ASTM C1026-23

(Test Method)Standard Test Method for Measuring the Resistance of Ceramic and Glass Tile to Freeze-Thaw Cycling

Standard Test Method for Measuring the Resistance of Ceramic and Glass Tile to Freeze-Thaw Cycling

SIGNIFICANCE AND USE

4.1 The test for resistance to freezing and thawing functions as a guide to the selection of ceramic and glass tiles suitable for outdoor service in geographic areas subjected to freezing. It can serve as a test method to verify compliance with specifications for ceramic and glass tiles, and provides a control test for determining the freeze/thaw resistance of tiles being manufactured for exterior installations.

SCOPE

1.1 This test method describes the procedures and equipment required to test either glazed or unglazed ceramic or glass tiles for resistance to repeated cycles of freezing and thawing. Tiles of any size or shape may be tested by this test method.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1026 − 23

Standard Test Method for

Measuring the Resistance of Ceramic and Glass Tile to

1

Freeze-Thaw Cycling

This standard is issued under the fixed designation C1026; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope the tile specimens are partially submerged. A thermocouple is

inserted into the bottom of the metal container such that the

1.1 This test method describes the procedures and equip-

water surrounding the thermocouple is the last location to

ment required to test either glazed or unglazed ceramic or glass

freeze and thaw. Freezing is followed by a thawing cycle using

tiles for resistance to repeated cycles of freezing and thawing.

water that flows over the test load. The number of freeze-thaw

Tiles of any size or shape may be tested by this test method.

cycles is recorded and after 300 cycles, the test load is visually

1.2 The values stated in inch-pound units are to be regarded

examined for damage and checked for total weight loss.

as the standard. The values given in parentheses are for

information only.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 The test for resistance to freezing and thawing functions

safety concerns, if any, associated with its use. It is the

as a guide to the selection of ceramic and glass tiles suitable for

responsibility of the user of this standard to establish appro-

outdoor service in geographic areas subjected to freezing. It

priate safety, health, and environmental practices and deter-

can serve as a test method to verify compliance with specifi-

mine the applicability of regulatory limitations prior to use.

cations for ceramic and glass tiles, and provides a control test

1.4 This international standard was developed in accor-

for determining the freeze/thaw resistance of tiles being

dance with internationally recognized principles on standard-

manufactured for exterior installations.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Apparatus

