ASTM D8252-19

(Test Method)Standard Test Method for Vanadium and Nickel in Crude and Residual Oil by X-ray Spectrometry

Standard Test Method for Vanadium and Nickel in Crude and Residual Oil by X-ray Spectrometry

SIGNIFICANCE AND USE

5.1 This test method provides a rapid and precise elemental measurement with simple sample preparation. Typical analysis times are approximately 4 min to 5 min per sample with a preparation time of approximately 1 min to 3 min per sample.

5.2 The quality of crude oil is related to the amount of sulfur present. Knowledge of the vanadium and nickel concentration is necessary for processing purposes as well as contractual agreements.

5.3 The presence of vanadium and nickel presents significant risks for contamination of the cracking catalysts in the refining process.

5.4 This test method provides a means of determining whether the vanadium and nickel content of crude meets the operational limits of the refinery and whether the metal content will have a deleterious effect on the refining process or when used as a fuel.

SCOPE

1.1 This test method covers the quantitative determination of total vanadium and nickel in crude and residual oil in the concentration ranges shown in Table 1 using X-ray fluorescence (XRF) spectrometry.

1.2 Sulfur is measured for analytical purposes only for the compensation of X-ray absorption matrix effects affecting the vanadium and nickel X-rays. For measurement of sulfur by standard test method use Test Methods D4294, D2622 or other suitable standard test method for sulfur in crude and residual oils.

1.3 This test method is limited to the use of X-ray fluorescence (XRF) spectrometers employing an X-ray tube for excitation in conjunction with wavelength dispersive detection system or energy dispersive high resolution semiconductor detector with the ability to separate signals of adjacent and near-adjacent elements.

1.4 This test method uses inter-element correction factors calculated from XRF theory, the fundamental parameters (FP) approach, or best fit regression.

1.5 Samples containing higher concentrations than shown in Table 1 must be diluted to bring the elemental concentration of the diluted material within the scope of this test method.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6.1 The preferred concentrations units are mg/kg for vanadium and nickel.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D8252 − 19

Standard Test Method for

Vanadium and Nickel in Crude and Residual Oil by X-ray

1

Spectrometry

This standard is issued under the fixed designation D8252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method covers the quantitative determination

mendations issued by the World Trade Organization Technical

of total vanadium and nickel in crude and residual oil in the

Barriers to Trade (TBT) Committee.

concentration ranges shown in Table 1 using X-ray fluores-

cence (XRF) spectrometry.

2. Referenced Documents

1.2 Sulfur is measured for analytical purposes only for the

2

compensation of X-ray absorption matrix effects affecting the 2.1 ASTM Standards:

vanadium and nickel X-rays. For measurement of sulfur by

D2622 Test Method for Sulfur in Petroleum Products by

standard test method use Test Methods D4294, D2622 or other

Wavelength Dispersive X-ray Fluorescence Spectrometry

suitable standard test method for sulfur in crude and residual

D4057 Practice for Manual Sampling of Petroleum and

oils.

Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and

1.3 This test method is limited to the use of X-ray fluores-

Petroleum Products

cence (XRF) spectrometers employing an X-ray tube for

D4294 Test Method for Sulfur in Petroleum and Petroleum

excitation in conjunction with wavelength dispersive detection

Products by Energy Dispersive X-ray Fluorescence Spec-

system or energy dispersive high resolution semiconductor

detector with the ability to separate signals of adjacent and trometry

near-adjacent elements. D6259 Practice for Determination of a Pooled Limit of

Quantitation for a Test Method

1.4 This test method uses inter-element correction factors

D6299 Practice for Applying Statistical Quality Assurance

calculated from XRF theory, the fundamental parameters (FP)

and Control Charting Techniques to Evaluate Analytical

approach, or best fit regression.

Measurement System Performance

1.5 Samplescontaininghigherconcentrationsthanshownin

D7343 Practice for Optimization, Sample Handling,

Table 1 must be diluted to bring the elemental concentration of

Calibration, and Validation of X-ray Fluorescence Spec-

the diluted material within the scope of this test method.

trometry Methods for Elemental Analysis of Petroleum

1.6 The values stated in SI units are to be regarded as

Products and Lubricants

standard. No other units of measurement are included in this

E1621 Guide for ElementalAnalysis by Wavelength Disper-

standard.

sive X-Ray Fluorescence Spectrometry

1.6.1 The preferred concentrations units are mg/kg for

vanadium and nickel.

