ASTM C1167-96

(Specification)Standard Specification for Clay Roof Tiles

Standard Specification for Clay Roof Tiles

SCOPE

1.1 This specification covers clay tiles intended for use as roof covering where durability and appearance are required to provide a weather-resistant surface of specified design.

1.2 Tiles are manufactured from clay, shale, or similar naturally occurring earthy substances and subjected to heat treatment at elevated temperatures (firing). The heat treatment must develop a fired bond between the particulate constitutents to provide the strength and durability requirements of this specification (see firing and fired bond in Terminology C43).

1.3 Tiles are shaped during manufacture by molding, pressing, or extrusion and it is permitted to use the shaping method to describe the tiles.

1.4 Tiles are generally planar or undulating rectangular shapes available in a variety of cross-sectional profiles, shapes, sizes, surface textures, and colors.

1.5 Three grades of tile having various degrees of resistance to weathering are covered in this specification. Three types of tile are defined to cover the features that influence appearance.

1.6 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1167 – 96

Standard Specification for

Clay Roof Tiles

This standard is issued under the fixed designation C 1167; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Classification

1.1 This specification covers clay tiles intended for use as 4.1 Clay roof tiles covered by this specification are classi-

roof covering where durability and appearance are required to fied by grade for durability and type for appearance as follows:

provide a weather-resistant surface of specified design. 4.1.1 Grades:

1.2 Tiles are manufactured from clay, shale, or similar 4.1.1.1 Grade 1—Providing resistance to severe frost ac-

naturally occurring earthy substances and subjected to heat tion.

treatment at elevated temperatures (firing). The heat treatment 4.1.1.2 Grade 2—Providing resistance to moderate frost

must develop a fired bond between the particulate constitutents action.

to provide the strength and durability requirements of this 4.1.1.3 Grade 3—Providing negligible resistance to any

specification (see firing and fired bond in Terminology C 43). frost action.

1.3 Tiles are shaped during manufacture by molding, press- 4.1.1.4 Grades relate to exposure to weather as defined in

ing, or extrusion and it is permitted to use the shaping method Table 1.

to describe the tiles. 4.2 Types:

1.4 Tiles are generally planar or undulating rectangular 4.2.1 Type I—High-profile tiles—tiles having a rise-to-

shapes available in a variety of cross-sectional profiles, shapes, width ratio greater than 1:5.

sizes, surface textures, and colors. 4.2.2 Type II—Low-profiles tiles—tiles having a rise-to-

1.5 Three grades of tile having various degrees of resistance width ratio equal to, or less than 1:5.

to weathering are covered in this specification. Three types of 4.2.3 Type III—All other tiles, including flat.

tile are defined to cover the features that influence appearance.

5. Material and Finish

1.6 The values stated in inch-pound units are to be regarded

as the standard. 5.1 Colors and textures produced by application of inor-

ganic coatings to the faces of the tiles are permissible provided

2. Referenced Documents

that evidence satisfactory to the purchaser is furnished regard-

2.1 ASTM Standards: ing the durability of the coatings. Tiles that are colored by

C 43 Terminology of Structural Clay Products flashing or textured by sanding, where the sand does not form

C 67 Test Methods of Sampling and Testing Brick and a continuous coating, are not considered as surface-colored

Structural Clay Tile tiles for the purpose of this specification.

C 297 Test Method for Tensile Strength of Flat Sandwich

NOTE 1—When surface colored tiles (other than sanded or flashed) are

Constructions in Flatwise Plane

specified, data satisfactory to the purchaser shall be submitted showing

C 554 Test Method for Crazing Resistance of Fired Glazed

that after 50 cycles of freezing-thawing (5.2) there is no observable

Ceramic Whitewares by a Thermal Shock Method

difference in the applied finish when viewed from a distance of 40 ft (12

m) under an illumination of not less than 50 fc (538 lm/m ) by an observer

3. Terminology

with normal vision. It is permitted to present service records of the

performance of the particular coated tiles in appropriate locations in place

3.1 Definitions—For definitions of terms relating to struc-

of the freezing and thawing test, with the consent of the purchaser.

tural clay products, and clay roof tiles, see Terminology C 43.

