ASTM D1795-96

(Test Method)Standard Test Method for Intrinsic Viscosity of Cellulose

Standard Test Method for Intrinsic Viscosity of Cellulose

SCOPE

1.1 This test method covers the determination of the intrinsic viscosity of purified celluloses such as bleached wood pulps, cotton linters, and regenerated cellulose. It is applicable to all cellulose samples with an intrinsic viscosity of 15 dl/g or less. Most native (unpurified) celluloses have intrinsic viscosity values too high for measurement by this test method.

Note 1—The use of cuprammonium hydroxide solution for regular viscosity determination is described in Method T 206 m-55 of the Technical Association of Pulp and Paper Industry on "Cuprammonium Disperse Viscosity of Pulp," and Joint Army-Navy Specifications JAN-C-206.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1795 – 96

Standard Test Method for

Intrinsic Viscosity of Cellulose

This standard is issued under the fixed designation D 1795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of the intrin- 4.1 This test is a sensitive measure of the degradation of

sic viscosity of purified celluloses such as bleached wood cellulose resulting from the action of heat, light, acids, alkalies,

pulps, cotton linters, and regenerated cellulose. It is applicable oxidizing and reducing agents, and the like, used in its

to all cellulose samples with an intrinsic viscosity of 15 dl/g or processing or purification. The intrinsic viscosity value may be

less. Most native (unpurified) celluloses have intrinsic viscos- converted to degree of polymerization (DP) or to intrinsic

ity values too high for measurement by this test method. fluidity, if desired.

4.2 Solutions of cellulose are not Newtonian liquids; that is,

NOTE 1—The use of cuprammonium hydroxide solution for regular

their viscosity depends upon the rate-of-shear or velocity

viscosity determination is described in Test Methods D 539, Method

gradient during measurement. This effect is smaller for samples

T 206 m-55 of the Technical Association of Pulp and Paper Industry on

“Cuprammonium Disperse Viscosity of Pulp,” and Joint Army-Navy of low molecular mass (DP) and at low concentrations than for

Specifications JAN-C-206.

high-DP samples and at high concentrations. For the celluloses

and concentrations included within the limits set forth in this

1.2 This standard does not purport to address all of the

test method, the effect of rate-of-shear is assumed to be

safety concerns, if any, associated with its use. It is the

negligible for referee purposes. For other conditions and for

responsibility of the user of this standard to establish appro-

research purposes this assumption may be invalid, but to

priate safety and health practices and determine the applica-

discuss ways of accounting for this effect is beyond the scope

bility of regulatory limitations prior to use.

of the present test method.

2. Referenced Documents

5. Apparatus

2.1 ASTM Standards:

5.1 Viscometer, Glass, Capillary Type— The Cannon-

D 445 Test Method for Kinematic Viscosity of Transparent

Fenske, Ubbelohde, or similar capillary type instrument as

and Opaque Liquids (and the Calculation of Dynamic

described in Test Method D 445 is recommended. Viscometers

Viscosity)

described in Test Methods D 539 are also suitable. In order to

D 539 Test Methods for Apparent Fluidity of Dispersions of

avoid correction for the kinetic energy effect, choose a viscom-

Cellulose Fibers

eter with a small enough capillary to give an outflow time of 80

D 629 Test Methods for Quantitative Analysis of Textiles

s or more for the Cannon-Fenske type. (A size 100 viscometer

E 1 Specification for ASTM Thermometers

is normally used for the sample solution and a size 50 for the

3. Summary of Test Method

solvent.)

5.2 Thermometer—ASTM Kinematic Viscosity Thermom-

3.1 A weighed sample of the material is dissolved in a 0.5 M

eter for use at 25°C, having a range from 19 to 27°C and

cupriethylenediamine hydroxide solution. The viscosity of this

conforming to the requirement for Thermometer 17C as

solution, and also that of the solvent, is determined at 25°C by

prescribed in Specification E 1.

means of a calibrated glass capillary-type viscometer. The

5.3 Bath—A constant-temperature bath at 25°C suitable for

relative viscosity is calculated and the corresponding intrinsic

immersion of the viscometer so that the reservoir or the top of

viscosity is read from a table.

the capillary, whichever is uppermost, is immersed at least 50

mm, and with provision for visibility of the instrument and the

thermometer. Firm supports for the viscometer shall be pro-

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of

vided; or the viscometer may be sealed in as an integral part of

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

the bath. Either a liquid bath with thermostatic regulation and

Current edition approved Nov. 10, 1996. Published January 1997. Originally

a stirrer or a vapor bath with pressure regulation is permissible.

published as D 1795 – 60. Last previous edition D 1795 – 94.

