ASTM C1377-97(2003)

(Test Method)Standard Test Method for Calibration of Surface/Stress Measuring Devices

Standard Test Method for Calibration of Surface/Stress Measuring Devices

SCOPE

1.1 This test method covers calibration or verification of calibration or both, of surface-stress measuring devices used to measure stress in annealed and heat-strengthened or tempered glass, using polariscopic or refractometry based principles.

1.2 This test method is nondestructive.

1.3 This test method uses transmitted light, and therefore, is applicable to light-transmitting glasses.

1.4 This test method is not applicable to chemically tempered glass.

1.5 Using the procedure described, surface stresses can be measured only on the "tin" side of float glass.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: C 1377 – 97 (Reapproved 2003)

Standard Test Method for

1

Calibration of Surface/Stress Measuring Devices

This standard is issued under the fixed designation C 1377; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers calibration or verification of 4.1 In this test method, a test bar is subjected to bending

calibration,orboth,ofsurface-stressmeasuringdevicesusedto using deadweights or calibrated load-cells to introduce surface

measure stress in annealed and heat-strengthened or tempered stressesthatcanbecalculatedfromthespecimengeometryand

glass using polariscopic or refractometry based principles. forces applied. At a point in which the stresses are calculated,

1.2 This test method is nondestructive. those same stresses also are measured using the instrument to

1.3 This test method uses transmitted light, and therefore, is be calibrated or verified. Since both the specimen dimension

applicable to light-transmitting glasses. and the applied forces can be established accurately using

1.4 This test method is not applicable to chemically tem- traceable (primary) standards, the method permits a fully

pered glass. traceable calibration of the stress-measuring instrument.

1.5 Using the procedure described, surface stresses can be

5. Significance and Use

measured only on the “tin” side of float glass.

5.1 The strength and performance of heat-strengthened and

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the fully tempered glass is greatly affected by the surface and edge

stress induced during the heat-treating process.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 5.2 The edge and surface stress levels are specified in

Specification C 1048, in the Engineering Standards Manual of

bility of regulatory limitations prior to use.

3

GANA , and in foreign specifications.

2. Referenced Documents

5.3 Surfacestressescanbemeasurednondestructivelyusing

2

2.1 ASTM Standards: methods, such as Test Method C 1279. The calibration of

C 158 Test Methods for Strength of Glass by Flexure surface measuring devices used in those procedures and

(Determination of Modulus of Rupture) periodicverificationofcalibrationareneeded.Thistestmethod

C 162 Terminology of Glass and Glass Products offers a convenient way to accomplish this task.

C 770 Test Method for Measurements of Glass Stress—

6. Principle of Operation

Optical Coefficient

C 1048 Specification for Heat-Treated Flat Glass—Kind 6.1 The instrument to be calibrated is placed on the surface

of the calibration specimen. Stresses at a point where the

HS, Kind FT Coated and Uncoated Glass

C 1279 Test Method for Nondestructive Photoelastic Mea- instrument is placed are calculated using expressions shown in

Section 9. To increase the precision of measurement, several

surement of Edge and Surface Stresses in Annealed,

Heat-Strengthened, and Fully Tempered Flat Glass levels of stress are produced by applying forces incrementally.

Measurement of stress using the instrument to be calibrated is

3. Terminology

repeated for each stress level and these measurements are used

3.1 Definitions—For terminology used in this test method, to calibrate the instrument.

refer to Terminology C 162.

