ASTM B267-07(2018)

(Specification)Standard Specification for Wire for Use In Wire-Wound Resistors

Standard Specification for Wire for Use In Wire-Wound Resistors

ABSTRACT

This specification covers round wires and ribbons with controlled electrical properties made from magnetic and nonmagnetic class 1a-11 alloys. The wires and ribbons, which may have insulated coverings or enamel coatings, are recommended for use in wire-wound resistance units like precision resistors and other similar applications, but not for use as electrical heating elements. Each bare wire should conform to the requirements for nominal resistivity, elongation, thermal electromotive force with respect to copper, and the temperature coefficient of resistance contained in this specification. The nominal resistance per unit length for a round wire is calculated from the nominal resistivity and nominal cross-sectional area.

SCOPE

1.1 This specification covers round wire and ribbon with controlled electrical properties for use in wire-wound resistance units and similar applications, but not for use as electrical heating elements.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B267 −07 (Reapproved 2018)

Standard Specification for

Wire for Use In Wire-Wound Resistors

This standard is issued under the fixed designation B267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

3.1 This specification on wire and ribbon contains the

1.1 This specification covers round wire and ribbon with

generic chemistry and requirements for resistivity, temperature

controlled electrical properties for use in wire-wound resis-

coefficient of resistance, thermal emf versus copper resistance

tanceunitsandsimilarapplications,butnotforuseaselectrical

tolerances, and mechanical properties of bare wire, as well as

heating elements.

thewireenamelsandinsulationsofalloysnormallyusedinthe

1.2 The values stated in inch-pound units are to be regarded

manufacture of wound resistors.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

4. Alloy Classes

and are not considered standard.

4.1 Fifteenclassesofalloysarecoveredbythisspecification

1.3 This standard does not purport to address all of the

as listed in Table 1.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to become familiar

5. Elongation

with all hazards including those identified in the appropriate

5.1 The wire shall conform to the requirements for elonga-

Safety Data Sheet (SDS) for this product/material as provided

tionasprescribedinTable1,whentestedona10-in.(254-mm)

by the manufacturer, to establish appropriate safety, health,

length.

and environmental practices, and determine the applicability

of regulatory limitations prior to use.

6. Resistivity

1.4 This international standard was developed in accor-

6.1 The bare wire shall conform to the requirements for

dance with internationally recognized principles on standard-

nominal resistivity as prescribed in Table 1.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

6.2 Actualresistivityshallnotvaryfromnominalresistivity

mendations issued by the World Trade Organization Technical by more than 65% for Alloy Classes 1 to 4 inclusive, and

Barriers to Trade (TBT) Committee.

610% for Alloy Classes 5 to 11 inclusive.

7. Nominal Electrical Resistance per Unit Length

2. Referenced Documents

7.1 The nominal resistance per unit length for round wire

2.1 ASTM Standards:

shallbecalculatedfromthenominalresistivityandthenominal

B63Test Method for Resistivity of Metallically Conducting

cross-sectional area.

Resistance and Contact Materials

B77Test Method for Thermoelectric Power of Electrical-

NOTE 1—When ribbon or flat wire is produced by rolling from round

Resistance Alloys wire, the cross section departs from that of a true rectangle by an amount

depending on the width-to-thickness ratio and the specific manufacturing

B84Test Method for Temperature-Resistance Constants of

practice. The conventional formula for computing ohms per foot and feet

Alloy Wires for Precision Resistors

perpoundistoconsiderthecrosssectionas17%lessthanatruerectangle

when width is more than 15 times the thickness and 6% less than a true

rectangle in other cases. This is not valid in view of modern rolling

equipment and practices, but still is widely used as a basis of description.

This specification is under the jurisdiction of ASTM Committee B02 on

Ribbonactuallyismadetoaspecifiedresistanceperfoot,andnotolerance

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

isspecifiedforthickness.Analternativeandacloserapproximationwould

B02.10 on Thermostat Metals and Electrical Resistance Heating Materials.

be that for ribbon rolled round wire, the electrical resistance would be

Current edition approved April 1, 2018. Published April 2018. Originally

calculated on a cross 6% less than a true rectangle.

approved in 1952. Last previous edition approved in 2013 as B267– 07 (2013).

DOI: 10.1520/B0267-07R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 8. Temperature Coefficient of Resistance

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

8.1 The change in resistance with change in temperature,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. expressed as the mean temperature coefficient of resistance

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B267−07 (2018)

TABLE 1 Classes of Alloys and Requirements

Mean Temperature Coefficient of Resistance, α ppm for Maximum Thermal emf

m

Elongation in 10 in., min, %

B

°C Over Temperature Range,∆ T versus Copper, mV/°C

Resistivity,

Alloy Alloy Composition,

Over 0.002 to

0.0009

Ω·cmil/ft

A

Class approximate, % D

Temperature 0.002 0.001

in. in

(µΩ·m)