mendations issued by the World Trade Organization Technical

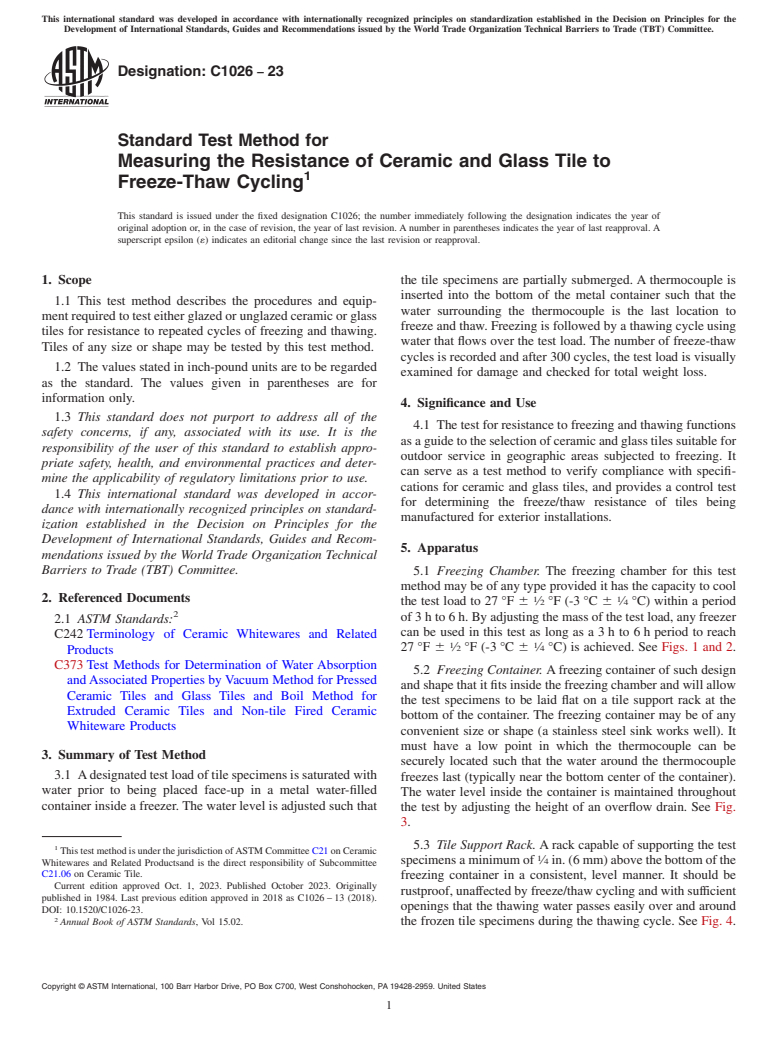

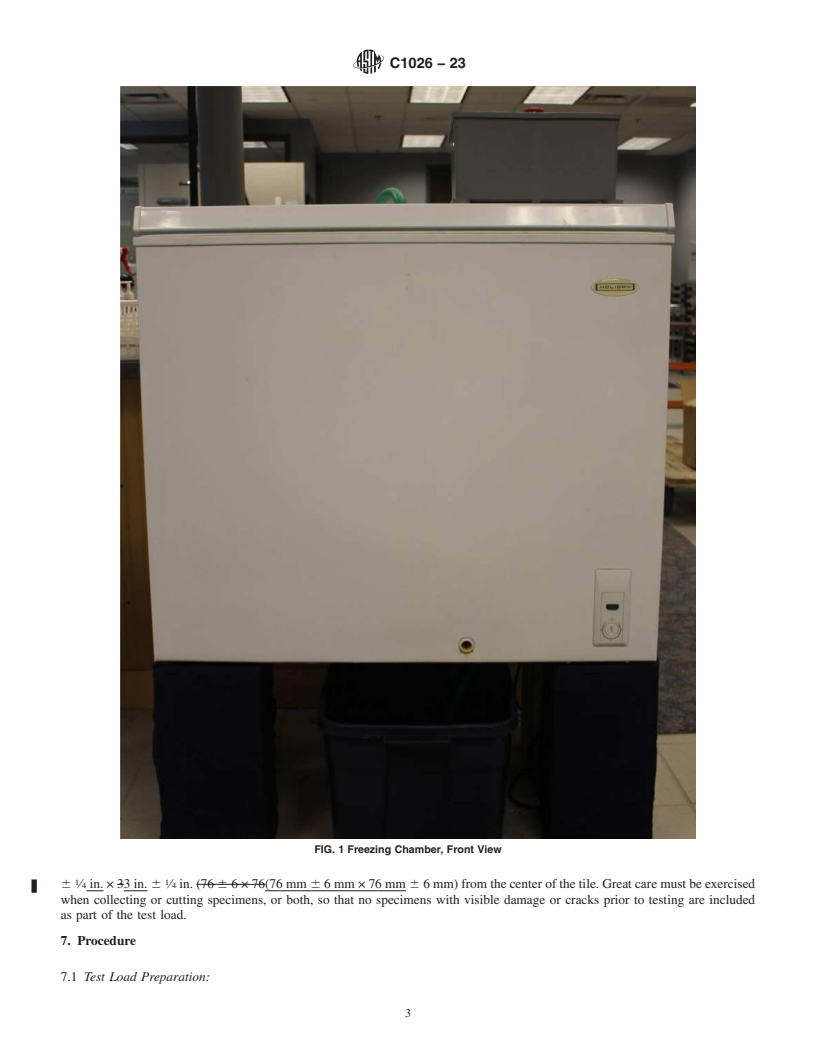

Barriers to Trade (TBT) Committee. 5.1 Freezing Chamber. The freezing chamber for this test

