ASTM D3676-18

(Specification)Standard Specification for Rubber Cellular Cushion Used for Carpet or Rug Underlay

Standard Specification for Rubber Cellular Cushion Used for Carpet or Rug Underlay

ABSTRACT

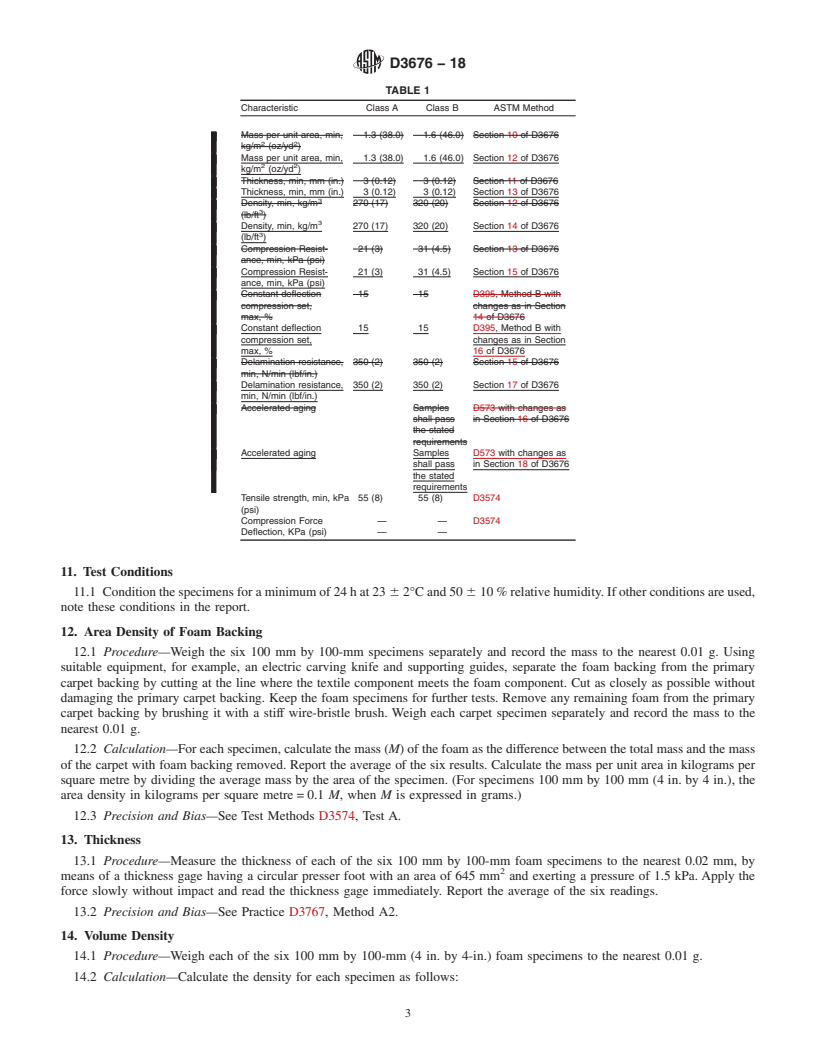

This specification covers material and dimensional requirements for high-density rubber cellular cushion adhered to carpet, rugs, or various substrates intended for use as a separate underlay. However, this specification does not include requirements for burning characteristics. Material covered in this specification comprises Class A and Class B flexible, cellular, high-density rubber. Tests for compression set, compression resistance or compression force deflection, delaminations strength, tensile strength, and accelerated aging shall be performed and shall conform to the requirements specified.

SIGNIFICANCE AND USE

5.1 The purpose of this specification is to provide meaningful tests for rubber cellular cushion used for carpet or rug underlay.

SCOPE

1.1 This specification covers high-density cellular rubber adhered to carpet and rugs. This specification can also be applied to various substrates, such as blown sponge rubber, used independently as carpet underlay.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D3676 −18

Standard Specification for

1

Rubber Cellular Cushion Used for Carpet or Rug Underlay

This standard is issued under the fixed designation D3676; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 Federal Standard:

Fed. Std. No. 191Textile Test Methods, Method5100—

1.1 This specification covers high-density cellular rubber

Breaking Strength and Elongation of Woven Cloth; Grab

adhered to carpet and rugs. This specification can also be

3

Method

applied to various substrates, such as blown sponge rubber,

used independently as carpet underlay.

3. Terminology

1.2 This standard does not purport to address all of the

3.1 Definitions—For definitions used in this test method,

safety concerns, if any, associated with its use. It is the

refer to Terminology D883.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

3.2.1 rubber—a material that is capable of recovering from

mine the applicability of regulatory limitations prior to use.

largedeformationsquicklyandforcibly,andcanbe,oralready

NOTE 1—There is no known ISO equivalent to this standard.

is, modified to a state in which it is essentially insoluble (but

1.3 This international standard was developed in accor- can swell) in boiling solvent (such as benzene, methyl ethyl

dance with internationally recognized principles on standard-

ketone, and ethanol-toluene azeotrope).

ization established in the Decision on Principles for the

3.2.2 cellular material—a generic term for materials con-

Development of International Standards, Guides and Recom-

taining many cells (either open or closed, or both) dispersed

mendations issued by the World Trade Organization Technical

throughout the mass.

