ASTM C4-04(2014)

(Specification)Standard Specification for Clay Drain Tile and Perforated Clay Drain Tile

Standard Specification for Clay Drain Tile and Perforated Clay Drain Tile

SCOPE

1.1 This specification establishes the criteria for acceptance, prior to installation, of drain tile and perforated drain tile to be used for underdrainage, filter fields, leaching fields, and similar subdrainage installations.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the Test Methods portion of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1: Attention is called to Test Methods C301 and Terminology C896.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C4 −04 (Reapproved 2014)

Standard Specification for

Clay Drain Tile and Perforated Clay Drain Tile

This standard is issued under the fixed designation C4; the number immediately following the designation indicates the year of original

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 4. Classification

4.1 Four classes of clay drain tile are specified:

1.1 Thisspecificationestablishesthecriteriaforacceptance,

4.1.1 Standard.

prior to installation, of drain tile and perforated drain tile to be

4.1.2 Extra Quality.

usedforunderdrainage,filterfields,leachingfields,andsimilar

4.1.3 Heavy Duty.

subdrainage installations.

4.1.4 Extra Strength.

1.2 The values stated in inch-pound units are to be regarded

4.2 Drain tile of a higher strength classification than that

as standard. The values given in parentheses are mathematical

specified by the purchaser may be furnished by the seller,

conversions to SI units that are provided for information only

provided the substituted drain tile meets the physical require-

and are not considered standard.

ments of the class specified.

1.3 The following safety hazards caveat pertains only to the

Test Methods portion of this specification: This standard does

5. Materials and Manufacture

not purport to address all of the safety concerns, if any,

5.1 Drain tile shall be manufactured from clay, fire clay,

associated with its use. It is the responsibility of the user of this

shale, surface clay, or a combination of these materials, that,

standard to establish appropriate safety and health practices

when formed into tile and fired to suitable temperatures, yields

and determine the applicability of regulatory limitations prior

a product that conforms to this specification.

to use.

NOTE 1—Attention is called to Test Methods C301 and Terminology

6. Physical Properties

C896.

6.1 Drain tile shall meet the physical test requirements for

the class, as specified in Table 1.

2. Referenced Documents

6.2 Themaximumwaterabsorption(5-hboiling)shallbeas

2.1 ASTM Standards:

follows:

C301Test Methods for Vitrified Clay Pipe

Average, % Individual, %

C896Terminology Relating to Clay Products

Standard 13 16

Extra Quality 11 13

3. Terminology Heavy Duty 11 13

Extra Strength 11 13

3.1 Definitions:

6.3 The requirements for water absorption (5–h boiling)

3.1.1 Clay, fire clay, shale,and surface clayareasdefinedin

shallbewaived,providedthattestspecimensmeettherequire-

Terminology C896.

ments of the freezing and thawing test, Section 13, of this

3.1.2 Within this specification, the terms tile, drain tile, and

specification

clay drain tile are synonyms.

7. Sizes and Perforations

7.1 The size of drain tile shall be designated by inside

This specification is under the jurisdiction of ASTM Committee C04 on

diameter. Not all sizes and strengths may be available from all

Vitrified Clay Pipe and is the direct responsibility of Subcommittee C04.20 on

manufacturers.

Methods of Test and Specifications.

Current edition approved Sept. 1, 2014. Published September 2014. Originally

7.2 The minimum length of drain tile smaller than 10 in.

approved in 1914. Last previous edition approved in 2009 as C4–04 (2009). DOI:

(255 mm) diameter shall be approximately 12 in. (305 mm).

10.1520/C0004-04R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.3 The length of drain tile 10 in. (255 mm) through 30 in.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(760 mm) diameter shall be not less than 1 ⁄2 times their

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. diameter.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C4−04 (2014)

TABLE 1 Physical Test Requirements for Clay Drain Tile

Standard Extra Quality Heavy Duty Extra Strength

Internal

A A A A

Diameter Minimum Crushing Strength, Minimum Crushing Strength, Minimum Crushing Strength, Minimum Crushing Strength,

lbf/linear ft (kN/m) lbf/linear ft (kN/m) lbf/linear ft (kN/m) lbf/linear ft (kN/m)

of Tile,

in.

