ASTM D6576-07

(Specification)Standard Specification for Flexible Cellular Rubber Chemically Blown

Standard Specification for Flexible Cellular Rubber Chemically Blown

ABSTRACT

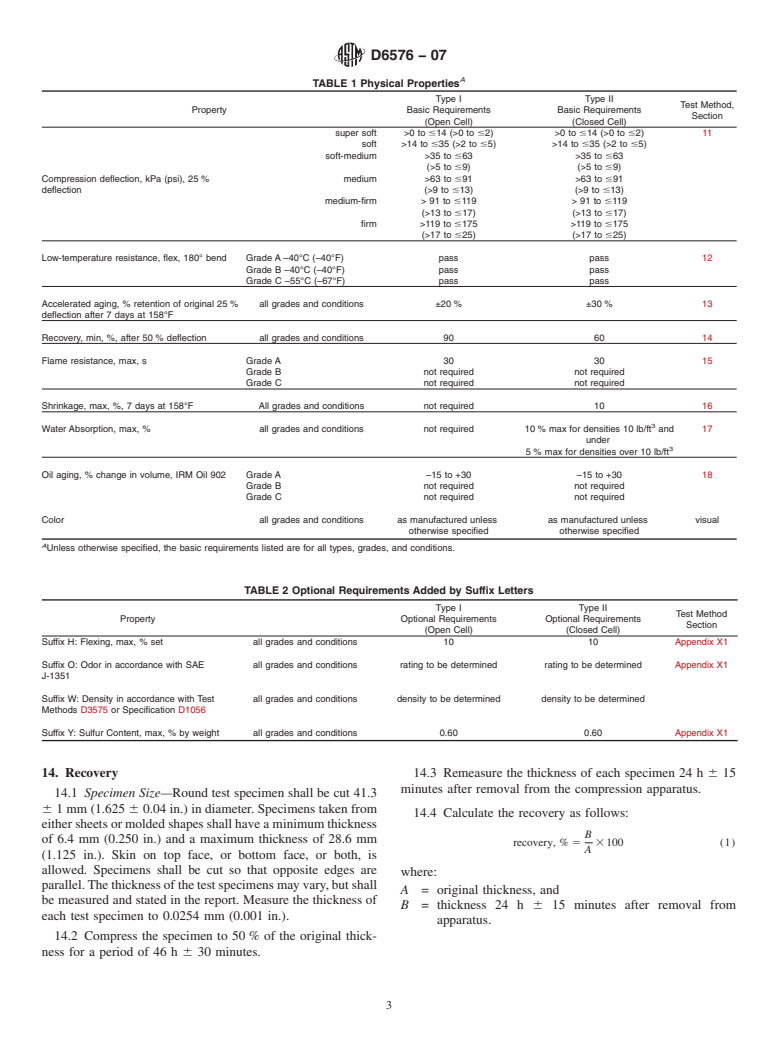

This specification establishes requirements for chemically blown cellular rubber. Cellular rubber may be classified into two types: Type I which is open cell or sponge rubber and Type II which is closed cell or expanded rubber. Both types are divided into three grades: Grade A which is oil-and flame-resistant, Grade B which has no requirements for oil ,flame resistance, or low temperature, and Grade C which is low-temperature resistant. Each type and class has been divided into three different conditions. Each condition is based on a specific range of firmness as expressed by compression deflection as follows: super soft, soft, soft-medium, medium, medium-firm, and firm conditions. Several tests shall be performed in order to determine the following physical properties of cellular rubber: compression deflection, low-temperature resistance, accelerated aging, recovery, flame resistance, shrinkage, water absorption, oil aging, and color.

SCOPE

1.1 This specification establishes requirements for chemically blown cellular rubber.

1.2 In the case of conflict between the provisions of this specification and those of detailed specifications or test methods for a particular product, the latter shall take precedence.