3. Terminology

1.7 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 alpha corrections, n—influence correction factors that

responsibility of the user of this standard to establish appro-

compensate for inter-element X-ray matrix effects; alpha cor-

priate safety, health, and environmental practices and deter-

rections may be determined by best-fit regression, XRF Fun-

mine the applicability of regulatory limitations prior to use.

damental Parameters (FP), or XRF theory (called theoretical

1.8 This international standard was developed in accor-

alphas).

dance with internationally recognized principles on standard-

1

This test method is under the jurisdiction of ASTM Committee D02 on

2

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee D02.03 on Elemental Analysis. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Aug. 1, 2019. Published August 2019. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D8252-19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8252 − 19

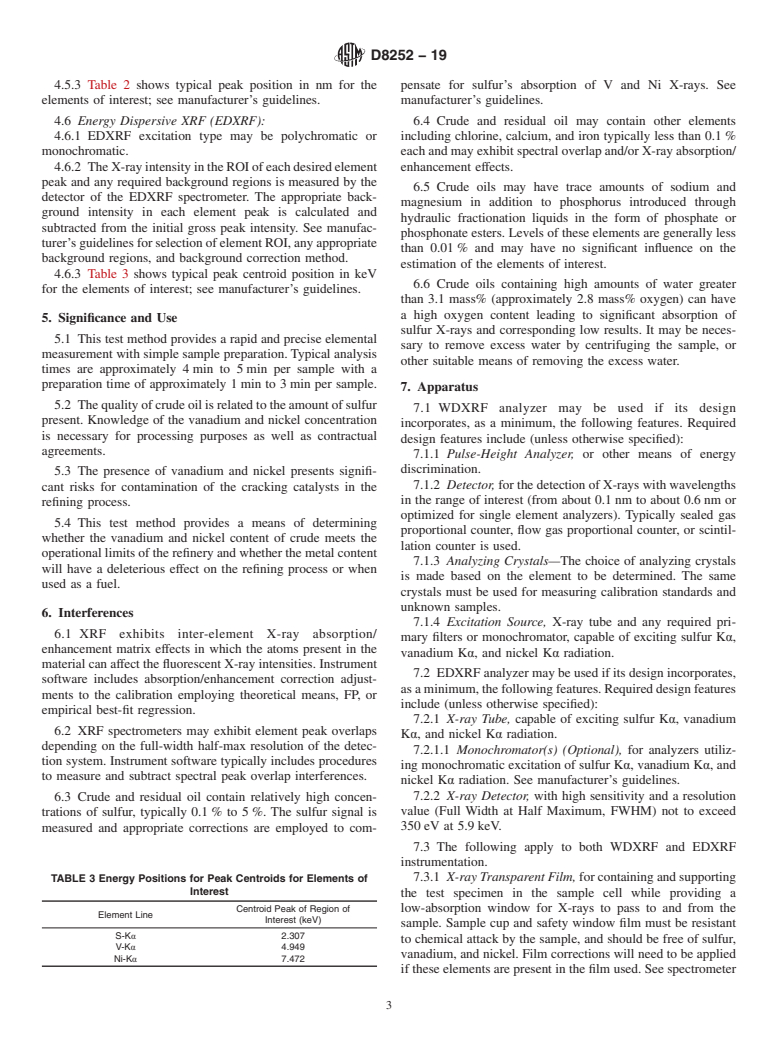

TABLE 1 Elements and Ranges of Applicability

3.2.5 PLOQ—pooled limited of quantification based on

Max Concentration in pooled data of instrumentation used in the ILS (see Practice

Element PLOQ in mg/kg

mg/kg

D6259)

Vanadium 1.9 50

3.2.6 PXRF—polychromatic XRF (can be EDXRF or

Nickel 2.2 50

WDXRF)

3.2.7 ROI—region of interest

3.2.8 WDXRF—wavelength dispersive X-ray fluorescence

3.2.9 XRF—X-ray fluorescence

3.1.2 Bremsstrahlung

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.