Annual Book of ASTM Standards, Vol 05.01. The efficiency of the stirring and the balance between heat

Discontinued, see 1973 Annual Book of ASTM Standards, Part 24.

losses and heat input must be such that the temperature of the

Annual Book of ASTM Standards, Vol 07.01.

bath medium does not vary by more than 60.1°C over the

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 1795

NOTE 4—Calibration of the viscometers may be avoided if both solvent

length of the viscometer, or from viscometer to viscometer in

and solution are measured in the same instrument. Then the relative

the various bath positions. If a vapor bath is used, there must

viscosity is nearly the ratio of outflow times for solution and solvent,

be no temperature gradient over the length of the viscometer

respectively. This simplification involves two assumptions. The first, that

greater than that permitted in a liquid bath.

the densities of solution and solvent are equal, holds very well for the

5.4 Timer—A stop watch or other spring-activated timing

dilute solutions used in these tests. The second, that the kinetic energy

device or electrical timing device shall be used, graduated in

correction is zero, depends upon the choice of viscometer. If the one used

divisions of 0.2 s or less, and accurate to within 0.05 % when gives convenient outflow times for the solution of less than 150 s, then it

will be too fast for the solvent. The kinetic energy correction is zero,

tested over not less than a 10-min period. Such electrical

depending upon flow. On the other hand, if one is chosen so that the

timing devices shall be used only on electrical circuits of

outflow time for the solvent is large enough (80 s or more), then the times

continuously controlled frequency. Frequency-controlled de-

for the solutions will in most cases be inconveniently long. For some

vices of suitable capacity for laboratory purposes, accurate to

work, however, it may be desirable to make some sacrifice in accuracy or

within 1 part in 10 000 should be used. Errors exceeding

in convenience during measurement in order to avoid calibration and

0.05 % of a 10-min interval may occur in timing devices

using two sizes of viscometers.

actuated by electrical synchronous motors driven by most

8.2 By means of a pipet, add 7.0 mL of the calibrating liquid

public power systems, which are intermittently and not con-

to the viscometer, in a constant-temperature bath at 25 6 0.1°C

tinuously controlled.

(or fill as described in Test Method D 445, Appendix A).

8.3 When the liquid has reached temperature equilibrium

6. Reagent

with the bath (in about 5 min), determine the outflow time t by

6.1 Cupriethylenediamine Hydroxide Solution (1.00 6 0.01

drawing the top meniscus of the liquid above the mark between

M), in copper, with the molar ratio of ethylenediamine to

the two bulbs and measuring the time required for the meniscus

copper of 2 6 0.1 to 1. This solvent may be prepared in the

to pass from this mark to the mark below the lower bulb. Take

laboratory as described in Test Methods D 539. It is also

the average of two or more observations, which should differ

commercially available.

by not more than 0.2 s.

7. Reference Materials 8.4 Determine the viscometer constant C by the equation:

C5h/dt (1)

7.1 Viscosity Oil Standards—Calibrating oils in the speci-

fied ranges of viscosity. Aqueous solutions of glycerol may be

where:

used instead of standardized oils; the compositions for various

h = viscosity of the calibrating liquid, cP,

viscosities are given in chemical handbooks. The applicable

d = density, g/mL, and

viscosity oil standards (Note 2) are listed in Table 1.

t = time, s.

TABLE 1 Viscosity Oil Standards

9. Preparation of Sample

Viscometer Viscosity Oil Standard

9.1 To avoid undesirable effects from long heating at high

Approximate

Absolute Viscosity

temperature, samples should be air-dried and the moisture

Size Designation Absolute Viscosity

A

Range, cP

at 77°F (25°C), cP

content determined on a portion that is not used for measure-

50 0.9 to 3.5 S-3 3.3

ment of viscosity. The mass of air-dried samples is then

100 3.3 to 13.3 S-6 7.7

corrected for moisture to obtain the mass of oven-dried

A

For solution with density of 0.9.

cellulose used to calculate concentration.

