ASTM D6426-01

(Test Method)Standard Test Method for Determining Filterability of Distillate Fuel Oils

Standard Test Method for Determining Filterability of Distillate Fuel Oils

SCOPE

1.1 This test method covers a procedure for determining the filterability of distillate fuel oils within the viscosity range from 1.70 to 6.20 nm2/s (cSt) at 40 °C.

Note 1—ASTM specification fuels falling within the scope of this test method are Specification D 396 Grade Nos. 1 and 2, Specification D 975 Grades 1-D, low sulfur 1-D, 2-D, and low sulfur 2-D, and Specification D 2880 Grade Nos. 1-GT and 2-GT.

1.2 This test method is not applicable to fuels that contain undissolved water.

1.3 The values stated in SI units shall be considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: D 6426 – 01 An American National Standard

Standard Test Method for

1

Determining Filterability of Distillate Fuel Oils

This standard is issued under the fixed designation D 6426; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 For this test method, filterability is a measure of the

rapidity with which a standard filter medium is plugged by

1.1 This test method covers a procedure for determining the

insoluble matter in fuel and can be described in either of the

filterability of distillate fuel oils within the viscosity range from

2

following two ways:

1.70 to 6.20 mm /s (cSt) at 40°C.

3.1.1.1 filterability—the pressure drop across a filter me-

NOTE 1—ASTM specification fuels falling within the scope of this test

dium when 300 mL of fuel is passed at a rate of 20 mL/min.

method are Specification D 396 Grade Nos. 1 and 2, Specification D 975

3.1.1.2 filterability—the volume of fuel passed when 104

Grades 1-D, low sulfur 1-D, 2-D, and low sulfur 2-D, and Specification

kPa (15 psi) is reached. This method of report is used when less

D 2880 Grade Nos. 1-GT and 2-GT.

than 300 mL passes at that pressure.

1.2 This test method is not applicable to fuels that contain

3.1.1.3 filterability quality factor (F-QF)—a value that de-

undissolved water.

fines the filter plugging tendency of a fuel caused by particu-

1.3 The values stated in SI units shall be considered

late. The value is calculated using the volume and pressure

standard.

attained at the end of the test cycle. Depending on the outcome

1.4 This standard does not purport to address all of the

of the test, two different equations are applied.

safety concerns, if any, associated with its use. It is the

3.1.1.4 Discussion—Eq 1 is applied if the total sample was

responsibility of the user of this standard to establish appro-

discharged prior to reaching the maximum pressure or Eq 2 if

priate safety and health practices and determine the applica-

the maximum pressure was reached prior to discharging the

bility of regulatory limitations prior to use.

entire sample. The equations proportion the results so that a

continuous range of 0 – 100 is attained. Eq 1 yields values

2. Referenced Documents

from 50 to 100, whereas, Eq 2 yields values from 0 to 50.

2.1 ASTM Standards:

Higher values signify less particulate that can plug a filter of a

2

D 396 Specification for Fuel Oils

given pore size and porosity.

2

D 975 Specification for Diesel Fuel Oils

3

If the total sample (300 mL) is discharged prior to reaching the

D 2880 Specification for Gas Turbine Fuel Oils

maximum pressure (104 kPa or 15 psi), the F-QF is calculated by the

D 4057 Practice for Manual Sampling of Petroleum and

following equation:

3

Petroleum Products

F2QF 5 15 psi 2 P !/15 psi! 50! 1 50! (1)

~~ ~ ~

D 4176 Test Method for Free Water and Particulate Con- ~300 mL at P ~F! ~F!

tamination in Distillate Fuels (Visual Inspection Proce-

where:

3

dures)

P = final pressure when the total sample (300 mL) was

(F)

