ASTM E208-95a

(Test Method)Standard Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

Standard Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

SCOPE

1.1 This test method covers the determination of the nil-ductility transition (NDT) temperature of ferritic steels, 5/8 in. (15.9 mm) and thicker.

1.2 This test method may be used whenever the inquiry, contract, order, or specification states that the steels are subject to fracture toughness requirements as determined by the drop-weight test.

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 208 – 95a An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Conducting Drop-Weight Test to Determine Nil-Ductility

Transition Temperature of Ferritic Steels

This standard is issued under the fixed designation E 208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This drop-weight test was developed at the Naval Research Laboratory in 1952 and has been used

extensively to investigate the conditions required for initiation of brittle fractures in structural steels.

Drop-weight test facilities have been established at several Naval activities, research institutions, and

industrial organizations in this country and abroad. The method is used for specification purposes by

industrial organizations and is referenced in several ASTM specifications and the ASME Boiler and

Pressure Vessel Code. This procedure was prepared to ensure that tests conducted at all locations

would have a common meaning.

1. Scope conducted by subjecting each of a series (generally four to

eight) of specimens of a given material to a single impact load

1.1 This test method covers the determination of the nil-

at a sequence of selected temperatures to determine the

ductility transition (NDT) temperature of ferritic steels, ⁄8 in.

maximum temperature at which a specimen breaks. The impact

(15.9 mm) and thicker.

load is provided by a guided, free-falling weight with an energy

1.2 This test method may be used whenever the inquiry,

of 250 to 1200 ft-lbf (340 to 1630 J) depending on the yield

contract, order, or specification states that the steels are subject

strength of the steel to be tested. The specimens are prevented

to fracture toughness requirements as determined by the

by a stop from deflecting more than a few tenths of an inch.

drop-weight test.

3.2 The usual test sequence is as follows: After the prepa-

1.3 The values stated in inch-pound units are to be regarded

ration and temperature conditioning of the specimen, the initial

as the standard.

drop-weight test is conducted at a test temperature estimated to

1.4 This standard does not purport to address all of the

be near the NDT temperature. Depending upon the results of

safety concerns, if any, associated with its use. It is the

the first test, tests of the other specimens are conducted at

responsibility of the user of this standard to establish appro-

suitable temperature intervals to establish the limits within

priate safety and health practices and determine the applica-

10°F (5°C) for break and no-break performance. A duplicate

bility of regulatory limitations prior to use.

test at the lowest no-break temperature of the series is

2. Terminology

conducted to confirm no-break performance at this tempera-

ture.

2.1 Definitions:

3.3 In 1984, the method of applying the crack-starter weld

2.1.1 ferritic—the word ferritic as used hereafter refers to

bead was changed from a two-pass technique to the current

all a-Fe steels. This includes martensitic, pearlitic, and all

single-pass procedure, and the practice of repair-welding of the

other nonaustenitic steels.

crack-starter weld bead was prohibited. For steels whose

2.1.2 nil-ductility transition (NDT) temperature—the maxi-

properties are influenced by tempering or are susceptible to

mum temperature where a standard drop-weight specimen

temper embrittlement, the nil-ductility transition (NDT) tem-

breaks when tested according to the provisions of this method.

perature obtained using the single-pass crack-starter weld bead

3. Summary of Test Method

may not agree with that obtained using the previous two-pass

crack-starter weld bead, or when the crack-starter bead was

3.1 The drop-weight test employs simple beam specimens

repaired.

specially prepared to create a material crack in their tensile

surfaces at an early time interval of the test. The test is

4. Significance and Use

4.1 The fracture-strength transitions of ferritic steels used in

This test method is under the jurisdiction of the ASTM Committee E-28 on

the notched condition are markedly affected by temperature.

Mechanical Testing and is the direct responsibility of Subcommittee E28.07 on

For a given “low” temperature, the size and acuity of the flaw

Impact Testing.

Current edition approved Aug. 15, 1995. Published October 1995. Originally

(notch) determines the stress level required for initiation of

published as E 208 – 63 T. Last previous edition E 208 – 95.