method may be of any type provided it has the capacity to cool

1 1

2. Referenced Documents

the test load to 27 °F 6 ⁄2 °F (-3 °C 6 ⁄4 °C) within a period

2

of 3 h to 6 h. By adjusting the mass of the test load, any freezer

2.1 ASTM Standards:

can be used in this test as long as a 3 h to 6 h period to reach

C242 Terminology of Ceramic Whitewares and Related

1 1

27 °F 6 ⁄2 °F (-3 °C 6 ⁄4 °C) is achieved. See Figs. 1 and 2.

Products

C373 Test Methods for Determination of Water Absorption

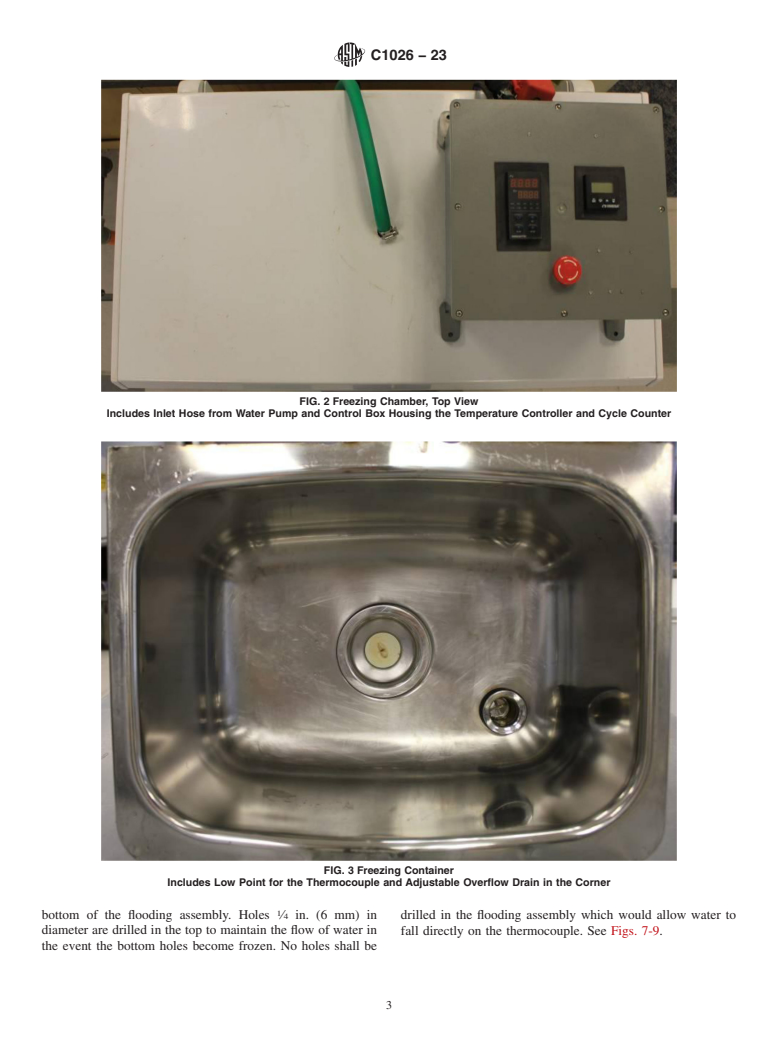

5.2 Freezing Container. A freezing container of such design

and Associated Properties by Vacuum Method for Pressed

and shape that it fits inside the freezing chamber and will allow

Ceramic Tiles and Glass Tiles and Boil Method for

the test specimens to be laid flat on a tile support rack at the

Extruded Ceramic Tiles and Non-tile Fired Ceramic

bottom of the container. The freezing container may be of any

Whiteware Products

convenient size or shape (a stainless steel sink works well). It

must have a low point in which the thermocouple can be

3. Summary of Test Method

securely located such that the water around the thermocouple

3.1 A designated test load of tile specimens is saturated with

freezes last (typically near the bottom center of the container).

water prior to being placed face-up in a metal water-filled

The water level inside the container is maintained throughout

container inside a freezer. The water level is adjusted such that

the test by adjusting the height of an overflow drain. See Fig.