Average Individual Average Individual Average Individual Average Individual

3 ⁄2 800 (12) 680 (10) 1100 (16) 990 (14) 1400 (20) 1260 (18) 2000 (29) 1800 (26)

4 800 (12) 680 (10) 1100 (16) 990 (14) 1400 (20) 1260 (18) 2000 (29) 1800 (26)

5 800 (12) 680 (10) 1100 (16) 990 (14) 1400 (20) 1260 (18) 2000 (29) 1800 (26)

6 800 (12) 680 (10) 1100 (16) 990 (14) 1400 (20) 1260 (18) 2000 (29) 1800 (26)

8 800 (12) 680 (10) 1100 (16) 990 (14) 1500 (22) 1350 (20) 2140 (31) 1920 (28)

10 800 (12) 680 (10) 1100 (16) 990 (14) 1550 (23) 1400 (20) 2200 (32) 1980 (29)

12 800 (12) 680 (10) 1100 (16) 990 (14) 1700 (25) 1530 (22) 2420 (35) 2170 (32)

14 840 (12) 720 (11) 1100 (16) 990 (14) 1850 (27) 1660 (24) 2640 (39) 2370 (35)

15 870 (13) 740 (11) 1150 (17) 1030 (15) 1980 (29) 1780 (26) 2800 (41) 2620 (38)

16 . . . . . . 1200 (18) 1080 (16) 2100 (31) 1890 (28) 3000 (44) 2700 (39)

18 . . . . . . 1300 (19) 1170 (17) 2340 (34) 2100 (31) 3300 (48) 2970 (43)

21 . . . . . . 1450 (21) 1300 (19) 2680 (39) 2410 (35) . . . . . .

24 . . . . . . 1600 (23) 1440 (21) 3000 (44) 2700 (39) . . . . . .

27 . . . . . . 1800 (26) 1620 (24) 3330 (49) 3000 (44) . . . . . .

30 . . . . . . 2000 (29) 1800 (26) 3590 (52) 3230 (47) . . . . . .

A

Strengths of sizes not listed may be interpolated between tabular values of sizes and strengths of the nearest listed diameters.

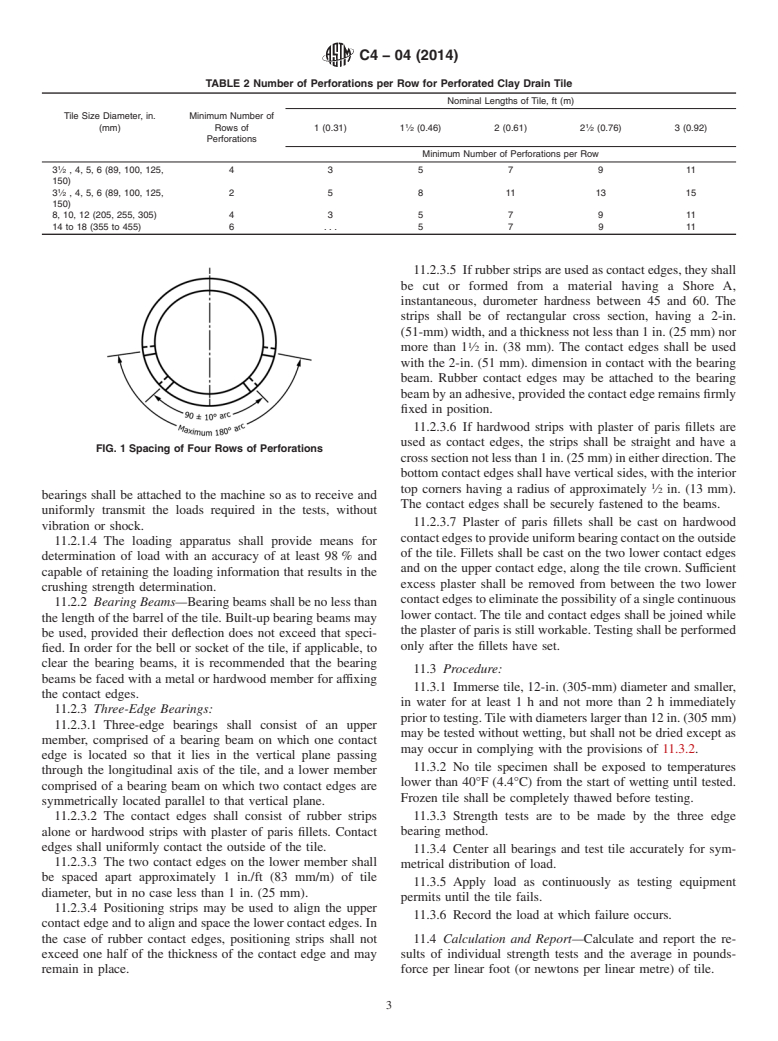

7.4 Perforations—Perforations shall be circular and cleanly purchase order is issued. The manufacturer or seller shall

cut through the tile wall. They shall be arranged in rows furnish test tile without charge.

