ASTM F2340-05(2016)

(Specification)Standard Specification for Developing and Validating Prediction Equation(s) or Model(s) Used in Connection with Livestock, Meat, and Poultry Evaluation Device(s) or System(s) to Determine Value

Standard Specification for Developing and Validating Prediction Equation(s) or Model(s) Used in Connection with Livestock, Meat, and Poultry Evaluation Device(s) or System(s) to Determine Value

ABSTRACT

This specification covers the standard procedures used to collect and analyze data, document the results, and make predictions for any characteristic used to quantify the value of any livestock, meat, and poultry species as measured by appropriate evaluation devices or systems. The procedures described here shall be used particularly when new prediction equations or models are established, or when a change is experienced that could affect the performance of existing equations.

SCOPE

1.1 This specification covers methods to collect and analyze data, document the results, and make predictions by any objective method for any characteristic used to determine value in any species using livestock, meat, and poultry evaluation devices or systems.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2340 −05 (Reapproved 2016)

Standard Specification for

Developing and Validating Prediction Equation(s) or

Model(s) Used in Connection with Livestock, Meat, and

Poultry Evaluation Device(s) or System(s) to Determine

Value

This standard is issued under the fixed designation F2340; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.3 coeffıcient of determination, n—percentageofvariabil-

ity in the response (dependent) variable that can be explained

1.1 Thisspecificationcoversmethodstocollectandanalyze

by the prediction equation.

data, document the results, and make predictions by any

objectivemethodforanycharacteristicusedtodeterminevalue

~y 2 yˆ!

(

R 51 2

in any species using livestock, meat, and poultry evaluation 2

y 2 y¯

~ !

(

devices or systems.

3.2.4 root mean square error for calibration, n—squareroot

1.2 This standard does not purport to address all of the

of the sum of squared residuals divided by n −(k+1), where

c

safety concerns, if any, associated with its use. It is the

n is the sample size for the calibration data set, and k is the

c

responsibility of the user of this standard to establish appro-

number of explanatory variables in the prediction equation.

priate safety and health practices and determine the applica-

bility of regulatory requirements prior to use. ~y 2 yˆ!

(

Œ

n 2 k11

~ !

c

2. Referenced Documents

3.2.5 root mean square error for validation, n—square root

2.1 ASTM Standards:

of the sum of squared residuals divided by n , where n is the

y y

F2463Terminology for Livestock, Meat, and Poultry Evalu-

sample size for the validation data set.

ation Systems

y 2 yˆ

~ !

(

3. Terminology

Œ

n

v

3.1 For definitions of terms used in this specification, refer

3.2.6 validation data set, n—the data set used to test the

to Terminology F2463.

predictive accuracy of the equations developed from the

3.2 Definitions of Terms Specific to This Standard:

calibration data set.

3.2.1 accuracy, n—statement of the exactness with which a

3.2.7 value, commerce, n—measure of economic worth in

measurement approaches the true measure for that character-

commerce.

istic;accuracyiscontrastedwithprecision,whichisconcerned

with the repeatability of the measurements. Therefore, with a 4. Significance and Use

largebias,ameasurementmaybeofhighprecision,butoflow

4.1 Theproceduresinthisspecificationaretobeusedbyall

accuracy.

parties interested in predicting composition or quality, or both,

3.2.2 calibration data set, n—data set used to develop the

for the purpose of establishing value based upon device or

initial prediction equations; same as developmental or predic-

system measurements.Whenever new prediction equations are

tion data set.

established, or when a change is experienced that could affect

the performance of existing equations, these procedures shall

This specification is under the jurisdiction of ASTM Committee F10 on be used.

Livestock, Meat, and Poultry Evaluation Systems and is the direct responsibility of

Subcommittee F10.40 on Predictive Accuracy.

5. Procedure

Current edition approved Sept. 1, 2016. Published September 2016. Originally

5.1 Experimental Design:

approved in 2004. Last previous edition approved in 2010 as F2340–05 (2010).

DOI: 10.1520/F2340-05R16.

5.1.1 Define the Population for Development of a Prediction

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Equation:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.1.1 To establish the predictive ability and validity of an

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. equation(s) using measures (independent variables) from an

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2340−05 (2016)

evaluation device or system, it is necessary to define the the device or system would be expected to operate. In

population on which the prediction model is intended to be particular, the validity of the approach and the repeatability of

used. the procedure must be documented and demonstrated. For

(1)Thespeciesonwhichmeasurementswillbemademust many of the common characteristics to be predicted (such as

be defined. percent lean), there are a number of reference methods com-

(2)Thepopulationforscopeofusemustbeclearlydefined. monlyacceptedwithinthediscipline.Whereacceptedmethods

This may include, but is not limited to, factors such as exist, they should be used and cited. Where accepted methods

geographical location, gender, age, breed type, or any other do not exist, a sound, science-based process of method

factor that may affect the equation accuracy. development should be followed. Consideration should be

(3)The characteristic to be predicted must be clearly given to sources of variation for the measurements and

defined. strategies to minimize any bias that may exist.