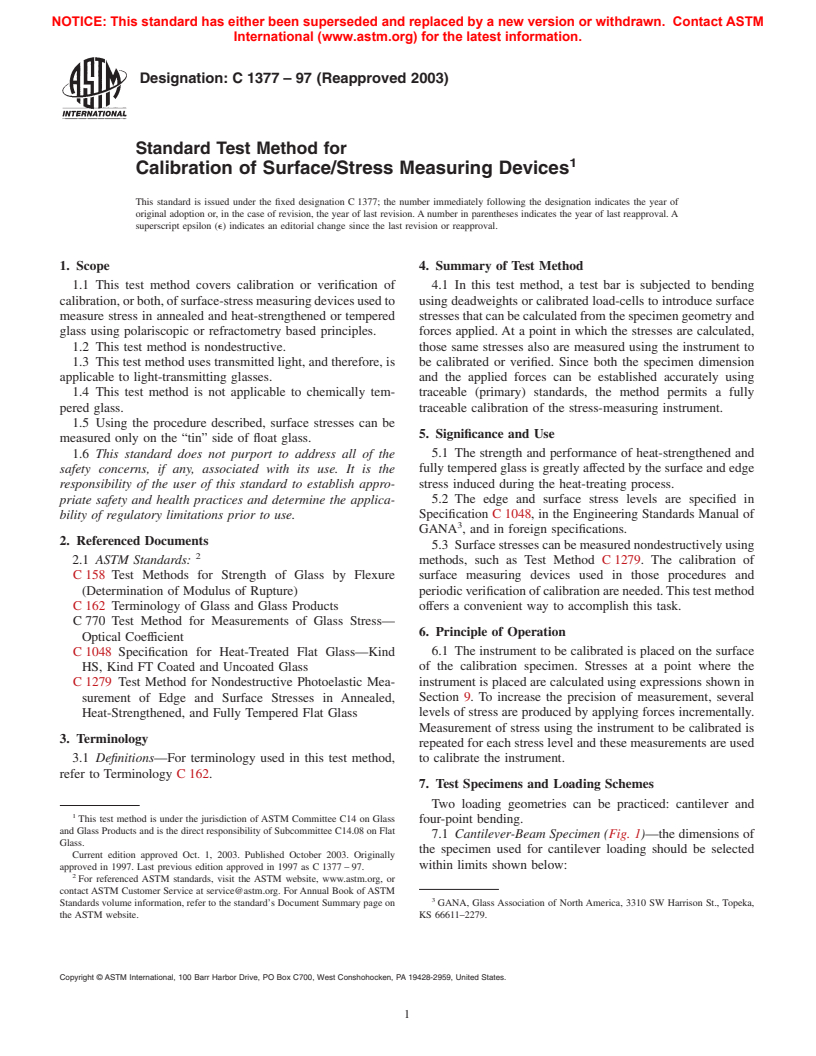

7. Test Specimens and Loading Schemes

Two loading geometries can be practiced: cantilever and

1

This test method is under the jurisdiction of ASTM Committee C14 on Glass

four-point bending.

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat

7.1 Cantilever-Beam Specimen (Fig. 1)—the dimensions of

Glass.

the specimen used for cantilever loading should be selected

Current edition approved Oct. 1, 2003. Published October 2003. Originally

within limits shown below:

approved in 1997. Last previous edition approved in 1997 as C 1377 – 97.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contactASTM Customer Service at service@astm.org. ForAnnual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on GANA, Glass Association of North America, 3310 SW Harrison St., Topeka,

the ASTM website. KS 66611–2279.

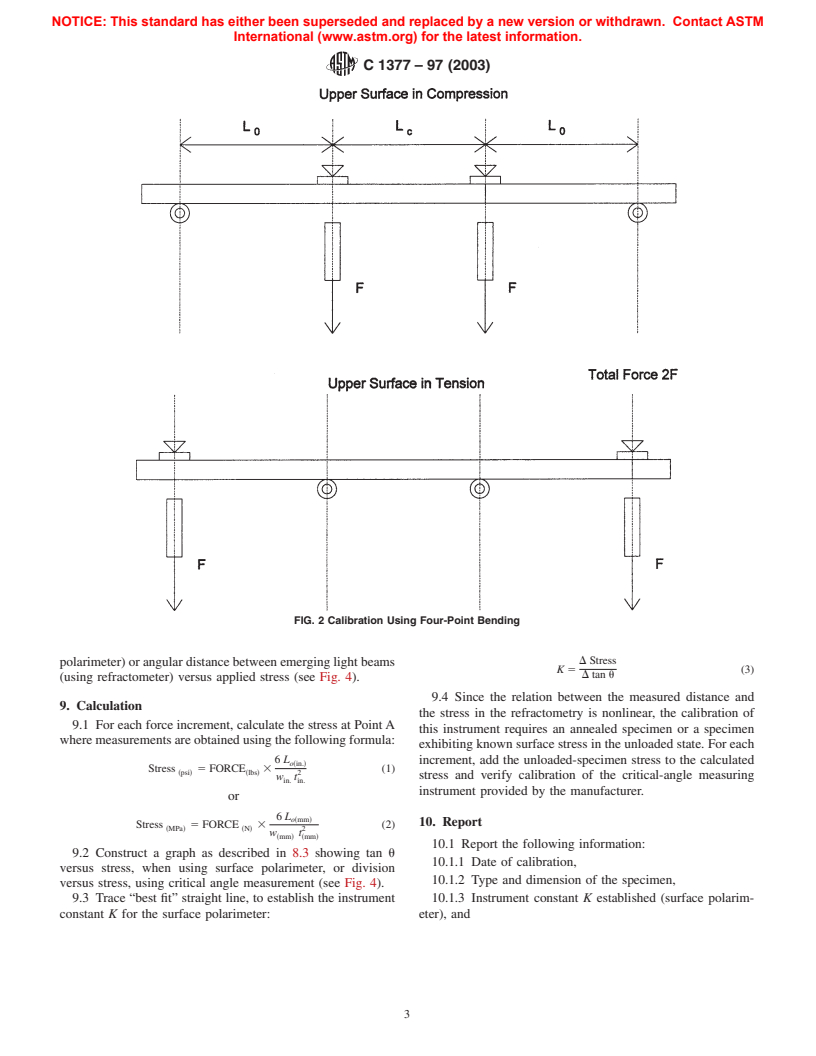

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.