∆T α ∆T mV/°C

m C

D D

Range, ∆T Diameter

in. in in. in

and Finer

Diameter Diameter

12 3 4 5 6 7 8 9 10 11 12

1a nickel base, nonmagnetic 800 (1.330) 0, ±20 +25 to −55 0, ±20 +25 to +105 +0.003 −65 to +250 10 5 3

1b nickel base, nonmagnetic 800 (1.330) 0, ±10 +25 to −55 0, ±10 +25 to +105 +0.003 −65 to +150 10 5 3

1c nickel base, nonmagnetic 800 (1.330) 0, ±5 +25 to −55 0, ±5 +25 to +105 +0.003 −65 to +150 10 5 3

2a iron base, magnetic 800 (1.330) 0, ±20 +25 to −55 0, ±20 +25 to +105 −0.004 −65 to +200 10 5 3

2b iron base, magnetic 800 (1.330) 0, ±10 +25 to −55 0, ±10 +25 to +105 −0.004 −65 to +150 10 5 3

3a 80 nickel, 20 chromium 650 (1.081) +80, ±20 +25 to −55 +80, ±20 +25 to +105 +0.006 −65 to +250 15 5 3

3b 80 nickel, 20 chromium, 675 (1.122) +60, ±20 +25 to −55 +60, ±20 +25 to +105 +0.006 −65 to +250 15 5 3

stabilized

4 60 nickel, 16 chromium, 675 (1.122) +140, ±30 +25 to −55 +140, ±30 +25 to +105 +0.002 −65 to +200 15 5 3

balance iron

5a 55 copper, 45 nickel 300 (0.499) 0, ±20 +25 to −55 0, ±20 +25 to +105 −0.045 −65 to + 150 15 5 3

5b 55 copper, 45 nickel 300 (0.499) 0, ±40 +25 to −55 0, ±40 +25 to +105 −0.045 −65 to +150 15 5 3

EE EE

6 manganin type 290 (0.482) 0, ±15 0, ±15 −0.003 +15 to +35 15 5 3

7 77 copper, 23 nickel 180 (0.299) +180, ±30 +25 to −55 +180, ±30 +25 to +105 −0.037 −65 to +150 15 5 3

8 70 nickel, 30 iron 125 (0.199) +3600, ±400 +25 to −50 +4300, ±400 +25 to +104 −0.040 −50 to +100 15 5 3

9 90 copper, 10 nickel 90 (0.150) +450, ±50 +25 to −55 +450, ±50 +25 to +105 −0.026 −65 to +150 15 5 3

10 94 copper, 6 nickel 60 (0.100) +700, ±200 +25 to −55 +700, ±200 +25 to +105 −0.022 −65 to +150 15 5 3

11 98 copper, 2 nickel 30 (0.050) +1400, ±300 +25 to −55 +1400, ±300 +25 to +105 0.014 −65 to +150 15 5 3

A

Alloy Classes 1a to 8 inclusive are designed to provide controlled temperature coefficients. Values shown for other classes are for information only. All values are based

on a reference temperature of 25°C.

B

Alloy Classes 1a, 1b, 1c, 2a, 2b, 3a, 4, and 6 are designed to give a low emf versus copper. Values shown for other classes are for information only. Maximum indicates

the maximum deviation from zero and the plus or minus sign the polarity of the couple.

C

The maximum temperature values listed apply to the alloy wire only. Caution should be exercised pending knowledge of the maximum temperature of use for the coating

material involved.

D

If metric sizes are desired, 1 in. = 25.4 mm.

E

Alloy Class 6 (manganin type for resistors), has a temperature-resistance curve of parabolic shape with the maximum resistance normally located between 25 and 30°C.

m

Thus, Columns 5 and 7 cannot indicate 25°C as a limit butα may be expressed as a maximum of +15 ppm for 15°C to the temperature of maximum resistance and a

maximum of −15 ppm from the temperature of maximum resistance to 35°C. All of the information included in this note is based on measurements made in accordance

with Test Method B84.

A

TABLE 2 Dimensions of Enamel Coated Wire

Nominal Bare Wire Size Light Coated Wire Medium Coated Wire Heavy Coated Wire

Outside Diameter, Outside Diameter, Outside Diameter, Outside Diameter, Outside Diameter, Outside Diameter,

B&S Gage No. Diameter, in.

min, in. max, in. min, in. max, in. min, in. max, in.