parallel to the longitudinal axis of the tile. The minimum

9.3 Each tile shall be individually marked so that it is

number of rows of perforations shall be as shown in Table 2.

identifiable within the testing period.

7.4.1 Where two rows of perforations are used, the rows

10. Basis of Acceptance

shall be separated by an arc of 90 6 15°.

7.4.2 Where four rows of perforations are used, the rows

10.1 Acceptability of nonperforated drain tile is determined

shall be symmetrical around a vertical centerline. The lower-

by compliance with the requirements of Table 1, Table 3, and

most rows of perforations shall be separated by an arc of 90 6

the inspection requirements of Section 14.

10°,andtheuppermostrowsshallbeseparatedbyanarcofnot

10.2 Acceptability of perforated drain tile is determined by

over 160° measured around the lower part of the tile (Fig. 1).

compliance with the requirements of Tables 1-3 and the

7.4.3 If more than four rows of perforations are used, the

inspection requirements of Section 14.

spacing of rows shall be uniform between the limits in 7.4.2.

7.4.4 The purchaser shall specify the desired perforation

TEST METHODS

1 1 1

diameter option of: (1) ⁄4 6 ⁄16 in. (6.4 6 1.6 mm) or (2) ⁄2

11. Crushing Strength Test

6 ⁄8in. (13 6 3.2 mm), and the number of rows of perfora-

tions.

11.1 Test Samples:

7.4.5 Perforations shall not be spaced more than approxi-

11.1.1 Test tile shall be sound, full size, and selected by the

mately 3 in. (76 mm) center-to-center along the rows.

purchaser or his representative.

11.1.2 Thenumberoftiletobetestedshallnotexceed0.5%

8. Workmanship and Finish

of the number of tile of each size furnished, except that no less

8.1 Drain tile shall be free of cracks, checks, or chips that than five tile of each size shall be tested.

decrease the strength.

11.2 Loading Apparatus (see Fig. 2):

8.2 Drain tile shall conform to the permissible dimensional 11.2.1 Testing Machine:

11.2.1.1 Theloadingapparatusmayconsistofanymechani-

variations in Table 3.

callydrivenorhand-powereddevicethatiscapableofapplying

8.3 Plain-end tile shall be furnished unless otherwise speci-

the necessary loads, with upper and lower bearings capable of

fied by the purchaser.

transmitting these loads to the tile. The bearings shall be

8.3.1 The ends of plain-end tile shall be sufficiently square

bearing beams and contact edges.

as to make close joints.

11.2.1.2 Any device that is capable of applying a load at a

uniform rate, from 500 to 2000 lbf/linear ft·min (7.3 to 29

9. Sampling and Testing

KN/linear m·min) of tile length, may be used for making the

9.1 Tile shall be sampled and tested in accordance with

test.

Sections 11 through 13.

11.2.1.3 The testing machine shall be sufficiently rigid so

9.2 Fortestpurposes,full-sizedraintileshallbeselectedby thattheloaddistributionwillnotbeappreciablyaffectedbythe

the purchaser or his authorized representative. Tile shall be deformation or yielding of any part.The machine and bearings

representative of the lot from which they are selected. The shall be constructed to transmit the load in a vertical plane

place or places of selection shall be designated when the through the longitudinal axes of the bearings and tile. The

C4−04 (2014)

TABLE 2 Number of Perforations per Row for Perforated Clay Drain Tile

Nominal Lengths of Tile, ft (m)

Tile Size Diameter, in. Minimum Number of

1 1

(mm) Rows of 1 (0.31) 1 ⁄2 (0.46) 2 (0.61) 2 ⁄2 (0.76) 3 (0.92)

Perforations

Minimum Number of Perforations per Row

3 ⁄2 , 4, 5, 6 (89, 100, 125, 4 3579 11

150)

3 ⁄2 , 4, 5, 6 (89, 100, 125, 25 8 11 13 15

150)

8, 10, 12 (205, 255, 305) 4 3579 11

14 to 18 (355 to 455) 6 . . . 5 7 9 11

11.2.3.5 Ifrubberstripsareusedascontactedges,theyshall

be cut or formed from a material having a Shore A,

instantaneous, durometer hardness between 45 and 60. The

strips shall be of rectangular cross section, having a 2-in.

