ASTM E1773-00

(Practice)Standard Practice for Sealing Rigid Wall Tactical Shelters with Polysulfide Based Sealants

Standard Practice for Sealing Rigid Wall Tactical Shelters with Polysulfide Based Sealants

SCOPE

1.1 This practice establishes the recommended procedures for sealing rigid wall tactical shelters. It outlines the recommended techniques for the storage, mixing, handling, and application of polysulfide based sealants.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E 1773 – 00

Standard Practice for

Sealing Rigid Wall Tactical Shelters with Polysulfide Based

Sealants

This standard is issued under the fixed designation E1773; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2.2 adhesion—see Terminology D907.

3.2.3 application time (sealants)—the time available for

1.1 This practice establishes the recommended procedures

sealant application after mixing or time available after thawing

for sealing rigid wall tactical shelters. It outlines the recom-

a premixed and frozen cartridge of sealant.

mended techniques for the storage, mixing, handling, and

3.2.3.1 Discussion—Acceptability limits for Class B ex-

application of polysulfide based sealants.

trudablesealantsareexpressedintermsoftheextrusionrateof

1.2 This standard does not purport to address all of the

a sealant froma6floz (180 mL) cartridge through a nozzle

safety concerns, if any, associated with its use. It is the

witha0.125in.(3.2mm)diameterorifice,usingairpressureof

responsibility of the user of this standard to establish appro-

90 6 5 psi (620 6 34 kPa) in a pneumatic sealant gun. The

priate safety and health practices and determine the applica-

extrusion rate is expressed in grams per minute or on cc per

bility of regulatory limitations prior to use.

minute. A minimum extrusion rate after the stated application

2. Referenced Documents time is given as the acceptable limit. Sealant applied after the

application time is exceeded tends not to wet the surface well

2.1 ASTM Standards:

andthusnottoformagoodbond.Thistermshouldnotbeused

D907 Terminology of Adhesives

interchangeably with work life.

E1749 Terminology Relating to Rigid Wall Relocatable

3.2.4 assembly time—the amount of time available after a

Shelters

two-part sealant is mixed, before the faying surfaces, to which

2.2 Military Specification:

sealant is applied, shall be assembled and the sealant squeezed

MIL-S-8802 Sealing Compound, Temperature-Resistant,

out.

IntergalFuelTankandFuelCellCavities,HighAdhesion

3.2.4.1 Discussion—If the assembly time is exceeded, the

2.3 Other Document:

cure will have progressed too far to permit most of the sealant

AMS 3819 Cleaning Cloths

to be squeezed out for the desired surface to surface contact.

3. Terminology

The term assembly time is used in reference to faying-surface

sealants. Also called work life and open time.

3.1 Definitions—See Terminology E1749 for definitions of

3.2.5 base compound—the major component of a two-part

general terms used in this practice.

curing sealant that contains the polysulfide polymer.

3.2 Definitions of Terms Specific to This Standard:

3.2.6 bridging—see Terminology E1749.

3.2.1 accelerator—the term accelerator is used by sealant

3.2.7 cartridge—a plastic container which contains an inte-

formulatorstodenoteaningredientincludedintheformulation

gral plunger.

to accelerate the rate of cure. It is also used separately in a

3.2.7.1 Discussion—Thecartridgeisusedtocontaineithera

mixturetoacceleratesurfacecuringonlyofappliedpolysulfide

frozen quantity of premixed base compound and curing com-

sealant, that is, tack free time accelerator.

pound or simply the base compound in unmixed injection kits.

3.2.8 cohesion strength (sealant)—the internal forces hold-

ThispracticeisunderthejurisdictionofASTMCommitteeE-6onPerformance

ing a cured sealant together.

of Buildings and is the direct responsibility of Subcommittee E06.53 on Materials

3.2.9 contaminant—anyforeignsubstancethatdegradesthe

and Processes for Durable Rigidwall Relocatable Structures.

performance of the sealant.

Current edition approved May 10, 2000. Published July 2000. Originally

published as E 1773–95. Last previous edition E 1773–95. 3.2.10 cure rate—the rate at which a sealant polymerizes or

Annual Book of ASTM Standards, Vol 15.06.

crosslinks (that is, solidifies), a measure of which is the

Annual Book of ASTM Standards, Vol 04.11.

hardness of a sealant at a specified cure time.

