ASTM F821/F821M-01(2012)

(Specification)Standard Specification for Domestic Use Doors and Frames, Steel, Interior, Marine

Standard Specification for Domestic Use Doors and Frames, Steel, Interior, Marine

ABSTRACT

This specification covers the design and dimensional requirements for the construction of standard and custom-built interior steel doors and frames intended for use in staterooms, lavatories, passageways, and other weather-protected areas of ships, including U.S. Coast Guard certificated vessels, with domestic routes. The doors and frames are to be of hollow metal construction with the door insulated for sound or fire. The doors and frames shall conform to the specified dimensional and construction procedures established for each class and type, which shall be indicated in the ordering information.

SCOPE

1.1 This specification covers the construction of standard and custom-built interior steel doors and frames for ships including U.S. Coast Guard certificated vessels with domestic routes.

1.2 Doors and frames are to be hollow metal construction with the door insulated for sound or fire.

1.3 The doors are intended for use in staterooms, lavatories, passageways, and other areas protected from weather.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F821/F821M −01 (Reapproved 2012) An American National Standard

Standard Specification for

Domestic Use Doors and Frames, Steel, Interior, Marine

This standard is issued under the fixed designation F821/F821M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E136Test Method for Behavior of Materials in a Vertical

Tube Furnace at 750°C

1.1 This specification covers the construction of standard

2.2 Code of Federal Regulations (CFR) Title 46—Shipping:

and custom-built interior steel doors and frames for ships

Subchapter D—Tank Vessels,Subpart 32.57—Structural

including U.S. Coast Guard certificated vessels with domestic

Fire Protection

routes.

Subchapter H—Passenger Vessels, Subpart 72.05—

1.2 Doors and frames are to be hollow metal construction 3

Structural Fire Protection

with the door insulated for sound or fire.

Subchapter I—Cargo and Miscellaneous Vessels,Subpart

1.3 Thedoorsareintendedforuseinstaterooms,lavatories, 92.07—Structural Fire Protection

SubchapterT—SmallPassengerVessels,Subpart177.300—

passageways, and other areas protected from weather.

Hull Structure

1.4 The values stated in either inch-pound units or SI units

Subchapter U—Oceanographic Vessels,Subpart 190.07—

are to be regarded separately as standard. Within the text, the

Structural Fire Protection

SI units are shown in brackets. The values stated in each

Structural Insulations,Subpart 164.007

system are not exact equivalents; therefore, each system must

Structural Insulations,Subpart 164.107

be used independently of the other.

Noncombustible Materials for Merchant Vessels,Subpart

1.5 This international standard was developed in accor-

164.009

dance with internationally recognized principles on standard- 3

Noncombustible Materials,Subpart 164.109

ization established in the Decision on Principles for the

2.3 Builders Hardware Manufacturers Association, Inc.:

Development of International Standards, Guides and Recom- 4

A156.18Materials and Finishes

mendations issued by the World Trade Organization Technical

2.4 U.S. Public Health Service:

Barriers to Trade (TBT) Committee.

Publication No. 393,Handbook on Sanitation of Vessel

Construction

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions of Terms Specific to This Standard:

A240/A240MSpecification for Chromium and Chromium-

3.1.1 hands of doors—a term used to describe a door from

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

the outside or key side of the door.

Vessels and for General Applications

A582/A582MSpecification for Free-Machining Stainless

3.1.2 right-hand regular door—a door having hinges on the

Steel Bars

right side when swinging door away from the individual

A1008/A1008MSpecification for Steel, Sheet, Cold-Rolled,

opening it.

Carbon, Structural, High-Strength Low-Alloy, High-

3.1.3 left-hand regular door—a door having hinges on the

Strength Low-Alloy with Improved Formability, Solution

leftsidewhenswingingdoorawayfromtheindividualopening

Hardened, and Bake Hardenable

it.

3.1.4 right-hand reverse bevel door—a door having hinges

on right side when swinging door towards the individual

This specification is under the jurisdiction ofASTM Committee F25 on Ships

opening it.

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

Outfitting and Deck Machinery.

Current edition approved June 1, 2012. Published October 2012. Originally Available from the Superintendent of Documents, U.S. Government Printing

approved in 1983. Last previous edition approved in 2001 as F821/F821M– 01 Office, Washington, DC 20402.