(51-mm)width,andathicknessnotlessthan1in.(25mm)nor

more than 1 ⁄2 in. (38 mm). The contact edges shall be used

with the 2-in. (51 mm). dimension in contact with the bearing

beam. Rubber contact edges may be attached to the bearing

beambyanadhesive,providedthecontactedgeremainsfirmly

fixed in position.

11.2.3.6 If hardwood strips with plaster of paris fillets are

used as contact edges, the strips shall be straight and have a

FIG. 1Spacing of Four Rows of Perforations

crosssectionnotlessthan1in.(25mm)ineitherdirection.The

bottomcontactedgesshallhaveverticalsides,withtheinterior

top corners having a radius of approximately ⁄2 in. (13 mm).

bearings shall be attached to the machine so as to receive and

The contact edges shall be securely fastened to the beams.

uniformly transmit the loads required in the tests, without

11.2.3.7 Plaster of paris fillets shall be cast on hardwood

vibration or shock.

contactedgestoprovideuniformbearingcontactontheoutside

11.2.1.4 The loading apparatus shall provide means for

of the tile. Fillets shall be cast on the two lower contact edges

determination of load with an accuracy of at least 98% and

and on the upper contact edge, along the tile crown. Sufficient

capable of retaining the loading information that results in the

excess plaster shall be removed from between the two lower

crushing strength determination.

contactedgestoeliminatethepossibilityofasinglecontinuous

11.2.2 Bearing Beams—Bearingbeamsshallbenolessthan

lower contact. The tile and contact edges shall be joined while

the length of the barrel of the tile. Built-up bearing beams may

theplasterofparisisstillworkable.Testingshallbeperformed

be used, provided their deflection does not exceed that speci-

only after the fillets have set.

fied. In order for the bell or socket of the tile, if applicable, to

clear the bearing beams, it is recommended that the bearing

11.3 Procedure:

beams be faced with a metal or hardwood member for affixing

11.3.1 Immerse tile, 12-in. (305-mm) diameter and smaller,

the contact edges.

in water for at least 1 h and not more than 2 h immediately

11.2.3 Three-Edge Bearings:

priortotesting.Tilewithdiameterslargerthan12in.(305mm)

11.2.3.1 Three-edge bearings shall consist of an upper

may be tested without wetting, but shall not be dried except as

member, comprised of a bearing beam on which one contact

may occur in complying with the provisions of 11.3.2.

edge is located so that it lies in the vertical plane passing

11.3.2 No tile specimen shall be exposed to temperatures

through the longitudinal axis of the tile, and a lower member

lower than 40°F (4.4°C) from the start of wetting until tested.

comprised of a bearing beam on which two contact edges are

Frozen tile shall be completely thawed before testing.

symmetrically located parallel to that vertical plane.

11.2.3.2 The contact edges shall consist of rubber strips 11.3.3 Strength tests are to be made by the three edge

bearing method.

alone or hardwood strips with plaster of paris fillets. Contact

edges shall uniformly contact the outside of the tile.

11.3.4 Center all bearings and test tile accurately for sym-

11.2.3.3 The two contact edges on the lower member shall

metrical distribution of load.

be spaced apart approximately 1 in./ft (83 mm/m) of tile

11.3.5 Apply load as continuously as testing equipment

diameter, but in no case less than 1 in. (25 mm).

permits until the tile fails.

11.2.3.4 Positioning strips may be used to align the upper

11.3.6 Record the load at which failure occurs.

contactedgeandtoalignandspacethelowercontactedges.In

the case of rubber contact edges, positioning strips shall not 11.4 Calculation and Report—Calculate and report the re-

exceed one half of the thickness of the contact edge and may sults of individual strength tests and the average in pounds-

remain in place. force per linear foot (or newtons per linear metre) of tile.

