ASTM D566-97

(Test Method)Standard Test Method for Dropping Point of Lubricating Grease

Standard Test Method for Dropping Point of Lubricating Grease

SCOPE

1.1 This test method covers the determination of the dropping point of lubricating grease.

1.2 This test method is not recommended for use at bath temperatures above 288°C. For higher temperatures Test Method D2265 should be used.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 6.4 and 8.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 566 – 97 An American National Standard

British Standard 2877

Designation 132/97

Standard Test Method for

1

Dropping Point of Lubricating Grease

This standard is issued under the fixed designation D 566; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method was adopted as a joint ASTM-IP standard in 1964.

This test method has been adopted for use by government agencies to replace Method 1421 of Federal Test Method Standard No. 791b.

1. Scope surface tension and other physical forces. Other ingredients are

commonly included to impart special properties. D 217

1.1 This test method covers the determination of the drop-

3.1.2 thickener, n—in lubricating grease, a substance com-

ping point of lubricating grease.

posed of finely-divided particles dispersed in a liquid to form

1.2 This test method is not recommended for use at bath

the product’s structure.

temperatures above 288°C. For higher temperatures Test

3.1.2.1 Discussion—Thickeners can be fibers (such as vari-

Method D 2265 should be used.

ous metallic soaps) or plates or spheres (such as certain

1.3 This standard does not purport to address all of the

non-soaps thickeners), which are insoluble or, at most, only

safety concerns, if any, associated with its use. It is the

very slightly soluble in the liquid lubricant. The general

responsibility of the user of this standard to establish appro-

requirements are that the solid particles are extremely small,

priate safety and health practices and determine the applica-

uniformly dispersed and capable of forming a relatively stable,

bility of regulatory limitations prior to use. For specific hazard

gel-like structure with the liquid lubricant. D 217

statements, see Note 2.

3.2 Definitions of Terms Specific to This Standard:

2. Referenced Documents

3.2.1 dropping point, n—a numerical value assigned to a

grease composition representing the temperature at which the

2.1 ASTM Standards:

first drop of material falls from the test cup; that temperature

D 217 Test Methods for Cone Penetration of Lubricating

2

being the average of the thermometer readings of the sample

Grease

and bath.

D 235 Specification for Mineral Spirits (Petroleum Spirits)

3

3.2.1.1 Discussion—In the normal and proper operation of

(Hydrocarbon Dry Cleaning Solvents)

this test method the temperature of the interior of the grease

D 2265 Test Method for Dropping Point of Lubricating

3

test cup and the temperature of the oil bath are monitored

Grease Over Wide Temperature Range

4

simultaneously as the bath is heated. When the first drop of

E 1 Specification for ASTM Thermometers

material falls from the cup, the temperature of the grease test

3. Terminology

cup and the bath temperature are averaged and recorded as the

result of the test.

3.1 Definitions:

3.1.1 lubricating grease, n—a semi-fluid to solid product of

4. Summary of Test Method

a thickener in a liquid lubricant.