5.1.2 Select a Sample Population for Development of a 5.1.4 Independent Third-Party Consultation—After the ex-

Prediction Equation: perimental process has been established (but before initiation

5.1.2.1 The sample size for the calibration data set must be of the sampling), it is recommended that the users obtain an

at a minimum 10k, where k is the number of variables in the independent third-party consultation to review the procedures

prediction equation, or 100 observations, whichever is greater. for compliance with the guidelines established in the previous

The sample size for the validation data set must be at least sections. The consultation should focus on areas such as the

20% of the size of the calibration validation data set. For number of samples, the sample selection protocol, and the

example, if the prediction equation has five explanatory project procedures to ensure that the process will allow the

variables, the calibration data set will require a minimum of userstodetermineeffectivelythepredictiveabilityandvalidity

100 observations and the validation set must have at least 20 of the equation or model.

observations. These are minimal requirements; larger sample 5.1.5 Develop the Model or Equation:

sizes are encouraged, keeping in mind that the calibration data 5.1.5.1 Collectdataforthecalibration(developmental)data

set must be larger than the validation data set. set and develop the model or equation. Report the value of the

5.1.2.2 The sample size must be large enough to be repre- coefficient of determination, R , for the calibration data set.

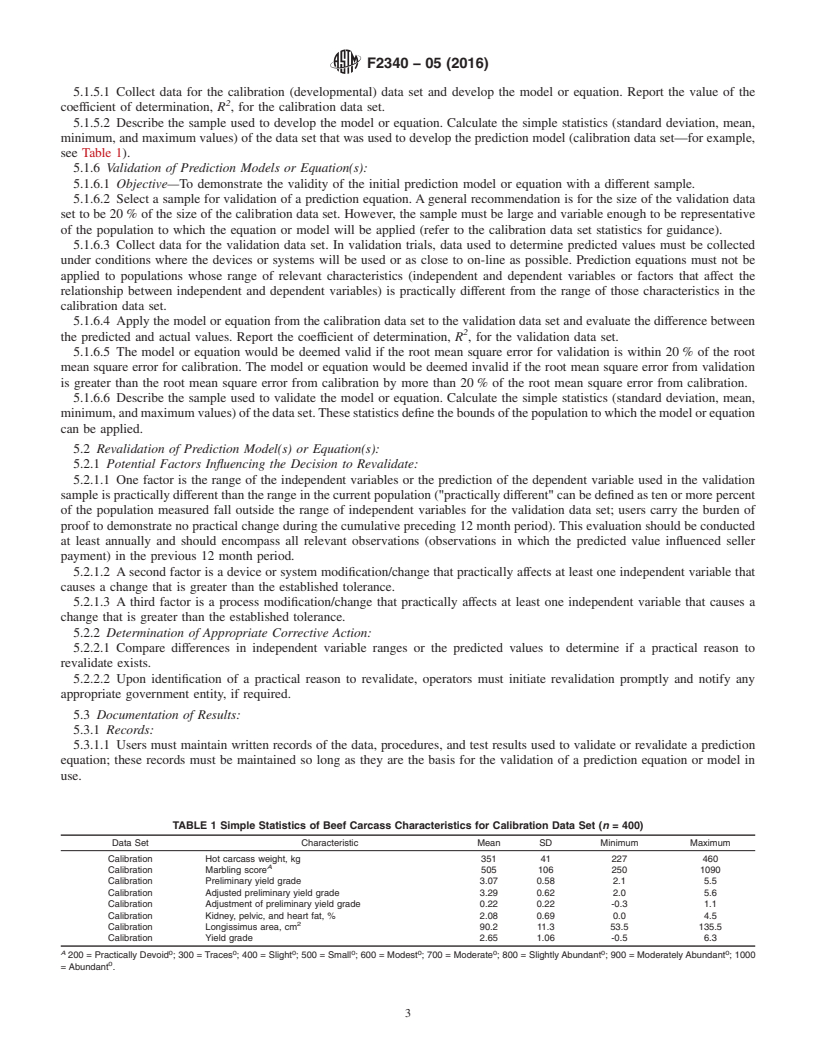

sentative of the population; otherwise the resultant equation 5.1.5.2 Describe the sample used to develop the model or

will not be suitable for use in the population to which the equation. Calculate the simple statistics (standard deviation,

equationwillbeapplied.Thismayrequirealargersamplesize mean,minimum,andmaximumvalues)ofthedatasetthatwas

thantheminimalrequirementin5.1.2.1.Whenpossible,itmay used to develop the prediction model (calibration data set—for

be useful to refer to existing data sets that describe a particular example, see Table 1).

population to ensure that the sample includes most of the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2340 − 05 (Reapproved 2010) F2340 − 05 (Reapproved 2016)

Standard Specification for

Developing and Validating Prediction Equation(s) or

Model(s) Used in Connection with Livestock, Meat, and

Poultry Evaluation Device(s) or System(s) to Determine

Value

This standard is issued under the fixed designation F2340; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers methods to collect and analyze data, document the results, and make predictions by any objective

method for any characteristic used to determine value in any species using livestock, meat, and poultry evaluation devices or

systems.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2.1 ASTM Standards:

F2463 Terminology for Livestock, Meat, and Poultry Evaluation Systems

3. Terminology

3.1 For definitions of terms used in this specification, refer to Terminology F2463.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 accuracy, n—statement of the exactness with which a measurement approaches the true measure for that characteristic;

accuracy is contrasted with precision, which is concerned with the repeatability of the measurements. Therefore, with a large bias,

a measurement may be of high precision, but of low accuracy.