C4−04 (2014)

TABLE 3 Permissible Variations in Dimensions

Standard Extra Quality, Heavy Duty,

Physical Properties Specified

and Extra Strength

Permissible variation of average diameter below specified diameter, % 3 3

Permissible variation between maximum and minimum diameters of same tile, percentage 75 65

of wall thickness

Permissible variation of average length of tile sampled below manufacturer’s specified 33

length, %

Permissible variation from straightness, percentage of length 3 3

Permissible thickness of exterior blisters, lumps, and flakes, percentage of wall thickness 20 15

Permissible diameters of blisters, lumps, and flakes, percent of inside diameter 15 10

test, and shall be of the full thickness of the barrel with all

edgesbrokenorcut.Eachpieceshallhaveanareanotlessthan

2 2

25 in. (160 cm ) as measured on one barrel surface. Average

absorption of the three pieces shall be considered to be the

absorption for that tile.

12.2 Apparatus:

12.2.1 A ventilated oven capable of holding a 500°F

(260°C

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C4 − 04 (Reapproved 2009) C4 − 04 (Reapproved 2014)

Standard Specification for

Clay Drain Tile and Perforated Clay Drain Tile

This standard is issued under the fixed designation C4; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification establishes the criteria for acceptance, prior to installation, of drain tile and perforated drain tile to be used

for underdrainage, filter fields, leaching fields, and similar subdrainage installations.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the Test Methods portion of this specification:This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

NOTE 1—Attention is called to Test Methods C301 and Terminology C896.

2. Referenced Documents

2.1 ASTM Standards:

C301 Test Methods for Vitrified Clay Pipe

C896 Terminology Relating to Clay Products

3. Terminology

3.1 Definitions:

3.1.1 Clay, fire clay, shale, and surface clay are as defined in Terminology C896.

3.1.2 Within this specification, the terms tile, drain tile, and clay drain tile are synonyms.

4. Classification

4.1 Four classes of clay drain tile are specified:

4.1.1 Standard.

4.1.2 Extra Quality.

4.1.3 Heavy Duty.

4.1.4 Extra Strength.

4.2 Drain tile of a higher strength classification than that specified by the purchaser may be furnished by the seller, provided

the substituted drain tile meets the physical requirements of the class specified.

5. Materials and Manufacture

5.1 Drain tile shall be manufactured from clay, fire clay, shale, surface clay, or a combination of these materials, that, when

formed into tile and fired to suitable temperatures, yields a product that conforms to this specification.

6. Physical Properties

6.1 Drain tile shall meet the physical test requirements for the class, as specified in Table 1.

6.2 The maximum water absorption (5-h boiling) shall be as follows:

This specification is under the jurisdiction of ASTM Committee C04 on Vitrified Clay Pipe and is the direct responsibility of Subcommittee C04.20 on Methods of Test

and Specifications.

Current edition approved Oct. 1, 2009Sept. 1, 2014. Published October 2009September 2014. Originally approved in 1914. Last previous edition approved in 20042009

ε1

as C4 – 04 (2009). . DOI: 10.1520/C0004-04R09.10.1520/C0004-04R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C4 − 04 (2014)

TABLE 1 Physical Test Requirements for Clay Drain Tile

Standard Extra Quality Heavy Duty Extra Strength

Internal

A A A A

Diameter Minimum Crushing Strength, Minimum Crushing Strength, Minimum Crushing Strength, Minimum Crushing Strength,

lbf/linear ft (kN/m) lbf/linear ft (kN/m) lbf/linear ft (kN/m) lbf/linear ft (kN/m)

of Tile,

in.

Average Individual Average Individual Average Individual Average Individual

3 ⁄2 800 (12) 680 (10) 1100 (16) 990 (14) 1400 (20) 1260 (18) 2000 (29) 1800 (26)

4 800 (12) 680 (10) 1100 (16) 990 (14) 1400 (20) 1260 (18) 2000 (29) 1800 (26)

5 800 (12) 680 (10) 1100 (16) 990 (14) 1400 (20) 1260 (18) 2000 (29) 1800 (26)

6 800 (12) 680 (10) 1100 (16) 990 (14) 1400 (20) 1260 (18) 2000 (29) 1800 (26)

8 800 (12) 680 (10) 1100 (16) 990 (14) 1500 (22) 1350 (20) 2140 (31) 1920 (28)

10 800 (12) 680 (10) 1100 (16) 990 (14) 1550 (23) 1400 (20) 2200 (32) 1980 (29)

