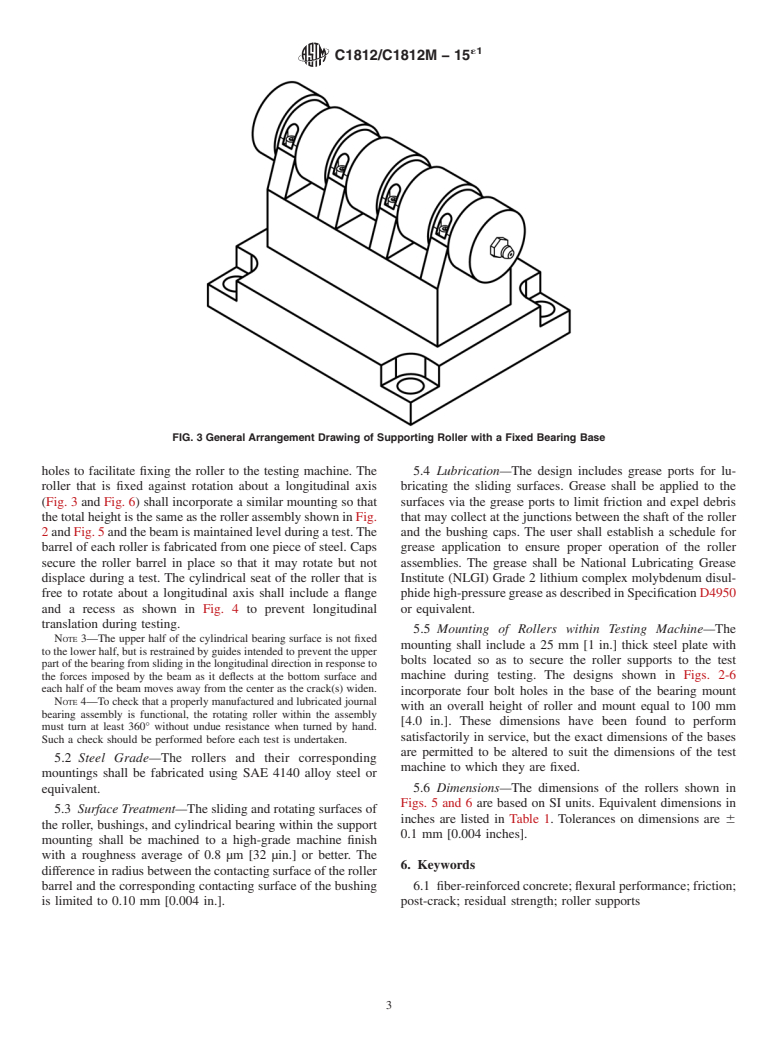

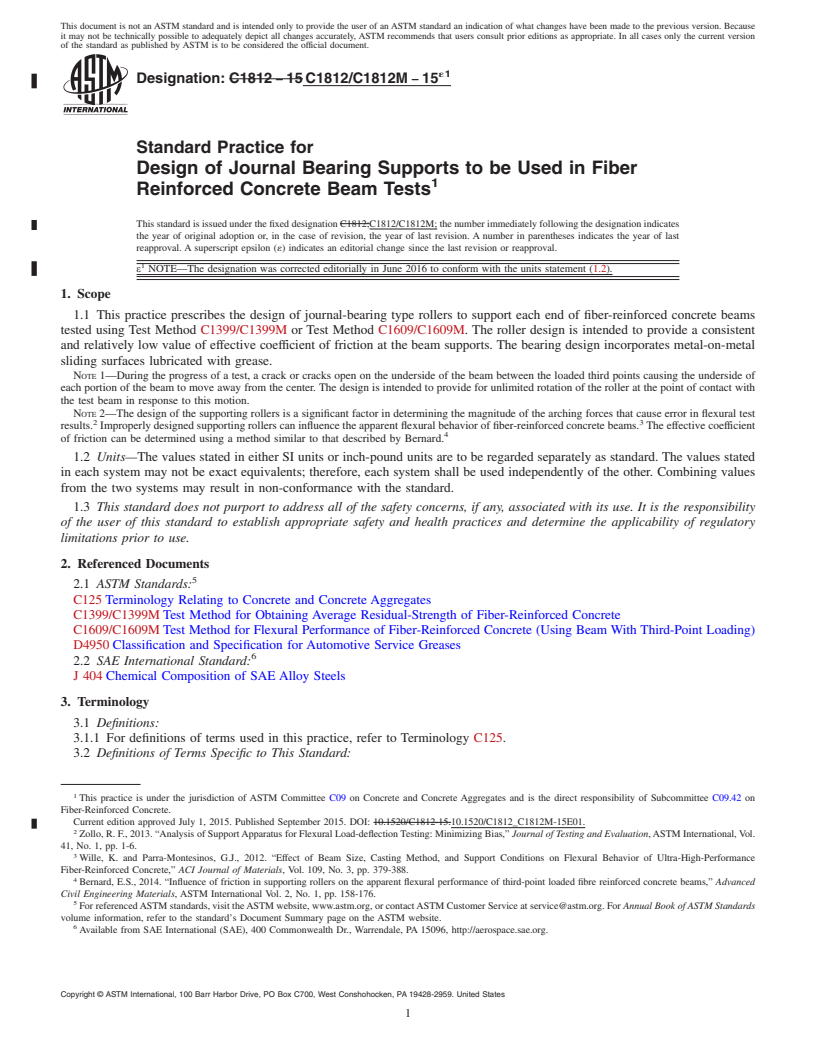