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Available from SAE, 400 Commonwealth Dr., Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1773–00

3.2.11 cure time (sealants)—the time required for a sealant 5. Hazards

to polymerize and develop its full physical/mechanical prop-

5.1 Materials—The precautions outlined in the manufactur-

erties.

ers’materialsafetydatasheets(MSDS)forthematerialsbeing

3.2.11.1 Discussion—In practice, however, it is the time

used shall become a part of this practice.

required to reach a designated hardness.

5.2 Work Place:

3.2.12 curing compound—the crosslinking agent for the

5.2.1 All lights and other electrical equipment used for the

base compound.

sealant application within an enclosed shelter shall be explo-

3.2.13 hardness—see Shore A hardness and REX Hard-

sion proof. Extension cords shall be long enough to make

ness in Terminology E1749.

electrical connections outside the shelter.

3.2.14 interference seal—a seal produced between a given

5.2.2 When use of compressed air is required, proper safety

diameter mechanical fastener and a smaller diameter hole in a

equipment shall be provided and used.

member into which it is inserted.

3.2.14.1 Discussion—An interference seal is also produced

6. Storage

when a fastener shank is expanded by the installation process.

6.1 Premixed and Frozen Sealant—Sealants that are sup-

3.2.15 primary seal—a seal which, in combination with the

plied premixed and frozen shall be stored in a cold box or a

structure and optional brush coat or secondary seal, forms a

room maintained at−40 6 5°F (−40 6 2.8°C).

continuous, durable seal in the sealing plane and requires no

6.2 Two-Component Sealant Kits—Two-component seal-

additional seals.

antssuppliedaseitherinjectionkitsorbulksealantkitsshallbe

3.2.16 self-sealing fastener—a fastener that provides a tight

stored in areas maintained at a temperature not to exceed 80°F

seal without the need for sealant materials or the use of a

(27°C).

mechanical seal.

3.2.16.1 Discussion—An interference fit fastener is an ex-

7. Labeling

ample.

7.1 Sealant containers shall have attached labels which

3.2.17 tack free time—the time required for a curing sealant

clearly identify the product, manufacturer, matched base and

to lose its surface tackiness to polyethylene.

curing compounds (if applicable), batch and lot numbers, date

3.2.17.1 Discussion—Refer to MIL-S-8802.

of manufacture, recommended mix ratio (if applicable), and

3.2.18 tooled fillet—a fillet formed by working an applied

expiration date under specified storage conditions.

bead of sealant to a feathered edge using a shaped tool.

3.2.18.1 Discussion—The goal is to ensure good surface

8. Material Handling

contact at the feathered edges, to eliminate voids, trapped air

8.1 Premixed and Frozen—Sealants are supplied premixed

and reentrant edges, and to produce a contour of the correct

and frozen, used prior to the manufacturer’s expiration date on

thickness and shape over the area being sealed.

the label, and shall be ready for immediate use following

3.2.19 two-component sealant injection kit—a kit designed

thawing of the contents. With the addition of a nozzle, the

for the mixing and application of a two part sealant. The kit

material is dispensed directly from the cartridge.

consists of a plastic (usually polyethylene) cartridge filled with

8.2 Two-Component Sealant Injection Kits—Sealants sup-

base compound, a hollow dasher rod containing curing com-

plied in this form shall be mixed according to the manufactur-

pound, and a plunger. The dasher rod extends into one end of

er’s instructions and used before the expiration date provided

the cartridge; at the end of the dasher rod inside the cartridge,

onthelabelandwithintheapplicationtimedeterminedforthat

a multi-armed agitator is attached. The plunger caps the other

sealant.

end of the cartridge.

8.3 Bulk Sealant—Two-part sealants are supplied in a wide

3.2.19.1 Discussion—To use, a ram rod is inserted into the

range of kit sizes from ⁄2 pt to 50 gal drums plus 5 gal pail of

dasher rod and the curing compound is forced into the base

curing compound. In every case there is a small percentage of

compound. The dasher rod is then pulled back and forth at a

extra curing compound included, ranging from 2 to 10% to

specified rate with periodic rotation to add to the efficiency of

compensate for losses in the transfer of the curing compound.

the agitator. When the sealant is mixed thoroughly, the dasher

Althoughkitsizesaregenerallyquotedintermsofvolume,the

rod is unscrewed from the agitator and removed. A nozzle is

base and curing compound are matched on basis of weight

screwed onto the cartridge and the unit inserted into a sealant

ratio.Bothweightandvolumeratioareusuallyincludedonthe

gun. Sealant is dispensed as the plunger is pushed further into

label.

the cartridge.