3.

5.3 Tile Support Rack. A rack capable of supporting the test

1

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic

1

specimens a minimum of ⁄4 in. (6 mm) above the bottom of the

Whitewares and Related Productsand is the direct responsibility of Subcommittee

C21.06 on Ceramic Tile.

freezing container in a consistent, level manner. It should be

Current edition approved Oct. 1, 2023. Published October 2023. Originally

rustproof, unaffected by freeze/thaw cycling and with sufficient

published in 1984. Last previous edition approved in 2018 as C1026 – 13 (2018).

openings that the thawing water passes easily over and around

DOI: 10.1520/C1026-23.

2

Annual Book of ASTM Standards, Vol 15.02. the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1026 − 13 (Reapproved 2018) C1026 − 23

Standard Test Method for

Measuring the Resistance of Ceramic and Glass Tile to

1

Freeze-Thaw Cycling

This standard is issued under the fixed designation C1026; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes the procedures and equipment required to test either glazed or unglazed ceramic or glass tiles for

resistance to repeated cycles of freezing and thawing. Tiles of any size or shape may be tested by this test method.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C242 Terminology of Ceramic Whitewares and Related Products

C373 Test Methods for Determination of Water Absorption and Associated Properties by Vacuum Method for Pressed Ceramic

Tiles and Glass Tiles and Boil Method for Extruded Ceramic Tiles and Non-tile Fired Ceramic Whiteware Products

3. Summary of Test Method

3.1 A designated test load of tile specimens is saturated with water prior to being placed face-up in a metal water-filled container

inside a freezer. The water level is adjusted such that the tile specimens are partially submerged. A thermocouple is inserted into

the bottom of the metal container such that the water surrounding the thermocouple is the last location to freeze and thaw. Freezing

is followed by a thawing cycle using water that flows over the test load. The number of freeze-thaw cycles is recorded and after

300 cycles, the test load is visually examined for damage and checked for total weight loss.

4. Significance and Use

4.1 The test for resistance to freezing and thawing functions as a guide to the selection of ceramic and glass tiles suitable for

1

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Productsand is the direct responsibility of Subcommittee C21.06

on Ceramic Tile.

Current edition approved Feb. 1, 2018Oct. 1, 2023. Published February 2018October 2023. Originally published in 1984. Last previous edition approved in 20132018 as

C1026 – 13.C1026 – 13 (2018). DOI: 10.1520/C1026-13R18.10.1520/C1026-23.

2

Annual Book of ASTM Standards, Vol 15.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1026 − 23

outdoor service in geographic areas subjected to freezing. It can serve as a test method to verify compliance with specifications

for ceramic and glass tiles, and provides a control test for determining the freeze/thaw resistance of tiles being manufactured for

exterior installations.

5. Apparatus

5.1 Freezing Chamber. The freezing chamber for this test method may be of any type provided it has the capacity to cool the test

1 1

load to 2727 °F 6 ⁄2 °F (-3 °F (-3 °C 6 ⁄4 °C) °C) within a period of 33 h to 6 h. By adjusting the mass of the test load, any

1 1

freezer can be used in this test as long as a 3- to 6-h3 h to 6 h period to reach 2727 °F 6 ⁄2 °F (-3 °F (-3 °C 6 ⁄4 °C) °C) is

achieved. See Figs. 1 and 2.

5.2 Freezing Container. A freezing container of such design and shape that it fits inside the freezing chamber and will allow the

test specimens to be laid flat on a tile support rack at the bottom of the container. The freezing container may be of any convenient

size or shape (a stainless steel sink works well). It must have a low point in which the thermocouple can be securely located such

that the water around the thermocouple freezes last (typically near the bottom center of the container). The water level inside the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.