5.2 The tiles shall be free of defects, deficiencies, or

bloating, that would interfere with the proper laying of the tiles,

This specification is under the jurisdiction of ASTM Committee C-15 on

the performance of the roof, or the requirements of this

Manufactured Masonry Units and is the direct responsibility of Subcommittee

specification.

C15.06 on Roofing Tile.

5.2.1 Tiles, when broken, may have a dark area that has a

Current edition approved Feb. 10, 1996. Published April 1996. Originally

published as C 1167. Last previous edition C 1167 – 94a. steely appearance and is sharply delineated from the surround-

Annual Book of ASTM Standards, Vol 04.05.

ing normal color of tile. This area is known as black heart or

Annual Book of ASTM Standards, Vol 15.03.

black core. Black heart is generally the result of the reduction

Annual Book of ASTM Standards, Vol 15.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C1167–96

TABLE 1 Grade Classification for Clay Roof Tiles

both. Such a tile is completely unacceptable for use regardless of its other

properties such as strength.

Grade

Weathering Index (see Annex A1)

(All Types)

NOTE 3—The resistance of clay roof tiles to weathering cannot be

predicted with complete assurance using any of the physical tests

1 500 and greater

prescribed. However, practical experience has demonstrated satisfactory

2 50to500

3 less than 50

performance of clay roof tiles, some for hundreds of years, and this

experience forms the basis of the prescriptive requirements of Table 2.

There is generally excellent correlation between field performance and the

requirements. However, it is possible that some tiles that meet this

of iron minerals during the firing process. Its presence,

specification are not suitable for severe climates. Furthermore, it is also

regardless of the size in the tile that otherwise meets the

possible for other tiles that do not meet this specification to show

physical performance of this specification, shall not be cause acceptable serviceability in the most severe climates. The best indication

of clay roof tile durability is the service record of experience with the

for rejection.

specified product in the environment of its intended use.

5.3 The exposed tile surface shall be free of chippage or

other imperfections detracting from the appearance of the

6.1.1 Measure the water absorption, and calculate the satu-

designated sample when viewed from a distance 40 ft (12 m)

ration coefficient, in accordance with Test Methods C 67. The

under an illumination of not less than 50 fc (538 lm/m )byan

test specimen shall consist of five whole tiles.

observer with normal vision.

6.1.2 The physical requirements in Table 2 shall be achieved

5.4 Unless otherwise agreed upon between the purchaser

as a result of the firing process and associated thermal reactions

and the seller, a delivery of tiles shall contain not less than

within the tile body (and glaze, if present) which include

95 % whole tiles. In this specification, the term whole tiles

development of the fired bond, increase in density, increase in

shall be understood to mean tiles meeting the appearance

strength, and reduction in water absorption. Tiles shall not

requirements of this specification.

comply with this specification if other processes, for example,

5.5 After tiles are placed in usage, the manufacturer or his

immersion in solutions of organic materials to effect impreg-

agent shall not be held responsible for compliance of tiles with

nation or surface sealing, are used to change the physical

the requirements of this specification for dimensional toler-

properties which result from the firing process.

ances, finish, texture, or color.

6.2 Freezing and Thawing—The requirements specified in

6.1 for water absorption (5-h boiling) and saturation coefficient

6. Performance Requirements

shall not be required for all grades provided that a sample of

6.1 Durability—The tiles shall conform to the physical

five tiles, meeting all of the other requirements, experiences no

requirements for the grade specified as prescribed in Table 2.

breakage and not greater than 0.5 % loss in dry weight when

Unless otherwise specified by the purchaser, tiles of a higher

subjected to 50 cycles of the freezing-and-thawing test of Test

grade (greater weathering index) shall be accepted instead of a

Methods C 67, modified in accordance with 6.2.1.