8.3.1 Mixing:

3.2.20 wet installed fasteners—fasteners that are coated on

8.3.1.1 Hand Mixing—Kits under 5 gal are packaged such

the shank and under the head with a curing-type sealant to

that the base compound container will permit the addition and

provide a corrosion barrier and a secondary seal.

mixing of the curing compound. Mix the entire kit at one time

4. Significance and Use

and use ALL the curing compound. By mixing and using the

4.1 This recommended practice is intended to provide entire kit at once, the user is assured that the correct amounts

informationonthestorage,mixing,handlingandapplicationof have been used and the resultant sealant properties will be

polysulfide based sealants. Tooling and equipment require- thoseexpected.Someofthepitfallsofattemptingtousepartial

mentsforthesatisfactoryapplicationofthesealantstojointsin kitsinclude:(1)thepossibleuseofincorrectratio;(2)incorrect

tactical shelters are also provided. weighing; ( 3) failure to thoroughly stir the curing compound

E1773–00

in the container before removing the desired quantity; (4) (a) (a) Stir the 5 gal pail of catalyst thoroughly with a

incomplete transfer of base or curing compound, or both; and mechanical agitator, being careful not to whip air into the

(5) compromising the remaining material by failure to supply curing compound or excessively heat the material.

an inert atmosphere or failure to set the can lid completely. (b) (b) Scrape down the walls of the pail.

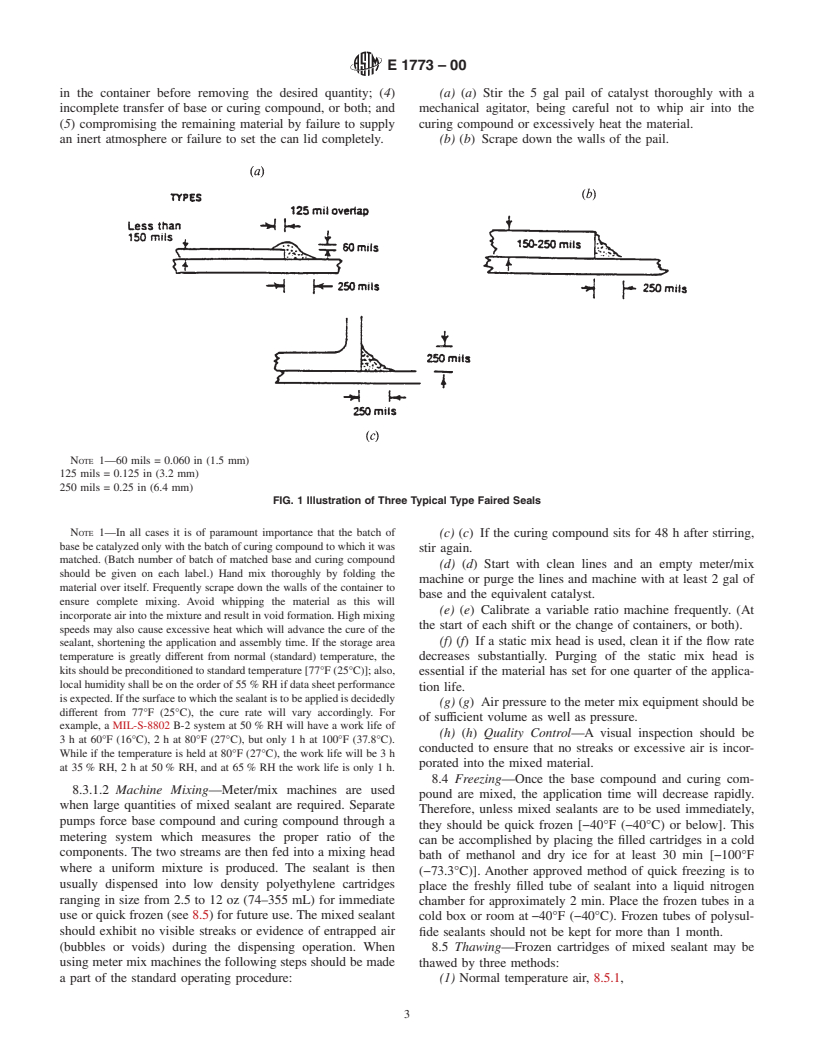

NOTE 1—60 mils = 0.060 in (1.5 mm)