28 0.0126 0.0130 0.0134 0.0134 0.0139 0.0139 0.0144

29 0.0113 0.0116 0.0120 0.0120 0.0125 0.0125 0.0130

30 0.010 0.0103 0.0107 0.0107 0.0112 0.0112 0.0116

31 0.0089 0.0092 0.0096 0.0096 0.0100 0.0100 0.0103

32 0.008 0.0083 0.0086 0.0086 0.0090 0.0090 0.0093

33 0.0071 0.0073 0.0076 0.0076 0.0080 0.0080 0.0083

34 0.0063 0.0064 0.0067 0.0067 0.0071 0.0071 0.0074

35 0.0056 0.0057 0.0060 0.0060 0.0064 0.0064 0.0067

36 0.005 0.0051 0.0054 0.0054 0.0057 0.0057 0.0060

37 0.0045 0.0046 0.0049 0.0049 0.0052 0.0052 0.0055

38 0.004 0.0041 0.0043 0.0043 0.0046 0.0046 0.0049

39 0.0035 0.0036 0.0038 0.0038 0.0041 0.0041 0.0043

40 0.0031 0.0032 0.0034 0.0034 0.0037 0.0037 0.0039

0.00275 0.0029 0.0031 0.0031 0.0033 0.0033 0.0035

0.0025 0.0026 0.0028 0.0028 0.0030 0.0030 0.0032

0.00225 0.00235 0.0025 0.0025 0.0027 0.0027 0.0029

0.002 0.0021 0.0022 0.0022 0.0024 0.0024 0.0026

0.00175 . 0.0019 0.0019 0.0021 0.0021 0.0023

0.0015 . 0.0016 0.0016 0.0018 0.0018 0.0020

0.0014 . 0.0015 0.0015 0.0017 0.0017 0.0019

0.0013 . 0.0014 0.0014 0.0016 0.0016 0.0018

0.0012 . 0.0013 0.0013 0.0015 0.0015 0.0017

0.0011 . 0.0012 0.0012 0.0014 0.0014 0.0016

0.001 . 0.0011 0.0011 0.0013 0.0013 0.0015

0.0009 . 0.0010 0.0010 0.0012 0.0012 0.0014

0.0008 . 0.0009 0.0009 0.0010 0.0010 0.0012

0.0007 . 0.0008 0.0008 0.0009 0.0009 0.0010

0.0006 . 0.0007 0.0007 0.0008 0.0008 0.0009

0.0005 . 0.0006 0.0006 0.0007 0.0007 0.0008

A

To convert from inches to millimetres multiply by 25.4.

B267−07 (2018)

basedonthereferencetemperatureof25°C,shallbewithinthe 13. Enamel Coatings

limits specified in Table 1, Columns 4 and 6, over the

13.1 Enamel coatings shall include any baked-on film of

corresponding temperature ranges specified in Columns 5 and

insulating material, such as varnish enamel, polyurethane,

7. The mean temperature coefficient of resistance referred to

vinyl acetal, etc. and shall con

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B267 − 07 (Reapproved 2018)

Standard Specification for

Wire for Use In Wire-Wound Resistors

This standard is issued under the fixed designation B267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

3.1 This specification on wire and ribbon contains the

1.1 This specification covers round wire and ribbon with

generic chemistry and requirements for resistivity, temperature

controlled electrical properties for use in wire-wound resis-

coefficient of resistance, thermal emf versus copper resistance

tance units and similar applications, but not for use as electrical

tolerances, and mechanical properties of bare wire, as well as

heating elements.

the wire enamels and insulations of alloys normally used in the

1.2 The values stated in inch-pound units are to be regarded

manufacture of wound resistors.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

4. Alloy Classes

and are not considered standard.

4.1 Fifteen classes of alloys are covered by this specification

1.3 This standard does not purport to address all of the

as listed in Table 1.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to become familiar

5. Elongation

with all hazards including those identified in the appropriate

5.1 The wire shall conform to the requirements for elonga-

Safety Data Sheet (SDS) for this product/material as provided

tion as prescribed in Table 1, when tested on a 10-in. (254-mm)

by the manufacturer, to establish appropriate safety, health,

length.

and environmental practices, and determine the applicability

of regulatory limitations prior to use.

6. Resistivity

1.4 This international standard was developed in accor-

6.1 The bare wire shall conform to the requirements for

dance with internationally recognized principles on standard-

nominal resistivity as prescribed in Table 1.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 6.2 Actual resistivity shall not vary from nominal resistivity

mendations issued by the World Trade Organization Technical

by more than 65 % for Alloy Classes 1 to 4 inclusive, and

Barriers to Trade (TBT) Committee. 610 % for Alloy Classes 5 to 11 inclusive.

7. Nominal Electrical Resistance per Unit Length

2. Referenced Documents

7.1 The nominal resistance per unit length for round wire

2.1 ASTM Standards:

shall be calculated from the nominal resistivity and the nominal

B63 Test Method for Resistivity of Metallically Conducting

cross-sectional area.

Resistance and Contact Materials

B77 Test Method for Thermoelectric Power of Electrical-

NOTE 1—When ribbon or flat wire is produced by rolling from round

Resistance Alloys wire, the cross section departs from that of a true rectangle by an amount

depending on the width-to-thickness ratio and the specific manufacturing

B84 Test Method for Temperature-Resistance Constants of

practice. The conventional formula for computing ohms per foot and feet

Alloy Wires for Precision Resistors

per pound is to consider the cross section as 17 % less than a true rectangle

when width is more than 15 times the thickness and 6 % less than a true

rectangle in other cases. This is not valid in view of modern rolling

equipment and practices, but still is widely used as a basis of description.