1.3 Unless specifically stated otherwise, by agreement between the purchaser and the supplier, all test methods shall be performed in accordance with the test methods specified in this specification.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 There is no known ISO equivalent to this specification.Note 1

This specification was revised using the updated test methods and specifications in Specification D 1056 - 07.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6576 −07

StandardSpecification for

1

Flexible Cellular Rubber Chemically Blown

This standard is issued under the fixed designation D6576; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D1056 Specification for Flexible Cellular Materials—

Sponge or Expanded Rubber

1.1 This specification establishes requirements for chemi-

D3575 Test Methods for Flexible Cellular Materials Made

cally blown cellular rubber.

From Olefin Polymers

1.2 In the case of conflict between the provisions of this 3

2.2 SAE Standard:

specification and those of detailed specifications or test meth-

SAE J 1351-1993 Hot Odor Test for Insulation Materials

ods for a particular product, the latter shall take precedence. 4

2.3 Military Standards/Specifications:

MIL STD 105 Sampling Procedures and Tables for Inspec-

1.3 Unless specifically stated otherwise, by agreement be-

tween the purchaser and the supplier, all test methods shall be tion by Attributes

MIL STD 129 Marking for Shipment and Storage

performed in accordance with the test methods specified in this

specification. MIL STD 293 Visual Inspection Guide for Cellular Rubber

Items

1.4 The values stated in SI units are to be regarded as the

MIL R 6130C Standard Specification for Flexible Cellular

standard. The inch-pound units given in parentheses are for

Rubber Chemically Blown

information only.

4

2.4 Federal Standards/Specifications:

1.5 This standard does not purport to address all of the

PPP-B576 Box, Wood, Cleated, Veneer, Paper Overlaid

safety concerns, if any, associated with its use. It is the

PPP-B591 Box, Fiberboard, Wood-Cleated

responsibility of the user of this standard to establish appro-

PPP-B601 Box, Wood, Cleated Plywood

priate safety and health practices and determine the applica-

PPP-B621 Box, Wood, Nailed and Lock-Corner

bility of regulatory limitations prior to use.

PPP-B636 Box, Shipping, Fiberboard

1.6 There is no known ISO equivalent to this specification.

3. Terminology

NOTE 1—This specification was revised using the updated test methods

and specifications in Specification D1056 – 07. 3.1 For definitions of technical terms pertaining to cellular

flexible rubber used in this specification, refer to Terminology

2. Referenced Documents

D883.

2

2.1 ASTM Standards:

3.2 Definitions:

D297 Test Methods for Rubber Products—ChemicalAnaly-

3.2.1 cellular material—a generic term for materials con-

sis

taining many cells (either open or closed, or both) dispersed

D471 Test Method for Rubber Property—Effect of Liquids

throughout the mass.

D635 Test Method for Rate of Burning and/or Extent and

3.2.2 closed cell—a product whose cells are totally enclosed

Time of Burning of Plastics in a Horizontal Position

by its walls and hence not interconnecting with other cells.

D883 Terminology Relating to Plastics

3.2.3 open cell—a product whose cells are not totally

D1055 SpecificationsforFlexibleCellularMaterials—Latex

Foam enclosed by its walls and open to the surface, either directly or

by interconnecting with other cells.

1

This specification is under the jurisdiction of ASTM Committee D20 on

4. Classification

Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular

Materials - Plastics and Elastomers.

4.1 Types—This specification covers two types of cellular

Current edition approved Sept. 1, 2007. Published October 2007. Originally

rubber designated as follows:

approved in 2000. Last previous edition approved in 2000 as D6576 - 00. DOI:

10.1520/D6576-07.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Society of Automotive Engineers (SAE), 400 Commonwealth

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Dr., Warrendale, PA 15096-0001, http://www.sae.org.

4

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6576−07

4.1.1 Type I—Open cell (sponge rubber). 6.5 Cut or Split Sheets (Type II Only)—When two or more

sheets are derived from one thick sheet, the cut or split sheets

4.1.2 Type II—Closed cell (expanded rubber).

shall not be required to posses a skin or rind on either major

4.2 Grades—Both types are divided into three grades des-

surface.

ignated by the lettersA, B, an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.