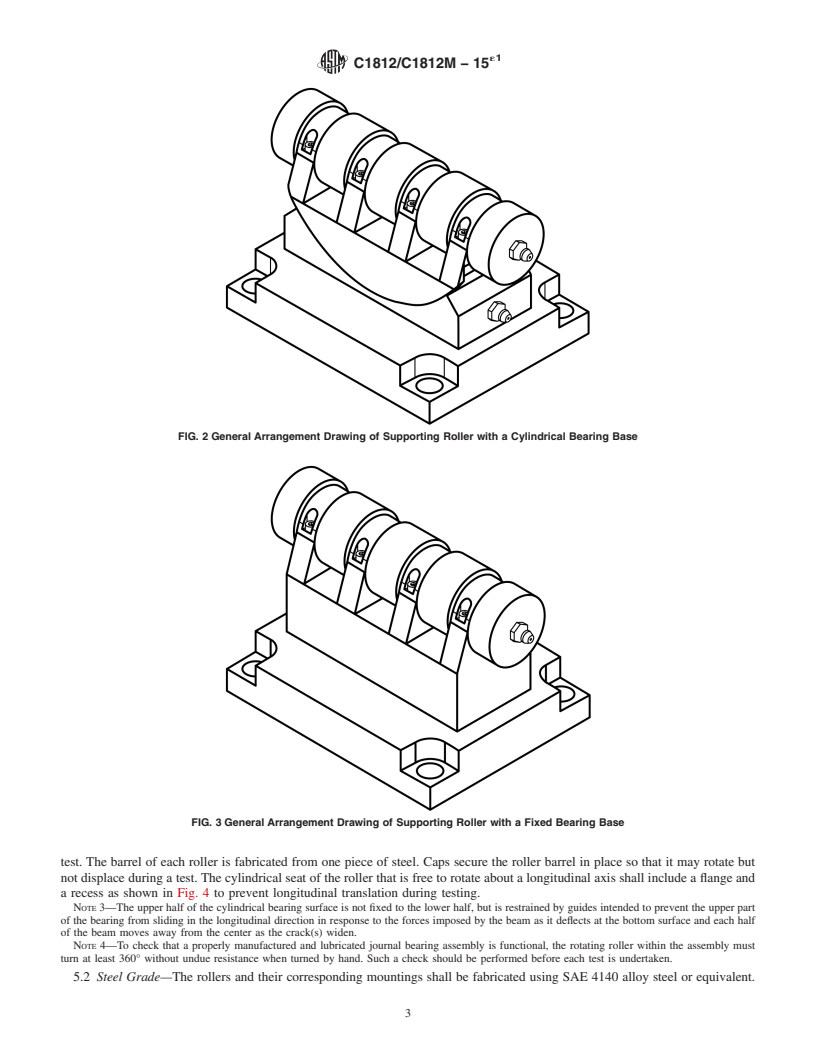

point (see Fig. 1).