12 800 (12) 680 (10) 1100 (16) 990 (14) 1700 (25) 1530 (22) 2420 (35) 2170 (32)

14 840 (12) 720 (11) 1100 (16) 990 (14) 1850 (27) 1660 (24) 2640 (39) 2370 (35)

15 870 (13) 740 (11) 1150 (17) 1030 (15) 1980 (29) 1780 (26) 2800 (41) 2620 (38)

16 . . . . . . 1200 (18) 1080 (16) 2100 (31) 1890 (28) 3000 (44) 2700 (39)

18 . . . . . . 1300 (19) 1170 (17) 2340 (34) 2100 (31) 3300 (48) 2970 (43)

21 . . . . . . 1450 (21) 1300 (19) 2680 (39) 2410 (35) . . . . . .

24 . . . . . . 1600 (23) 1440 (21) 3000 (44) 2700 (39) . . . . . .

27 . . . . . . 1800 (26) 1620 (24) 3330 (49) 3000 (44) . . . . . .

30 . . . . . . 2000 (29) 1800 (26) 3590 (52) 3230 (47) . . . . . .

A

Strengths of sizes not listed may be interpolated between tabular values of sizes and strengths of the nearest listed diameters.

Average, % Individual, %

Standard 13 16

Extra Quality 11 13

Heavy Duty 11 13

Extra Strength 11 13

6.3 The requirements for water absorption (5–h boiling) shall be waived, provided that test specimens meet the requirements

of the freezing and thawing test, Section 13, of this specification

7. Sizes and Perforations

7.1 The size of drain tile shall be designated by inside diameter. Not all sizes and strengths may be available from all

manufacturers.

7.2 The minimum length of drain tile smaller than 10 in. (255 mm) diameter shall be approximately 12 in. (305 mm).

7.3 The length of drain tile 10 in. (255 mm) through 30 in. (760 mm) diameter shall be not less than 1 ⁄2 times their diameter.

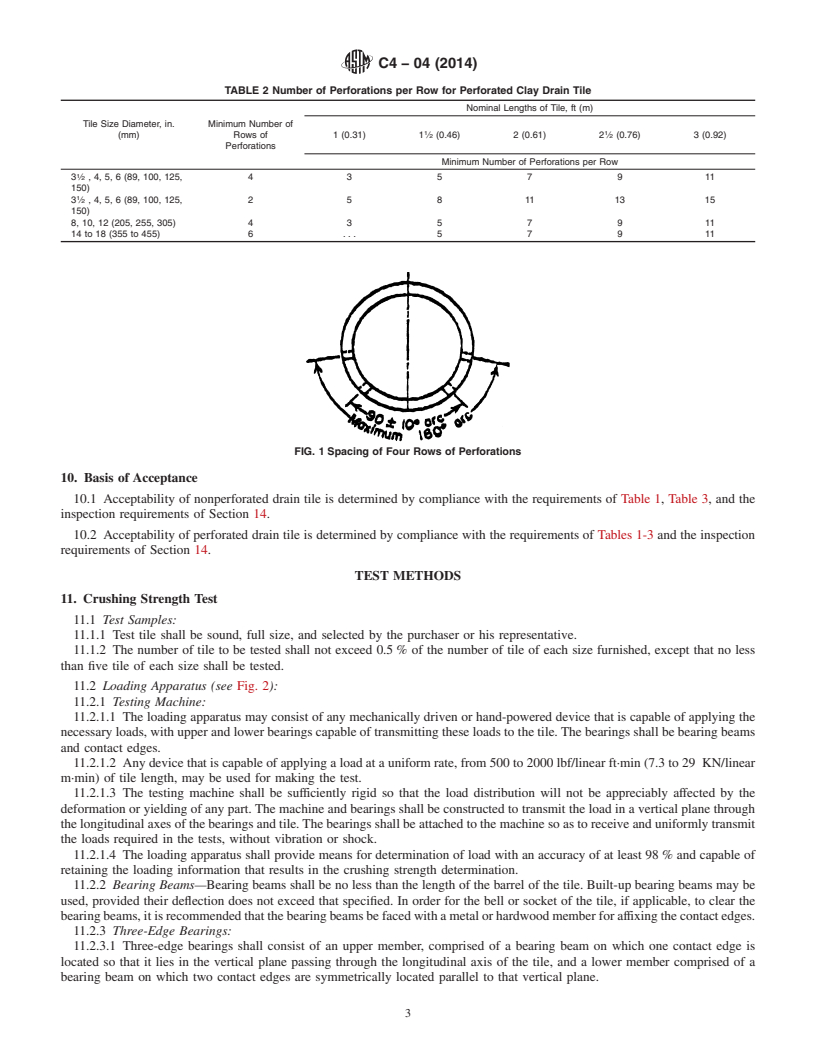

7.4 Perforations—Perforations shall be circular and cleanly cut through the tile wall. They shall be arranged in rows parallel

to the longitudinal axis of the tile. The minimum number of rows of perforations shall be as shown in Table 2.