lower grade. It is permitted to waive the saturation coefficient

6.2.1 Modify Test Methods C 67, Section 8, as follows: The

requirement when the average cold water absorption of a

test specimens shall consist of five whole tiles. The freezing

random sample of five tiles does not exceed 6 %, no more than

trays and containers shall be of sufficient size and depth to

one tile of the sample exceeds 6 % and its cold water

allow the tiles to be completely submerged in water when

absorption is less than 8 %. When Grade 3 tiles are used in

placed horizontally. The tiles shall be completely submerged in

regions where the weathering index is less than 50 (see Annex

water when the trays are placed in the freezing chamber. It is

A1), unless otherwise specified, the requirements for water

permitted to test individual tile or to stack tile on top of each

absorption and for saturation coefficient shall be waived. 1

other in the tray, provided that spacers at least ⁄4 in. (6 mm)

thick are used between adjacent tiles and that the total stack is

NOTE 2—Frost is of profound importance in mechanical weathering

completely submerged.

where its effectiveness is dependent on the frequency of temperature

fluctuation across the freezing point in the presence of water. The ability

NOTE 4—A large capacity freezer is generally necessary to accomplish

of a tile to resist failure in a wet and freezing environment is, therefore, of

freezing in the manner specified in Test Methods C 67 for trays containing

paramount importance. If a tile fails in such an environment, its use will

more than one tile. It is permitted to use custom trays to enclose the tile(s)

result in an unacceptable deterioration of appearance or more likely, a total

and minimize the volume of water required to completely submerge the

failure to function (that is, protect the underlying structure from rain), or

tile(s).

6.2.2 A lot of tiles shall be given the Grade 1 rating without

TABLE 2 Physical Requirements

repeating a freezing and thawing test provided that a previous

Absorption Requirements

lot made by the supplier from similar materials, by the same

Cold Water Absorption Maximum Saturation

process, at the same production plant, and within the previous

A

Maximum Percent Coefficient

Grade 12 months, had passed the test, and provided also that a sample

Average of Individual Average of Individual

of five tiles selected from the lot has an average and individual

Five Tiles Tile Five Tiles Tile

minimum transverse strength not less than the previously

1 6 8 0.74 0.76

graded sample and has average and individual maximum water

2 11 13 0.80 0.82

3 13 15 0.84 0.86

absorption and saturation coefficient not greater than those of

A

The saturation coefficient is the ratio of absorption by 24-h submersion in water the previously graded sample.

at a temperature of 75 6 10°F (24 6 6°C) to that after 5 h submersion in boiling

water. NOTE 5—Unless specifically requested by the purchaser, the 50-cycle

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C1167–96

freezing and thawing test is specified only as an alternative when tiles do

used and the required minimum values in Table 3 shall be

not conform to either Table 2 requirements for maximum water absorption

increased proportionately to the reduction in span, that is,

and saturation coefficient, or to the restrictive absorption requirements in

multiplied by:

6.1.

(1)