This specification is under the jurisdiction of ASTM Committee B02 on

Ribbon actually is made to a specified resistance per foot, and no tolerance

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

is specified for thickness. An alternative and a closer approximation would

B02.10 on Thermostat Metals and Electrical Resistance Heating Materials.

be that for ribbon rolled round wire, the electrical resistance would be

Current edition approved April 1, 2018. Published April 2018. Originally

calculated on a cross 6 % less than a true rectangle.

approved in 1952. Last previous edition approved in 2013 as B267 – 07 (2013).

DOI: 10.1520/B0267-07R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 8. Temperature Coefficient of Resistance

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

8.1 The change in resistance with change in temperature,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. expressed as the mean temperature coefficient of resistance

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B267 − 07 (2018)

TABLE 1 Classes of Alloys and Requirements

Mean Temperature Coefficient of Resistance, α ppm for Maximum Thermal emf

m

Elongation in 10 in., min, %

B

°C Over Temperature Range,Δ T versus Copper, mV/°C

Resistivity,

Alloy Alloy Composition,

Over 0.002 to

0.0009

Ω·cmil/ft

A

Class approximate, % D

Temperature

0.002 0.001

in. in

(µΩ·m)

ΔT α ΔT mV/°C

m C

D D

Range, ΔT in. in in. in Diameter

Diameter Diameter and Finer

1 2 3 4 5 6 7 8 9 10 11 12

1a nickel base, nonmagnetic 800 (1.330) 0, ±20 +25 to −55 0, ±20 +25 to +105 +0.003 −65 to +250 10 5 3

1b nickel base, nonmagnetic 800 (1.330) 0, ±10 +25 to −55 0, ±10 +25 to +105 +0.003 −65 to +150 10 5 3

1c nickel base, nonmagnetic 800 (1.330) 0, ±5 +25 to −55 0, ±5 +25 to +105 +0.003 −65 to +150 10 5 3

2a iron base, magnetic 800 (1.330) 0, ±20 +25 to −55 0, ±20 +25 to +105 −0.004 −65 to +200 10 5 3

2b iron base, magnetic 800 (1.330) 0, ±10 +25 to −55 0, ±10 +25 to +105 −0.004 −65 to +150 10 5 3

3a 80 nickel, 20 chromium 650 (1.081) +80, ±20 +25 to −55 +80, ±20 +25 to +105 +0.006 −65 to +250 15 5 3

3b 80 nickel, 20 chromium, 675 (1.122) +60, ±20 +25 to −55 +60, ±20 +25 to +105 +0.006 −65 to +250 15 5 3

stabilized

4 60 nickel, 16 chromium, 675 (1.122) +140, ±30 +25 to −55 +140, ±30 +25 to +105 +0.002 −65 to +200 15 5 3

balance iron

5a 55 copper, 45 nickel 300 (0.499) 0, ±20 +25 to −55 0, ±20 +25 to +105 −0.045 −65 to + 150 15 5 3

5b 55 copper, 45 nickel 300 (0.499) 0, ±40 +25 to −55 0, ±40 +25 to +105 −0.045 −65 to +150 15 5 3

E E E E

6 manganin type 290 (0.482) 0, ±15 0, ±15 −0.003 +15 to +35 15 5 3

7 77 copper, 23 nickel 180 (0.299) +180, ±30 +25 to −55 +180, ±30 +25 to +105 −0.037 −65 to +150 15 5 3

8 70 nickel, 30 iron 125 (0.199) +3600, ±400 +25 to −50 +4300, ±400 +25 to +104 −0.040 −50 to +100 15 5 3

9 90 copper, 10 nickel 90 (0.150) +450, ±50 +25 to −55 +450, ±50 +25 to +105 −0.026 −65 to +150 15 5 3

10 94 copper, 6 nickel 60 (0.100) +700, ±200 +25 to −55 +700, ±200 +25 to +105 −0.022 −65 to +150 15 5 3

11 98 copper, 2 nickel 30 (0.050) +1400, ±300 +25 to −55 +1400, ±300 +25 to +105 0.014 −65 to +150 15 5 3

A

Alloy Classes 1a to 8 inclusive are designed to provide controlled temperature coefficients. Values shown for other classes are for information only. All values are based

on a reference temperature of 25°C.

B

Alloy Classes 1a, 1b, 1c, 2a, 2b, 3a, 4, and 6 are designed to give a low emf versus copper. Values shown for other classes are for information only. Maximum indicates

the maximum deviation from zero and the plus or minus sign the polarity of the couple.

C

The maximum temperature values listed apply to the alloy wire only. Caution should be exercised pending knowledge of the maximum temperature of use for the coating

material involved.

D

If metric sizes are desired, 1 in. = 25.4 mm.

E

Alloy Class 6 (manganin type for resistors), has a temperature-resistance curve of parabolic shape with the maximum resistance normally located between 25 and 30°C.

m

Thus, Columns 5 and 7 cannot indicate 25°C as a limit but α may be expressed as a maximum of +15 ppm for 15°C to the temperature of maximum resistance and a

maximum of −15 ppm from the temperature of maximum resistance to 35°C. All of the information included in this note is based on measurements made in accordance

with Test Method B84.