3.2.2 roller, n—a journal bearing capable of continuous

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete

andConcreteAggregatesandisthedirectresponsibilityofSubcommitteeC09.42on rotation without exhibiting a significant variation in resistance

Fiber-Reinforced Concrete.

to rotation.

Current edition approved July 1, 2015. Published September 2015. DOI:

10.1520/C1812_C1812M-15E01.

4. Significance and Use

2

Zollo,R.F.,2013.“AnalysisofSupportApparatusforFlexuralLoad-deflection

Testing: Minimizing Bias,” Journal of Testing and Evaluation,ASTM International, 4.1 The presence of friction in the supporting rollers used

Vol. 41, No. 1, pp. 1-6.

when testing a fiber-reinforced concrete beam will increase the

3

Wille, K. and Parra-Montesinos, G.J., 2012. “Effect of Beam Size, Casting

Method, and Support Conditions on Flexural Behavior of Ultra-High-Performance

5

Fiber-Reinforced Concrete,” ACI Journal of Materials, Vol. 109, No. 3, pp. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

379-388. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Bernard, E.S., 2014. “Influence of friction in supporting rollers on the apparent Standards volume information, refer to the standard’s Document Summary page on

flexural performance of third-point loaded fibre reinforced concrete beams,” the ASTM website.

6

Advanced Civil Engineering Materials, ASTM International Vol. 2, No. 1, pp. Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

158-176. PA 15096, ht

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: C1812 − 15 C1812/C1812M − 15

Standard Practice for

Design of Journal Bearing Supports to be Used in Fiber

1

Reinforced Concrete Beam Tests

This standard is issued under the fixed designation C1812;C1812/C1812M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—The designation was corrected editorially in June 2016 to conform with the units statement (1.2).

1. Scope

1.1 This practice prescribes the design of journal-bearing type rollers to support each end of fiber-reinforced concrete beams

tested using Test Method C1399/C1399M or Test Method C1609/C1609M. The roller design is intended to provide a consistent

and relatively low value of effective coefficient of friction at the beam supports. The bearing design incorporates metal-on-metal

sliding surfaces lubricated with grease.

NOTE 1—During the progress of a test, a crack or cracks open on the underside of the beam between the loaded third points causing the underside of

each portion of the beam to move away from the center. The design is intended to provide for unlimited rotation of the roller at the point of contact with

the test beam in response to this motion.

NOTE 2—The design of the supporting rollers is a significant factor in determining the magnitude of the arching forces that cause error in flexural test

2 3

results. Improperly designed supporting rollers can influence the apparent flexural behavior of fiber-reinforced concrete beams. The effective coefficient

4

of friction can be determined using a method similar to that described by Bernard.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

5

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C1399/C1399M Test Method for Obtaining Average Residual-Strength of Fiber-Reinforced Concrete

C1609/C1609M Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading)

D4950 Classification and Specification for Automotive Service Greases

6

2.2 SAE International Standard:

J 404 Chemical Composition of SAE Alloy Steels

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this practice, refer to Terminology C125.

3.2 Definitions of Terms Specific to This Standard:

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.42 on

Fiber-Reinforced Concrete.

Current edition approved July 1, 2015. Published September 2015. DOI: 10.1520/C1812-15.10.1520/C1812_C1812M-15E01.

2

Zollo, R. F., 2013. “Analysis of Support Apparatus for Flexural Load-deflection Testing: Minimizing Bias,” Journal of Testing and Evaluation, ASTM International, Vol.

41, No. 1, pp. 1-6.

3

Wille, K. and Parra-Montesinos, G.J., 2012. “Effect of Beam Size, Casting Method, and Support Conditions on Flexural Behavior of Ultra-High-Performance

Fiber-Reinforced Concrete,” ACI Journal of Materials, Vol. 109, No. 3, pp. 379-388.

4

Bernard, E.S., 2014. “Influence of friction in supporting rollers on the apparent flexural performance of third-point loaded fibre reinforced concrete beams,” Advanced

Civil Engineering Materials, ASTM International Vol. 2, No. 1, pp. 158-176.

5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

6

Available from SAE International (SAE), 400 Commonwealth Dr., Warrendale, PA 15096, http://aerospace.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

C1812/C1812

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.