E 208

brittle fracture. The significance of this test method is related to when it strikes the specimen. The striking tup of the weight

establishing that temperature, defined herein as the NDT shall be a steel cylindrical surface with a radius of 1 in. (25.4

temperature, at which the “small flaw” initiation curve, Fig. 1, mm) and a minimum hardness of HRC 50 throughout the

FIG. 1 Generalized Fracture Analysis Diagram Indicating the Approximate Range of Flaw Sizes Required for Fracture Initiation at

,

Various Levels of Nominal Stress, as Referenced by the NDT Temperature

falls to nominal yield strength stress levels with decreasing section. The weight shall be between 50 and 300 lb (22.7 and

temperature, that is, the point marked NDT in Fig. 1. 136 kg). The rails and hoisting device shall permit raising the

4.2 Interpretations to other conditions required for fracture weight various fixed distances to obtain potential energies of

initiation may be made by the use of the generalized flaw-size, 250 to 1200 ft-lbf (340 to 1630 J).

stress-temperature diagram shown in Fig. 1. The diagram was 5.3 A horizontal base, located under the guide rails, shall be

derived from a wide variety of tests, both fracture-initiation

provided to hold and position precisely the several styles of

and fracture-arrest tests, as correlated with the NDT tempera- anvils required for the standard specimens. The anvil guides

ture established by the drop-weight test. Validation of the NDT

shall position the anvil with the center-line of the deflection

concept has been documented by correlations with numerous stops under the center-line of the striking tup of the weight. In

service failures encountered in ship, pressure vessel, machinery

general, the base will also support the guide rails, but this is not

component, forged, and cast steel applications. a requirement. The base shall rest on the rigid foundation. The

base-foundation system shall be sufficiently rigid to allow the

5. Apparatus

normal drop-weight energy (Table 1) to deflect a standard

specimen to the stop at temperatures above the NDT. The base

5.1 The drop-weight machine is of simple design based on

shall not jump or shift during the test, and shall be secured to

the use of readily available structural steel products. The

the foundation if necessary to prevent motion.

