ASTM C485-24

(Test Method)Standard Test Method for Measuring Warpage of Ceramic Tile

Standard Test Method for Measuring Warpage of Ceramic Tile

SIGNIFICANCE AND USE

5.1 This test method provides a means for determining whether or not a lot of ceramic tile meets the warpage requirements that may appear in specifications to assure satisfactory tile installations. In accordance with this test method, warpage is calculated as a percentage of the length of the edge or diagonal being tested. It is realized that the percentage values based on the overall edge length, or on the overall diagonal length of a tile will be slightly lower than those based on the distance between reference points. However, the ratio of the overall lengths to the distance between reference points will be practically constant for any particular size of tile and, therefore, the percentage values will be comparable and equally indicative of warpage.

SCOPE

1.1 This test method covers procedures for measuring the corner, diagonal, and edge warpages of ceramic tile.

1.1.1 Tile Requirements for Corner, Diagonal, and Edge Warpage Measurement

Tile should be nominally flat, uniform in overall thickness, smooth faced, and rectangular in shape, including square.

1.1.2 Tile Requirements for Corner Warpage Measurement

All facial edge dimensions equal to or greater than 2.36 in. (60 mm) in length.

1.1.3 Tile Requirements for Edge and Diagonal Warpage Measurement

All facial edge dimensions equal to or greater than 2 in. (51 mm) in length.

1.1.4 Trim Tile meeting the descriptions in 1.1.1 – 1.1.3 except that only a part of the tile surface is flat. (Surface trim tile should be treated as flat tile whenever possible.)

1.2 This test method is not applicable to tile having embossed surfaces that are not flat, or that have a combination of variable body thickness and an irregular face.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C485 − 24

Standard Test Method for

1

Measuring Warpage of Ceramic Tile

This standard is issued under the fixed designation C485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers procedures for measuring the

C242 Terminology of Ceramic Whitewares and Related

corner, diagonal, and edge warpages of ceramic tile.

Products

1.1.1 Tile Requirements for Corner, Diagonal, and Edge

2.2 ASTM Adjuncts:

Warpage Measurement Tile should be nominally flat, uniform

3

Warpage Gage for Ceramic Tile

in overall thickness, smooth faced, and rectangular in shape,

including square.

3. Terminology

1.1.2 Tile Requirements for Corner Warpage Measurement

3.1 Definitions:

All facial edge dimensions equal to or greater than 2.36 in.

3.1.1 contact warpage device, n—consisting of a fixture that

(60 mm) in length.

has reference pins, contact gauges, and zero blank plates. The

1.1.3 Tile Requirements for Edge and Diagonal Warpage

device can be specific to a tile size or adjustable. Typically the

Measurement All facial edge dimensions equal to or greater

tile rests on the pins and the zero plane is fixed from these

than 2 in. (51 mm) in length.

contact points.

1.1.4 Trim Tile meeting the descriptions in 1.1.1 – 1.1.3

3.1.2 non-contact warpage device, n—a device that uses

except that only a part of the tile surface is flat. (Surface trim

some form of non-contact method to take measurements. An

tile should be treated as flat tile whenever possible.)

example would be laser measurement. These devices can use a

1.2 This test method is not applicable to tile having em- fixed reference plane (zero with flat blanks) or calculate a

theoretical reference plane.

bossed surfaces that are not flat, or that have a combination of

variable body thickness and an irregular face.

3.1.3 reference plane, n—the zero plane from which tile

planar deviations are measured.

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3.1.4 tile, n—see Definitions C242.

conversions to SI units that are provided for information only

3.1.5 warpage, n—curvature of a flat tile measured as

and are not considered standard.

deviation of the tile surface from a true plane along the edges,

at the corners, or the diagonals. The deviation is measured at

1.4 This standard does not purport to address all of the

the mid-length of an edge or diagonal, or at a corner, expressed

safety concerns, if any, associated with its use. It is the

as a percentage of the length of the edge, diagonal, or corner,

responsibility of the user of this standard to establish appro-

and called convex or concave with respect to the face of the

priate safety, health, and environmental practices and deter-

tile.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

4. Summary of Test Method

dance with internationally recognized principles on standard-

4.1 This method calculates the deviation of a ceramic tile

ization established in the Decision on Principles for the

from a flat plane. Measurements are made along the edges,

Development of International Standards, Guides and Recom-

diagonals, and corners of a tile. The deviation is expressed as

mendations issued by the World Trade Organization Technical

convex (positive) or concave (negative) warpage in relation to

Barriers to Trade (TBT) Committee.

the tile face.

1 2

This method is under the jurisdiction of ASTM Committee C21 on Ceramic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Whitewares and Related Productsand is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

C21.06 on Ceramic Tile. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2024. Published February 2024. Originally the ASTM website.