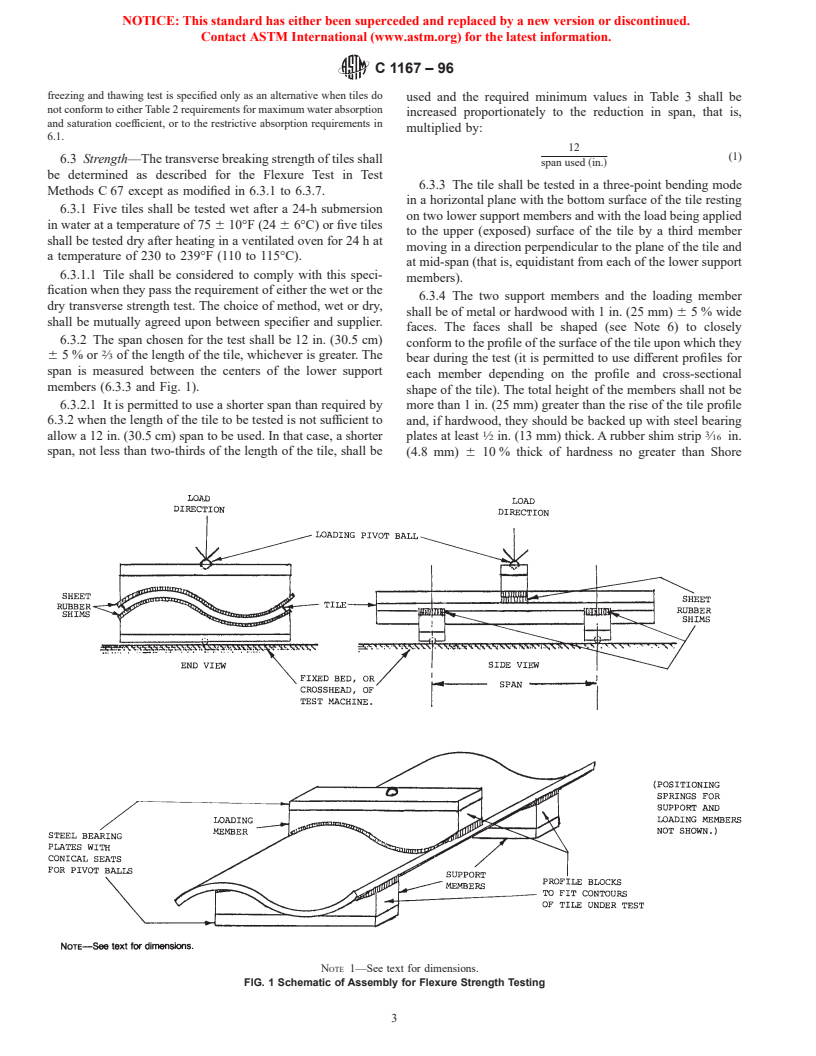

6.3 Strength—The transverse breaking strength of tiles shall

span used ~in.!

be determined as described for the Flexure Test in Test

6.3.3 The tile shall be tested in a three-point bending mode

Methods C 67 except as modified in 6.3.1 to 6.3.7.

in a horizontal plane with the bottom surface of the tile resting

6.3.1 Five tiles shall be tested wet after a 24-h submersion

on two lower support members and with the load being applied

in water at a temperature of 75 6 10°F (24 6 6°C) or five tiles

to the upper (exposed) surface of the tile by a third member

shall be tested dry after heating in a ventilated oven for 24 h at

moving in a direction perpendicular to the plane of the tile and

a temperature of 230 to 239°F (110 to 115°C).

at mid-span (that is, equidistant from each of the lower support

6.3.1.1 Tile shall be considered to comply with this speci-

members).

fication when they pass the requirement of either the wet or the

6.3.4 The two support members and the loading member

dry transverse strength test. The choice of method, wet or dry,

shall be of metal or hardwood with 1 in. (25 mm) 6 5 % wide

shall be mutually agreed upon between specifier and supplier.

faces. The faces shall be shaped (see Note 6) to closely

6.3.2 The span chosen for the test shall be 12 in. (30.5 cm)

conform to the profile of the surface of the tile upon which they

6 5% or ⁄3 of the length of the tile, whichever is greater. The

bear during the test (it is permitted to use different profiles for

span is measured between the centers of the lower support

each member depending on the profile and cross-sectional

members (6.3.3 and Fig. 1).

shape of the tile). The total height of the members shall not be

6.3.2.1 It is permitted to use a shorter span than required by more than 1 in. (25 mm) greater than the rise of the tile profile

6.3.2 when the length of the tile to be tested is not sufficient to and, if hardwood, they should be backed up with steel bearing

1 3

allow a 12 in. (30.5 cm) span to be used. In that case, a shorter

plates at least ⁄2 in. (13 mm) thick. A rubber shim strip ⁄16 in.

span, not less than two-thirds of the length of the tile, shall be (4.8 mm) 6 10 % thick of hardness no greater than Shore

NOTE 1—See text for dimensions.

FIG. 1 Schematic of Assembly for Flexure Strength Testing

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C1167–96

TABLE 3 Transverse Breaking Strength Requirements

6.4.1 Modify 10.4.1 of Test Methods C 67 as follows: Set

Wet Transverse Strength, Dry Transverse Strength, one specimen of each of the five pairs, with appropriate support

min, lbf (N) min, lbf (N)

formed from corrosion-resistant material to maintain the tile in

Type (All Grade

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.