7.4.1 Where two rows of perforations are used, the rows shall be separated by an arc of 90 6 15°.

7.4.2 Where four rows of perforations are used, the rows shall be symmetrical around a vertical centerline. The lowermost rows

of perforations shall be separated by an arc of 90 6 10°, and the uppermost rows shall be separated by an arc of not over 160°

measured around the lower part of the tile (Fig. 1).

7.4.3 If more than four rows of perforations are used, the spacing of rows shall be uniform between the limits in 7.4.2.

1 1 1 1

7.4.4 The purchaser shall specify the desired perforation diameter option of: (1) ⁄4 6 ⁄16 in. (6.4 6 1.6 mm) or (2) ⁄2 6 ⁄8 in.

(13 6 3.2 mm), and the number of rows of perforations.

7.4.5 Perforations shall not be spaced more than approximately 3 in. (76 mm) center-to-center along the rows.

8. Workmanship and Finish

8.1 Drain tile shall be free of cracks, checks, or chips that decrease the strength.

8.2 Drain tile shall conform to the permissible dimensional variations in Table 3.

8.3 Plain-end tile shall be furnished unless otherwise specified by the purchaser.

8.3.1 The ends of plain-end tile shall be sufficiently square as to make close joints.

9. Sampling and Testing

9.1 Tile shall be sampled and tested in accordance with Sections 11 through 13.

9.2 For test purposes, full-size drain tile shall be selected by the purchaser or his authorized representative. Tile shall be

representative of the lot from which they are selected. The place or places of selection shall be designated when the purchase order

is issued. The manufacturer or seller shall furnish test tile without charge.

9.3 Each tile shall be individually marked so that it is identifiable within the testing period.

C4 − 04 (2014)

TABLE 2 Number of Perforations per Row for Perforated Clay Drain Tile

Nominal Lengths of Tile, ft (m)

Tile Size Diameter, in. Minimum Number of

1 1

(mm) Rows of 1 (0.31) 1 ⁄2 (0.46) 2 (0.61) 2 ⁄2 (0.76) 3 (0.92)

Perforations

Minimum Number of Perforations per Row

3 ⁄2 , 4, 5, 6 (89, 100, 125, 4 3 5 7 9 11

150)

3 ⁄2 , 4, 5, 6 (89, 100, 125, 2 5 8 11 13 15

150)

8, 10, 12 (205, 255, 305) 4 3 5 7 9 11

14 to 18 (355 to 455) 6 . . . 5 7 9 11

FIG. 1 Spacing of Four Rows of Perforations

10. Basis of Acceptance

10.1 Acceptability of nonperforated drain tile is determined by compliance with the requirements of Table 1, Table 3, and the

inspection requirements of Section 14.

10.2 Acceptability of perforated drain tile is determined by compliance with the requirements of Tables 1-3 and the inspection

requirements of Section 14.

TEST METHODS

11. Crushing Strength Test

11.1 Test Samples:

11.1.1 Test tile shall be sound, full size, and selected by the purchaser or his representative.

11.1.2 The number of tile to be tested shall not exceed 0.5 % of the number of tile of each size furnished, except that no less

than five tile of each size shall be tested.

11.2 Loading Apparatus (see Fig. 2):

11.2.1 Testing Machine:

11.2.1.1 The loading apparatus may consist of any mechanically driven or hand-powered device that is capable of applying the

necessary loads, with upper and lower bearings capable of transmitting these loads to the tile. The bearings shall be bearing beams

and contact edges.

11.2.1.2 Any device that is capable of applying a load at a uniform rate, from 500 to 2000 lbf/linear ft·min (7.3 to 29 KN/linear

m·min) of tile length, may be used for making the test.