ε1

(2007) . DOI: 10.1520/F0821_F0821M-01R12. Available from BHMA, Inc., 355 Lexington Ave., 17th Floor, New York, NY

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 10017.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from United States Public Health Services, Division of Engineering

Standards volume information, refer to the standard’s Document Summary page on Services, Parklawn Library, Room 1315, 5600 Fishers Lane, Rockville, MD 20857,

the ASTM website. Attention: Ms. Bonnie Scott.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F821/F821M−01 (2012)

3.1.5 left-hand reverse bevel door—adoorhavinghingeson 5.1.4 Hardware, sill caps, lock sets, latches, door closers,

leftsidewhenswingingdoortowardstheindividualopeningit. and hold backs if other than manufacturer’s standard. Master

keying of door locks will not be provided unless required and

3.1.6 face plates—the exterior metal skins that enclose the

definedbyorderingdocuments.Instead,eachdoorlockwillbe

internal supporting structure of the door.

keyed differently.

3.1.7 latch—a device normally installed in the vertical edge

5.1.5 Colorchipanddesiredpaintingspecificationsorother

of door, opposite hinge edge, that when latched retains door in

commercial designation for final finish. If not specified, doors

closed position.

will have manufacturer’s prime coat applied.

3.1.8 throw—the extension, or reach, of the latch bolt. This

5.1.6 For Type II and III doors, sizes and any other

throw is measured from latch face plate to extreme outer edge

supplementary requirements.

of latch bolt with latch bolt in fully extended position.

5.1.7 Sill Heights—0 in. (0 mm), 1 ⁄2 in. (38 mm), or 6 in.

3.1.9 padlock eye—a means for securing door in closed (152 mm). See Figs. 1-3.

5.1.8 Cut out for light switch; if not requested in ordering

position by the use of a padlock.

data, no provisions will be made.

4. Classification

6. Materials and Manufacture

4.1 Classes of doors and frames shall be as indicated in the

6.1 For typical design, see Figs. 1-3.

ordering information. (See AnnexA1 for definition of various

class divisions.)

6.2 Steel for doors and frames shall be cold-rolled sheet,

4.1.1 Class A-O for installation in Class A-O divisions.

commercial quality in accordance with Specification A1008/

4.1.2 ClassAfor installation in ClassA-15,A-30, andA-60

A1008M. Other materials shall be as indicated.

divisions.

6.3 ClassA-O Doors (See Fig. 1 and Table 1 and Table 2):

4.1.3 Class B for installation in Class B divisions.

6.3.1 Door shall be 1 ⁄4-in. (45-mm) thick hollow steel with

4.1.4 Class C for installation in Class C divisions.

0.055-in. (1.4-mm) minimum face plates or equivalent metal

4.2 Doors and frames shall be of the following types as

construction.

indicated in ordering information. 3

6.3.2 Doors shall have a latch with a minimum throw of ⁄4

4.2.1 Type I standard doors are of the following widths.

in. (19 mm).

Height and details shall conform to Tables 1-6 and Figs. 1-3.

6.3.3 Doorframesshallbeofsteelwithanominalthickness

Size 1—22-in. (559-mm) clear jamb width

of 0.055 in. (1.4 mm) and shall be installed so that any flame

Size 2—24-in. (610-mm) clear jamb width

penetration would be through at least two thicknesses of 0.055

Size 3—26-in. (660-mm) clear jamb width

in. (1.4 mm) or equivalent.

Size 4—30-in. (762-mm) clear jamb width 5

6.3.4 Door frames shall provide a stop of ⁄8in. (16 mm)

Size 5—36-in. (914-mm) clear jamb width

minimum at the sides and top.

4.2.2 Type II doors conforming generally to specifications

6.3.5 Forundercutatbottomofdoor,seeFig.1andTable2.

but requiring special requirements as indicated in the ordering

6.3.6 Doors other than those that are normally locked shall

information (see also 6.7.9).

be self closing and capable of closing against a 3½° list.

4.2.3 Type III double doors using two of Type I doors.

6.3.7 Doors shall be insulated with sufficient noncombus-

4.2.4 Type IV double doors using two of Type II doors.

tible fibrous insulation to sound dampen the door adequately.

1 This insulation shall be selected from those listed under

NOTE 1—Door widths are approximately 1 ⁄4 in. (approximately 32

mm) greater than clear jamb width. Section 164.007, Structural Insulations, or Section 164.009,

Noncombustible Materials.

5. Ordering Information

6.3.8 Options for Class A-O and A Doors:

5.1 Orders for items under this specification shall include 6.3.8.1 Vision lights may be installed using wire-inserted

2 2

the following information by the purchaser: glass of not more than 100 in. (645 cm ) in size.