A

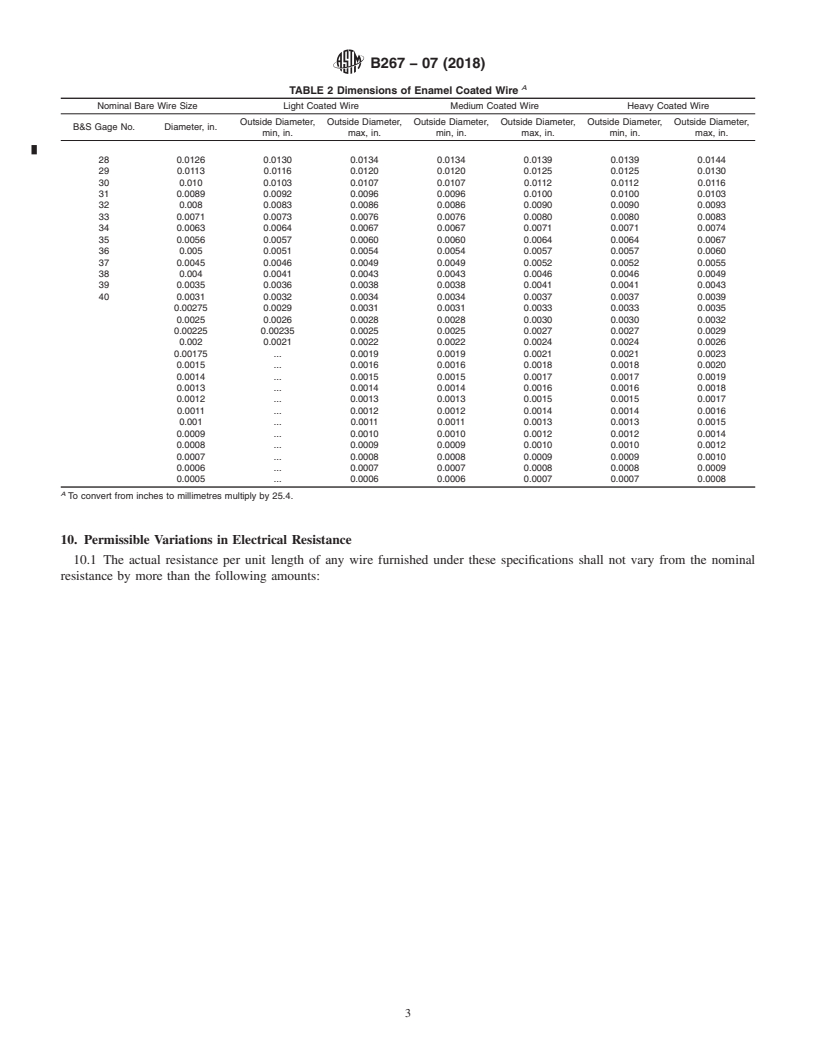

TABLE 2 Dimensions of Enamel Coated Wire

Nominal Bare Wire Size Light Coated Wire Medium Coated Wire Heavy Coated Wire

Outside Diameter, Outside Diameter, Outside Diameter, Outside Diameter, Outside Diameter, Outside Diameter,

B&S Gage No. Diameter, in.

min, in. max, in. min, in. max, in. min, in. max, in.