principal components of a drop-weight machine are a vertically

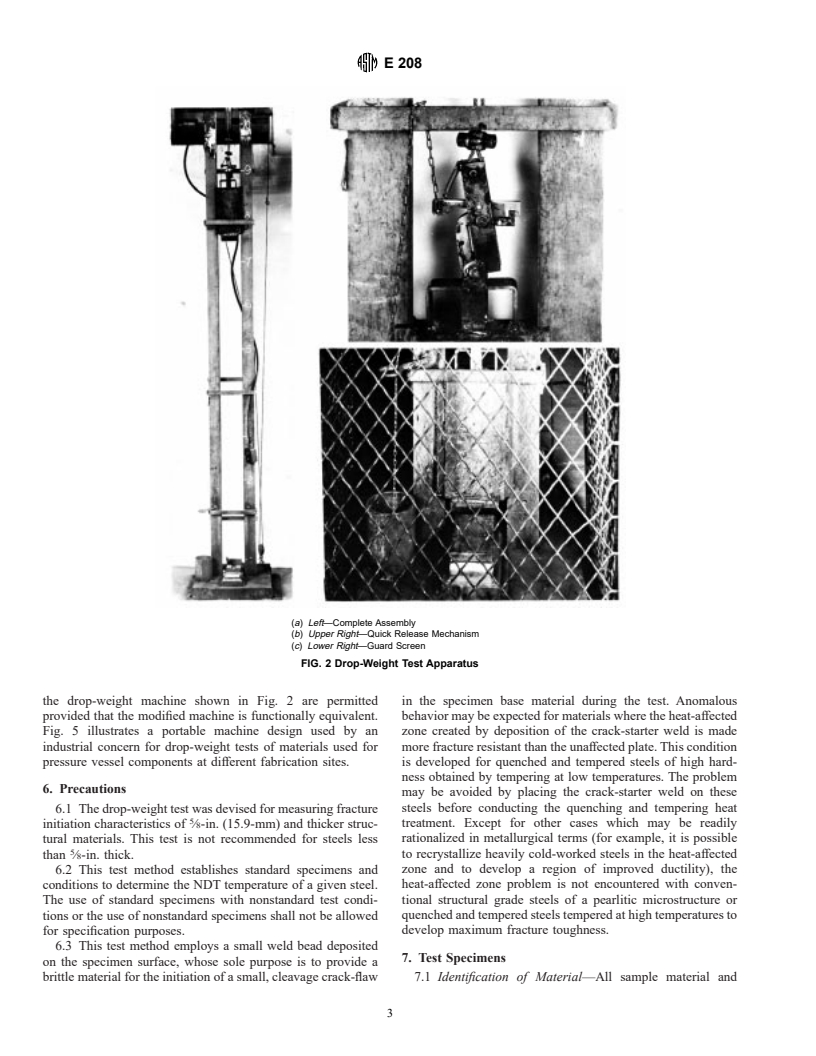

5.4 A guard screen, similar to that shown in Fig. 2(c), is

guided, free-falling weight, and a rigidly supported anvil which

provides for the loading of a rectangular plate specimen as a recommended to stop broken specimen halves of the very

brittle steels which break into two pieces with both halves

simple beam under the falling weight. Fig. 2(a) illustrates a

typical drop-weight machine built of standard structural being ejected forcefully from the machine.

5.5 The general characteristics of two of the anvils required

shapes.

5.2 A rail, or rails, rigidly held in a vertical position and in are illustrated in Fig. 3. The anvils shall be made in accordance

with the dimensions shown in Fig. 4. The anvil supports and

a fixed relationship to the base shall be provided to guide the

weight. The weight shall be provided with suitable devices deflection stops shall be steel-hardened to a minimum hardness

of HRC 50 throughout their cross section. The space between

which engage the rail, or rails, and ensure that it will drop

freely in a single, vertical plane. The weight may be raised by the two stops is provided as clearance for the crack-starter weld

on the specimen. The deflection stops may be made in two

any convenient means. A weight-release mechanism, function-

ing similarly to that shown in Fig. 2(b), shall be provided to separate pieces, if desired. The anvil-base system shall be

sufficiently rigid to allow the normal drop-weight energy

release the weight quickly without affecting its free fall. The

(Table 1) to deflect the specimen to the stop at temperatures

weight shall be made in one piece, or if made of several pieces,

well above the NDT.

its construction shall be rigid to ensure that it acts as a unit

5.6 A measuring system shall be provided to assure that the

weight is released from the desired height for each test, within

the limits of +10, −0 %.

Detail drawings for the construction of this machine are available from ASTM

Headquarters. Order PCN 12-502080-00. 5.7 Modifications of the equipment or assembly details of

E 208

(a) Left—Complete Assembly

(b) Upper Right—Quick Release Mechanism

(c) Lower Right—Guard Screen

FIG. 2 Drop-Weight Test Apparatus

the drop-weight machine shown in Fig. 2 are permitted in the specimen base material during the test. Anomalous

provided that the modified machine is functionally equivalent. behavior may be expected for materials where the heat-affected

Fig. 5 illustrates a portable machine design used by an zone created by deposition of the crack-starter weld is made

industrial concern for drop-weight tests of materials used for more fracture resistant than the unaffected plate. This condition

pressure vessel components at different fabrication sites. is developed for quenched and tempered steels of high hard-

ness obtained by tempering at low temperatures. The problem

6. Precautions

may be avoided by placing the crack-starter weld on these

steels before conducting the quenching and tempering heat

6.1 The drop-weight test was devised for measuring fracture

initiation characteristics of ⁄8-in. (15.9-mm) and thicker struc- treatment. Except for other cases which may be readily

rationalized in metallurgical terms (for example, it is possible

tural materials. This test is not recommended for steels less

than ⁄8-in. thick. to recrystallize heavily cold-worked steels in the heat-affected

zone and to develop a region of improved ductility), the

6.2 This test method establishes standard specimens and

conditions to determine the NDT temperature of a given steel. heat-affected zone problem is not encountered with conven-

tional structural grade steels of a pearlitic microstructure or

The use of standard specimens with nonstandard test condi-

tions or the use of nonstandard specimens shall not be allowed quenched and tempered steels tempered at high temperatures to

develop maximum fracture toughness.

for specification purposes.