5.1.1 Class A-O, A, B, or C. 6.3.8.2 An escape panel of 16- by 18-in. (406- by 457-mm)

5.1.2 Type, hand, clear jamb width, and sill height. minimum size in lower half of door.

5.1.3 Options such as vent grills, louvers, vision lights, and 6.3.8.3 Where hose ports are required, they shall be cut in

hose ports. the lower corner of the door on the side opposite the hinges so

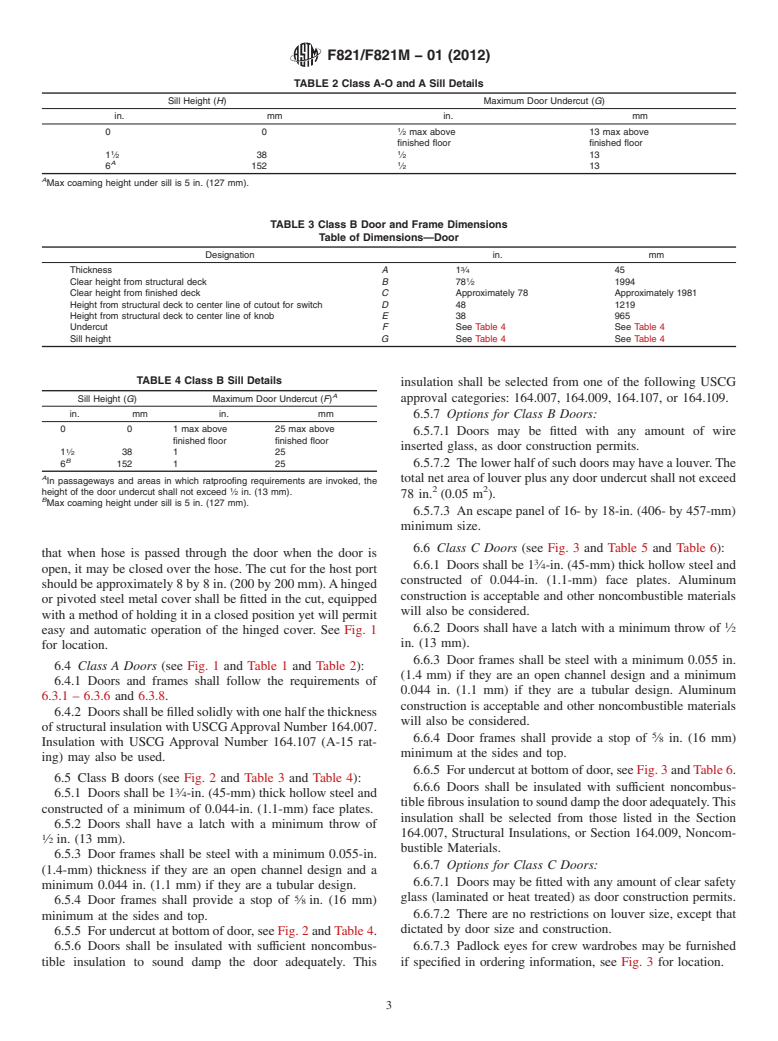

TABLE 1 Class A-O and Class A Door Dimension

Table of Dimensions—Door

Designation in. mm

Thickness A 1 ⁄4 45

Clear height from structural deck B 78 ⁄2 1994

Clear height from finished deck C approximately 78 approximately 1981

Height from structural deck to center line of vision light D 64 1626

Height from structural deck to center line of cutout for switch E 48 1219

Height from structural deck to center line of knob F 38 965

Undercut G see Table 2 see Table 2

Sill height H see Table 2 see Table 2

F821/F821M−01 (2012)

TABLE 2 Class A-O and A Sill Details

Sill Height (H) Maximum Door Undercut (G)

in. mm in. mm

00 ⁄2 max above 13 max above

finished floor finished floor

1 1

1 ⁄2 38 ⁄2 13

A

6 152 ⁄2 13

A

Max coaming height under sill is 5 in. (127 mm).

TABLE 3 Class B Door and Frame Dimensions

Table of Dimensions—Door

Designation in. mm

Thickness A 1 ⁄4 45

Clear height from structural deck B 78 ⁄2 1994

Clear height from finished deck C Approximately 78 Approximately 1981

Height from structural deck to center line of cutout for switch D 48 1219

Height from structural deck to center line of knob E 38 965

Undercut F See Table 4 See Table 4

Sill height G See Table 4 See Table 4

TABLE 4 Class B Sill Details

insulation shall be selected from one of the following USCG

A

Sill Height (G) Maximum Door Undercut (F) approval categories: 164.007, 164.009, 164.107, or 164.109.

in. mm in. mm

6.5.7 Options for Class B Doors:

0 0 1 max above 25 max above

6.5.7.1 Doors may be fitted with any amount of wire

finished floor finished floor

inserted glass, as door construction permits.