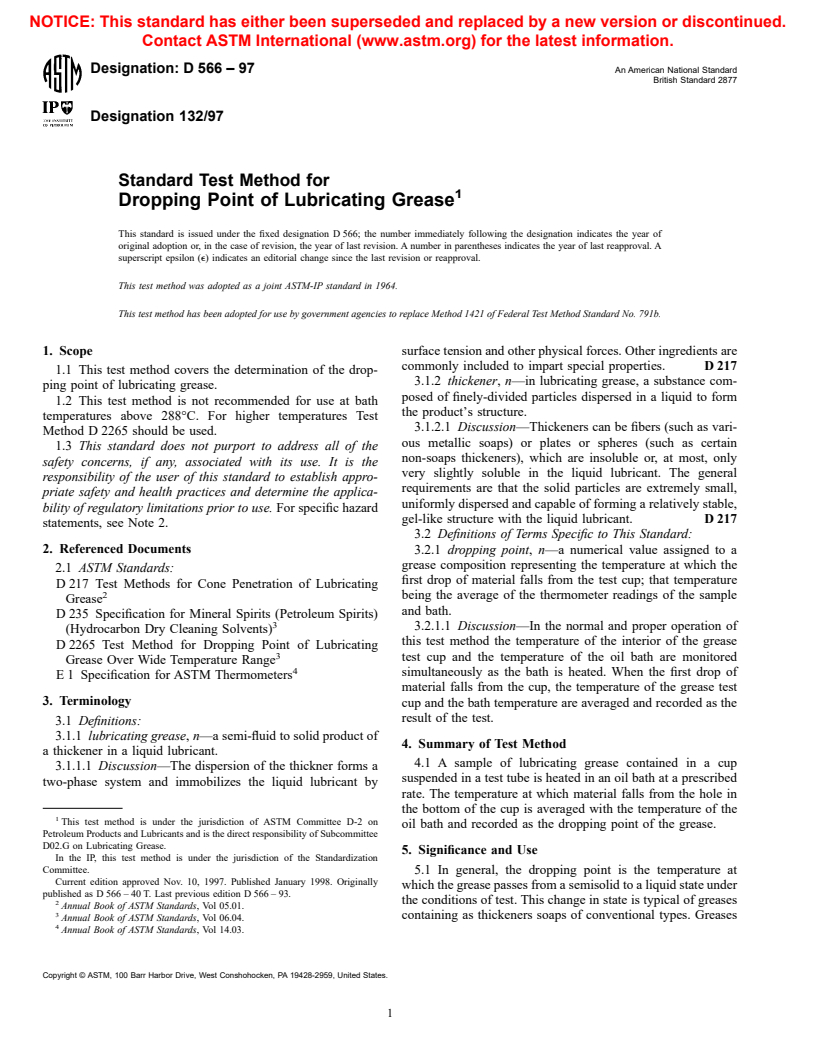

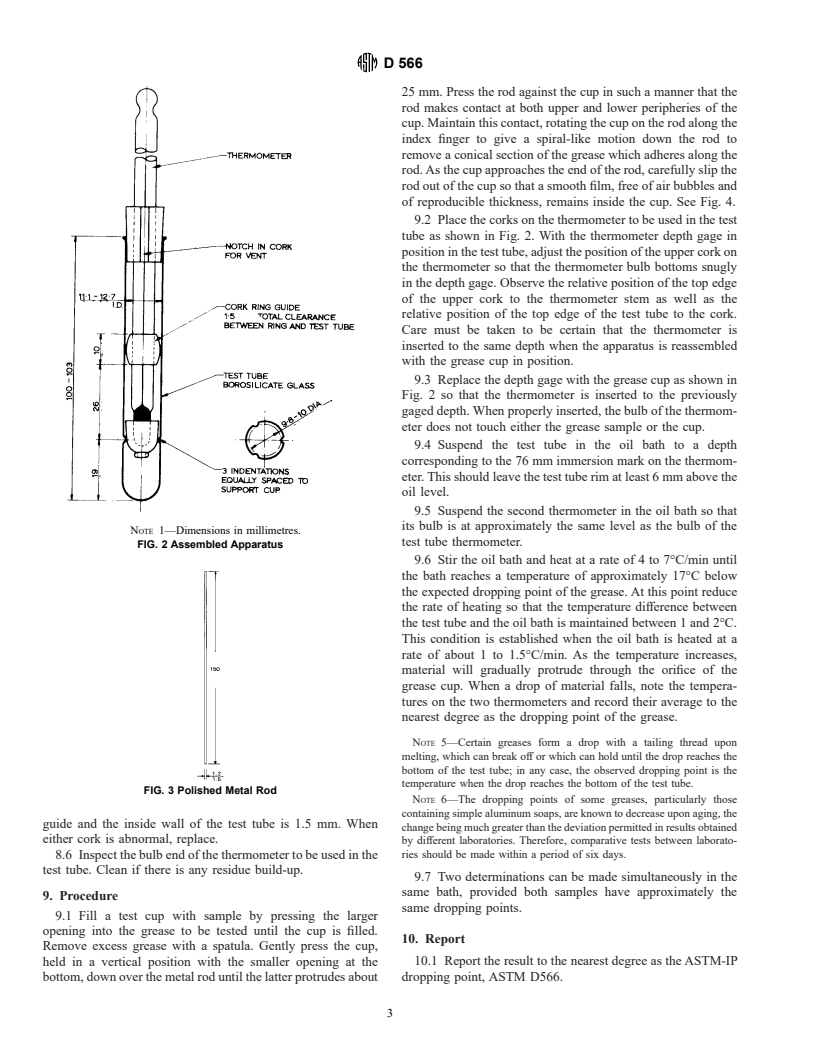

4.1 A sample of lubricating grease contained in a cup

3.1.1.1 Discussion—The dispersion of the thickner forms a

suspended in a test tube is heated in an oil bath at a prescribed

two-phase system and immobilizes the liquid lubricant by

rate. The temperature at which material falls from the hole in

the bottom of the cup is averaged with the temperature of the

1

This test method is under the jurisdiction of ASTM Committee D-2 on

oil bath and recorded as the dropping point of the grease.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.G on Lubricating Grease.

5. Significance and Use

In the IP, this test method is under the jurisdiction of the Standardization

Committee.

5.1 In general, the dropping point is the temperature at

Current edition approved Nov. 10, 1997. Published January 1998. Originally

which the grease passes from a semisolid to a liquid state under

published as D 566 – 40 T. Last previous edition D 566 – 93.

2 the conditions of test. This change in state is typical of greases

Annual Book of ASTM Standards, Vol 05.01.

3

containing as thickeners soaps of conventional types. Greases

Annual Book of ASTM Standards, Vol 06.04.

4

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 566

containing as thickeners materials other than conventional

soaps can, without change in state, separate oil. This test

method is useful to assist in identifying the grease as to type

and for establishing and maintaining bench marks for quality

control. The results are considered to have only limite

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.