Barriers to Trade (TBT) Committee.

3.2.3 flexible cellular material—a flexible cellular organic

polymeric material that will not rupture within 60 s when a

2. Referenced Documents

specimen 8 by 1 in. (200 by 25 by 25 mm) is bent around a

2

2.1 ASTM Standards:

1-in. (25-mm) diameter mandrel at a uniform rate of 1 lap/5 s

D395Test Methods for Rubber Property—Compression Set

intheformofahelixatatemperaturebetween65and85°F(18

D573Test Method for Rubber—Deterioration in an Air

and 29°C).

Oven

3.2.4 open cell—a product whose cells are not totally

D751Test Methods for Coated Fabrics

enclosed by its walls and open to the surface, either directly or

D883Terminology Relating to Plastics

by interconnecting with other cells.

D1056 Specification for Flexible Cellular Materials—

3.2.5 closed cell—aproductwhosecellsaretotallyenclosed

Sponge or Expanded Rubber

by its walls and hence not interconnecting with other cells.

D3574Test Methods for Flexible Cellular Materials—Slab,

3.2.6 sponge rubber—cellular rubber consisting predomi-

Bonded, and Molded Urethane Foams

nantly of open cells made from a solid rubber compound.

D3767Practice for Rubber—Measurement of Dimensions

D6576Specification for Flexible Cellular Rubber Chemi-

4. Summary of Test Method

cally Blown

4.1 This specification provides material and dimensional

requirements and test methods for specific properties of com-

pression set, compression resistance or compression force

1

This specification is under the jurisdiction of ASTM Committee D20 on

deflection, delamination strength, and accelerated aging.

Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular

Materials - Plastics and Elastomers.

NOTE 2—This specification does not include requirements for burning

Current edition approved Aug. 1, 2018. Published August 2018. Originally

characteristics. It shall be noted that Flammable Fabrics Act Regulations

approved in 1978. Last previous edition approved in 2013 as D3676- 13. DOI:

FF1-70, Standard for the Surface Flammability of Carpets and Rugs, and

10.1520/D3676-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111–5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3676 − 13 D3676 − 18

Standard Specification for

1

Rubber Cellular Cushion Used for Carpet or Rug Underlay

This standard is issued under the fixed designation D3676; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers high-density cellular rubber adhered to carpet, rugs, or various substrates for use as separate

underlay. It is also acceptable to use this standard as a specification for separately blown sponge used carpet and rugs. This

specification can also be applied to various substrates, such as blown sponge rubber, used independently as carpet underlay.

1.2 This specification provides material and dimensional requirements and test methods for specific properties of compression

set, compression resistance or compression force deflection, delamination strength, and accelerated aging.

NOTE 1—This specification does not include requirements for burning characteristics. It shall be noted that Flammable Fabrics Act Regulations FF1-70,

2

Standard for the Surface Flammability of Carpets and Rugs, and FF2-70, Standard for the Surface Flammability of Small Carpets and Rugs, may be

applicable for carpets and rugs with integral backing of rubber cellular cushion.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D395 Test Methods for Rubber Property—Compression Set

D573 Test Method for Rubber—Deterioration in an Air Oven

D751 Test Methods for Coated Fabrics

D883 Terminology Relating to Plastics

D1056 Specification for Flexible Cellular Materials—Sponge or Expanded Rubber

D3574 Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams

D3767 Practice for Rubber—Measurement of Dimensions

D6576 Specification for Flexible Cellular Rubber Chemically Blown

2.2 Federal Standard:

3

Fed. Std. No. 191 Textile Test Methods, Method 5100—Breaking Strength and Elongation of Woven Cloth; Grab Method

3. Terminology

3.1 Definitions—For definitions used in this test method, refer to Terminology D883.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 rubber—a material that is capable of recovering from large deformations quickly and forcibly, and can be, or already is,

modified to a state in which it is essentially insoluble (but can swell) in boiling solvent (such as benzene, methyl ethyl ketone, and

ethanol-toluene azeotrope).

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular Materials - Plastics

and Elastomers.

Current edition approved April 15, 2013Aug. 1, 2018. Published April 2013August 2018. Originally approved in 1978. Last previous edition approved in 20072013 as

D3676 - 01.D3676 - 13. DOI: 10.1520/D3676-13.10.1520/D3676-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111–5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3676 − 18

3.2.2 cellular material—a generic term for materials containing many cells (either open or closed, or both) dispersed throughout

the mass.

3.2.3 flexible cellular material—a flexible cellular organic polymeric material that will not rupture within 60 s when a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.