1 ⁄2 38 1 25

B

6 152 1 25 6.5.7.2 Thelowerhalfofsuchdoorsmayhavealouver.The

A

totalnetareaoflouverplusanydoorundercutshallnotexceed

In passageways and areas in which ratproofing requirements are invoked, the

1 2 2

height of the door undercut shall not exceed ⁄2 in. (13 mm).

78 in. (0.05 m ).

B

Max coaming height under sill is 5 in. (127 mm).

6.5.7.3 An escape panel of 16- by 18-in. (406- by 457-mm)

minimum size.

6.6 Class C Doors (see Fig. 3 and Table 5 and Table 6):

that when hose is passed through the door when the door is

6.6.1 Doors shall be 1 ⁄4-in. (45-mm) thick hollow steel and

open, it may be closed over the hose. The cut for the host port

constructed of 0.044-in. (1.1-mm) face plates. Aluminum

shouldbeapproximately8by8in.(200by200mm).Ahinged

construction is acceptable and other noncombustible materials

or pivoted steel metal cover shall be fitted in the cut, equipped

will also be considered.

with a method of holding it in a closed position yet will permit

6.6.2 Doors shall have a latch with a minimum throw of ⁄2

easy and automatic operation of the hinged cover. See Fig. 1

in. (13 mm).

for location.

6.6.3 Door frames shall be steel with a minimum 0.055 in.

6.4 Class A Doors (see Fig. 1 and Table 1 and Table 2):

(1.4 mm) if they are an open channel design and a minimum

6.4.1 Doors and frames shall follow the requirements of

0.044 in. (1.1 mm) if they are a tubular design. Aluminum

6.3.1 – 6.3.6 and 6.3.8.

construction is acceptable and other noncombustible materials

6.4.2 Doorsshallbefilledsolidlywithonehalfthethickness

will also be considered.

ofstructuralinsulationwithUSCGApprovalNumber164.007.

6.6.4 Door frames shall provide a stop of ⁄8 in. (16 mm)

Insulation with USCG Approval Number 164.107 (A-15 rat-

minimum at the sides and top.

ing) may also be used.

6.6.5 Forundercutatbottomofdoor,seeFig.3andTable6.

6.5 Class B doors (see Fig. 2 and Table 3 and Table 4):

6.6.6 Doors shall be insulated with sufficient noncombus-

6.5.1 Doors shall be 1 ⁄4-in. (45-mm) thick hollow steel and

tiblefibrousinsulationtosounddampthedooradequately.This

constructed of a minimum of 0.044-in. (1.1-mm) face plates.

insulation shall be selected from those listed in the Section

6.5.2 Doors shall have a latch with a minimum throw of

164.007, Structural Insulations, or Section 164.009, Noncom-

⁄2in. (13 mm).

bustible Materials.

6.5.3 Door frames shall be steel with a minimum 0.055-in.

6.6.7 Options for Class C Doors:

(1.4-mm) thickness if they are an open channel design and a

6.6.7.1 Doors may be fitted with any amount of clear safety

minimum 0.044 in. (1.1 mm) if they are a tubular design.

5 glass (laminated or heat treated) as door construction permits.

6.5.4 Door frames shall provide a stop of ⁄8in. (16 mm)

6.6.7.2 There are no restrictions on louver size, except that

minimum at the sides and top.

dictated by door size and construction.

6.5.5 Forundercutatbottomofdoor,seeFig.2andTable4.

6.5.6 Doors shall be insulated with sufficient noncombus- 6.6.7.3 Padlock eyes for crew wardrobes may be furnished

tible insulation to sound damp the door adequately. This if specified in ordering information, see Fig. 3 for location.

F821/F821M−01 (2012)

TABLE 5 Class C Door Dimensions

Designation in. mm

Thickness A 1 ⁄4 45

1 Clear height from structural deck B 78 ⁄2 1994

Clear height from finished deck C Approximately 78 Approximately 1981

Height from structural deck to center line of cutout for switch D 48 1219

Height from structural deck to center line of padlock eye E 46 1168

Height from structural deck to center line of knob F 38 965

Undercut G See Table 6 See Table 6

Sill height H See Table 6 See Table 6

TABLE 6 Class C Sill Details

A

Sill Height (H) Maximum Door Undercut (G)

in. mm in. mm

0 0 1 max above 25 max above

finished floor finished floor

1 ⁄2 38 1 25

B

6 152 1 25

A

In passageways and areas in which ratproofing requirements are invoked, the

height of the door undercut shall not exceed ⁄2 in. (13 mm).

B

Max coaming height under sill is 5 in. (127 mm).

NOTE 1—For Class B door requirements, see 6.5.

FIG. 2Class “B” Door and Frame

NOTE1—ForClassA-OandClassAdoorrequirements,see6.3and6.4,

respectively.

FIG. 1Class A-O and Class A Do

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.