28 0.0126 0.0130 0.0134 0.0134 0.0139 0.0139 0.0144

29 0.0113 0.0116 0.0120 0.0120 0.0125 0.0125 0.0130

30 0.010 0.0103 0.0107 0.0107 0.0112 0.0112 0.0116

31 0.0089 0.0092 0.0096 0.0096 0.0100 0.0100 0.0103

32 0.008 0.0083 0.0086 0.0086 0.0090 0.0090 0.0093

33 0.0071 0.0073 0.0076 0.0076 0.0080 0.0080 0.0083

34 0.0063 0.0064 0.0067 0.0067 0.0071 0.0071 0.0074

35 0.0056 0.0057 0.0060 0.0060 0.0064 0.0064 0.0067

36 0.005 0.0051 0.0054 0.0054 0.0057 0.0057 0.0060

37 0.0045 0.0046 0.0049 0.0049 0.0052 0.0052 0.0055

38 0.004 0.0041 0.0043 0.0043 0.0046 0.0046 0.0049

39 0.0035 0.0036 0.0038 0.0038 0.0041 0.0041 0.0043

40 0.0031 0.0032 0.0034 0.0034 0.0037 0.0037 0.0039

0.00275 0.0029 0.0031 0.0031 0.0033 0.0033 0.0035

0.0025 0.0026 0.0028 0.0028 0.0030 0.0030 0.0032

0.00225 0.00235 0.0025 0.0025 0.0027 0.0027 0.0029

0.002 0.0021 0.0022 0.0022 0.0024 0.0024 0.0026

0.00175 . 0.0019 0.0019 0.0021 0.0021 0.0023

0.0015 . 0.0016 0.0016 0.0018 0.0018 0.0020

0.0014 . 0.0015 0.0015 0.0017 0.0017 0.0019

0.0013 . 0.0014 0.0014 0.0016 0.0016 0.0018

0.0012 . 0.0013 0.0013 0.0015 0.0015 0.0017

0.0011 . 0.0012 0.0012 0.0014 0.0014 0.0016

0.001 . 0.0011 0.0011 0.0013 0.0013 0.0015

0.0009 . 0.0010 0.0010 0.0012 0.0012 0.0014

0.0008 . 0.0009 0.0009 0.0010 0.0010 0.0012

0.0007 . 0.0008 0.0008 0.0009 0.0009 0.0010

0.0006 . 0.0007 0.0007 0.0008 0.0008 0.0009

0.0005 . 0.0006 0.0006 0.0007 0.0007 0.0008

A

To convert from inches to millimetres multiply by 25.4.

B267 − 07 (2018)

based on the reference temperature of 25°C, shall be within the 13. Enamel Coatings

limits specified in Table 1, Columns 4 and 6, over the

13.1 Enamel coatings shall include any baked-on film of

corresponding temperature ranges specified in Columns 5 and

insulating material, such as varnish enamel, polyurethane,

7. The mean temperature coefficient of resistance referred to

vinyl acetal, etc. and shall conform to the requirements

25°C is defined as the slope of a chord of an arc. This slope is

presc

...

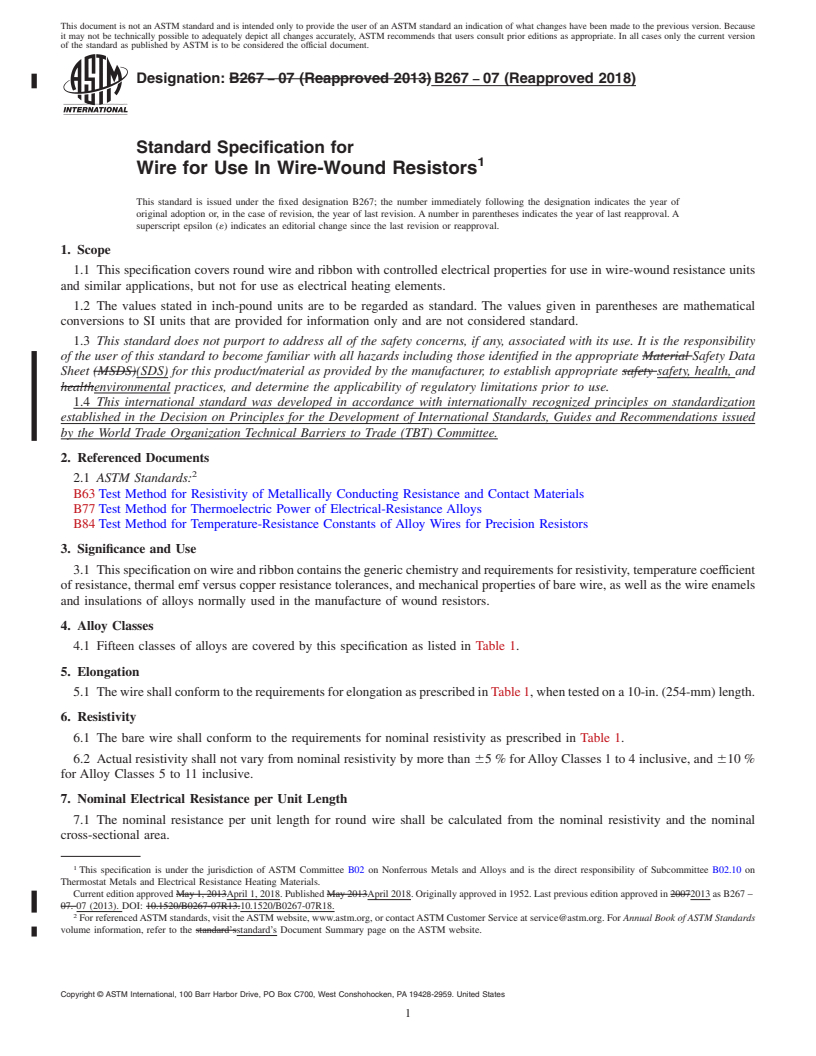

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B267 − 07 (Reapproved 2013) B267 − 07 (Reapproved 2018)

Standard Specification for

Wire for Use In Wire-Wound Resistors

This standard is issued under the fixed designation B267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers round wire and ribbon with controlled electrical properties for use in wire-wound resistance units

and similar applications, but not for use as electrical heating elements.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS)(SDS) for this product/material as provided by the manufacturer, to establish appropriate safety safety, health, and

healthenvironmental practices, and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

B63 Test Method for Resistivity of Metallically Conducting Resistance and Contact Materials

B77 Test Method for Thermoelectric Power of Electrical-Resistance Alloys

B84 Test Method for Temperature-Resistance Constants of Alloy Wires for Precision Resistors

3. Significance and Use

3.1 This specification on wire and ribbon contains the generic chemistry and requirements for resistivity, temperature coefficient

of resistance, thermal emf versus copper resistance tolerances, and mechanical properties of bare wire, as well as the wire enamels

and insulations of alloys normally used in the manufacture of wound resistors.