3

approved in 1961. Last previous edition approved in 2016 as C485 – 16. DOI: Three drawings showing construction details are available from ASTM

10.1520/C0485-24. Headquarters. Order ADJC0485.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C485 − 24

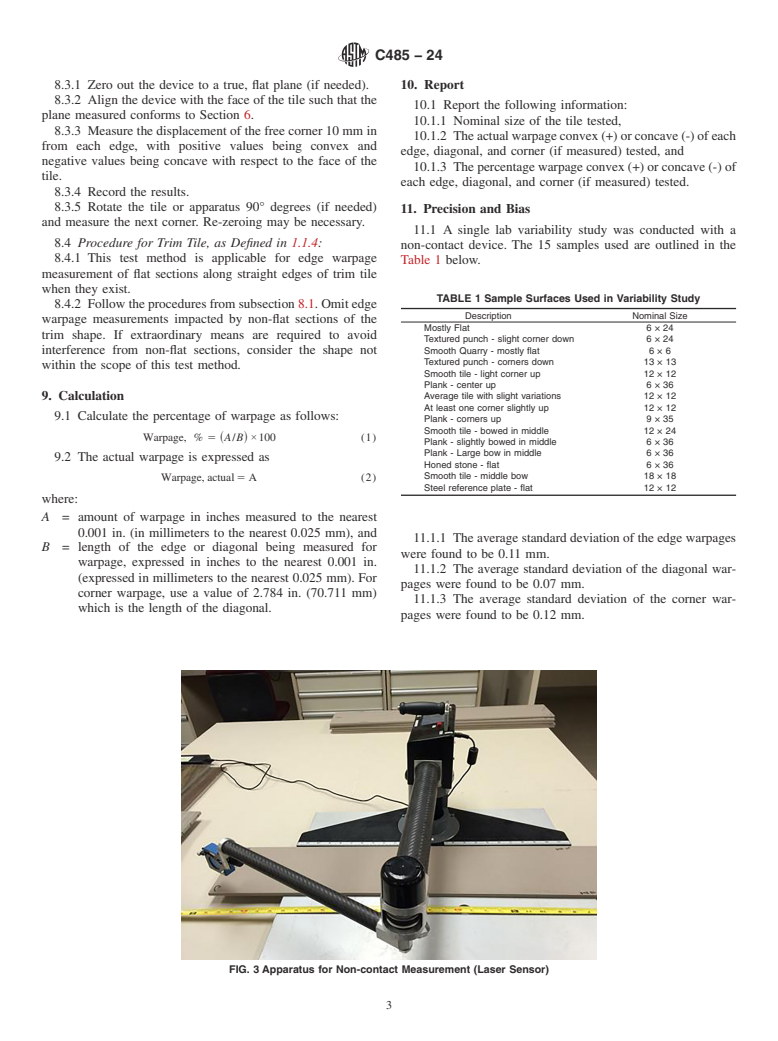

FIG. 2 Apparatus as Shown in Fig. 1, Showing Arrangement of

Stem Ext

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C485 − 16 C485 − 24

Standard Test Method for

1

Measuring Warpage of Ceramic Tile

This standard is issued under the fixed designation C485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers procedures for measuring the corner, diagonal, and edge warpages of the following categories of

ceramic tile:ceramic tile.

1.1.1 Square Tile, Tile Requirements for Corner, Diagonal, and Edge Warpage Measurement 2 by 2 in. (51 by 51 mm) or larger,

that are nominally flat, of uniform overall thickness, and have a smooth face of one of the types: unglazed, bright glazed, matte

glazed, or finely crystalline glazed.Tile should be nominally flat, uniform in overall thickness, smooth faced, and rectangular in

shape, including square.

1.1.2 Oblong Tile, no facial dimension smaller than 2 in. (51 mm), that are flat, of uniform overall thickness, and have a smooth

face of one of the types: unglazed, bright glazed, matte glazed, or finely crystalline glazed.

1.1.2 Square and Oblong Tile, Tile Requirements for Corner Warpage Measurement no facial dimension smaller than 2 in. (51

mm), that are flat, but have an irregular face such as embossed, sloped, bumpy, wavy, coarsely crystalline, or wire-cut textured.All

facial edge dimensions equal to or greater than 2.36 in. (60 mm) in length.

1.1.3 Nonrectilinear Tile, Tile Requirements for Edge and Diagonal Warpage Measurement larger than 4 in.All facial edge

2 2

dimensions (26 cm ), that are flat and of uniform body thickness with smooth or irregular face, such as hexagonal, diamond,

Spanish type, and so forth. equal to or greater than 2 in. (51 mm) in length.

1.1.4 Trim Tile meeting one of the descriptions in 1.1.1 – 1.1.31.1.4 except that only a part of the tile surface is flat. (Surface trim

tile should be treated as flat tile whenever possible.)

2 2

1.1.6 Square or Oblong Tile with facial area less than 4 in. (26 cm ) and at least two straight sides equal to or greater than 1.0

in. (25 mm) long. (Modular 1- by 1-in. tile are not in the scope of this test method.)

1.2 This test method is not applicable to tile having embossed surfaces that are not flat, or that have a combination of variable

body thickness and an irregular face.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1

This method is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Productsand is the direct responsibility of Subcommittee C21.06

on Ceramic Tile.

Current edition approved Dec. 1, 2016Feb. 1, 2024. Published January 2017February 2024. Originally approved in 1961. Last previous edition approved in 20092016 as

C485 – 09.C485 – 16. DOI: 10.1520/C0485-16.10.1520/C0485-24.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C485 − 24

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C242 Terminology of Ceramic Whitewares and Related Products

2.2 ASTM Adjuncts:

3

Warpage Gage for Ceramic Tile

3. Terminology

3.1 Definitions:

3.1.1 contact warpage device, n—consisting of a fixture that has reference pins, contact gauges, and zero blank plates. The device

can be specific to a tile size or adjustable. Typically the tile rests on the pins and the zero plane is fixed from these contact points.

3.1.2 non-contact warpage device, n—a device that uses some form of non-contact method to take measurements. An example

would be laser measurement. These devices can useduse a fi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.