D 4177 Practice for Automatic Sampling of Petroleum and

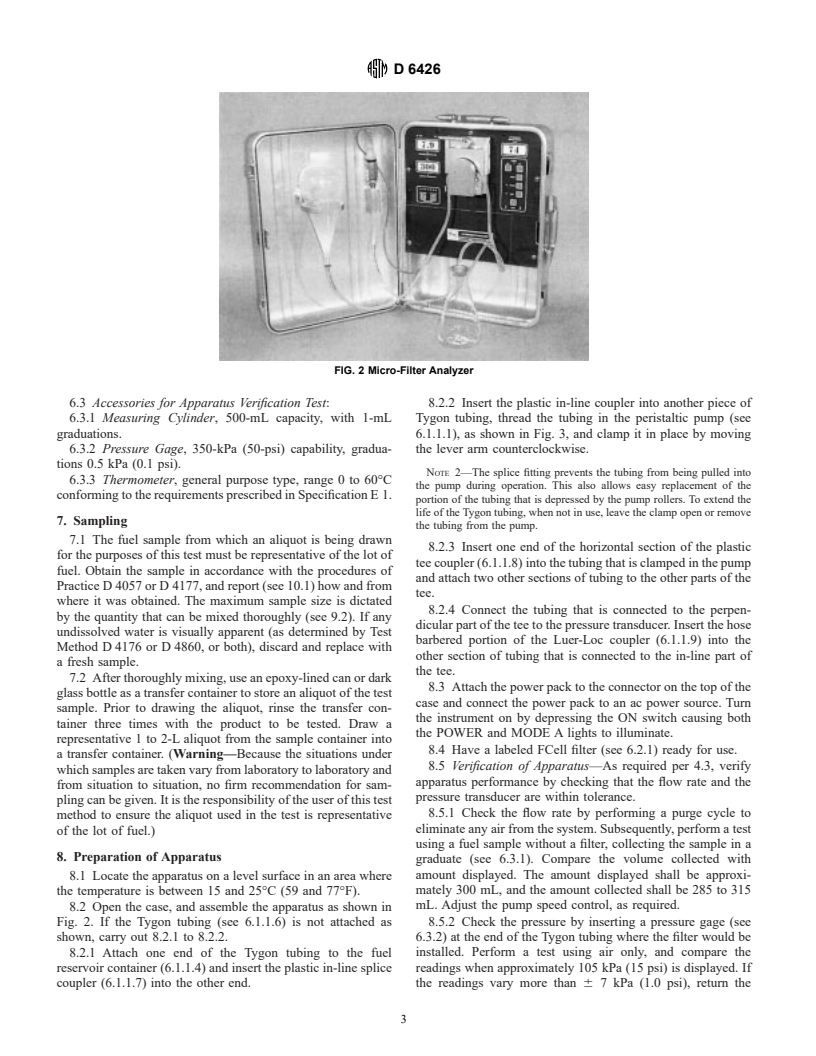

discharged.

3

Petroleum Products

D 4860 Test Method for Free Water and Particulate Con-

If the total sample is not discharged prior to reaching the maximum

tamination in Mid-Distillate Fuels (Clear and Bright Nu-

pressure (104 kPa or 15 psi), the F-QF is calculated by the following

4

merical Rating)

equation:

5

E 1 Specification for ASTM Thermometers

F2QF 5 V / 6 (2)

~V ~F! at 15 psi! ~F!

3. Terminology

where:

3.1 Definitions of Terms Specific to This Standard:

V = final volume when the maximum pressure was

(F

reached.

1

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.1.5 Discussion—The final pressure (V ) is divided by

(F)

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

six, since the maximum possible volume is 300 mL. By

D02.14 on Stability and Cleanliness of Liquid Fuels.

dividing by six, the values for that test result are proportioned

Current edition approved June 10, 2001. Published October 2001. Originally

published as D 6426 – 99. Last previous edition D 6426 – 99. to fit the range from 0 to 50.

2

Annual Book of ASTM Standards, Vol 05.01.

3

Annual Book of ASTM Standards, Vol 05.02.

4. Summary of Test Method

4

Annual Book of ASTM Standards, Vol 05.03.

5

4.1 A sample is passed at a constant rate (20 mL/min)

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 6426

through a standard porosity filter medium. The pressure drop upstream of the filtering element and the volume of sample

across the filter and the volume of filtrate are monitored. The passed through the filter at two discrete preset pressure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.