11.2.1.3 The testing machine shall be sufficiently rigid so that the load distribution will not be appreciably affected by the

deformation or yielding of any part. The machine and bearings shall be constructed to transmit the load in a vertical plane through

the longitudinal axes of the bearings and tile. The bearings shall be attached to the machine so as to receive and uniformly transmit

the loads required in the tests, without vibration or shock.

11.2.1.4 The loading apparatus shall provide means for determination of load with an accuracy of at least 98 % and capable of

retaining the loading information that results in the crushing strength determination.

11.2.2 Bearing Beams—Bearing beams shall be no less than the length of the barrel of the tile. Built-up bearing beams may be

used, provided their deflection does not exceed that specified. In order for the bell or socket of the tile, if applicable, to clear the

bearing beams, it is recommended that the bearing beams be faced with a metal or hardwood member for affixing the contact edges.

11.2.3 Three-Edge Bearings:

11.2.3.1 Three-edge bearings shall consist of an upper member, comprised of a bearing beam on which one contact edge is

located so that it lies in the vertical plane passing through the longitudinal axis of the tile, and a lower member comprised of a

bearing beam on which two contact edges are symmetrically located parallel to that vertical plane.

C4 − 04 (2014)

TABLE 3 Permissible Variations in Dimensions

Standard Extra Quality, Heavy Duty,

Physical Properties Specified

and Extra Strength

Permissible variation of average diameter below specified diameter, % 3 3

Permissible variation between maximum and minimum diameters of same tile, percentage 75 65

of wall thickness

Permissible variation of average length of tile sampled below manufacturer’s specified 3 3

length, %

Permissible variation from straightness, percentage of length 3 3

Permissible thickness of exterior blisters, lumps, and flakes, percentage of wall thickness 20 15

Permissible diameters of blisters, lumps, and flakes, percent of inside diameter 15 10

FIG. 2 Loading Apparatus

11.2.3.2 The contact edges shall consist of rubber strips alone or hardwood strips with plaster of paris fillets. Contact edges shall

uniformly contact the outside of the tile.

11.2.3.3 The two contact edges on the lower member shall be spaced apart approximately 1 in./ft (83 mm/m) of tile diameter,

but in no case less than 1 in. (25 mm).

11.2.3.4 Positioning strips may be used to align the upper contact edge and to align and space the lower contact edges. In the

case of rubber contact edges, positioning strips shall not exceed one half of the thickness of the contact edge and may remain in

place.

11.2.3.5 If rubber strips are used as contact edges, they shall be cut or formed from a material having a Shore A, instantaneous,

durometer hardness between 45 and 60. The strips shall be of rectangular cross section, having a 2-in. (51-mm) width, and a

thickness not less than 1 in. (25 mm) nor more than 1 ⁄2 in. (38 mm). The contact edges shall be used with the 2-in. (51 mm).

dimension in contact with the bearing beam. Rubber contact edges may be attached to the bearing beam by an adhesive, provided

the contact edge remains firmly fixed in position.

11.2.3.6 If hardwood strips with plaster of paris fillets are used as contact edges, the strips shall be straight and have a cross

section not less than 1 in. (25 mm) in either direction. The bottom contact edges shall have vertical sides, with the interior top

corners having a radius of approximately ⁄2 in. (13 mm). The contact edges shall be securely fastened to the beams.

11.2.3.7 Plaster of paris fillets shall be cast on hardwood contact edges to provide uniform bearing contact on the outside of the

tile. Fillets shall be cast on the two lower contact edges and on the upper contact edge, along the tile crown. Sufficient excess plaster

shall be removed from between the two lower contact edges to eliminate the possibility of a single continuous lower contact. The

tile and contact edges shall be joined while the plaster of paris is still workable. Testing shall be performed only after the fillets

have set.

11.3 Procedure:

11.3.1 Immerse tile, 12-in. (305-mm) diameter and smaller, in water for at least 1 h and not more than 2 h immediately prior

to testing. Tile with diameters larger than 12 in. (305 mm) may be tested without wetting, but shall not be dried except as may

occur in complying with the provisions of 11.3.2.

11.3.2 No tile specimen shall be exposed to temperatures lower than 40°F (4.4°C) from the start of wetting until tested. Frozen

tile shall be completely thawed before testing.

11.3.3 Strength tests are to be made by the three edge bearing method.

11.3.4 Center all bearings and test tile accurately for symmetrical distribution of load.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.