9.2 Soft, sheeted pulp should be picked apart with tweezers

NOTE 2—The viscosity oil standards are available only as 1-pt (4.7- m

or scraped with a dull knife. Hard-pressed or harsh pulp should

3) samples. More than 1 pt of any given oil (for example, duplicate

6 be slurried in water, formed into thin sheets on a Büchner

samples) are supplied only when it is established that 1 pt is inadequate.

funnel, and dried at a temperature below 100°C (preferably

8. Calibration of Viscometer

room temperature). Loose pulp should be picked apart by hand

to break up any lumps. Slurried or slush pulps should be

8.1 The following directions apply to the Cannon-Fenske

formed into thin sheets and dried. Yarn and staple should be

viscometer (Note 3). They should be modified according to the

washed in warm water containing a little detergent to remove

operating instructions for other types of viscometers. The

the finish, rinsed thoroughly, dried (at low temperature), and

viscometers shall be calibrated (Note 4) by means of liquids

fluffed. (It will be found helpful to cut yarn and long staple into

having known viscosities approximately equal to those of the

short lengths, say ⁄2 in. (13 mm), before washing.) Fabrics

solvent and cellulose solutions respectively (1.2 and 12 cP,

should be cut into small pieces, desized (see Test Methods

approximately).

D 629, Section 8), thoroughly washed, and dried. Raveling will

NOTE 3—Detailed specifications and directions for filling, calibrating,

be helpful before dissolving samples that tend to get in the

and measurement with types of capillary viscometers most used are given

solvent. Materials containing a considerable amount of non-

in Test Method D 445.

cellulosic matter must first be purified; such treatments lie

outside the scope of this test method.

The sole source of supply of the viscosity oil standards known to the committee

at this time is Cannon Instrument Co., P. O. Box 16, State College, PA 16801. If you

10. Preparation of Solution

are aware of alternative suppliers, please provide this information to ASTM

10.1 The sample size is dependent upon the nature of the

Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. material, smaller masses of high-viscosity celluloses and larger