125 mils = 0.125 in (3.2 mm)

250 mils = 0.25 in (6.4 mm)

FIG. 1 Illustration of Three Typical Type Faired Seals

NOTE 1—In all cases it is of paramount importance that the batch of

(c) (c) If the curing compound sits for 48 h after stirring,

basebecatalyzedonlywiththebatchofcuringcompoundtowhichitwas

stir again.

matched. (Batch number of batch of matched base and curing compound

(d) (d) Start with clean lines and an empty meter/mix

should be given on each label.) Hand mix thoroughly by folding the

machine or purge the lines and machine with at least 2 gal of

material over itself. Frequently scrape down the walls of the container to

base and the equivalent catalyst.

ensure complete mixing. Avoid whipping the material as this will

(e) (e) Calibrate a variable ratio machine frequently. (At

incorporate air into the mixture and result in void formation. High mixing

the start of each shift or the change of containers, or both).

speeds may also cause excessive heat which will advance the cure of the

(f) (f) If a static mix head is used, clean it if the flow rate

sealant, shortening the application and assembly time. If the storage area

decreases substantially. Purging of the static mix head is

temperature is greatly different from normal (standard) temperature, the

kitsshouldbepreconditionedtostandardtemperature[77°F(25°C)];also,

essential if the material has set for one quarter of the applica-

localhumidityshallbeontheorderof55%RHifdatasheetperformance

tion life.

isexpected.Ifthesurfacetowhichthesealantistobeappliedisdecidedly

(g) (g) Air pressure to the meter mix equipment should be

different from 77°F (25°C), the cure rate will vary accordingly. For

of sufficient volume as well as pressure.

example, a MIL-S-8802 B-2 system at 50% RH will have a work life of

(h) (h) Quality Control—A visual inspection should be

3 h at 60°F (16°C),2hat 80°F (27°C), but only1hat 100°F (37.8°C).

conducted to ensure that no streaks or excessive air is incor-

While if the temperature is held at 80°F (27°C), the work life will be 3 h

porated into the mixed material.

at35%RH,2hat50%RH,andat65%RHthe work life is only 1 h.

8.4 Freezing—Once the base compound and curing com-

8.3.1.2 Machine Mixing—Meter/mix machines are used

pound are mixed, the application time will decrease rapidly.

when large quantities of mixed sealant are required. Separate

Therefore, unless mixed sealants are to be used immediately,

pumps force base compound and curing compound through a

they should be quick frozen [−40°F (−40°C) or below]. This

metering system which measures the proper ratio of the

can be accomplished by placing the filled cartridges in a cold

components. The two streams are then fed into a mixing head

bath of methanol and dry ice for at least 30 min [−100°F

where a uniform mixture is produced. The sealant is then

(−73.3°C)]. Another approved method of quick freezing is to

usually dispensed into low density polyethylene cartridges

place the freshly filled tube of sealant into a liquid nitrogen

ranging in size from 2.5 to 12 oz (74–355 mL) for immediate

chamber for approximately 2 min. Place the frozen tubes in a

use or quick frozen (see 8.5) for future use. The mixed sealant

cold box or room at−40°F (−40°C). Frozen tubes of polysul-

should exhibit no visible streaks or evidence of entrapped air fide sealants should not be kept for more than 1 month.

(bubbles or voids) during the dispensing operation. When 8.5 Thawing—Frozen cartridges of mixed sealant may be

using meter mix machines the following steps should be made thawed by three methods:

a part of the standard operating procedure: (1) Normal temperature air, 8.5.1,

E1773–00

(2) Enclosed heating bath, 8.5.2, and “non-sag” or low block flow characteristics and by their

thixotropic nature which permits the easy extrusion of very

(3) Microwave oven, 8.5.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.