3.2.2 calibration data set, n—data set used to develop the initial prediction equations; same as developmental or prediction data

set.

3.2.3 coeffıcient of determination, n—percentage of variability in the response (dependent) variable that can be explained by the

prediction equation.

~y 2 yˆ!

(

R 5 12

y 2 y¯

~ !

(

~y 2 yˆ !

(

R 5 12

~y 2 y¯!

(

3.2.4 root mean square error for calibration, n—square root of the sum of squared residuals divided by n − (k + 1), where n

c c

is the sample size for the calibration data set, and k is the number of explanatory variables in the prediction equation.

y 2 yˆ

~ !

(

Œ

n 2 k11

~ !

c

This specification is under the jurisdiction of ASTM Committee F10 on Livestock, Meat, and Poultry Evaluation Systems and is the direct responsibility of Subcommittee

F10.40 on Predictive Accuracy.

Current edition approved Sept. 1, 2010Sept. 1, 2016. Published December 2010September 2016. Originally approved in 2004. Last previous edition approved in 20052010

as F2340 – 05.F2340 – 05 (2010). DOI: 10.1520/F2340-05R10.10.1520/F2340-05R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2340 − 05 (2016)

y 2 yˆ

~ !

(

Œ

n 2 ~k11!

c

3.2.5 root mean square error for validation, n—square root of the sum of squared residuals divided by n , where n is the sample

y y

size for the validation data set.

~y 2 yˆ!

(

Œ

n

v

y 2 yˆ

~ !

(

Œ

n

v

3.2.6 validation data set, n—the data set used to test the predictive accuracy of the equations developed from the calibration

data set.

3.2.7 value, commerce, n—measure of economic worth in commerce.

4. Significance and Use

4.1 The procedures in this specification are to be used by all parties interested in predicting composition or quality, or both, for

the purpose of establishing value based upon device or system measurements. Whenever new prediction equations are established,

or when a change is experienced that could affect the performance of existing equations, these procedures shall be used.

5. Procedure

5.1 Experimental Design:

5.1.1 Define the Population for Development of a Prediction Equation:

5.1.1.1 To establish the predictive ability and validity of an equation(s) using measures (independent variables) from an

evaluation device or system, it is necessary to define the population on which the prediction model is intended to be used.

(1) The species on which measurements will be made must be defined.

(2) The population for scope of use must be clearly defined. This may include, but is not limited to, factors such as geographical

location, gender, age, breed type, or any other factor that may affect the equation accuracy.

(3) The characteristic to be predicted must be clearly defined.

5.1.2 Select a Sample Population for Development of a Prediction Equation:

5.1.2.1 The sample size for the calibration data set must be at a minimum 10k, where k is the number of variables in the

prediction equation, or 100 observations, whichever is greater. The sample size for the validation data set must be at least 20 %

of the size of the calibration validation data set. For example, if the prediction equation has five explanatory variables, the

calibration data set will require a minimum of 100 observations and the validation set must have at least 20 observations. These

are minimal requirements; larger sample sizes are encouraged, keeping in mind that the calibration data set must be larger than

the validation data set.

5.1.2.2 The sample size must be large enough to be representative of the population; otherwise the resultant equation will not

be suitable for use in the population to which the equation will be applied. This may require a larger sample size than the minimal

requirement in 5.1.2.1. When possible, it may be useful to refer to existing data sets that describe a particular population to ensure

that the sample includes most of the variation in the population. For example, if one were developing an equation to predict yield

grade in U.S. fed beef packing plants, one would want to make sure that the samples used to develop and validate the regression

model encompassed most of the normal variation in yield grade, yield grade factors, and factors that might affect the accuracy of

the model. In this example, the simple statistics of these characteristics in the calibration data sets should be compared to the simple

statistics of these characteristics in references such as the National Beef Quality Audits. Users are encouraged to work with a

statistician.

5.1.3 Develop an Experimental Process: Process—A clearly defined process must be established and documented. That process,

which includes consistent, repeatable methods, should be used to obtain the measurements under the same conditions in which the

device or system would be expected to operate. In particular, the validity of the approach and the repeatability of the procedure

must be documented and demonstrated. For many of the common characteristics to be predicted (such as percent lean), there are

a number of reference methods commonly accepted within the discipline. Where accepted methods exist, they should be used and

cited. Where accepted methods do not exist, a sound, science-based process of method development should be followed.

Consideration should be given to sources of variation for the measurements and strategies to minimize any bias that may exist.

5.1.4 Independent Third-Party

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.