D 1795

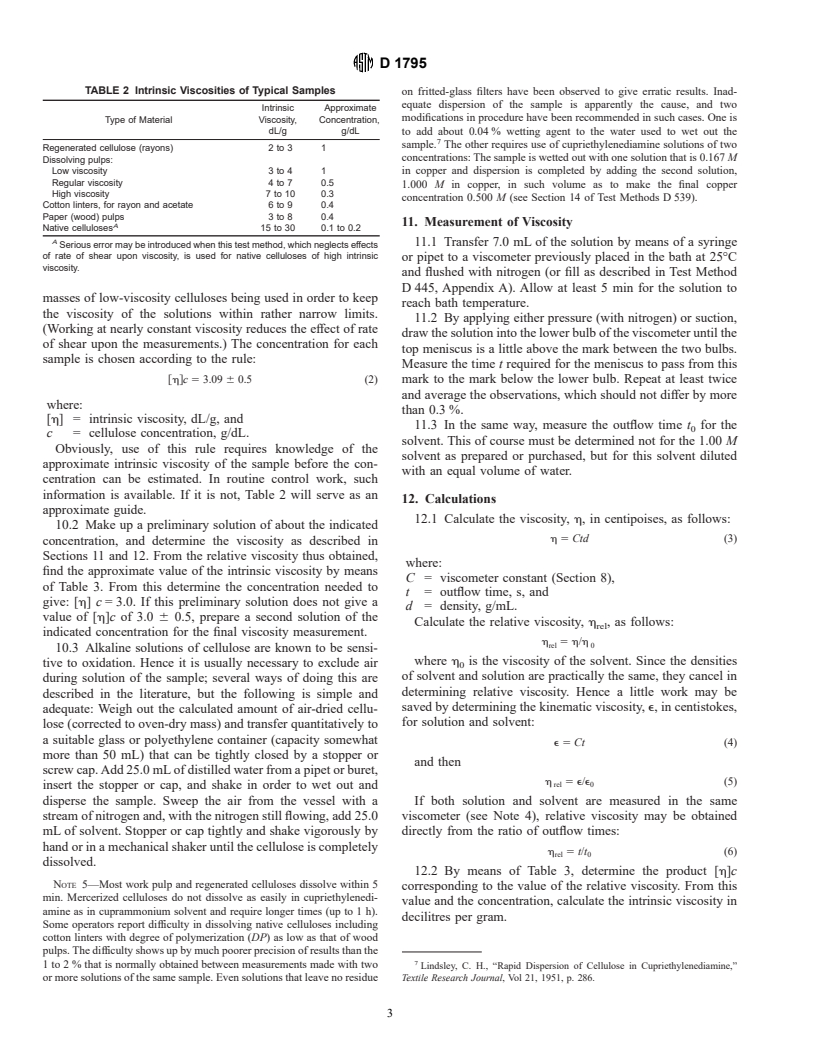

TABLE 2 Intrinsic Viscosities of Typical Samples on fritted-glass filters have been observed to give erratic results. Inad-

equate dispersion of the sample is apparently the cause, and two

Intrinsic Approximate

modifications in procedure have been recommended in such cases. One is

Type of Material Viscosity, Concentration,

dL/g g/dL to add about 0.04 % wetting agent to the water used to wet out the

sample. The other requires use of cupriethylenediamine solutions of two

Regenerated cellulose (rayons) 2 to 3 1

concentrations: The sample is wetted out with one solution that is 0.167 M

Dissolving pulps:

Low viscosity 3 to 4 1 in copper and dispersion is completed by adding the second solution,

Regular viscosity 4 to 7 0.5

1.000 M in copper, in such volume as to make the final copper

High viscosity 7 to 10 0.3

concentration 0.500 M (see Section 14 of Test Methods D 539).

Cotton linters, for rayon and acetate 6 to 9 0.4

Paper (wood) pulps 3 to 8 0.4

11. Measurement of Viscosity

A

Native celluloses 15 to 30 0.1 to 0.2

A

11.1 Transfer 7.0 mL of the solution by means of a syringe

Serious error may be introduced when this test method, which neglects effects

of rate of shear upon viscosity, is used for native celluloses of high intrinsic

or pipet to a viscometer previously placed in the bath at 25°C

viscosity.

and flushed with nitrogen (or fill as described in Test Method

D 445, Appendix A). Allow at least 5 min for the solution to

masses of low-viscosity celluloses being used in order to keep

reach bath temperature.

the viscosity of the solutions within rather narrow limits.

11.2 By applying either pressure (with nitrogen) or suction,

(Working at nearly constant viscosity reduces the effect of rate

draw the solution into the lower bulb of the viscometer until the

of shear upon the measurements.) The concentration for each

top meniscus is a little above the mark between the two bulbs.

sample is chosen according to the rule:

Measure the time t required for the meniscus to pass from this

@h#c 5 3.09 6 0.5 (2) mark to the mark below the lower bulb. Repeat at least twice

and average the observations, which should not differ by more

where:

than 0.3 %.

[h] = intrinsic viscosity, dL/g, and

11.3 In the same way, measure the outflow time t for the

c = cellulose concentration, g/dL.

solvent. This of course must be determined not for the 1.00 M

Obviously, use of this rule requires knowledge of the

solvent as prepared or purchased, but for this solvent diluted

approximate intrinsic viscosity of the sample before the con-

with an equal volume of water.

centration can be estimated. In routine control work, such

information is available. If it is not, Table 2 will serve as an

12. Calculations

approximate guide.

12.1 Calculate the viscosity, h, in centipoises, as follows:

10.2 Make up a preliminary solution of about the indicated

h5 Ctd (3)

concentration, and determine the viscosity as described in

Sections 11 and 12. From the relative viscosity thus obtained,

where:

find the approximate value of the intrinsic viscosity by means

C = viscometer constant (Section 8),

of Table 3. From this determine the concentration needed to

t = outflow time, s, and

give: [h] c = 3.0. If this preliminary solution does not give a

d = density, g/mL.

value of [h]c of 3.0 6 0.5, prepare a second solution of the

Calculate the relative vi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.