4. Alloy Classes

4.1 Fifteen classes of alloys are covered by this specification as listed in Table 1.

5. Elongation

5.1 The wire shall conform to the requirements for elongation as prescribed in Table 1, when tested on a 10-in. (254-mm) length.

6. Resistivity

6.1 The bare wire shall conform to the requirements for nominal resistivity as prescribed in Table 1.

6.2 Actual resistivity shall not vary from nominal resistivity by more than 65 % for Alloy Classes 1 to 4 inclusive, and 610 %

for Alloy Classes 5 to 11 inclusive.

7. Nominal Electrical Resistance per Unit Length

7.1 The nominal resistance per unit length for round wire shall be calculated from the nominal resistivity and the nominal

cross-sectional area.

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.10 on

Thermostat Metals and Electrical Resistance Heating Materials.

Current edition approved May 1, 2013April 1, 2018. Published May 2013April 2018. Originally approved in 1952. Last previous edition approved in 20072013 as B267 –

07. 07 (2013). DOI: 10.1520/B0267-07R13.10.1520/B0267-07R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B267 − 07 (2018)

TABLE 1 Classes of Alloys and Requirements

Mean Temperature Coefficient of Resistance, α ppm for Maximum Thermal emf

m

Elongation in 10 in., min, %

B

°C Over Temperature Range,Δ T versus Copper, mV/°C

Resistivity,

Alloy Alloy Composition,

Over 0.002 to

0.0009

Ω·cmil/ft

A Temperature

Class approximate, % D

0.002 0.001

in. in. in

(μΩ·m)

ΔTΔT α ΔTΔT mV/°C Range, Δ

m

D D

Diameter

in. in. in in. in. in

C

TΔT

and Finer

Diameter Diameter

1 2 3 4 5 6 7 8 9 10 11 12

1a nickel base, nonmagnetic 800 (1.330) 0, ±20 +25 to −55 0, ±20 +25 to +105 +0.003 −65 to +250 10 5 3

1b nickel base, nonmagnetic 800 (1.330) 0, ±10 +25 to −55 0, ±10 +25 to +105 +0.003 −65 to +150 10 5 3

1c nickel base, nonmagnetic 800 (1.330) 0, ±5 +25 to −55 0, ±5 +25 to +105 +0.003 −65 to +150 10 5 3

2a iron base, magnetic 800 (1.330) 0, ±20 +25 to −55 0, ±20 +25 to +105 −0.004 −65 to +200 10 5 3

2b iron base, magnetic 800 (1.330) 0, ±10 +25 to −55 0, ±10 +25 to +105 −0.004 −65 to +150 10 5 3

3a 80 nickel, 20 chromium 650 (1.081) +80, ±20 +25 to −55 +80, ±20 +25 to +105 +0.006 −65 to +250 15 5 3

3b 80 nickel, 20 chromium, 675 (1.122) +60, ±20 +25 to −55 +60, ±20 +25 to +105 +0.006 −65 to +250 15 5 3

stabilized

4 60 nickel, 16 chromium, 675 (1.122) +140, ±30 +25 to −55 +140, ±30 +25 to +105 +0.002 −65 to +200 15 5 3

balance iron

5a 55 copper, 45 nickel 300 (0.499) 0, ±20 +25 to −55 0, ±20 +25 to +105 −0.045 −65 to + 150 15 5 3

5b 55 copper, 45 nickel 300 (0.499) 0, ±40 +25 to −55 0, ±40 +25 to +105 −0.045 −65 to +150 15 5 3

E E E E

6 manganin type 290 (0.482) 0, ±15 0, ±15 −0.003 +15 to +35 15 5 3

7 77 copper, 23 nickel 180 (0.299) +180, ±30 +25 to −55 +180, ±30 +25 to +105 −0.037 −65 to +150 15 5 3

8 70 nickel, 30 iron 125 (0.199) +3600, ±400 +25 to −50 +4300, ±400 +25 to +104 −0.040 −50 to +100 15 5 3

9 90 copper, 10 nickel 90 (0.150) +450, ±50 +25 to −55 +450, ±50 +25 to +105 −0.026 −65 to +150 15 5 3

10 94 copper, 6 nickel 60 (0.100) +700, ±200 +25 to −55 +700, ±200 +25 to +105 −0.022 −65 to +150 15 5 3

11 98 copper, 2 nickel 30 (0.050) +1400, ±300 +25 to −55 +1400, ±300 +25 to +105 0.014 −65 to +150 15 5 3

A

Alloy Classes 1a to 8 inclusive are designed to provide controlled temperature coefficients. Values shown for other classes are for information only. All values are based

on a reference temperature of 25°C.