6.3 This test method employs a small weld bead deposited

7. Test Specimens

on the specimen surface, whose sole purpose is to provide a

brittle material for the initiation of a small, cleavage crack-flaw 7.1 Identification of Material—All sample material and

E 208

TABLE 1 Standard Drop-Weight Test Conditions

Drop-Weight Energy for Given

Specimen Size, Deflection Stop, Yield Strength Level, A

Yield Strength Level

Type of Specimen Span, in. (mm)

in. (mm) in. (mm) ksi (MPa)

ft-lbf J

P-1 1by3 ⁄2 by 14 12.0 0.3 30 to 50 (210 to 340) 600 800

(25.4 by 89 by 356) (305) (7.6) 50 to 70 (340 to 480) 800 1100

70 to 90 (480 to 620) 1000 1350

90 to 110 (620 to 760) 1200 1650

P-2 ⁄4 by2by5 4.0 0.06 30 to 60 (210 to 410) 250 350

(19 by 51 by 127) (102) (1.5) 60 to 90 (410 to 620) 300 400

90 to 120 (620 to 830) 350 450

120 to 150 (830 to 1030) 400 550

P-3 ⁄8 by2by5 4.0 0.075 30 to 60 (210 to 410) 250 350

(15.9 by 51 by 127) (102) (1.9) 60 to 90 (410 to 620) 300 400

90 to 120 (620 to 830) 350 450

120 to 150 (830 to 1030) 400 550

A

Initial tests of a given strength level steel shall be conducted with the drop-weight energy stated in this column. In the event that insufficient deflection is developed

(no-test performance) an increased drop-weight energy shall be employed for other specimens of the given steel.

FIG. 3 General Appearance of the Anvils Required for Drop-Weight NDT Tests

specimens removed from a given plate, shape, forging, or specimens (for example, mechanical test specimens) required

casting product shall be marked to identify their particular for evaluation of other material properties.

source (heat number, slab number, etc.). A simple identification 7.4 Special Conditions for Forgings and Castings—Where

system shall be used which can be employed in conjunction drop-weight testing of cast or forged material is specified, the

with an itemized table to obtain all the pertinent information. size and location of integrally attached pad projections or

7.2 Orientation—The drop-weight test is insensitive to prolongations to be used for specimen fabrication shall be

specimen orientation with respect to rolling or forging direc- agreed to in advance by the purchaser. If the design of the

tion. However, unless otherwise agreed to, all specimens casting or forging does not allow an attached test-material

specified by the purchaser shall be of the same orientation and coupon, the following requirements shall apply:

it shall be noted in the test report. 7.4.1 Drop-weight specimens cast or forged separately to

7.3 Relation to Other Specimens—Unless otherwise speci- the dimensions required for testing shall be allowed only where

fied by the purchaser, the specimens shall be removed from the the product dimensions are equivalent and the purchaser

material at positions adjacent to the location of other type test agrees.

E 208

Specimen Type

Anvil Dimension Units Tolerance

P-1 P-2 P-3

S, Span in. 12.0 4.0 4.0 60.05

mm 305 100 100 61.5

D, Deflection stop in. 0.30 0.060 0.075 60.002

mm 7.60 1.50 1.90 60.05

A, Anvil length ←——————––not critical––——————→

B, Anvil width ←——————––not critical––——————→

C, Anvil thickness in. 1.5 min 1.5 min 1.5 min

mm 38 min 38 min 38 min

E, Support length in. 3.5 min 2.0 min 2.0 min

mm 90 min 50 min 50 min

F, Support width ←——————not less than G——————→

G, Support height in. 2.0 2.0 2.0 61

mm 50 50 50 625

R, Support radius in. 0.075 0.075 0.075 60.025

mm 1.0 1.0 1.0 60.1

H, Stop width in. 3.5 min 2.0 mi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.