B

Alloy Classes 1a, 1b, 1c, 2a, 2b, 3a, 4, and 6 are designed to give a low emf versus copper. Values shown for other classes are for information only. Maximum indicates

the maximum deviation from zero and the plus or minus sign the polarity of the couple.

C

The maximum temperature values listed apply to the alloy wire only. Caution should be exercised pending knowledge of the maximum temperature of use for the coating

material involved.

D

If metric sizes are desired, 1 in. = 25.4 mm.

E

Alloy Class 6 (manganin type for resistors), has a temperature-resistance curve of parabolic shape with the maximum resistance normally located between 25 and 30°C.

m

Thus, Columns 5 and 7 cannot indicate 25°C as a limit but α may be expressed as a maximum of + 15of +15 ppm for 15°C to the temperature of maximum resistance

and a maximum of − 15 of −15 ppm from the temperature of maximum resistance to 35°C. All of the information included in this note is based on measurements made

in accordance with Test Method B84.

NOTE 1—When ribbon or flat wire is produced by rolling from round wire, the cross section departs from that of a true rectangle by an amount

depending on the width-to-thickness ratio and the specific manufacturing practice. The conventional formula for computing ohms per foot and feet per

pound is to consider the cross section as 17 % less than a true rectangle when width is more than 15 times the thickness and 6 % less than a true rectangle

in other cases. This is not valid in view of modern rolling equipment and practices, but still is widely used as a basis of description. Ribbon actually is

made to a specified resistance per foot, and no tolerance is specified for thickness. An alternative and a closer approximation would be that for ribbon

rolled round wire, the electrical resistance would be calculated on a cross 6 % less than a true rectangle.

8. Temperature Coefficient of Resistance

8.1 The change in resistance with change in temperature, expressed as the mean temperature coefficient of resistance based on

the reference temperature of 25°C, shall be within the limits specified in Table 1, Columns 4 and 6, over the corresponding

temperature ranges specified in Columns 5 and 7. The mean temperature coefficient of resistance referred to 25°C is defined as

the slope of a chord of an arc. This slope is determined from the following equation:

α 5 ΔR/R ΔT 310

~ !

m 25

where:

α = mean temperature coefficient of resistance, ppm/°C, Table 1, Columns 4 and 6,

m

Δ R = change in resistance over temperature range indicated in Table 1, Columns 5 and 7,

ΔR = change in resistance over temperature range indicated in Table 1, Columns 5 and 7,

R = resistance at 25°C,

ΔT = temperature range indicated in Table 1, Columns 5 and 7.

8.2 For Alloy Classes 1, 2, and 5, the temperature coefficient as specified in Table 1 of any 10-ft (3-m) length shall not vary

more than 3 ppm/°C from that of any other 10-ft length on the same spool or coil.

9. Thermal EMF with Respect to Copper

9.1 The thermal electromotive force (emf) with respect to copper shall fall within the limits shown in Table 1, in the

corresponding temperature ranges.

B267 − 07 (2018)

A

TABLE 2 Dimensions of Enamel Coated Wire

Nominal Bare Wire Size Light Coated Wire Medium Coated Wire Heavy Coated Wire

Outside Diameter, Outside Diameter, Outside Diameter, Outside Diameter, Outside Diameter, Outside Diameter,

B&S Gage No. Diameter, in.

min, in. max, in. min, in. max, in. min, in. max, in.

28 0.0126 0.0130 0.0134 0.0134 0.0139 0.0139 0.0144

29 0.0113 0.0116 0.0120 0.0120 0.0125 0.0125 0.0130

30 0.010 0.0103 0.0107 0.0107 0.0112 0.0112 0.0116

31 0.0089 0.0092 0.0096 0.0096 0.0100 0.0100 0.0103

32 0.008 0.0083 0.0086 0.0086 0.0090 0.0090 0.0093

33 0.0071 0.0073 0.0076 0.0076 0.0080 0.0080 0.0083

34 0.0063 0.0064 0.0067 0.0067 0.0071 0.0071 0.0074

35 0.0056 0.0057 0.0060 0.0060 0.0064 0.0064 0.0067

36 0.005 0.0051 0.0054 0.0054 0.0057 0.0057 0.0060

37 0.0045 0.0046 0.0049 0.0049 0.0052 0.0052 0.0055

38 0.004 0.0041 0.0043 0.0043 0.0046 0.0046 0.0049

39 0.0035 0.0036 0.0038 0.0038 0.0041 0.0041 0.0043

40 0.0031 0.0032 0.0034 0.0034 0.0037 0.0037 0.0039

0.00275 0.0029 0.0031 0.0031 0.0033 0.0033 0.0035

0.0025 0.0026 0.0028 0.0028 0.0030 0.0030 0.0032

0.00225 0.00235 0.0025 0.0025 0.0027

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.